Abstract

Characterization of SuperLig® 620 solid phase extraction resin was performed in order to develop an automated on-line process monitor for 90Sr. The main focus was on strontium separation from barium, with the goal of developing an automated separation process for 90Sr in high-level wastes. High-level waste contains significant 137Cs activity, of which 137mBa is of great concern as an interference to the quantification of strontium. In addition barium, yttrium and plutonium were studied as potential interferences to strontium uptake and detection. A number of complexants were studied in a series of batch Kd experiments, as SuperLig® 620 was not previously known to elute strontium in typical mineral acids. The optimal separation was found using a 2 M nitric acid load solution with a strontium elution step of ~0.49 M ammonium citrate and a barium elution step of ~1.8 M ammonium citrate. 90Sr quantification of Hanford high-level tank waste was performed on a sequential injection analysis microfluidics system coupled to a flow-cell detector. The results of the on-line procedure are compared to standard radiochemical techniques in this paper.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Aqueous wastes from the production of special nuclear materials during the “cold war” are being stored in single-wall and double-walled tanks within the Department of Energy Complex, most notably at the Hanford reservation near Richland, WA and the Savannah River Site near Aiken, SC. Storage of these wastes was assumed to be temporary. Numerous tanks are leaking, and the contents of these tanks need to be stabilized for long-term storage. A majority of the tank waste radioactivity is made up of strontium, cesium, and barium radionuclides that are present as fission products from the production of plutonium. 137Cs/137mBa represents 38% of the radioactivity in Hanford waste tanks, which is a close second to 90Sr/90Y with 60% of the total activity.

Both cation- and anion-exchange chromatography methods have been developed for strontium/barium separation although these methods are not widely used [1]. Some of the earliest ion-exchange column research for strontium and barium separations were performed with the cation-exchange resins Dowex 50 and Amberlite IR-1 [2–5]. Because of the similar chemical properties and column retention of strontium and barium, a complexing agent has historically been required to allow for sufficient separation using ion-exchange. Ammonium citrate was used as a strontium/barium complexant in ion-exchange research [2–6]. Ammonium citrate was used for Sr/Ba separation on the Amberlite IR-1 and Dowex-50 resins; however, it was noted that Dowex 50 had a greater affinity for cations, and therefore, required conditions differing from those used with Amberlite [3, 7]. It was reported that strontium and barium were completely (100%) recovered within each respective elution, and the separation was nearly ideal [3, 7]. Anion-exchange has also been used with ammonium citrate as a pretreatment to a Dowex-1 column (to form a “citrate column”) followed by elution of a number of alkaline earth metals with varying molarities of ammonium citrate, H3-citrate or hydrochloric acid [6].

Extraction chromatographic resins represent a form of liquid–liquid extraction where a liquid extractant is embedded in the stationary phase of an inert resin. Extraction chromatographic resins are generally highly selective and an alternative to liquid–liquid solvent extraction with lessened worker loads and environmental waste concerns. Extraction chromatographic resins are available for the separation of strontium from barium. One of the DOE standard methods for strontium is the “Determination of Total Radioactive Strontium in High-Level Samples using Extraction Chromatography” RP501 method [8]. This method uses the Eichrom Sr-Resin™ to remove strontium from strong acids and weak acid to elute strontium from the resin. The chemical makeup of the Sr-Resin™ is an extractant, bis-t-butyl-cis-dicyclohexano-18-crown-6, dissolved in 1-octanol and supported on an inert substrate (Amberlite XAD-7) [9]. Researchers at France’s Institute of Protection and Nuclear Safety’s Laboratory of Environmental Radioactivity Measurements have studied the Eichrom Sr-Resin™ in comparison to precipitation methods for strontium separation from barium, calcium, and yttrium and found that it is a viable and faster alternative to precipitation [10].

In recent years, solid phase extraction (SPE) has come into play as a promising technique for strontium separation. IBC Technologies, Inc. (American Fork, UT) has been at the forefront of this technology with their “Molecular Recognition Technology” resins. IBC SPE compounds have been described as containing three parts, the ligand, a connecting spacer, and the solid phase [11]. The actual solid phase portion of the SPE compound is noted as a “proprietary support material” that is capable of being used in highly acidic separations (even with HF or F−), as opposed to a more common solid phase of silica gel, which is slightly soluble in solutions containing F− or OH− [11]. One such SPE compound, SuperLig® 620 resin, has been shown to separate strontium in 2 M nitric acid from a number of interfering metals such as Mg, Ca, Ba, Ra, Pb, Na, and K [12].

Automated separations techniques such as Flow Injection Analysis (FIA) have been used since the 1970s for research with serial based assays predominantly in the fields of biological and pharmaceutical measurements [13]. However, the application of FIA technology to radiochemical separations and detection has only recently been studied. FIA in its original form uses a continuous flow carrier stream pumped uni-directionally, and a sample analyte is injected into the carrier [14]. FIA provides the advantage of highly controlled reaction and dispersion conditions, which enhance the reproducibility and consistency between multiple runs. The evolution of FIA has led to a more complex system known as Sequential Injection Analysis (SIA). In SIA a carrier stream is still in place, but analyte and reagent are both sequentially aspirated into the carrier within a holding coil before reversal of the flow sends the solution to a reaction coil and the detector. A bi-directional pump with multiposition valves is required in SIA to accomplish flow reversal and multi-reagent usage [14–16]. Researchers at the Pacific Northwest National Laboratory (PNNL) have successfully used Sequential Injection Chromatography (SIC) systems for 99Tc and 90Sr monitoring [13, 17, 18]. High-level waste (HLW) cleanup process monitoring SIA instruments are being developed at PNNL.

The strontium/barium separation on an SIC system is the major goal addressed in this paper. Automated process monitoring has the potential to reduce the usage of laboratory materials, labor, and energy. The greatest benefits of automated radiochemical assay are (1) rapid analysis turn-around times, (2) decreased labor costs, and (3) significantly decreased human radiological dose. Human involvement will become limited to periodic maintenance of the automated system. The focus of this research was on the development of an automated separation and quantification scheme for 90Sr in the presence of other radionuclides typically found in a high-level waste process stream. Solid phase extraction was chosen as the optimum separation method because of its increased selectivity for strontium and its potential suitability as a re-usable resin for an automated process monitor.

Materials and methods

A series of batch sorption experiments were performed with the SuperLig® 620 (IBC Technologies, American Fork, UT) solid phase extraction resin in various solutions. The SuperLig® 620 resin used was a 230–430 mesh resin with the specific chemical identity being a trade secret. The sorption solutions were chosen based on their potential to be loading or eluting agents in a column separation scheme. Specific sorption solutions, prepared from analytical grade Fisher Scientific reagents, were made to various concentrations of sodium citrate, ammonium citrate, nitric acid and hydrochloric acid. The batch studies were performed using 85Sr, 133Ba, and 239Pu. A small amount of sodium nitrite (tip of a small spatula) was added to the plutonium solutions in order to ensure that all species of plutonium were oxidized to the tetravalent state. The complexant batch contact solutions were spiked to approximately 1,000 dpm/mL of a single radionuclide of interest using radiometric standards. A known volume (10–20 mL) of the batch contact solutions were placed into 20 mL glass scintillation vials along with a known mass of resin. The required masses for each Kd experiment were estimated based on an estimated Kd and ~50% radionuclide retention in each respective solution. Distribution constants (the ratio of the solid phase concentration to the aqueous phase concentration at equilibrium) from the initial batch contact experiments were used for subsequent calculations of the proper solid to aqueous phase ratio (suspended solids concentration), and this iterative process was used to determine a realistic and repeatable Kd value. Multiple batch experiments were performed for all of the tests in a given molarity solution using this idealized (50% retention) resin mass. The suspended solids concentration was initially on the order of 10−4 g/mL for strontium and 10−3 g/mL for barium. Later experiments utilized a suspended solids concentration on the order of 10−2 g/mL. The solutions were allowed to contact for at least 4 h at 150 rpm on a laboratory shaker. Solutions were then filtered through 0.45 μm syringe filter, and the filtrate was counted on a Packard 2550 TR/AB liquid scintillation counter for 10–30 min. A “No Contact” solution containing no resin was made for each complexant/radionuclide solution and allowed to shake for the same amount of time as the resin contacted solutions. This solution is used as the basis of comparison to the contacted solution in order to determine the Kd value.

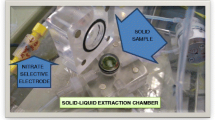

Column experiments were performed on the microfluidics SIC system developed at PNNL. The SIC system uses of a Kloehn Model 5300 syringe pump for aspiration/dispensing of loading and eluting solutions into either a 0.63 mL (or 0.83 mL for the 90Sr and 137Cs experiments) column that is packed with resin. The radionuclide (30,000–50,000 dpm) of interest is loaded into a 0.122 mL sample loop (or 0.25 mL for the 90Sr and 137Cs experiments). A two-position injection valve can be opened or closed to load the sample when needed, and there is also valving to enable reverse flow (RF) and forward flow (FF) through the column. The tubing within the system was Teflon® fluorinated ethylene propylene (FEP), and reagent bottles were made of polypropylene. Detection of the eluted solutions occurs via an IN/US Systems Beta Ram Model 2 flow-through detector with either a 1 mL volume solid lithium glass scintillation cell (for the 85Sr, 88Y, 133Ba experiments) or a 0.6 mL volume BC-400 organic scintillation cell (for the 90Sr and 137Cs experiments). Solid scintillation detection was utilized in this research due to its ease of use, sufficient detection efficiency, and no generation of organic waste. The BC-400 was used in the experiments with 137Cs because the sorption to BC-400 was determined to be negligible. The schematic diagram and a photograph of the microfluidics SIC system can be seen in Fig. 1a and b, respectively.

The optimized chromatographic scheme was determined by trial and error. Pretreatment/washing of the column consisted of running 5 mL of 2 M nitric acid through the column in a forward flow. Each radionuclide was loaded onto the column using a forward flow of 10 mL of 2 M nitric acid to the column while injecting from the sample loop. The sample loop was closed. Strontium was eluted using a forward flow of 7 mL of 0.49 M ammonium citrate, followed by a reverse flow of 10 mL of 1.8 M ammonium citrate for barium elution. All reagents were sent through the column at a flow rate of 1 mL/min, and the detector was set to output the number of counts per 5 s. Chromatograms were then generated from the combination of each radionuclide elution to demonstrate the expected chromatogram for a combined solution.

Results and discussion

Batch uptake tests were conducted to determine the feasibility of separation of strontium and barium using the SuperLig® 620 resin. These data are given in Fig. 2 as distribution constants of strontium and barium in nitric acid. The results indicated that the SuperLig® 620 resin has a strong affinity for strontium and barium in a wide range of acid molarities. Note the suspended solids concentration used in these experiments was ~10−4 g/mL for the strontium experiments and ~10−3 g/mL for the barium experiments, Fig. 2a. Follow-up batch Kd experiments were conducted with suspended solids concentrations on the order of 10−2 g/mL for both strontium and barium in all nitric acid molarities, Fig. 2b. The difference in experimental Kd values are attributed to the mass of resin used in the Kd analyses. There is a more profound difference in the Kd values between the low resin mass strontium experiments and the high resin mass experiments as compared to barium differences. There was also a greater difference between the resin masses used for strontium as compared to barium, which seems to indicate that the Kd values for SuperLig® 620 do vary with resin mass and indicate a non-linear sorption isotherm. Further characterization of the non-linear behavior was not conducted; however, the mass dependency of SuperLig® 620 resin warrants further research. The Kd values that were observed were all greater than 1,000 mL/g, and assumed to be sufficient for column loading in the SIC experiment.

Solutions of sodium citrate and ammonium citrate dibasic were made in order to test the complexation abilities of citrate compounds with barium and strontium. Sodium citrate and ammonium citrate Kd results for 0.1, 0.25, 0.7, and 1.8 M solutions are found in Fig. 3. All citrate molarities tested were performed in at least triplicate. Figure 3 indicates a direct relationship between increased molarity and decreased Kd values. The trend in lower Kd values with increasing molarity solutions and lower Kd values for ammonium citrate compared to sodium citrate. The latter seems to indicate that ammonium citrate is a better eluting agent than sodium citrate. Data shown in Fig. 3 indicate that there is a sufficient difference in the Kd values for barium and strontium in the same molarity of citrate, which is crucial for a sequential separation of these two metals to occur with no co-elution of the other metal. Based upon the results from the batch Kd experiments ammonium citrate was chosen as the elution complexant to be used in SIC column experiments.

The ideal column loading and elution agents, as determined from the batch Kd studies, were applied to the PNNL SIC microfluidics system. For the purpose of determining the optimal column separation conditions (i.e. column volumes and elution times) SIC system experiments were initially conducted using only radionuclides spiked into a 2 M nitric acid matrix. The optimized separation conditions were applied to later experiments with spiked AN-105 Hanford tank waste simulant. The optimized elution scheme was determined to be 10 mL of 2 M nitric acid in the forward flow regime for the elution of yttrium and cesium followed by 7 mL of 0.49 M ammonium citrate in the forward flow regime for the elution of strontium and finally 10 mL of 1.8 M ammonium citrate in a reverse flow regime for the elution of barium.

SIC experiments were performed using the optimized loading/elution scheme and AN-105 Hanford tank waste simulant spiked with the radionuclides of interest. Concentrated nitric acid was used to digest AN-105 tank waste simulant, which is initially highly basic (~2.7 M NaOH), to 2 M nitric acid. Four separate AN-105 in 2 M nitric acid solutions were spiked with 137Cs, 85Sr, 88Y, and 133Ba. Fractions were again collected throughout the experiments for determination of recoveries. Multiple runs of each radionuclide were completed. A blank run was performed between each radionuclide run to demonstrate that no carryover above the instrument background could be observed. The results from the elution profile using AN-105 digested in 2 M nitric acid show is shown in Fig. 4. The cesium recovery was 116% (n = 1), the average strontium recovery was 84.5 ± 8.0% (n = 7), the average yttrium recovery was 96.6 ± 6.7% (n = 3), and average barium recovery was 71.9 ± 10.5% (n = 5). Note that 137mBa is not visible in Fig. 4 during the analysis of 137Cs because the short half-life of 137mBa results in it decaying before it is eluted.

Figure 5 shows the chromatograms that result from 90Sr at several concentrations. In these experiments the 90Sr is spiked into the simulated AN-105 tank waste digested in 2 M HNO3. Figure 5 shows good chromatographic peak resolution while the insert indicates good linearity and a detection efficiency of 56%. The average 90Sr recovery from these experiments was 98%.

Conclusions

A viable method using SuperLig® 620 solid phase extraction resin for the rapid separation of strontium from aged high-level Hanford tank wastes was developed. A SuperLig® 620 automated column separation scheme was developed that was able to quantify yttrium, strontium, and barium in AN-105 Hanford tank waste simulant. The recovery of 90Sr in AN-105 Hanford tank waste simulant was 98%, and there was no overlap of yttrium or barium elution chromatograms. The SuperLig® 620 resin showed no signs of degradation after 20 runs through the SIC system (or approximately 80 actual individual chromatographic analyses through the column). The optimized chemistry makes it possible for strontium detection with an automated on-line process monitor that would ultimately lead to a reduction of labor and radiation dose to workers.

References

U.S. E.P.A. (2004) Multi-agency radiological laboratory analytical protocols manual (MARLAP). EPA 402-B-04-001A, -001B, -001C, NUREG-1576, p 1420

Tompkins ER, Khym JX, Cohn WE (1947) J Am Chem Soc 69:2769

Tompkins ER (1948) J Am Chem Soc 70:3520

Schallert PO (1952) Production separations of fission-product groups for the radioisotope program. Oak Ridge National Laboratory, ORNL-1144

Bonner OD, Smith LL (1957) J Phys Chem 61:326

Nelson F, Kraus KA (1955) J Am Chem Soc 77:801

Power WH, Kirby HW, McCluggage WC, Nelson GD, Payne JH Jr (1959) Anal Chem 31:1077

United States Department of Energy (USDOE). DOE methods compendium—RP501(a), Rev.1 determination of total radioactive strontium in high-level samples using extraction chromatography

Horwitz EP, Chiarizia R, Dietz ML (1992) Solvent Extr Ion Exch 10:313

Goutelard F, Nazard R, Bocquet C, Coquenlorge N, Letessier P, Calmet D (2000) Appl Radiat Isot 53:145

Izatt RM, Bradshaw JS, Bruening RL (1996) Pure Appl Chem 68:1237

Izatt SR, Bruening RL, Krakowiak KE (2003) In: WM’03 conference, Tuscon, AZ

Grate JW, Strebin R, Janata J, Egorov O, Ruzicka J (1996) Anal Chem 68:333

Ruzicka J, Hansen EH (1988) Flow injection analysis, 2nd edn. Wiley-Interscience, New York

Ivaska A, Ruzicka J (1993) Analyst 118:885

Ruzicka J (1994) Analyst 119:1925

Egorov O, O’Hara MJ, Grate JW, Ruzicka J (1999) Anal Chem 71:345

Grate JW, Egorov OB (1998) Anal Chem 70(23):779A

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

DeVol, T.A., Clements, J.P., Farawila, A. et al. Characterization and application of SuperLig® 620 solid phase extraction resin for automated process monitoring of 90Sr. J Radioanal Nucl Chem 282, 623–628 (2009). https://doi.org/10.1007/s10967-009-0219-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-009-0219-z