Abstract

Lutetium has been used as a radiochemistry detector to measure neutron fluence in NTS tests. A measure of the neutron capture cross sections on 173Lu is needed to improve the interpretation value of the Lu radiochemistry isotopic ratios. A natural hafnium target was irradiated with protons to produce neutron poor lutetium radioisotopes. The short lived species were allowed to decay prior to chemical processing resulting in predominantly 173Lu with a small amount of 174Lu. This material was deposited on a titanium foil for use in the neutron capture cross section measurement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Past use of lutetium as a radiochemistry detector to measure neutron fluence in NTS tests has resulted in an interest to measure the neutron capture cross sections of 173Lu. These measurements have not previously been performed because of the challenge of producing an essentially isotopically pure sample of this radioisotope. To manufacture a target for this purpose, a natural hafnium target was irradiated to produce a suitable amount of 173Lu. The target was chemically processed to separate the lutetium activity from the mass of the hafnium target. The resulting lutetium fraction was further purified to remove other elemental contaminants, then molecular plated onto a titanium foil to produce a target for the cross section measurement. Process chemistry was monitored through gamma and optical emission spectroscopy.

Experimental

Hafnium target

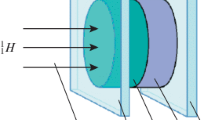

The hafnium target was commercially obtained as a natural hafnium, 99.95% pure, metal sputter target selected for low concentrations of lanthanide contaminants, (LEICO industries, INC). Lutetium levels were reported as less than 0.1 ppm, no other lanthanides were reported in the certificate of analysis. Dimensions were 38 mm in diameter by 3.33 mm thick, the mass was 49.02 g. This material was electron beam welded into a 5.7 cm by 0.4 cm inconel-625 target shell with 0.25 mm thick windows.

Irradiation

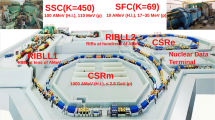

The hafnium target was inserted into the Los Alamos Isotope Production Facility target irradiation station at the Los Alamos Neutron Science Center (LANSCE) at Los Alamos National Laboratory. Over the period of 10 days the target received 49,073 μA h. Beam current was 250 μA with an incident energy of 92 MeV and an exit energy of 73 MeV. Cooling was performed by circulating pressurized water around the entire target. After irradiation, the target windows showed a distinctive heat discoloration mottling associated with portions of the hafnium metal touching the inconel windows and uneven heat transfer. Upon removing the hafnium from the encapsulation there were signs of unexpected regional softening of the hafnium metal during the irradiation that matched the pattern on the windows.

Separation of lutetium isotopes from hafnium target

After irradiation, the hafnium target was transferred to the radiochemistry hot cell facility at Los Alamos. Since 173Lu has a half life of 500 days, the target was allowed to cool for several months assuring that all shorter lived lutetium isotopes had decayed away. Upon removal from the encapsulation, the irradiated hafnium was transferred to a Teflon beaker. Approximately 50 mL of water was added followed by the drop wise addition of concentrated hydrofluoric acid. The energetic reaction was allowed to subside before subsequent additions of acid. Once the solution turned cloudy, it was transferred to a second container and the dissolution process continued. Approximately 60 mL of concentrated hydrofluoric acid was used in the process. The resulting solution was slowly evaporated to dryness under gentle heat and an air stream. The residue was brought back into solution in 400 mL of 0.1 molar HF and filtered through a 0.4 micron cellulose nitrate filter, then sampled for gamma analysis. The gamma ray spectrum was dominated by gamma rays produce by the 6.7 day half life 72Lu from the decay of the 1.85 year parent 172Hf. 173Lu gamma rays were present in the spectrum and provided an initial estimate of material produced in the irradiation. Because of the several month cooling period of the target, only longer lived radioisotopes were observed.

Longer lived isotopes produced in irradiated hafnium

Isotope | Half life | Curies produced at EOB |

|---|---|---|

172Hf | 1.85 years | 547 mCi |

175Hf | 70 days | 5,438 mCi |

173Lu | 500 days | 980 mCi |

174Lu | 3.3 years | 9.0 mCi |

88Y | 107 days | 13.6 mCia |

88Z | 83 days | 7.6 mCia |

A 300 mL anion exchange column was prepared (Bio-Rad™ AG 1-X8 100–200 mesh) and equilibrated with 0.1 molar HF. It was determined experimentally that 75 mL of the hafnium solution could be loaded onto the column without hafnium breakthrough occurring. The column was then washed with 50 mL volumes of 0.1 M HF to remove lutetium activity. Lutetium cuts deemed free of hafnium activity were combined. When hafnium activity was observed beginning to come off the column, the column was stripped with 450 mL of 2 M HCl and then re-equilibrated with 0.1 M HF. This procedure was repeated until all of the dissolved hafnium solution was processed. Approximately 97% of the lutetium was separated from the bulk of the hafnium material. The solutions containing lutetium activity were combined, taken to dryness, brought up in 50 mL of 0.1 M HF and taken though this procedure a second time with an emphasis on discarding any cuts that might contain hafnium material. During this process, lutetium activity was monitored using the 172Lu, 1093 keV and 173Lu, 272 keV gamma rays while hafnium activity was monitored using the 172Hf, 126 keV gamma ray. Solutions were counted through a counting port penetration in the hot cell shielding wall with an Ortec™ model CEM-5C intrinsic germanium detector. A 20.8 mCi 173Lu source was prepared and placed in the hot cell for calibration of this unique counting geometry. At the end of this portion of the project, a sample of the lutetium solution was removed from the hot cells for analysis. Gamma ray analysis of 173Lu and optical emission spectroscopic analysis for hafnium showed an 86% recovery of the lutetium with 6.8 mg of hafnium contamination remaining. The relatively small quantity of hafnium remaining made it no longer possible to count the 172Hf, 126 keV gamma ray through a counting port in the hot cell shielding wall to monitor hafnium decontamination chemistry.

Purification of the lutetium fraction

To remove the remaining hafnium, the lutetium activity was taken to dryness and brought up in 15 mL of 0.1 M HF and placed on a 10 mL cation exchange column (Bio-Rad™ AG 50-X8 100–200 mesh). The column was washed with 100 mL of 1 M HF followed by 30 mL of 0.5 M HNO3. The lutetium activity was stripped from the column using 120 mL of 6 M HNO3. Again a sample was removed from the hot cell and an optical emission spectroscopic analysis performed for hafnium. Total hafnium mass was determined to be 26 μg. This level was significantly higher than anticipated, back contamination from the processing hot cell was considered the likely source. The lutetium activity was transferred to a different clean hot cell and the previous cation column procedure repeated. Removal of other contaminants was performed using a 10 mL Eichrom™ RE resin column. The 6 M HNO3 strip solution from the cation column was taken to dryness and the activity brought up 15 mL of 10 M HNO3. This was placed on the RE column followed by 35 mL of 10 M HNO3. This was followed by 30 mL of 5 M HNO3, then successive 5 mL volumes of 2 M HNO3. The 2 M HNO3 fractions were monitored for lutetium breakthrough. After 30 mL, lutetium activity was observed coming off the column and the activity was stripped using 100 mL of 0.1 M HNO3. The resulting solution was evaporated to dryness and taken up in 15 mL of 0.1 M HNO3. Once again, a sample was removed from the hot cell for optical emission spectroscopic analysis. Hafnium levels in the sample analyzed were below the instrument’s 1 μg/L level of detection. Because of a significant dilution factor of the sample, hafnium levels could only be estimated at less than 5.5 μg total mass in the lutetium product.

Manufacture of 173Lu target

A 2.5 micron thick high purity titanium foil was chosen to support the 173Lu sample. Using epoxy, the titanium foil was mounted on a 1 3/8 inch diameter by 0.014 inch thick aluminum ring. An electrolytic cell was fabricated using an 8.5 cm long glass chimney with an 8 mm inside diameter. This was mounted vertically with springs on a ¼ inch thick brass plate. The titanium foil was cleaned with acetone and placed on the brass plate. A 0.004 inch thick vinyl gasket bearing a 0.25 inch hole was placed between the glass chimney and the foil. To molecular plate the 173Lu onto the foil, 1.5 mL of isopropyl alcohol and 50 μL of 0.1 M HCl were added to the cell. Fifty-eight mCi of 173Lu activity were added as 50 μL of 0.1 M HNO3. A constant current electrolysis was performed at 30 μA for 30 min. At the end of the electrolysis, 0.25 mL of concentrated ammonia was added to neutralize any residual acid and the current continued for another minute. The foil with the lutetium deposit was removed from the cell assembly, rinsed with water, and dried. The target was gamma counted through the hot cell counting port with a yield of 32 mCi 173Lu, 55%. Previous work counting samples in this manner have been accurate to approximately 5%. Optical emission spectroscopy was performed using a PerkinElmer Optima 4300DV inductively coupled plasma-atomic emission spectrometer. All acids used in the chemistry processes were trace metal grade or better. De-ionized water was prepared to 18 Mega ohm using a Barnsted™ water polishing system (Figs. 1, 2).

Results and discussion

During the purification process, solutions and cuts containing 173Lu that had or were suspected of having hafnium or other potential contaminates were set aside in reserve if additional lutetium activity was needed. This resulted in a yield from the chemical purification process of 239 mCi of 173Lu. With decay correction to End of Bombardment, this represented a 39% recovery of the lutetium activity produced in the original irradiated hafnium target. Radioactive materials identified in the processed lutetium were limited to lutetium isotopes and 88Y. Yttrium would have followed the lanthanide separations chemistry and is believed to have been produced from zirconium contamination of the hafnium target during its irradiation. Emission spectroscopic analysis was performed to identify stable elemental contaminates. An expected amount of stable ytterbium was observed having been produced during the irradiation and from decay of lutetium isotopes. Thulium mass is also believed to have been produced from the decay of lutetium and ytterbium radioisotopes. 173Lu specific activity was 33% of theoretical. Concern that the Eichrom™ RE column would not completely remove iron was realized [1].

Radioactive species identified in the purified lutetium fraction

172Lu | 0.23 mCi |

173Lu | 239 mCi |

174Lu | 3.8 mCi |

88Y | 2.8 mCi |

Mass of elements identified in the purified lutetium fraction

Lutetium | 481 μg |

Ytterbium | 470 μg |

Thulium | 26 μg |

Iron | 8.9 μg |

Molecular plating at low potentials traditionally does not produce high yields so the 55% yield was not unexpected and was considered adequate to provide sufficient material for an acceptable target.

Future work

The fabricated 173Lu target has been inserted into the Detector for Advanced Neutron Capture Experiments (DANCE) at LANSCE. Neutron capture cross section data is currently being analyzed. A second Hafnium target has been irradiated and has been partially processed using a different approach to remove the bulk of the Hafnium [2]. This dissolved target was passed through a 15 mL cation column out of a matrix of 0.1 molar HF. The Lutetium was successfully held on the column while allowing the Hafnium to pass through. This eliminated the need for the large anion column step to remove the Hafnium target material. With the lutetium activity from the second hafnium target, we intend to perform a Rare Earth separation to produce an elementally pure Lutetium target.

References

Eichrom products technical information (2008). http://www.eichrom.com/products/info/re_resin.cfm. Accessed 11 July 2008

Mededev DG et al. (2008) Activation of natural Hf and Ta in relation to the production of 177Lu. Appl Radiat Isotop. doi:10.1016/j.apradiso.2008.02.009

Acknowledgments

The authors would like to thank Los National Laboratory groups C-IIAC, C-NR, LANSCE-NS, IPF, Lujan Center, LANSCE accelerator facility, LDRD support, and the LANS LLC. This measurement is supported out the stockpile stewardship program by DOE/NNSA under the auspices of the US Department of Energy at Los Alamos National Laboratory by the Los Alamos National Security LLC, Contract No. DE-AC52-06NA25396.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Taylor, W.A., Rundberg, R.S., Bond, E.M. et al. Production of a 173Lu target for neutron capture cross section measurements. J Radioanal Nucl Chem 282, 391–394 (2009). https://doi.org/10.1007/s10967-009-0278-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-009-0278-1