Abstract

Cardiovascular diseases (CVD) because of blood vessel disease are considered as one of the most frequent causes for mortality in all over the world. Recently, blood vessel tissue engineering is identified as one the promising strategies in order to overcome CVD. Accordingly, using Nano technology provides many benefits in blood vessel tissue engineering. In Present research Unique electrical, mechanical and biochemical properties of SWNT combined with electrospun polyurethane nanofiber was investigated as a functional composite scaffold for vascular tissue engineering. SWNT and polyurethane nanofibers incorporation indicated a biomechanical behavior similar to native artery. The scaffold morphological properties have been investigated by the use of scanning electron microscopy. With respect to the results, nanofiber diameter distribution was narrowed down by increasing SWNT content, while mean nanofiber diameter increased from 40 nm up to 140 nm. Physico-chemical characterization using FTIR, DSC, XRD and Raman test, demonstrated the nanoparticle appropriate dispersion and interaction to the polyurethane macromolecule. Along with increasing SWNT content up to the 2% (W/W) ultimate stress and young modulus increased 3 and 11 time, compared to pure PU, respectively. Structures electrical conductivity was increased from 0.0013 s/cm to 0.36 s/cm along with the increasing of SWNT content up to 2%. SWNT unique properties modulated samples hydrophilicity, and also contact angle of nanofiber scaffolds decreased from 1000 to 770. By passing 7 days, in vitro cell culture demonstrated dense layer of endothelial cells, which is crucial for blood vessel tissue engineering. Obtained results confirmed that electrospun poly urethane-SWNT scaffold could be considered as an appropriate candidate for blood vessel tissue engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Regarding the literatures, cardiovascular diseases are identified as one of the important causes of mortality and morbidity in all over the world [1]. a plaque Formation in coronary arteries branch would result in blood vessels obstruction, and also inhibition of oxygenated blood delivery in long term, which leads to myocardial infarction [2]. In addition, one of the current approaches in bypass surgery is using autologous arterial or venous grafts instead of diseased vessels. However, this strategy has some limitations due to pre-existing vascular disease, prior surgery, limited length or poor histocompatibility [3].

Therefore, many strategies like using artificial blood vessels were developed in order to overcome these limitations. This prosthesis was made from polytetrafluoroethylene (ePTFE) or polyethyleneterephthalate (Dacron) that were used instead of impaired blood vessel. Some insufficiencies like thrombus formation, intimal hyperplasia and compliance mismatch often result in complete graft failure. These grafts could not be permanently administrated for replacing every diseased blood vessel [4]. Although, autologous blood vessels possessed essential blood compatibility, biocompatibility and flexibility, but approximately 30% patient who passed vascular surgery doesn’t have suitable graft with appropriate length and size [5, 6].

Therefore, blood vessel tissue engineering toward completely and biologically manufacturing the blood vessel was developed. Many crucial factors were required in order to design and engineer functional blood vessel. From the mechanical properties point of view, appropriate scaffold should mimic the target tissue mechanical behavior [7, 8]. Necessary mechanical strength, which includes compliance in terms of native blood vessel, with the ability to tolerate long-term hemodynamic stress without any rupture and indicating no permanent creep sign, which can lead to aneurysm formation, are the key engineering factor that should be considered in designing and preparation of blood vessel scaffold [9,10,11].

In tissue engineering principles, it has been widely approved that physical structure and chemical composition of scaffold should be according to the native extracellular matrix. Scaffolds play crucial role in development of functional tissue engineering strategies [12, 13]. All of the constructive elements of native extra cellular matrix are in the size range of nanometer (which always were considered in scaffolds fabrication) [14]. Therefore, nanofiber administration as template for vascular tissue engineering could potentially be effective, and also guide the constructive cells behavior to forming neo tissue.

It is extensively approved that scaffold mechanical properties should exhibit strain-stress response in comparison with the tissue, which is intended to be replaced. And it is still axiomatic that the way in which stress or the load transmitted to the cells should be considered in designing the scaffold [15]. This research attempted to achieve this purpose.

Much effort has been devoted to fabricating effective scaffold materials in order to improve the cellular attachment, proliferation, and differentiation. Nanomaterials determinative characteristics in order to modulate cell behavior have received increasing interest in the last several years. Electrospinning represents an attractive technique for the polymeric biomaterials processing into nanofibers. Approximately 50 to 150 nm diameter of natural extra cellular matrix element could guide tissue cells to perform special behaviors. Scaffold nano scale properties could simulate this condition effectively [16].

Electrospinning of nanofiber can produce structure to simulate nature environment of living cells similar to versatile as effective and inexpensive procedure. However, this is important that the morphology and the organization of cell cytoskeleton protein changes in contact with electrospun nanofiber [8, 17]. Despite of that, this important electrospun nanofiber could modulate stress transmission to the cells similar to native tissue [18, 19]. Also, many studies investigated the electrospun nano fibers applications, especially for blood vessel tissue engineering [20].

With respect to polyurethane known biocompatibility and superior tensile and elastic properties, they are considered as appropriate candidates for blood vessel tissue engineering scaffolds [21, 22]. Therefore, polyurethane was administrated during this research as main polymer in order to reach special target.

Polyurethanes own the highest degree of elasticity low thrombogenicity and compliance matching to the native vascular tissue amongst those polymers, which had been administrated in blood vessel tissue engineering [23]. But the poor bio stability and cell interaction limited their long term in vivo application [24, 25].

In a study accomplished by Nieponice et al. interaction of muscle stem cells by tubular polyurethane structure was investigated using rotational vacuum seeding device. Results indicated that without any cell toxicity morphology, the cells were remained unchanged after seven days [26].

It has been reported that carbon nanotube incorporation in electrospun nanofiber increases final structure physical, mechanical and thermal properties [27, 28].

Carbon nanotube by low density, one dimensional structure, high aspect ratio and high young moduli attracted many attentions in the past decade. Carbon Nano tube good dispersion, orientation and interfacial adhesion in polymer matrix would dramatically improve the composites mechanical and physical properties [29,30,31].

It is well experienced that carbon nano tube is an appropriate candidate for improving properties of scaffolds and biomaterials, due to its chemical structure, excellent conductive properties and binding capacity to the biomolecules [32, 33].

using electrospinning as effective technique to orient carbon nanotube along nanofiber direction was investigated, Especially for bone tissue engineering, and indicated good osteoblast cells interaction [34].

In a study accomplished by Turk et al. composite porous structures were characterized that were made of chitosan-functionalized multi walled carbon nanotube-collagen. Incorporation of MWNT particle enhanced the scaffolds bioactivity which had no cytotoxic effect [35]. Also, in a study done by Zhang et al. multi walled carbon nanotube administration in poly lactic co glycolic acid was investigated, and the results indicated appropriate cells adhesion to the electrospun Nano fibers [36].

Moreover, weakening of young modulus of electrospun nanofiber happens because of high shearing force that was created during electrospinning and strong electric field interaction. Also, incorporation of carbon nanotube as reinforcement agent could be helpful in order to overcome this limitation [37]. With respect to this important point, electrospinning could appropriately modulate the carbon nanotube orientation to the nanofibers direction, which is important for scaffold anisotropic mechanical properties in special direction.

Without using expensive and rare materials, in this research effect of single-walled carbon nanotube to modified biological, physical and mechanical properties of polyurethane nanofibers would be examined.

With inexpensive and simple method prepared scaffolds for directing and modulating endothelial cells behaviors were evaluated.

In this research, composite nanofiber scaffolds of polyurethane were prepared with different amount of single walled carbon nanotube (SWNT). Their physico-mechanical properties and interaction with endothelial cells were characterized in order to examine the PU-SWNT scaffolds capability as template for blood vessel tissue engineering.

Materials and methods

Single walled carbon nanotube was purchased from Chemistry & Chemical Engineering Research Center of Iran. Its purity was about 95% and its diameter was in the range between 12 and 20 nm, and also it has average length of 45 nm. Poly ester urethane (Desmopan-3458A) was purchased from Bayer material science. It has 1200 kg/m3 density, and 260 KDa N molecular weight, N-dimethyl formamide (DMF) was purchased from Sigma-Aldrich Company as solvent. Dublicouse modified eagle medium (DMEM) and HAMs F12 in 1:1 volume ratio as culture media, Penicillin-streptomycin and fetal bovine serum was purchased from Bio Sera Company. Human umbilical vein endothelial cell was purchased from Pasteur Institute of Iran. All of the chemical reagents were in analytical grade.

Electrospinning process

For electrospinning solution preparing, carbon nanotube should be surface modified in order to produce a homogenously disperse with polyurethane solution. Briefly explain, SWNT Nano particles were treated in H2SO4/HNO3 with aspect ratio of 3:1 in ultrasonic bath (VWR, model 50HT, 45 W) for 30 min. After SWNTs acidic treatment, Nano particles were rinsed thoroughly by distilled water in order to remove residual acids, and being filtrated using polycarbonate filter membrane with pore size of 0.8 μm [38, 39].

DMF solution was selected as amide solvent for preparing carbon nanotube homogenous dispersion in polyurethane solution. Poly urethane 12% w/v solution was prepared by dissolving in DMF by passing 12 h using magnetic stirrer (Corning Hot Plate Stirrer PC 351), and acid treated SWNT was dispersed in prepared solution in various weights percent (w/w%) of 0, 0.5, 1, 2, respectively.

Electrospinning process was operated with respect to the following parameters listed in Table 1.

This procedure was accomplished in order to achieve enough electrospun nanofiber thickness, with respect to the listed parameters for 4 h. Samples were placed in laminar flow hood overnight in order to remove residual solvent.

Characterization

Scanning electron microscopy imaging

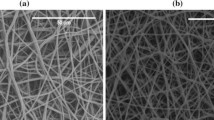

Electrospinning process produces nanofiber using different diameter distribution. Scanning electron microscopy process was accomplished in order to determine the effect of producing parameter and composition in nanofiber diameter and scaffold, and before the time that imaging samples were sputter coated by thin layer of gold in vacuum sputter coating machine (SC7620-EMITECH). SEM Process was operated in accelerating voltage of 25 kV and 18 μA current (AIS2100-SERONTech). Average fiber diameter and histogram diagram of diameter distribution were analyzed using Diameter J software with respect to the SEM images [40, 41].

Measurements of mechanical properties

Scaffold Mechanical properties play significant role in vascular tissue engineering strategies. For evaluating these properties, tensile test was accomplished using a 10 N load cell at 10 mm/min extension rate (Dynamic Testing Machine- Hct400/25-Germany). Therefore, square specimen from different samples were cut into the dimeter of 1 × 2 cm2 [42].

Contact angle measurement

Static contact angle measurement of nanofibers was operated in drop test, in order to investigate the hydrophilicity level of composite electrospun nanofiber. Surface contact angle of electrospun nanofiner scaffolds was measured using a Digital Contact Angle Measurement System equipped with a CCD camera (KGV-5000). 600 μL droplet of distilled water was carefully placed on the nanofibers surface, which were fixed in camera view. For each samples 5 droplet was located in 5 different parts of samples (1 × 2 cm2) [43].

FT-IR analysis

Characterization of the nanofiber samples chemical structure was accomplished using FT-IR technique (Perkin-Elmer SRG 1100G). All data were documented by means of potassium bromide internal reflective element ranged from 400 to 4000 cm−1.

X-ray diffraction

To investigate the carbon nanotube content and electrospinning process effect on crystallinity of structure, The X-ray diffraction (XRD) patterns were recorded using EQUINOX 3000 diffractometer. This process was performed with2D area detector operating under a 40 kV voltage and a 40 mA current. (Using Cu KR radiation in 0.15418 nm). Process was operated in the 5o-50o range at a scan rate of 5o/min.

Dynamic scanning calorimetry

Dynamic scanning calorimetry (DSC) experiments were accomplished using Thermal analyzer (DS 2010) at temperature ranged from 25 to 300 °C. process was operated at 10 °C/min heating rate in nitrogen atmosphere, in order to investigate the SWNT effect on thermal behavior of different samples of electrospun [40].

Raman spectroscopy

Moreover, Raman spectroscopy (BRUKER, RFS, 100/s) were operated in order to evaluate structural interaction of surface modified SWNT to the polyurethane chain. A 632.8 nm He-Ne laser was used as the light source [44].

Electrical properties

Electrical conductivity of poly urethane-SWNT nanofibers were assessed by the use of standard 2-point method. Electrical resistances were measured for different places, and also were averaged in order to ignore any directional effect. Electrical conductivity of samples was calculated using Eq. (1):

Where σ is the electrical conductivity (S/cm), R stands for the electrical resistance in Ω, l (cm) is the length and A (cm2) is the cross section area for different samples [45].

Culture of endothelial cells

Endothelial cells interaction to the electrospun polyurethane carbon nanotube structure was evaluated to assess the fabricated scaffold potential for application in blood vessel engineering. By passing third passage, cells were detached from the flask in medium solution containing the 1 × 106 cell/m cell concentration. Cells were seeded on the samples, which were washed and incubated in solution of 10% FBS in HAMs/DMEM culturing media all over the night before cell seeding.

Evaluation of biocompatibility of endothelial cells using MTT-assay

MTT assay by tetrazolium salts reduction is extensively administrated currently as a reliable way for cell proliferation examining. By passing 7 days from culture, cell seeded electrospun scaffolds were incubated in MTT solution (0.5 mg/ml, 37 °C, 5% CO2) for 3 h. At final stage, the samples were analyzed using ELISA spectrophotometer and the amount of absorbance was measured at 570 nm. MTT test was performed 3 times for each sample, and the mean with standard deviation was reported [46].

Evaluation of endothelial cells morphology using scanning electron microscopy

By passing 3 and 7 days from culture, culture media was removed and cell-scaffold structure was rinsed by phosphate buffer solution. Afterward, for observing the cells interaction with the structure, at first, the cell-scaffolds were fixed with 2.5% glutaraldehyde solution for 30 min, and after the removing stage, the solution samples were dehydrated for 30 min by graded ethanol with different concentration (50, 60, 70, 80, 95, and 100 ethanol concentration, respectively). Finally fixed samples were sputter coated with gold nano layer and SEM image were taken in 20KV in order to investigate the cell morphology and spreading [47].

Result and discussion

Morphology investigation of samples using SEM

Each electrospun scaffolds SEM micrographs are displayed in Fig. 1, which also demonstrated distribution of nanofiber diameter of prepared samples. Table 2 indicated summarized information of dimeter j analyzer about electrospun nanofiber contain different SWNT content. Nanofiber samples owns smooth surface by fibers, which are closed in diameter distribution. Some beads formed in structures were associated to the increased electrospinning solution viscosity by SWNT particles incorporation with unstable Taylor cone formation associated to SWNT incorporation. With respect to the information of Fig. 1, the samples average fiber diameter along with increasing the SWNT content up to the 0.5%, increased 30%, and afterward indicated no noticeable change. Fibers Diameter with high frequency moved from 40 nm to 140 nm. Minimum fiber diameter had no noticeable change from 19 nm to 20 nm but the maximum observed nanofiber amongst the samples changed from 613 nm up to the 1120 nm. As it was proved in literature, fibers diameter increases in electrospinning as the conductivity and viscosity of the solution enhances [48]. Viscosity enhancement may be associated to the conformation changes in solution produced, in terms of adding SWNT. It could be reported that nanofibers average diameter was 139 nm for polyurethane, which was increased up to the 240 nm for sample by 2% SWNT. It could be observed that nanofibers diameter distribution were limited in samples contain 1% and 2% SWNTs. It could be in association with less branch formation during solution stretching in electrospinning process that lead to uniform nanofiber diameter distribution in comparison with other samples.

According to the information of Table 2, samples porosity percentage (related to measurement method) are ranged from 75% up to maximum of 85%, which is related to the software segmentation. Porosity percentage and pore size are very important similar to scaffold for tissue engineering, which their result indicated high surface area for cells adhesion, proliferation, and spreading.

Electrospinning attracted great attention for SWNT nano particle incorporation in the nanofiber direction, as an appropriate way for introducing individual carbon nanotubes in an oriented direction, in order to express their unique anisotropic properties. As it was observed, nanofiber structure contains different fiber dimeter distribution. Structures are highly porous during they are interconnected (considered as key factor for tissue engineering [49]). The nanofibers of PU-SWNT composite are relatively uniformed with smooth surface. Uniform nanofiber dimeter distribution and specific surface area to the volume ratio make the manufactured scaffolds as appropriate candidates for blood vessel tissue engineering, especially for adhesion and proliferation of endothelial cells [39, 50].

Mechanical properties

Identifying the mechanical properties of PU-SWNT composite nanofiber is essential at the time of trying to design scaffold that must have long-term exposure resistance against systolic blood vessel pressure.

Figure 2 represented different samples stress-strain curves. According to that, along with increasing SWNT to the nanofiber structure, the samples ultimate stress improved while elongation at break point was decreased from 107% for pure PU and 64% for PU-2% SWNT, respectively. With respect to the SWNT nature as bio ceramic, strength enhancement and ductility decreasing could be observed. By SWNT content increasing, ultimate stress enhanced from 7.25 MPa up to the 22.92 MPa, in terms of the Table 3. In addition, the samples young modulus was increased from 3.57 MPa to 39.78 MPa. Young modulus and ultimate strength enhancement was more than elongation decreasing at break and it means that SWNT incorporation positive effect in poly urethane nanofiber is more than it’s negative consequences. In the stress-strain curve of native blood vessel (an artery), the behavior named collagen recruitment is observable. It means that by increasing the stress after activation and also elastin fibers directing to the load direction, collagen fiber begins the loads bearing by a probability density function to the recruitment stretch [51].

This behavior could be observed by the curve slope increasing. In addition, this could be shown in sample contain 1 and 2% SWNT behavior, especially. Appropriate SWNT content anchoring and dispersion in electrospun nanofiber matrix may explain this phenomenon while the load transmitted to the nanoparticle in order to bear as a reinforced component.

In addition to homogeneous SWNTs dispersion in the PU matrix and strong bonding between the nanotubes, polymer chains are recognized as useful for transferring the load to the SWNT as a reinforced agent in PU matrix. It was approved in many studies that carbon nano tube network formation, especially when the stress reaches more than matrix elastic point could transfer the load dramatically [52]. Appropriate load transferring from Polyurethane chains to the SWNTs could explain such biomimetic mechanical properties of prepared scaffolds like a normal blood vessel. By considering blood compatibility and as a vascular substitute, biomimetic mechanical properties of Polyurethane-SWNT composites could improve long them patency rate of graft.

Particularly, nanotube dispersion, interfacial adhesion and volume content determinative role on mechanical properties of structure was investigated by recent research [53]. (This enhancement in the mechanical properties is indicator of efficient load transfer to the SWNTs in the composite membranes). However, nanotube agglomeration was observed in the relatively high reinforcing filler concentration region, which act as stress-concentration point and accelerates failure that were observable in sample contain high SWNT level [54].

Effective load transferring from polymer nanofiber to the SWNT particles, and also nanofiber directing to the stress direction could control the composite scaffold mechanical behavior like the normal blood vessel, which is crucial for blood vessel tissue engineering substitute.

After SWNTs acidic treatment, some defects forms were made on the structure surface. These defects could act as anchoring sites for PU in order to lock in. the acid-treatment attached some carboxylic acid groups, which could enhance the SWNTs interaction with the OH groups of PU chains. Also, this was reported by Jason et al.

It was recognized that nanofiber membrane mechanical properties, similar to young modulus, is very weak compared to the bulk with same composition. These are also in accordance with very porous structure and high shearing force produced during electrospinning, which reduces molecular entanglement density, and leads to the lower structure mechanical properties. However, this study results indicated that this weakness was compensated by SWNTs unique properties.

Contact angle of nano structures

Figure 3 represents the hydrophilicity changes level in fabricated scaffolds. By SWNT content increasing, samples contact angle decreases from average of 1000 to the 77 degrees. Appropriate entrapped SWNT desperation in nanofiber especially in 2%, leads to more hydrophilic structure formation reacted to the drop, and therefore, contact angle decreases. Sufficient nanofiber interfacial adhesion to the SWNT is associated with water contact angle decrease as the SWNT content increases [55].

With respect to the uniform distribution of Nano particle in polymer matrix, along with the SWNT content increasing, decreasing of contact angle value is observable. Acquiring more carbon nanotube to the nanofiber film surface results in the roughness enhancing and creates open structure that could decrease the water contact angle. It is noteworthy to state that surface modification of SWNT powder to introduce hydrophilic functional group affects water contact angle of scaffolds. Another reason that describes changing the scaffold contact angle is attributed to the nanofiber diameter distribution. By decreasing the mean fibers dimeter, and also along with increasing the surface area to the volume ratio, water contact angle decreases as more hydrophilic surface (some protruding SWNTs presence at the surface) contacted to the droplet [56].

FT-IR analysis

Figure 4 indicate different samples FT-IR diagram. Semi sharp adsorption Peak was observed in 3451 cm−1, which is associated to the O-H stretching vibration adsorption (Functional group acquired in SWNT surface modification). Observed peak in 3351 cm−1 is related to the N-H stretching vibration. In 2924 cm−1 and 2860 cm−1adsorption peak is associated to C-H vibration mode of alkane functional group. Adsorption peak in 2371 cm−1could be attributed to the N=C=O (isocyanate functional group) in 1758 cm−1, and also stretching vibration of ester (C=O) bound was observed. Another functional group of stretching vibration of ester (O-C=O) group could be seen in 1731 cm−1. In 1342 cm−1 and 1630 cm−1 bending vibration probably belonged to amide (N-H) group could be observed, respectively. In 1529 cm−1, N-O group stretch vibration could be observed in association with poly urethane group. In 1456 cm−1, carboxylic acid (O-H) group stretch vibration could be identified (this was attributed to the SWNT acid oxidation). In 1378 cm−1 alkane stretch vibration (methyl functional group C-H) was shown. Another function group could be observed in association with the secondary alcohol (C-O) in 1087 cm−1. Another aromatic ester could be observed in 1221 cm−1.(functional group could be observed related to the diphenyl methane diisocyanate or hexamethylene diisocyanate) [57].

There is difference amongst the samples in the 1731 cm−1 peak sharpness. It could be described that interaction of SWNT to the ester functional group of Polyurethane matrix may alter this functional group amount, probably. It means that good covalently adhesion between matrix and reinforcement agent occurred. In 1530 cm−1 adsorption frequency (which is correlated to the N-O functional group), another difference amongst the sample demonstrated that it means from the site of nitro component covalent bond between poly urethane and SWNT particle formed. As the SWNT particle content increases, the peak sharpness enhances in 1456 cm−1 (related to acid oxidized SWNT) [58].

Molecular backbone of Polyurethane composed of some polar group, such as O=C-NH– and –CH2-O–, which are compatible with nanotube, could lead to the uniform nanotube dispersion in PU matrix. The area under these absorption peaks increased with the increase of SWNT content signifying the physical adhesion, with respect to hydrogen bond between the PU matrix amide group and C–O group, and also the SWNTs carboxylic group [59].

XRD analysis

As it is observable from in Fig. 5, XRD pattern of electrospun SWNT incorporated polyurethane nanofiber.

The broad peak appear in poly urethane XRD pattern of by different SWNT content associated to the hard segment part of semi crystalline. This peak does not dramatically changes amongst 4 samples, but as it was described earlier, SWNT particle acts as nucleation site for semi crystalline structure forming. Changing in polyurethane crystalline behavior may be associated to the high-integrated area and orientation of PU molecular chain around the carbon nanotube surface within the nanofiber.

As indicated in the sample by 2% SWNT content, the peak sharpness is higher in comparison with other samples (With SWNTs incorporation into the PU matrix). Diffraction peaks strength at around 22.58o significantly increased, in which composite peak seems broad in pure PU and PU-0.5%SWNT.

As the main peak sharpness in XRD pattern for different samples changed, SWNT particle homogenous dispersion in nanofiberous scaffolds could be proved.

Dynamic scanning calorimetry

Regarding the Fig. 6, DSC thermogram is observable for different samples.

Various studies reported that introducing nanotubes in a polymer matrix increased glass transition, melting and thermal decomposition temperatures because of polymers hindered chain and segmental mobility.

Figure 6 indicates some of the endothermic peaks of the SWNT/PU composite films and nanofibrous mat shifting, especially at 220-230 °C. This behavior was associated to the hard segment of PU melting. Interactions of the hard segment to SWNTs. composite Thermal properties would be stabilized by hydrogen bonds formation between SWNT and polyurethane chains. As the polymer chain mobility was limited, the glass transition temperatures of Nano fibrous structures decreased.

Polyurethane soft segment melting point was observed in the range from 49 to 52 °C. By SWNT homogenous distribution in polymer, we could observe that the sharpness of soft segment melting point decreased. Along with increasing of the SWNT content, the melting temperature increased up to 52 °C.

As it was observed, incorporation of SWNT, which is well reacted to the polyurethane macromolecules, changes the polyurethane melting behavior to a range of temperature and not in specific point. It appears that we cannot exactly specify the determined temperature as composite melting point. Changing the composite melting behavior indicated the appropriate dispersion and compatibility between nanofiber and reinforcement agent [60,61,62]. According to a study accomplished by Orgile’s et al. carbon Nano tubes by steric hindrance would increase the poly urethane composites melting temperature [63].

In sample by 1% and 2% SWNT, nanoparticle acts as nucleating agent, and could intensify composite scaffolds crystallization, therefore scaffold crystalline formation was facilitated, and structures would be stabilized. This was confirmed also by XRD result in section 4.5. [54, 64].

Raman spectroscopy

Figure 7 indicated Raman spectra for those samples with different SWNT content. There is no characteristic peak with respect to the SWNT molecular structure in PU nanofiber sample. In SWNT incorporated PU nanofiber, there is three characteristic Peaks in 1338 cm−1 and 1569 cm−1 and 2650 cm−1, regarding the D-bonds (assigned to the in-plane vibration of the C–C bond) and G-bonds (activated by the presence of disorder in carbon systems), respectively. Also, Gˊbond peak is corresponding to the overtone of D-band in 2700 cm−1, which may be resulted due to broken sp2 bonds at the time that SWNTs are dispersed in the polymer matrix [65].

As consequence of some carbon atoms hybridization on the nanotube wall from sp2 to sp3 (acquired in SWNT functionalization) D bond increasing could be observed as nanoparticle incremented. These Peaks confirms a band existence, which corresponds to the defects and vacancies presence in sp2 hybridized carbon atoms in SWNTs structure. Peak sharpness is proportional to the defects concentration [66].

Electrical conductivity of electrospun poly urethane-SWNT nanofibers

As it could be observed form Table 4, nanofibers electrical conductivity was dramatically incremented along with increasing of the SWNT content. Electrical conductivity of pure polyurethane could not be measured. Sample electrical conductivity was increased of about 0.0013 s/cm for sample contains 0.5% SWNT, up to the 0.14 s/cm for sample by 2% SWNT. There are two important factors specify samples electrical conductivity. These factors are surface area and SWNT mass ratio. Amongst those samples contain different SWNT amount, no huge difference about surface area could be observed according to Table 2. Along with the reduction of nanofiber diameter, mean surface area increases, and electrical conductivity also decreases. Differences in nanostructure conductivity and crystallinity of structures may alter samples conductivity. Generally, with respect to the Table 4, by increasing the SWNT content, structure Electrical conductivity increases. Moreover, according to the Fig. 5, although the samples crystallinity increases, but this enhancement rate was limited [67]. Crystalline part in a conductive polymer composite, would act as insulators and may destroy some possible conductive pathways built by conductive fillers (SWNT) inside the composite. SWNT unique properties and its good distribution improved the nanofiber scaffolds electrical conductivity [68].

Scaffolds biocompatibility and cells proliferation using MTT assay

Figure 8 indicated MTT assay result of different samples as absorbed optical density value. On the contrary with the control for all the sample after 12 h, the cells density, which was adhered or reacted to the scaffold increased. It means that all of the structures are biocompatible. By passing 1 day from culture, the number of alive cells for all the samples increased except for polyurethane nanofiber. It seems this result may attribute to the lack of adequate hydrophilic functional group on the scaffold. By passing 7 days from culture this occurrence repeated and between samples contain 1 and 2% of SWNT, huge difference of absorption density was not observed. According to the result of a study accomplished by Huihui et al. proliferation of the fibroblast cells on electrospun PVA-chitosan carbon nanotube nanofiber was improved in coparison with control (according to the high surface are to volume ratio of scaffold, which facilitate the cells migration and growth) [69]. Dissimilar to the SWNT’s toxicity supposition, this study result indicated that good dispersion of SWNT and fabrication method can improve biological properties of final structure using SWNT special properties [70, 71]. This study result was also in agreement with the result of a study accomplished by Yahui et al. who produced vascular carbon nanotube containing structures. Their result demonstrated that no negative effect related to the incorporation of carbon Nano tube in proliferation of smooth muscle cells could be observed in short and long term [72].

SEM micrograph of cell-scaffold structure

Figure 9 indicate endothelial cells interacted with different nanofiber scaffold, by passing3 days from culture. Good colonization and completely spreading of the cells on the scaffolds surface are observable, especially in sample by 1 and 2% SWNT. According to the nanofiber direction, which was displayed in Fig. 1, we can observe that cell colonization is in parallel with the mean nanofiber direction.

As it is observable with respect to the Figs. 9 and 10, the number of adhered cells to the sample contain 1 and 2% SWNT are more in comparison with 0.5% SWNT and Pure PU nanofibers. One of the important reasons that describe this occurrence is SWNT particle capacity to adsorb culture media’s protein. It means that along with SWNT content increasing, nanofiber scaffolds could efficiently retain essential protein for longer time period [69, 73, 74]. Another reason appears to be related to contact angle of nanofiber scaffolds, in which hydrophilicity of scaffolds and endothelial cells interaction improved by increasing SWNT content (by respect to the contact angle measurement). As it is clear from Fig. 10, by passing seven days from culture, the adhered cells density significantly increased for all of the samples. In sample contains 1 and 2%, SWNT a thick layer of the adhered endothelial cells were formed on the basement membrane, which at first reacted to the electrospun composite scaffold. It appears that sample contain 1% SWNT would be the optimum in the cell reaction. it should be noted that By respect to the results of Table 2 the porosity percentage of structures is between 75 up to 85%. And by regarding the space between the fibers and small size of endothelial cells in comparison with other cell types it could be mentioned that noticeable cells population could infiltrate into the scaffolds. Meanwhile, as was observed in Fig. 1 and Table 2 enhancement of SWNTs content increased fiber diameter and therefore bigger interconnected pore created could promote cells infiltration into the scaffolds. Also, this statement was in agreement with the results of Hajiali et all who investigated the possibility of electrospun Polyglycolic acid-gelatin nanofibers for vascular tissue engineering [75]. During three days of culture, the presence of the cell’s lamellipodia and filopodia could be identified in the SEM images. But after 7 days of culture by the formation of dense, fused and integrated endothelium layer it could be hard to locate them. This endothelial cells behavior is so crucial for blood vessel tissue engineering in the way that they could completely cover and line the surface [76]. Also, it is noteworthy to state that according to the study of Ian Holt et al. array of SWNT particle could influence myoblast cells array and orientation, drastically. In electrospinning process electro conductive SWNT particle oriented to the main fiber axis and would help the cells adhesion and direct them to the specific direction [77,78,79]. This study result about cells adhesion and proliferation also were confirmed by research of Eyni et al. [79].

It could be noted that nanofiber dimeter and nanofiber diameter distribution play significant role approximately in all of cells behavior like adhesion and spreading. According to the of section 4.1 result, mean diameter of nanofiber were in the 139 nm to 240 nm. We could observe the dense topography of nanofiber which accelerate cells spreading. In addition, the mean diameter and diameter distribution of nanofibers were ideal for cells adhesion and colonization, which were consistent with the result of a study accomplished by Young et al. [80].

Endothelial cells secret prostacyclin and some important factors, which inhabit platelets activation in blood that prevent thrombus formation. Therefore, scaffolds complete surface covering by endothelial cell with no exposing site to platelet would be considered as important progress in tissue engineering of blood vessels or artificial blood vessel grafts [80].

Khang et al. established that high ratios of MWNT coated with polyurethane provided a more hydrophilic surface (because of greater Nano surface roughness), despite of surface modification in order to introduce hydrophilic functional group to the surface [81].

Another promising factor in which influences this great cells adhesion may associated to the surface electrical conductivity incremented in which with respect to the Table 4 as the SWNT content increases. Research of kai et al. Indicated that electospun conductive polymer composed of poly pyrrole incorporated poly caprolactone and gelatin noticeably affected cardio myocytes cell adhesion and proliferation. Their research indicated that conductive agent presence in the structure would affect cardio myocytes cell adhesion and proliferation strongly agent in the structure would strongly affect cardio myocytes cell adhesion and proliferation [82]. Also, this result was confirmed by research of soleimani et al. who investigated the conductive substrate positive effect using graphene and poly aniline in peripheral nervous system injury regeneration [83]. In this study, another promising reason that can describe high endothelial cell adhesion level may relevant to slightly positive charge of SWNT particle in matrix who interacted to the negatively charged cell membrane electrostatically a prepared stronger attachment sites [20, 84, 85].

It should be considered that most of cells behaviors was controlled by cell adhesion (cell morphology, migration, Apoptosis, growth, proliferation). Hydroxyl and carboxyl group Formation on the SWNT particle surface and changing the surface energy provides appropriate adhesion site in nanofiber structure. Therefore, good endothelial cell adhesion were provided with respect to the Figs. 8, 9 and 10.

Moreover, it is noteworthy to state that despite of appropriate cells adhesion and proliferation for vascular tissue engineering substitute, PU-SWNTs indicated having enough blood compatible properties. The surface of composites containing carbon nanotubes may have some special interactions with the adsorbed plasma proteins in order to make them undergo conformational changes and partly lose their activating and binding platelets functions, which led to the suppression of platelet adhesion and activation on the composite surface [38]. Therefore, suitable blood compatibility was provided by administration of SWNTs. Also, another outstanding achievement of the present study is efficient endothelialization of vascular graft which is critical for long term successful implantation of a vascular graft. By respect to appropriate mechanical properties, completely covering of surface using endothelial cells create the most antithrombotic layer would inhibit intima hyperplasia [86].

Conclusion

In this study physico-mechanical and biological properties of fabricated electrospun poly urethane-SWNT nanofiber scaffold were evaluated as a synthetic graft for vascular tissue engineering. With respect to the morphological assessment, nanofiber average diameter increased from 40 nm up to the 149 nm, by the SWNT content increasing. Homogenous dispersion and sufficient interaction of SWNT to poly urethane chain has positive effect on composite mechanical behavior like tensile and young modulus, which could mimic the blood vessel natural properties. Thermal properties of electrospun nano fibrous scaffolds indicated that SWNT particles increased melting temperature and changed the structures melting behavior. Hydrophilicity of scaffolds increased along with increasing of SWNT content, which was confirmed by contact angle reduction from 1000 to 770. Incorporation of SWNT causes adsorption and retention of culture media’s protein, which are beneficial for dense endothelial layer formation on electrospun nano fibrous scaffolds. In vitro evaluation represented SWNT possess unique physico-chemical properties that could increase cells proliferation. These results recommended that poly urethane nanofibers contain carbon nano tube mimic biological properties of blood vessel extracellular matrix in order to accomplishing vascular tissue engineering.

References

Gaziano TA, Opie LH, Weinstein MC (2006) Cardiovascular disease prevention with a multidrug regimen in the developing world: a cost-effectiveness analysis. Lancet 368(9536):679–686

Chaudhuri R, Ramachandran M, Moharil P, Harumalani M, Jaiswal AK (2017) Biomaterials and cells for cardiac tissue engineering: current choices. Mater Sci Eng C 79:950–957

Innocente F, Mandracchia D, Pektok E, Nottelet B, Tille J-C, De Valence S, Faggian G, Mazzucco A, Kalangos A, Gurny R (2009) Paclitaxel-eluting biodegradable synthetic vascular prostheses: a step towards reduction of neointima formation? Circulation 120(11 suppl 1):S37–S45

Ravi S, Qu Z, Chaikof EL (2009) Polymeric materials for tissue engineering of arterial substitutes. Cardiovasc Eng 17(1_suppl):45–54

Kumar VA, Brewster LP, Caves JM, Chaikof EL (2011) Tissue engineering of blood vessels: functional requirements, progress, and future challenges. Cardiovasc Eng Technol 2(3):137–148

Schmedlen RH, Elbjeirami WM, Gobin AS, West JL (2003) Tissue engineered small-diameter vascular grafts. Clin Plast Surg 30(4):507–517

Shalumon K, Deepthi S, Anupama M, Nair S, Jayakumar R, Chennazhi K (2015) Fabrication of poly (l-lactic acid)/gelatin composite tubular scaffolds for vascular tissue engineering. Int J Biol Macromol 72:1048–1055

Xu C, Inai R, Kotaki M, Ramakrishna S (2004) Aligned biodegradable nanofibrous structure: a potential scaffold for blood vessel engineering. Biomaterials 25(5):877–886

Prabhakaran MP, Venugopal J, Kai D, Ramakrishna S (2011) Biomimetic material strategies for cardiac tissue engineering. Mater Sci Eng C 31(3):503–513

Jing X, Mi H-Y, Salick MR, Cordie TM, Peng X-F, Turng L-S (2015) Electrospinning thermoplastic polyurethane/graphene oxide scaffolds for small diameter vascular graft applications. Mater Sci Eng C 49:40–50

Kucinska-Lipka J, Gubanska I, Janik H, Sienkiewicz M (2015) Fabrication of polyurethane and polyurethane based composite fibres by the electrospinning technique for soft tissue engineering of cardiovascular system. Mater Sci Eng C 46:166–176

Lanza R, Langer R, Vacanti JP (2011) Principles of tissue engineering. Academic press, Cambridge

Sadeghi A, Moztarzadeh F, Mohandesi JA (2019) Investigating the effect of chitosan on hydrophilicity and bioactivity of conductive electrospun composite scaffold for neural tissue engineering. Int J Biol Macromol 121:625–632

O'brien FJ (2011) Biomaterials & scaffolds for tissue engineering. Mater Today 14(3):88–95

Carleton JB, Rodin GJ, Sacks MS (2017) Layered elastomeric fibrous scaffolds: An in-Silico study of the achievable range of mechanical behaviors. ACS Biomater Sci Eng 3(11):2907–2921

Xiang P, Li M, Zhang C-Y, Chen D-L, Zhou Z-H (2011) Cytocompatibility of electrospun nanofiber tubular scaffolds for small diameter tissue engineering blood vessels. Int J Biol Macromol 49(3):281–288

Wang C, Wang M (2014) Electrospun multifunctional tissue engineering scaffolds. Front Mater Sci 8(1):3–19

Ercolani E, Del Gaudio C, Bianco A (2015) Vascular tissue engineering of small-diameter blood vessels: reviewing the electrospinning approach. J Tissue Eng Regen Med 9(8):861–888

Zong H, Xia X, Liang Y, Dai S, Alsaedi A, Hayat T, Kong F, Pan JH (2017) Designing function-oriented artificial nanomaterials and membranes via electrospinning and electrospraying techniques. Mater Sci Eng 92:1075–91

Pan X, Sun B, Mo X (2018) Electrospun polypyrrole-coated polycaprolactone nanoyarn nerve guidance conduits for nerve tissue engineering. Front Mater Sci 12(4):438–446

Bergmeister H, Grasl C, Walter I, Plasenzotti R, Stoiber M, Schreiber C, Losert U, Weigel G, Schima H (2012) Electrospun small-diameter polyurethane vascular grafts: ingrowth and differentiation of vascular-specific host cells. Artif Organs 36(1):54–61

Jaganathan SK, Mani MP, Palaniappan SK, Rathanasamy R (2018) Fabrication and characterisation of nanofibrous polyurethane scaffold incorporated with corn and neem oil using single stage electrospinning technique for bone tissue engineering applications. J Polym Res 25(7):146

Ma D-W, Zhu R, Wang Y-Y, Zhang Z-R, Wang X-Y (2015) Evaluation on biocompatibility of biomedical polyurethanes with different hard segment contents. Front Mater Sci 9(4):397–404

Haghjooy Javanmard S, Anari J, Zargar Kharazi A, Vatankhah E (2016) In vitro hemocompatibility and cytocompatibility of a three-layered vascular scaffold fabricated by sequential electrospinning of PCL, collagen, and PLLA nanofibers. J Biomater Appl 31(3):438–449

Bui HT, Friederich AR, Li E, Prawel DA, James SP (2018) Hyaluronan enhancement of expanded polytetrafluoroethylene cardiovascular grafts. J Biomater Appl: 0885328218776807

Nieponice A, Soletti L, Guan J, Deasy BM, Huard J, Wagner WR, Vorp DA (2008) Development of a tissue-engineered vascular graft combining a biodegradable scaffold, muscle-derived stem cells and a rotational vacuum seeding technique. Biomaterials 29(7):825–833

Naebe M, Lin T, Staiger MP, Dai L, Wang X (2008) Electrospun single-walled carbon nanotube/polyvinyl alcohol composite nanofibers: structure–property relationships. Nanotechnology 19(30):305702

Hanumansetty S, O’Rear E, Resasco DE (2017) Encapsulation of multi-walled carbon nanotubes with copolymer to disperse in aqueous media. J Polym Res 24(12):228

Vigolo B, Penicaud A, Coulon C, Sauder C, Pailler R, Journet C, Bernier P, Poulin P (2000) Macroscopic fibers and ribbons of oriented carbon nanotubes. Science 290(5495):1331–1334

Dalton AB, Collins S, Munoz E, Razal JM, Ebron VH, Ferraris JP, Coleman JN, Kim BG, Baughman RH (2003) Super-tough carbon-nanotube fibres. Nature 423(6941):703

Ghane N, Mazinani S, Gharehaghaji AA (2018) Fabrication and characterization of hollow nanofibrous PA6 yarn reinforced with CNTs. J Polym Res 25(3):80

Zhang Y, Bai Y, Yan B (2010) Functionalized carbon nanotubes for potential medicinal applications. Drug Discov Today 15(11–12):428–435

Sheikhpour M, Golbabaie A, Kasaeian A (2017) Carbon nanotubes: a review of novel strategies for cancer diagnosis and treatment. Mater Sci Eng C 76:1289–1304

Mazinani S, Ajji A, Dubois C (2009) Morphology, structure and properties of conductive PS/CNT nanocomposite electrospun mat. Polymer 50(14):3329–3342

Türk S, Altınsoy I, Efe GÇ, Ipek M, Özacar M, Bindal C (2018) 3D porous collagen/functionalized multiwalled carbon nanotube/chitosan/hydroxyapatite composite scaffolds for bone tissue engineering. Mater Sci Eng C 92:757–768

Zhang H (2011) Effects of electrospinning parameters on morphology and diameter of electrospun PLGA/MWNTs fibers and cytocompatibility in vitro. J Bioact Compat Polym 26(6):590–606

Liu LQ, Tasis D, Prato M, Wagner HD (2007) Tensile mechanics of electrospun multiwalled nanotube/poly (methyl methacrylate) nanofibers. Adv Mater 19(9):1228–1233

Meng J, Kong H, Xu H, Song L, Wang C, Xie S (2005) Improving the blood compatibility of polyurethane using carbon nanotubes as fillers and its implications to cardiovascular surgery. J Biomed Mater Res Part A 74(2):208–214

Zhijiang C, Cong Z, Jie G, Qing Z, Kongyin Z (2018) Electrospun carboxyl multi-walled carbon nanotubes grafted polyhydroxybutyrate composite nanofibers membrane scaffolds: preparation, characterization and cytocompatibility. Mater Sci Eng C 82:29–40

Sahoo NG, Jung YC, Yoo HJ, Cho JW (2006) Effect of functionalized carbon nanotubes on molecular interaction and properties of polyurethane composites. Macromol Chem Phys 207(19):1773–1780

Hotaling NA, Bharti K, Kriel H, Simon CG (2015) DiameterJ: a validated open source nanofiber diameter measurement tool. Biomaterials 61:327–338

Pauly HM, Kelly DJ, Popat KC, Trujillo NA, Dunne NJ, McCarthy HO, Donahue TLH (2016) Mechanical properties and cellular response of novel electrospun nanofibers for ligament tissue engineering: effects of orientation and geometry. J Mech Behav Biomed Mater 61:258–270

Marvizadeh MM, Oladzadabbasabadi N, Nafchi AM, Jokar M (2017) Preparation and characterization of bionanocomposite film based on tapioca starch/bovine gelatin/nanorod zinc oxide. Int J Biol Macromol 99:1–7

Ku SH, Park CB (2010) Human endothelial cell growth on mussel-inspired nanofiber scaffold for vascular tissue engineering. Biomaterials 31(36):9431–9437

Darbandi SMA, Nouri M, Mokhtari J (2012) Electrospun nanostructures based on polyurethane/MWCNTs for strain sensing applications. Fibers Polymers 13(9):1126–1131

Unnithan AR, Gnanasekaran G, Sathishkumar Y, Lee YS, Kim CS (2014) Electrospun antibacterial polyurethane–cellulose acetate–zein composite mats for wound dressing. Carbohydr Polym 102:884–892

Shor L, Güçeri S, Wen X, Gandhi M, Sun W (2007) Fabrication of three-dimensional polycaprolactone/hydroxyapatite tissue scaffolds and osteoblast-scaffold interactions in vitro. Biomaterials 28(35):5291–5297

Nasouri K, Shoushtari AM, Kaflou A, Bahrambeygi H, Rabbi A (2012) Single-wall carbon nanotubes dispersion behavior and its effects on the morphological and mechanical properties of the electrospun nanofibers. Polym Compos 33(11):1951–1959

Tamburaci S, Tihminlioglu F (2018) Biosilica incorporated 3D porous scaffolds for bone tissue engineering applications. Mater Sci Eng C 91:274–291

Veleva A, Heath D, Johnson J, Nam J, Patterson C, Lannutti J, Cooper S (2009) Interactions between endothelial cells and electrospun methacrylic terpolymer fibers for engineered vascular replacements. J Biomed Mater Res Part A 91(4):1131–1139

Weisbecker H, Unterberger MJ, Holzapfel GA (2015) Constitutive modelling of arteries considering fibre recruitment and three-dimensional fibre distribution. J R Soc Interface 12(105):20150111

Ma W, Liu L, Zhang Z, Yang R, Liu G, Zhang T, An X, Yi X, Ren Y, Niu Z (2009) High-strength composite fibers: realizing true potential of carbon nanotubes in polymer matrix through continuous reticulate architecture and molecular level couplings. Nano Lett 9(8):2855–2861

Hatui G, Das CK (2013) Modification of CNT and its effect on thermo mechanical, morphological as well as rheological properties of polyether imide (PEI)/liquid crystalline polymer (LCP) blend system. J Polym Res 20(2):77

Tijing LD, Park C-H, Choi WL, Ruelo MTG, Amarjargal A, Pant HR, Im I-T, Kim CS (2013) Characterization and mechanical performance comparison of multiwalled carbon nanotube/polyurethane composites fabricated by electrospinning and solution casting. Compos Part B 44(1):613–619

Verdejo R, Jell G, Safinia L, Bismarck A, Stevens MM, Shaffer MS (2009) Reactive polyurethane carbon nanotube foams and their interactions with osteoblasts. J Biomed Mater Res A 88(1):65–73

Sirivisoot S, Harrison BS (2011) Skeletal myotube formation enhanced by electrospun polyurethane carbon nanotube scaffolds. Int J Nanomedicine 6:2483

Wang H, Wang E, Liu Z, Gao D, Yuan R, Sun L, Zhu Y (2015) A novel carbon nanotubes reinforced superhydrophobic and superoleophilic polyurethane sponge for selective oil–water separation through a chemical fabrication. J Mater Chem A 3(1):266–273

Barick AK, Tripathy DK (2011) Preparation, characterization and properties of acid functionalized multi-walled carbon nanotube reinforced thermoplastic polyurethane nanocomposites. Mater Sci Eng B 176(18):1435–1447

Lu P, Hsieh Y-L (2010) Multiwalled carbon nanotube (MWCNT) reinforced cellulose fibers by electrospinning. ACS Appl Mater Interfaces 2(8):2413–2420

Jung YC, Kim HH, Kim YA, Kim JH, Cho JW, Endo M, Dresselhaus MS (2010) Optically active multi-walled carbon nanotubes for transparent, conductive memory-shape polyurethane film. Macromolecules 43(14):6106–6112

Sadek E, El-Nashar D, Ward A, Ahmed S (2018) Study on the properties of multi-walled carbon nanotubes reinforced poly (vinyl alcohol) composites. J Polym Res 25(12):249

Saligheh O, Forouharshad M, Arasteh R, Eslami-Farsani R, Khajavi R, Roudbari BY (2013) The effect of multi-walled carbon nanotubes on morphology, crystallinity and mechanical properties of PBT/MWCNT composite nanofibers. J Polym Res 20(2):65

Ouyang Z, Li J, Wang J, Li Q, Ni T, Zhang X, Wang H, Li Q, Su Z, Wei G (2013) Fabrication, characterization and sensor application of electrospun polyurethane nanofibers filled with carbon nanotubes and silver nanoparticles. J Mater Chem B 1(18):2415–2424

Askari F, Barikani M, Barmar M, Shokrollahi P (2017) Polyurethane/amino-grafted multiwalled carbon nanotube nanocomposites: microstructure, thermal, mechanical, and rheological properties. J Appl Polym Sci 134(4)

Bokobza L, Zhang (2012) Raman spectroscopic characterization of multiwall carbon nanotubes and of composites. Express Polym Lett 6 (7)

Heidari M, Bahrami H, Ranjbar-Mohammadi M (2017) Fabrication, optimization and characterization of electrospun poly (caprolactone)/gelatin/graphene nanofibrous mats. Mater Sci Eng C 78:218–229

Tian L, Prabhakaran MP, Hu J, Chen M, Besenbacher F, Ramakrishna S (2016) Synergistic effect of topography, surface chemistry and conductivity of the electrospun nanofibrous scaffold on cellular response of PC12 cells. Colloids Surf B: Biointerfaces 145:420–429

Lu X, Qiu Z, Wan Y, Hu Z, Zhao Y (2010) Preparation and characterization of conducting polycaprolactone/chitosan/polypyrrole composites. Compos Part A 41(10):1516–1523

Liao H, Qi R, Shen M, Cao X, Guo R, Zhang Y, Shi X (2011) Improved cellular response on multiwalled carbon nanotube-incorporated electrospun polyvinyl alcohol/chitosan nanofibrous scaffolds. Colloids Surf B: Biointerfaces 84(2):528–535

Shamosi A, Mehrabani D, Azami M, Ebrahimi-Barough S, Siavashi V, Ghanbari H, Sharifi E, Roozafzoon R, Ai J (2017) Differentiation of human endometrial stem cells into endothelial-like cells on gelatin/chitosan/bioglass nanofibrous scaffolds. Artificial Cells Nanomed Biotechnol 45(1):163–173

Jamadi ES, Ghasemi-Mobarakeh L, Morshed M, Sadeghi M, Prabhakaran MP, Ramakrishna S (2016) Synthesis of polyester urethane urea and fabrication of elastomeric nanofibrous scaffolds for myocardial regeneration. Mater Sci Eng C 63:106–116

Zhang Y, Yu Y, Dolati F, Ozbolat IT (2014) Effect of multiwall carbon nanotube reinforcement on coaxially extruded cellular vascular conduits. Mater Sci Eng C 39:126–133

Tonelli FM, Santos AK, Gomes KN, Lorencon E, Guatimosim S, Ladeira LO, Resende RR (2012) Carbon nanotube interaction with extracellular matrix proteins producing scaffolds for tissue engineering. Int J Nanomedicine 7:4511

Ma J, Wang J-N, Tsai C-J, Nussinov R, Ma B (2010) Diameters of single-walled carbon nanotubes (SWCNTs) and related nanochemistry and nanobiology. Front Mater Sci China 4(1):17–28

Hajiali H, Shahgasempour S, Naimi-Jamal MR, Peirovi H, JIjon (2011) Electrospun PGA/gelatin nanofibrous scaffolds and their potential application in vascular tissue engineering. Int J Nanomedicine 6:2133

Sahithi K, Swetha M, Ramasamy K, Srinivasan N, Selvamurugan N (2010) Polymeric composites containing carbon nanotubes for bone tissue engineering. Int J Biol Macromol 46(3):281–283

Holt I, Gestmann I, Wright AC (2013) Alignment of muscle precursor cells on the vertical edges of thick carbon nanotube films. Mater Sci Eng C 33(7):4274–4279

Fraczek-Szczypta A, Menaszek E, Blazewicz S, Adu J, Shevchenko R, Syeda TB, Misra A, Alavijeh M (2015) Influence of different types of carbon nanotubes on muscle cell response. Mater Sci Eng C 46:218–225

Eyni H, Ghorbani S, Shirazi R, Salari Asl L, Beiranvand PS, Soleimani M (2017) Three-dimensional wet-electrospun poly (lactic acid)/multi-wall carbon nanotubes scaffold induces differentiation of human menstrual blood-derived stem cells into germ-like cells. J Biomater Appl 32(3):373–383

Ko Y-G, Park JH, Lee JB, Oh HH, Park WH, Cho D, Kwon OH (2016) Growth behavior of endothelial cells according to electrospun poly (D, L-lactic-co-glycolic acid) fiber diameter as a tissue engineering scaffold. Tissue Eng Regen Med 13(4):343–351

Khang D, Kim SY, Liu-Snyder P, Palmore GTR, Durbin SM, Webster T (2007) Enhanced fibronectin adsorption on carbon nanotube/poly (carbonate) urethane: independent role of surface nano-roughness and associated surface energy. Biomaterials 28(32):4756–4768

Kai D, Prabhakaran MP, Jin G, Ramakrishna S (2011) Polypyrrole-contained electrospun conductive nanofibrous membranes for cardiac tissue engineering. J Biomed Mater Res Part A 99(3):376–385

Soleimani M, Mashayekhan S, Baniasadi H, Ramazani A, Ansarizadeh M (2018) Design and fabrication of conductive nanofibrous scaffolds for neural tissue engineering: process modeling via response surface methodology. J Biomater Appl 33(5):619–629

Mihardja SS, Sievers RE, Lee R (2008) The effect of polypyrrole on arteriogenesis in an acute rat infarct model. Biomaterials 29(31):4205–4210

Bendrea A-D, Cianga L, Cianga I (2011) Progress in the field of conducting polymers for tissue engineering applications. J Biomater Appl 26(1):3–84

Heath DE (2017) Promoting endothelialization of polymeric cardiovascular biomaterials. Macromol Chem Phys 218(8):1600574

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration of Conflicting interests

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tondnevis, F., Keshvari, H. & Mohandesi, J.A. Physico-mechanical and in vitro characterization of electrically conductive electrospun nanofibers of poly urethane/single walled carbon nano tube by great endothelial cells adhesion for vascular tissue engineering. J Polym Res 26, 256 (2019). https://doi.org/10.1007/s10965-019-1916-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1916-0