Abstract

New hydrogels (HG) were synthesized in aqueous medium by free radical polymerization of N,N-dimethylacrylamide (DMAA) and 2-oxazoline macromonomer (MM) initiated by potassium persulfate (KPS) and catalyzed by N,N,N,N′-tetramethylethylenediamine (TEMED). In this polymerization, the monomer DMAA was also used as a crosslinker because it has the ability of self-crosslinking in the presence of peroxodisulfate initiator type. The macromonomer (DP = 24) was a gradient copolymer of 2-methyl-2-oxazoline and methyl-3-(oxazol-2-yl)-propionate with a styryl end group. 1H high-resolution (HR)-MAS NMR spectroscopy allowed to confirm the structure of hydrogels and to determine the molar content of DMAA and MM in each of them. Hydrogels (HG-H) containing carboxylic groups were obtained by basic hydrolysis of HG. Hydrolyzed hydrogels (HG-H) were used for the adsorption of methylene blue (MB) in aqueous medium. It was found that the MB adsorption increased as the initial MB concentration increased, and maximum adsorption capacities were found. The influence of pH value on MB adsorption was evaluated, showing that the MB adsorption capacity of the hydrogels was higher at pH value ≥ 5.7. Adsorption isotherms were studied using Langmuir and Freundlich models. The latter model describes best the process suggesting a possible adsorption mechanism through electrostatic interactions between MB and HG-H hydrogels. The MB adsorbed inside the hydrogels, could be removed with an acidic solution and therefore the hydrogel could be applied to adsorb MB again.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use and application of organic dyes in different industries generally produce polluted and colored wastewater that can affect aquatic flora and fauna. Treatment and removal of pollutants from wastewater can be carried out using physical, chemical, and biological techniques [1, 2]. Among these, adsorption techniques stand out due, in general, to their high colorant adsorption values, a relatively low-cost process, low complexity, and no release of toxic products [2,3,4]. In recent years, there has been a great interest in the investigation of hydrogels that can generate high adsorption capacity and that may have different functional groups in their structure that would allow modifications and, therefore, could make them selective for certain contaminants [2, 5,6,7,8,9,10,11].

One of the most widely used substances in the textile industry for dyeing cotton, wool and silk is methylene blue (MB) [2, 7, 8]. However, its presence in textile wastewater can cause health damage such as permanent eye damage, tissue necrosis, shock, cyanosis, heart disease and allergic reactions [7, 8].

Dimethylacrylamide polymers have a hydrophilic and biocompatible character and exploiting this fact, a series of hydrogels have been prepared by polymerizing DMAA with various monomers, some of which were used to adsorb methylene blue [7,8,9]. For example, Hernandez et al. [7], obtained hydrogels of DMAA and Hydroxyethyl methacrylate (HEMA), with a macroporous structure, which have a maximum adsorption capacity of 80 mg MB g−1 HG in 4 h. On the other hand, Bekiari et al. [9], using DMAA and sodium acrylate hydrogels found that the adsorption capacity of MB was higher at basic than at acid aqueous medium and the maximum MB adsorption value obtained was 783 mg MB g−1 HG at pH 12. Normally, conventional crosslinkers have been used to obtain DMAA hydrogels [6, 7, 9], but Cipriano et al. used the extraordinary property that DMAA presents known as “self-crosslinking” [10, 11], which occurs when polymerizing this monomer via free radicals with potassium peroxodisulfate-type initiators or photoinitiation with camphorquinone and diphenyliodonium hexafluorophosphate [12]. In this way, hydrogels with excellent mechanical resistance and high water absorption were obtained. Which was attributed to its homogeneous crosslinking and high polarity.

On the other hand, poly (2-oxazolines) have attracted the interest of the international scientific community due to their special properties such as the biocompatibility of polymethyl- and polyethyloxazoline and the fact that polymers with a controlled molecular weight can be obtained and furthermore these macromolecules can be easily functionalized through appropriate initiators, terminators and monomers. All these properties are the product of the “living” ring-opening cationic polymerization of 2-oxazolines [13,14,15]. A series of hydrogels have been synthesized from the oxazolines which have properties to be used in the field of medicine and biotechnology because they have, for instance, the properties of biocompatibility, antifouling, adsorption of pigments and heavy metal cations and sensitivity to temperature [13,14,15,16,17,18,19]. For example, recently, Xu et al. synthesized new hydrogels from 2-isopropenyl-2-oxazoline) and pillar(5)arene with excellent mechanical properties and adjustable water absorption, which were able to adsorb different pigments, including methylene blue, obtaining a maximum adsorption of this dye of 45 mg g−1 hydrogel [17]. Applying the characteristics of the “living” polymerization of the 2-oxazolines it is possible to obtain 2-oxazoline macromonomers with predetermined polymerization degree, variable functionality and different chain end vinyl groups, such as styrene, acrylates, etc. [18, 19]. These materials can be incorporated into various architectures such as comb polymers, graft copolymers, star polymers, and hydrogels and these new materials can find application as surfactants, in controlled drug delivery, surface modification, adsorption of pollutants, etc. [14, 15, 18].

In the present study, the synthesis and characterization of new hydrogels obtained from the copolymerization of N,N-dimethylacrylamide (DMAA) and a 2-oxazoline macromonomer (MM) and the adsorption of methylene blue (MB) for these hydrogels was investigated.

Experimental part

Materials

Chloromethylstyrene (CMS) (Aldrich, mixture of isomers 70 mol% meta and 30 mol% para) and N, N, N′, N′-tetramethylethylenediamine (TEMED, Aldrich) were purified by distillation before use. Acetonitrile (Aldrich) was purified by fractional distillation (Merck). N,N-dimethylacrylamide (DMAA), potassium persulfate (KPS), methylene blue (MB) (Aldrich) and solvents were used as received. 2-Methyl-2-oxazoline (MeOxa) and methyl-3-(oxazol-2-yl)-propionate (EsterOxa) were synthesized and purified by methods reported in the literature [20,21,22]. All the solutions were prepared with ultrapure water, which was obtained from the Thermo Scientific NANOpure system.

Synthesis of 2-oxazoline macromonomer (MM)

The MM was synthesized using the method described in the literature [22]. In a round-bottomed flask, 6.89 g (81.0 mmol) MeOxa, 4.24 g (27.0 mmol) EsterOxa, 1.62 g (10.88 mmol) NaI were dissolved in 22 mL of acetonitrile. The polymerization was initiated by 0.828 g (5.4 mmol) CMS and carried out at 78 °C for 7 h. (yield: 96%). The molar composition (78 and 22 mol% for MeOxa and EsterOxa, respectively) and the degree of polymerization (DP = 24) were determined by the analysis of 1H NMR spectrum. Furthermore, the molecular weight was determined by gel permeation chromatography (GPC).

1H NMR (CD3OD) δ: 2.1 (CH3), 2.4–2.8 (COCH2CH2COO-), 3.5 (NCH2CH2), 3.7 (COOCH3), 5.2–5.3 and 5.7–5.9 (CH2=), 6.7–6.8 (=CH), 7.1–7.5 (Harom).

Synthesis of hydrogels (HG)

The hydrogels (HG) were synthesized using the self-crosslinking property of the DMAA in the presence of persulfate radical initiators such as, potassium persulfate (KPS) [10, 11]. In a typical procedure, 3.35 g (33.8 mmol) DMAA and 0.434 g (0.17 mmol) MM were dissolved in water under nitrogen for 45 min. Then 0.036 g (0.13 mmol) KPS were added and the solution was bubbled with nitrogen for further 15 min. Finally, 0.020 g (0.17 mmol) of TEMED were added and the final mixture was poured into a glass mold and left at 5 °C until gelation. The hydrogel formation took place in 15 min. The obtained hydrogel was purified by repeated washing with distilled water, dried at 40 °C in vacuum and stored. The experimental details and results are summarized in Table 1.

HG-1 (synthetized only with DMAA): HR-MAS 1H NMR (D2O) δ: 1.17–1.71 (CH2, DMAA, 2.56–3.04 ppm (N(CH3)2 + CH, DMAA).

HG-2: HR-MAS 1H NMR (D2O) δ: 1.38–1.80 (CH2, DMAA), 2.07–2.11 (CO-CH3, MM), 2.63–2.93 (N(CH3)2 + CH, DMAA), 3.00–3.14 (N-CO-CH2-CH2-COO, MM), 3.53 (NCH2CH2, MM) and 3.68 ppm (OCH3).

Hydrolysis of hydrogels

A 4 g portion of hydrogel HG, swollen in water, was immersed in 85 mL of 0.1 N NaOH solution for 48 h at 35 °C. After this time, the hydrolyzed hydrogel (HG-H) was washed with distilled water until neutrality, dried under vacuum and stored.

HG-2H: HR-MAS 1H NMR (D2O) δ: The signals were similar to HG-2, but the signal at 3.68 ppm (OCH3) disappeared due to the hydrolysis.

Water absorption degree (Q)

Typical procedure: A portion of dried hydrogel (Wd) was immersed in distilled water (pH = 5.7) at 20 °C for 48 h until reach equilibrium. Then, the hydrogel was removed from water, dried on the surface with tissue paper, and finally the swollen hydrogel was weighed (Ws). Water absorption degree of hydrogel (Q) was calculated using the following equation (Eq. (1)):

Analytical measurements

The NMR measurements were carried out on a Bruker Advance III 500 spectrometer operating at 500.13 MHz for 1H. For hydrogel analysis, a HR-MAS (high resolution – magic angle spinning) NMR probe with z-gradient was used. The hydrogel sample was placed in a 4 mm rotor and was swollen with D2O.

Attenuated Total Reflectance – Fourier transform infrared (ATR-FTIR) spectra were acquired in a Bruker Tensor 27 spectrometer in the range 4000–400 cm-1, with a resolution of 4 cm-1and accumulation of 32 scans. We have used 20 mg of sample.

Measurements of methylene blue (MB) concentration were carried out with a Thermo Electron Corporation Helios Gamma UV-Visible (UV-Vis) spectrophotometer. pH measurements were made with a Mettler Toledo pH-meter Seven Multi.

SEC analysis of MM was carried out on an Agilent Technologies LC 1100 apparatus equipped with PL Oligopore column and RI detector. The molecular weight calibration was performed with polyvinylpyridine standards and the sample was eluated with dimethylacetamide containing 2 vol% water and 3 g L−1 LiCl.

Methylene blue adsorption (MB)

Determination of the MB visible spectrum and elaboration of calibration curve

40 mg of MB were dissolved in 1 L of water. Then, in the UV-Vis spectrophotometer, a spectral scanning (400–800 nm) of this MB solution was performed, which allowed the determination of the wavelength value of MB λmax = 664 nm (Fig. S1) that produce the maximum absorbance. On the other hand, a 125 mg L−1 MB aqueous solution was prepared from which were obtained, through dilutions, MB standards of concentrations: 2.5, 5.0, 7.5 and 10.0 mg L−1. The absorbance of each MB standard was measured in the UV-Vis spectrophotometer. The calibration curve (Fig. S2) was obtained by the plot of absorbance (Abs) vs MB standard concentration (C):

Abs = 0.1538 C + 0.1885 (Eq. (2)), R2 = 0.9902, where: Abs: absorbance and C: concentration of MB (mg L−1).

Adsorption experiments

All adsorption experiments were performed at 20 °C and by immersing swollen hydrogels (previously, 20 mg of dried hydrogel was immersed in distilled water for 48 h) in 10 mL of MB solution (50 mg L−1) for 24 h. After this time, the residual concentration of dye was determined with the calibration curve.

The influence of initial dye concentration on the adsorption, was studied using MB aqueous solutions of different concentrations: 15, 36, 55, 80 and 96 mg L−1 (low concentrations range) and 417, 601, 799, 1004 (high concentrations range). It was possible to determine the values of adsorption capacity of MB (Qe), which represent the amount of adsorbed dye per unit mass of dried hydrogel (mg g−1), calculated with the following equation (Eq. (3)):

Where Ci and Cf are the initial and final concentrations of MB aqueous solution, Vsol is the volume used of MB solution and mads is the mass of dried hydrogel.

The influence of pH on MB adsorption by hydrogel was studied using a sample of hydrogel immersed in 50 mg L−1 MB aqueous solution adjusted to different pH values (2, 4, 5.7, 7, 8.5 and 10) using a pH-meter and solutions of 0.1 N NaOH and 0.1 N HCl, and a time of 24 h.

Langmuir and Freundlich models (Eqs. 4 and 5), respectively) were applied to determine the model that could best represent the process of MB adsorption on hydrogel [23,24,25,26]:

Where: Ce is the concentration of MB at equilibrium (mg L−1), Qe is the amount of adsorbed MB per gram of hydrogel at equilibrium (mg g−1), Qm is the maximum adsorption capacity per hydrogel mass unit in the monolayer (mg g−1), Kf and KL are Freundlich (L g−1) and Langmuir (L mg−1) constants, respectively, 1/n is a parameter associated to the adsorption intensity.

Finally, a test was carried out to demonstrate whether it is possible the desorption of MB in hydrogels. A portion of 3 g of hydrogel HG-3H (which had adsorbed MB in equilibrium) was divided into approximately equal parts. The first portion was immersed in 20 mL of a 0.1 N HCl aqueous solution for 24 h and the second portion was immersed in 20 mL of a 0.1 N aqueous NaOH solution for the same period. This process was carried out to evaluate the behavior of desorption of MB by the hydrogel in acid or basic medium.

Results and discussion

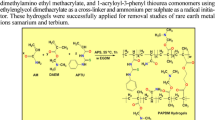

Synthesis of 2-oxazoline macromonomer (MM)

The MM was synthesized through ring-opening cationic copolymerization of 2-methyl-2-oxazoline (MeOxa) and methyl-3-(oxazol-2-yl)-propionate (EsterOxa), initiated by chloromethylstyrene, and catalyzed by sodium iodide in acetonitrile (Scheme 1). The polymerization proceeds successfully (yield: 96%). The premature polymerization of the vinyl groups was avoided because a relatively low reaction temperature, short reaction time and a low initiator concentration (CMS) was used [22]. The obtained macromonomer containing a styryl group at the end of the polymer chain, presented a degree of polymerization of 24 units and a molar content of 78.0 and 22.0 mol% of MeOxa and EsterOxa, respectively, determined by quantitative analysis of 1H-NMR spectrum. The degree of polymerization (DP = 24, theoretical value: 20) was determined by comparing the integral of the signal of NCH2CH2 groups of MeOxa and EsterOxa versus the integral of vinyl group signals (in 5.2–5.3 ppm, 5.7–5.9 ppm (CH2=) and 6.7–6.8 ppm (= CH)). The molar percentage of each monomer in MM was determined by comparing the integral to 2.1 ppm (corresponding to the methyl group of MeOxa) and the signal to 2.4–2.8 ppm (corresponding to the two methylene groups of EsterOxa). Mn,NMR: 2550 ± 150 g mol−1 was lower than the Mn,SEC: 3900 g mol−1, whereby the latter is based on calibration with polyvinylpyridine standards. Additionally, a low value of polydispersity (1.10) confirms the living character of the polymerization (Fig. S3).

2-oxazolines polymerize via living polymerization without termination or transfer reactions [27,28,29] as already discussed in a previous publication [22], it is postulated that iodomethylstyrene (IMS) (formed in situ as a product of reaction between CMS and sodium iodide) initiates the polymerization. According to Bouten et al. [27], there is a preferred incorporation of MeOxa than EsterOxa in the copolymer, the latter suggests the obtention of a gradient copolymer.

The m,p-vinylbenzyl (or “styryl”) group, at the end of the macromonomer chains, presents greater stability compared to acrylate or methacrylate groups, since it does not contain hydrolyzable groups like the ester group present in the latters.

Synthesis of hydrogels (HG, HG-H)

The hydrogels were obtained by free radical polymerization of DMAA and MM, initiated by potassium persulfate (KPS) and catalyzed by TEMED (Scheme 2). A series of hydrogels was synthesized varying the molar content of MM (HG-2 to HG-6). HG-1 was a reference hydrogel synthetized only with DMAA. The use of conventional crosslinkers was unnecessary due to the self-crosslinking property of DMAA. Different researchers [10, 11] proposed the formation of methylene radicals (consequence of the attack of persulfate radical on a methyl group of DMAA) which can initiate graft chains and result in a crosslinking structure.

The hydrogels HG-2 to HG-6 were hydrolyzed under mild basic conditions (0.1 NaOH, 35 °C, 48 h) in order to hydrolyze only the ester groups and to avoid the possible hydrolysis of amide groups.

The hydrogels produced by this method, in qualitative terms, presented good mechanical properties (they are elastic) although these were not measured in the present research. The good mechanical properties are probably due to the homogeneous distribution of the crosslinking points due to the random self-crosslinking of the DMAA [10].

NMR analysis of hydrogels

The characterization of hydrogels by HR-MAS 1H NMR spectroscopy allowed to confirm the proposed chemical structure (Fig. 1 and S4). DMAA-MM (HG-2 to HG-6) hydrogels result in 1H NMR similar spectra. All hydrogels were hydrolyzed, Fig. 1a shows, as an example, spectra of HG-6 and its respective hydrolyzed HG (HG-6H). From that, it could be seen the similarity between spectra, however HG-6H shows the disappearance of the methyl ester signal (3.6 ppm) which corroborates the complete hydrolysis.

HR-MAS 1H-NMR spectra of hydrolyzed hydrogels (Fig. 1b) allowed the quantification of the molar content of MM and DMAA in hydrogel (Table 1) by comparing the integrals to 3.4–3.9 ppm corresponding to the NCH2CH2 groups of the MM macromonomer and the integral to 1.2–1.9 ppm corresponding to the CH2 group of the DMAA monomer. The content of MM in hydrogels was always lower than in feed composition (Table 1), this could be explained by the fact that the MM (due to its greater size) presents a lower diffusion rate than the DMAA and therefore reacts to a lesser extent [22].

Furthermore, FTIR spectra of the macromonomer MM and HG-5H were obtained. While the FTIR spectrum of MM show ester and amide peaks at 1625 and 1734 cm−1 (Fig. S5) that can be attributed to the amide and ester groups [30]. The ester peak is absent in the FTIR spectrum of hydrolyzed hydrogel HG-5H (Fig. S6).

Water absorption degree

The synthesized hydrogels absorb water due to high polarity of MM and DMAA. The values of water absorption degree (Q) determined at pH = 5.7 are shown in Table 1.

It was determined that the Q values of the non-hydrolyzed hydrogels (HG-2 to HG-6) were lower than Q values of the hydrolyzed hydrogels (HG-2H to HG-6H) (Table 1). This could be explained due to the presence of polar carboxylic acid and carboxylated groups in hydrolyzed hydrogels, which have a strong interaction with water molecules through hydrogen bonds, compared to the weak interaction of ester and amide groups of non-hydrolyzed HG (possibly by dipole-dipole forces) with water. Furthermore, for hydrolyzed hydrogels, as the MM content in the hydrogel structure increased, the presence of carboxylic acid polar groups increased, resulting in greater water absorption values until 2 mol% MM (Table 1), but for HG-5 and HG-6 the Q values slightly decrease. This probably occurs due to the high ionic charge in HG or to the formation of hydrogen bonds in these HG.

Methylene blue adsorption with hydrogels

First, a spectral scanning of the MB aqueous solution in the range of 400–800 nm was performed (Fig. S1), and it was determined that the maximum absorbance was obtained at λmax = 664 nm, this value is in accordance with the value (λmax = 663 nm) mentioned in the literature [9]. Therefore, in this studio all the absorbance values of MB solutions were determined at 664 nm.

Plotting the absorbances (Abs) of MB aqueous solutions (concentrations: 2.5; 5.0; 7.5 and 10.0 mg L−1) against each MB concentration value (C) and performing a linear regression, leads to obtain the equation: Abs = 0.1538 C + 0.1885, used to measure concentrations of all MB solutions.

All MB adsorption experiments were performed only with hydrolyzed hydrogels HG-H because a previous MB adsorption test with non-hydrolyzed hydrogels showed a very low adsorption of MB (Fig. 2) compared to relatively high adsorption by hydrolyzed hydrogels. This is due to the weak interaction between non-hydrolyzed hydrogels (HG-2 to HG-6) and MB (Fig. 3).

Effect of MB initial concentration

The effect of the MB initial concentration on its adsorption on HG-H was evaluated. It was found, for hydrogel series HG-1, HG-2H to HG-6H in a concentration range of 15 to 96 mg L−1 and pH = 5.7 that the amount of adsorbed MB (Qe) increased with greater initial MB concentrations (Fig. 4). A higher concentration of dye in the solution leads to an increase of cations N+ of dye, which would interact with the hydrogel active sites (carboxylate anions, COO−) and therefore greater MB adsorption could occur.

In Fig. 4, it could be also observed that despite the increase of molar content of MM in hydrogel series HG-2H - HG-6H (from 0.3 to 2.7 mol%), there is no significant difference in the Qe values of the hydrogels, however, when a highest concentration range was evaluated (417 to 1004 mg L−1), higher Qe values as the MB concentration were obtained as the MM content increases in hydrogels (Fig. 5). The maximum values of Qe (Qe,max mg MB/g dried HG) were determined: 79.1, 158.2, 189.1 and 226.4 for hydrogels HG-3H, HG-4H, HG-5H, and HG-6H, respectively. These values are higher than, for example, the value obtained by Hernandez-Martinez et al. [7], who used nonionic hydrogels from DMAA and HEMA.

Furthermore, HG-1 showed the lowest Qe values, because it is only composed of DMAA and possibly its amide groups interact with the positive charge (N+) of the MB through dipole – dipole or similar forces. Those forces are weak compared to the strong electrostatic interactions of negatively charged carboxylate groups of HG-H hydrogels and the cation N+ of MB (Fig. 3).

Effect of pH

The influence of pH on MB adsorption was studied (Fig. 6). A 50 mg L−1 MB standard solution was used at 20 °C. MB adsorption by hydrogels HG-2H, HG-4H and HG-6H showed an increment, when the pH value was increased from 2 to 5.7. In acidic conditions, the values of Qe were low (lowest Q value at pH = 2). This probably occurs due to a competition for hydrogel active sites (carboxylate groups), between H+ ions (of the medium) and N+ ions (of the dye). It would prevent the occurrence of a high MB adsorption on the material.

The highest and constant values of adsorption capacity (Qe) were obtained at equal or greater pH values than 5.7 because in this state exist equal or more than 50 mol% of carboxylate groups (pKa = 5.6 for MM was previously determined in literature [29]) and the negative charges of the hydrogel would interact strongly with the positive charge of the MB. For HG-1 there is a little variation of MB adsorption with different pH because this hydrogel does not present polar carboxylate groups in its structure.

Adsorption isotherms

Adsorption isotherm can give evidence of the interaction mechanism between the adsorbent (HG-H hydrogels) and adsorbate (MB molecules), when the adsorption process reaches a state of equilibrium. Adsorption isotherms were evaluated by Langmuir model, plotting the Ce/Qe vs. Ce (Fig. 7) and by Freundlich model, plotting the Log Qe values vs. Log Ce (Fig. 8), where Ce is the concentration of MB at equilibrium (mg L−1) and Qe is the amount of adsorbed MB per gram of hydrogel at equilibrium (mg g−1). Calculations of both isotherms were performed in the concentration range of 15 to 96 mg L−1.

When submitting isotherms to the Langmuir model, the obtained curves present low values of correlation coefficients squared (R2: 0.01–0.75) and an adequate linearization is not achieved, reason why this model was discarded. However, when applying the Freundlich model, straight lines were obtained with relatively high values of correlation coefficients squared (R2 > 0.95) and therefore it was determined that this model was the one that could best represent the adsorption process of MB on hydrolyzed hydrogels (Table 2). This would indicate, as Freundlich model postulates that MB adsorption occurs on the heterogeneous hydrogel volume, with multiple sites available for adsorption [24,25,26]. Table 2 shows the parameters of the equations obtained for Freundlich curves of hydrogels 2H, 3H, 4H, 5H, and 6H. Values of n greater than 1 were obtained (Table 2) and can be related to a physisorption process, which would be in agreement with the fact that the MB adsorption process on HG-H hypothetically occurs mainly through the electrostatic interaction of carboxylated groups (COO−) of the hydrogels and the cation (N+) of the MB (Fig. 3).

To demonstrate the possible desorption of MB from hydrogel, a desorption test was performed in acidic and basic aqueous media with hydrogel HG-3H. The results showed that hydrogel desorbed the MB completely under acidic conditions (0.1 N HCl), the hydrogel becomes colorless again and the solution acquires the blue color of the MB (Fig. 9). On the contrary, the hydrogel does not desorb the MB under basic conditions and remains blue. This was to be expected because hydrolyzed hydrogel is composed of negative carboxylate groups, that would interact preferentially with protons of medium, and allow easy release of the dye.

For a next publication, we plan to make an in-depth research of the adsorption and desorption cycles of MB from the hydrogel, the parameters that influence this phenomenon, and the effectivity of using HCl in aqueous solution as an eluent.

Conclusions

New hydrogels were synthesized by free radical polymerization of DMAA and MM, catalyzed by TEMED, in aqueous medium and without the employment of a conventional crosslinker owing to the self-crosslinking ability of the DMAA in presence of potassium persulfate. It was determined by 1H high-resolution (HR)-MAS NMR spectroscopy that the macromonomer was a gradient copolymer with a degree of polymerization (DP) of 24 units, and a molar content of 78.0 and 22 mol% for MeOxa and EsterOxa, respectively. This technique also allowed to determine the complete hydrolysis of HG.

MB adsorption on HG-H hydrogels possibly occurs owing to the presence of carboxylate groups. Under basic pH values, the materials showed higher MB adsorption capacity values (Qe) compared to acid pH values due to electrostatic interactions between carboxylate anions of hydrogel and cation of MB. It was obtained the maximum adsorption values Qe,max (mg MB g−1 dried HG-H):79.1, 158.2, 189.1 and 226.4 for hydrogels HG-3H, HG-4H, HG-5H and HG-6H, respectively.

The dye adsorption process was well described by Freundlich model, indicating that the adsorption possibly occurs on the heterogeneous volume of the hydrogel. Besides, from this model, the obtained values of parameter “n” greater than one unit, allowed to conclude that possibly the adsorption mechanism would be governed by a process of physisorption based on electrostatic interactions between the MB and the hydrogel.

It was demonstrated that the hydrolyzed hydrogel HG-3H could desorb MB under acidic conditions. This indicates that the synthesized materials could be potentially applied for MB adsorption in wastewater.

References

Geetha K, Velmani N (2015) Diverse technology and methods for dye treatment. Asian J Chem 27:1177–1184

Zhou Y, Lu J, Zhou Y, Liu Y (2019) Recent advances for dyes removal using novel adsorbents: a review. Environ Pollut 252:352–365

Regti A, Lamari MR, Stiriba S, Haddad ME (2016) Removal of basic blue 41 dyes using Persea Americana-activated carbon prepared by phosphoric acid action. Int J Ind Chem 8:187–195

Adeyemo AA, Adeoye IO, Bello OS (2017) Adsorption of dyes using different types of clay: a review. Appl Water Sci 7:543–568

Sanchez L, Ollier R, Alvarez VA (2019) Sorption behavior of polyvinyl alcohol/bentonite hydrogels for dyes removal. J Polym Res 26:142

Jana S, Mondal B, Tripathy T (2019) Efficient and selective removal of cationic organic dyes from their aqueous solutions by a nanocomposite hydrogel katira gum-cl-poly(acrylic acid-co-N,N-dimethylacrylamide)-bentonite. Appl Clay Sci 173:46–64

Hernández-Martínez AR, Lujan-Montelongo JA, Silva-Cuevas C, Mota-Morales JD, Cortez-Valadez M, Ruíz-Baltazar A, Cruz M, Herrera-Ordonez J (2017) Swelling and methylene blue adsorption of poly(N,N-dimethylacrylamide-co-2-hydroxyethyl methacrylate) hydrogel. React Func Polym 122:75–84

Yi J, Li Y, Yang L, Zhang L-M (2019) Kinetics and thermodynamic adsorption of Cu2+ and methylene blue to casein hydrogels. J Polym Res 26:235

Bekiari V, Sotiropoulou M, Bokias G, Lianos P (2008) Use of poly(N,N-dimethylacrylamide-co-sodiumacrylate) hydrogel to extract cationic dyes and metals from water. Colloids Surface A Physicochem Eng Asp 312:214–218

Cipriano BH, Banik SJ, Sharma R, Rumore D, Hwang W, Briber RM, Raghavan R (2014) Superabsorbent hydrogels that are robust and highly stretchable. Macromolecules. 47:4445–4452

Needles HL, Whitfield RE (1956) Crosslinking of copolymers containing N,N-dimethylacrylamide. J Polym Sci Part A 3:3543–3548

Sun G, Huang Y, Li D, Chen E, Zhong Y, Fan Q (2019) Blue light initiated photopolymerization: kinetics and synthesis of superabsorbent and robust poly(N, N-dimethylacrylamide/sodium acrylate) hydrogels. Ind Eng Chem Res 58:9266–9275

Zschoche S, Rueda JC, Binner M, Komber H, Janke A, Appelhans D, Voit B (2017) Temperature and pH dependent aggregation behavior of hydrophilic dual-sensitive poly(2-oxazoline)s block copolymers as latent amphiphilic macromolecules. Eur Polym J 88:623–635

Dargaville TR, Park J-R, Hoogenboom R (2018) Poly(2-oxazoline) hydrogels: state-of-the-art and emerging applications. Macromol Biosci 18:1800070

Hartlieb M, Kempe K, Schubert US (2015) Covalently cross-linked poly(2-oxazoline) materials for biomedical applications – from hydrogels to self-assembled and template structures. J Mater Chem B 3:526–538

Jerca FA, Anghelache AM, Ghibu E, Cecoltan S, Stancu I-C, Trusca R, Valle E, Teodorescu M, Vuluga DM, Hoogenboom R, Jerca VV (2018) Poly(2-isopropenyl-2-oxazoline) hydrogels for biomedical applications. Chem Mater 30:7938–7949

Xu X, Jerca FA, Van Hecke K, Jerca VV, Hoogenboom R (2020) High compression strength single network hydrogels with pillar[5]arene junction points. Mater Horiz 7:566–573

Pizzi D, Humphries J, Morrow JP, Fletcher NL, Bell CA, Thurect KJ, Kempe K (2019) Poly(2-oxazoline) macromonomers as building blocks for functional and biocompatible polymer architectures. Eur Polym J 21:109258

Rueda JC, Suárez C, Komber H, Zschoche S, Voit B (2019) Synthesis and characterization of pH- and thermo-responsive hydrogels based on poly(2-cyclopropyl-2-oxazoline) macromonomer, sodium acrylate, and acrylamide. Polym Bull. https://doi.org/10.1007/s00289-019-03034-0

Witte H, Seeliger W (1974) Cyclische Imidsäureester aus Nitrilen und Aminoalkoholen. Liebligs Annalen der Chem 1974:996–1009

Zarka M, Nuyken T, Weberkirch R (2003) Am Amphiphilic polymer supports for the assymetric hydrogenation of amino acid precursors in water. Chem Eur J 9:3228–3234

Rueda JC, Campos E, Komber H, Zschoche S, Haussler L, Voit B (2013) Synthesis and characterization of new pH- and thermoresponsive hydrogels based on N-isopropylacrylamide and 2-oxazolines. Des Monomers Polym 17:208–216

Langmuir I (1918) The adsorption of gases on lane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Freundlich HMF (1906) Over the adsorption in solution. J Phys Chem 57:385–470

Ding C, Li Z, Jin J (2008) Adsorption behavior of p-chlorophenol on the reed wetland soils. J Environ Sci Technol 1:169–174

Milan K (2014) Adsorption, chemisorption and catalysis. Chem Pap 68:1625–1638

Bouten P, Hersten D, Vergaelen M, Monnery B, Boerman M, Goosens H, Catak S, Hesat J, Van Speybroeck V, Hoogenboom R (2015) Accelerated living cationic ring-opening polymerization of a methyl ester functionalized 2-oxazoline monomer. Polym Chem 6:514–518

Bouten P, Hersten D, Vergaelen M, Monnery B, Boerman M, Goosens H, Catak S, Hesat J, Van Speybroeck V, Hoogenboom R (2015) Synthesis of poly(2-oxazoline)s with side chain methyl ester functionalities: detailed understanding of living copolymerization behavior of methyl ester containing monomers with 2-alkyl-2-oxazolines. Polym Chem 53:2649–2661

Zschoche S, Rueda JC, Binner M, Komber H, Janke A, Arndt K, Lehmann S, Voit B (2012) Reversibly switchable pH- and thermoresponsive core-shell nanogels based on poly(NiPAAm)-graft-poly(2-carboxyethyl-2-oxazoline)s. Macromol Chem Phys 213:215–226

Guenzler H, Gremlich H-U (2002) IR spectroscopy – an introduction. Weinheim, Germany

Acknowledgements

The authors of this paper would like to thank the Research Department of the Pontifical Catholic of University of Peru (PUCP) for funding this research.

The authors thank Dr. Hartmut Komber and Prof. Brigitte Voit, of Leibniz Institute for Polymer Research Dresden Germany, for HR-MAS 1H NMR analysis and help with compiling the manuscript, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 258 kb)

Rights and permissions

About this article

Cite this article

Santillán, F., Rueda, J.C. Removal of Methylene Blue by Hydrogels based on N, N-Dimethylacrylamide and 2-Oxazoline macromonomer. J Polym Res 27, 263 (2020). https://doi.org/10.1007/s10965-020-02239-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02239-6