Abstract

Octadecyl acrylate (ODA) as hydrophobic monomer and N-isopropylacryamide (NIPAAm) as hydrophilic monomer were chosen to synthetize the thermo-sensitive block copolymers PODAx-PNIPAAmy-PODAx (BAB-type) via reversible-addition-fragmentation chain transfer (RAFT) polymerization, the block copolymers could self-assemble to flower-like micelles in aqueous solution with hydrophobic PODA as the inner core and stabilized by hydrophilic PNIPAAm as the outer shell. The characterizations of the micelles such as surfactivity, thermo-sensitivity, micelle hydrodynamic radius (R h ) and polydispersity index (PdI) were demonstrated by surface tension technique, UV-Vis, and dynamic light scattering (DLS) measurements, respectively. The longer the hydrophilic chain was, the higher the critical micellization concentration (CMC) would be, and the higher content of the PODA was, the lower the lower critical solution temperature (LCST) would be. The average R h remained at about 100 nm below LCST, but decreased sharply to about 42 nm and kept constant when reaching and above LCST, which meant the non-aggregation of BAB type block copolymers. The micelle was homogeneous with the small PdI within the range of research. B0.5mA24mB0.5m had the largest capacity to encapsulate lipophilic Sudan Red IV model drugs and the drug loading efficiency was 9.76%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Amphiphilic block copolymers, which could be synthetized by reversible addition-fragmentation chain transfer (RAFT) polymerization, atom transfer radical polymerization (ATRP) [1–3], and a wide variety of other methods [4], could self-assemble into the core-shell micelles that were comprised of hydrophobic cores and stabilized by the hydrophilic shell in aqueous solutions due to the phase separation of immiscible blocks [5, 6]. One of the most popular block groups which attracted much attention was N-isopropylacrylamide (NIPAAm) because its lower critical solution temperature (LCST) was about 32 °C [7], which was close to human body temperature [8–10] though the accurate transition point might depend on various factors. What’s more, the core-shell structure of such assemblies was ideally suited to the biomedical applications especially in controlled drug delivery. Consequently, a lot of effort had been made to amphiphilic block copolymers prepared by RAFT not only because of their special structure and controllability but also their advantageous combination properties of a number of copolymers. For instance, Nicholas et al. [11, 12] had made much effort on block copolymer nano-objects of controllable size, morphology, and surface functionality via RAFT polymerization. We also had done much on this project in our laboratory. For example, Yu et al. [13] had successfully prepared PEAn-PNIPAAmm-PEAn (BAB type) and PNIPAAmm-PEAn-PNIPAAmm (ABA type) block copolymer with ethylacrylate (EA) and NIPAAm as materials via RAFT polymerization and their characterizations, such as surfactivity, thermo-sensitivity and self-assembled micelles were investigated. However, the copolymer micelle was easy to aggregate without surfactant SDS above LCST. On the other hand, the hydrophobic monomer chains were too short to contain a large amount of drugs within the copolymer micelle, which led to lower drug loading efficiency.

To solve this problem, amphiphilic thermo-sensitive block copolymers PODAx-PNIPAAmy-PODAx (BAB type) was synthetized with octadecyl acrylate (ODA) as hydrophobic monomer and NIPAAm as thermo-sensitive monomer via RAFT polymerization. Their self-assembled nanostructures, as well as the other features occurring during self-assembly including surface tension, thermo-sensitivity and micelle size and distribution and so forth to be researched. In addition, their drug delivery behaviors were evaluated with Sudan Red IV as a hydrophobic model drug.

Experimental section

Materials

N-isopropylacryamide (NIPAAm, Tokyo Kaset Kogyo), 2,2-Azobis (isobutyronitrile) (AIBN, C.P., Shanghai Qianjin Chemical Agent, China), Octadecyl acrylate (ODA, Aladdin), Sudan Red IV (Aladdin), S,S′-Bis (α,α’-dimethylaceticacid)-trithiocarbonate (TTC) used as chain transfer agent was prepared according to a literature [14], and other agents were analytical grade purchased from Shanghai Fine Chemical, China, without purification.

Polymerization procedure

A series of block copolymers PODAx-PNIPAAmy-PODAx (BAB type) were synthetized with octadecyl acrylate (ODA) as hydrophobic monomer and N-isopropylacryamide (NIPAAm) as hydrophilic monomer via RAFT polymerization. The B0.5mA24mB0.5m block copolymer with the mass ratio (NIPAAm/ODA) 24:1 was regarded as a typical example and its synthesis procedure was described as follows.

Synthesis of macromolecule chain transfer agent (PODA-TTC)

TTC (0.282 g, 1.0 mmol), ODA (0.25 g, 0.77 mmol), AIBN as initiator (0.0246 g, 0.15 mmol), were dissolved in 15 mL THF, and added into a 100 mL three-neck round-bottom flask with magnetic stir and reflux condenser. The nitrogen gas was bubbled into the solution for 15 min to eliminate dissolved oxygen. The flask was then immersed into a water bath already heated to 70 °C to react for 5 h. The reactants were cooled to the room temperature, precipitated by n-hexane for three times, and dried under vacuum at 40 °C. The light yellow macromolecule chain transfer agent (PODA-TTC) powder was obtained.

Synthesis of B0.5mA24mB0.5m block copolymers

The resulting PODA-TTC, NIPAAm monomer (1.0 g, 8.8 mmol), and AIBN (0.028 g, 0.17 mmol) were dissolved into 15 mL THF, and added into a 100 mL three-neck round-bottom flask with magnetic stirring bars and reflux condenser. The nitrogen gas was bubbled into the solution for 15 min to eliminate dissolved oxygen. The flask was then immersed into a water bath already heated to 70 °C to react for 5 h. The reactants were cooled to the room temperature, and then purified by precipitating from n-hexane, drying under vacuum at 40 °C to obtain the white powder products.

Preparation of self-assembled micelles

Amphiphilic block copolymer nano-particles were prepared using a self-assembly method. Micellization was achieved by dissolving block copolymers (B0.5mA24mB0.5m, 50 mg) in ethanol (2.0 mL) and dropwise addition (1 drop/30 s) of the copolymer solutions to deionized water (50 mL) under moderate stirring at room temperature for 12 h to obtain the micelle solution with the concentration of 1.0 mg/mL.

Characterization

Critical micellization concentration (CMC)

The critical micellization concentration (CMC) value was an important parameter in studying self-assembling behaviors of amphiphilic block copolymers and it was determined by the interfacial tension values using JK99c type automatic surface tension meter (Shanghai ZhongChen Digital Technology Equipment Co., Ltd., China) with various copolymer concentrations ranging from 0.001 mg/mL to 0.280 mg/mL in deionized water at 25 °C. The surface tension of different concentration solution was measured three times and reported as average. Plotting surface tensions with copolymer concentration yielded the CMC indicated by intersection of the extrapolation of the two linear regimes where the curves showed abrupt change in slope.

Lower critical solution temperature (LCST)

The lower critical solution temperature (LCST) of copolymers was determined by measuring the change in light transmittance with temperature using an ultraviolet/visible (UV-Vis) spectrophotometer (723 P, Shanghai Spectrum Instruments, China) with super-heated water bath (Shanghai Precision & Scientific Instrument Co., Ltd., China). The concentration of the copolymer solution was 1.0 mg/mL in deionized water. The wavelength was set at 485 nm using deionized water as a reference to measure the transmittance from 15 to 45 °C at 0.1 °C/min increment to obtain the diagram of transmittance changes with temperature. The abrupt decreasing point of transmittance was the LCST.

Dynamic light scattering (DLS)

Dynamic light scattering (DLS) was performed to characterize the micelles in dilute solutions to determine the hydrodynamic radius (R h ) and polydispersity index (PdI) of copolymers at different temperature using Zetasizer Nano-ZS 90 instrument (Malvern Instruments, U.K.) at a scattering angle of θ = 90°. Data processing was carried out using cumulant analysis of the experimental correlation function and analyzed using Stokes-Einstein equation to calculate the hydrodynamic diameters of copolymer aggregates. All the block copolymer solutions were analyzed using disposable cuvettes using 150 mW argon ion laser light source at a wavelength of 633 nm. The micelle solution (1.0 mg/mL) was filtered through filter paper and the experiment was performed in triplicate from 15 to 45 °C to explore the relationship between temperature and micelle size. To ensure the accurity of the data, each sample was equilibrated for about 5 min at each temperature.

Drugs loading

Sudan Red IV was used as a hydrophobic model drug to investigate the drug encapsulation efficiency. Sudan Red IV 5.0 mg was dissolved in 10.0 mL micelle solution (1.0 mg/mL) with stirring for around 12 h at room temperature to induce the encapsulation of drugs. The excess Sudan Red was removed by centrifugation. The drug loading efficiency was confirmed by UV-Vis spectrophotometer (λ = 517 nm). The drug concentration entrapped in micelle was obtained according to standard absorbance curve of Sudan Red dissolved in ethanol (A = 0.0384c, R 2 = 0.9998). Drug loading capacity (DLC%) and drug loading efficiency(DLE%) were listed as the following equations.

W 1 represented the mass of Sudan Red IV in micelles, W 2 represented the mass of block copolymer in formulation, W 3 represented the mass of Sudan Red IV in the initial solution.

Results and discussion

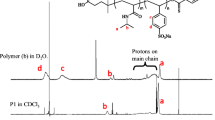

Synthesis of BAB block copolymers

A series of block copolymers PODAx-PNIPAAmy-PODAx (BAB type) with different mass ratio of octadecyl acrylate (ODA) and N-isopropylacryamide (NIPAAm) were synthetized via RAFT polymerization (Scheme 1). The synthesis condition was fixing the mass of TTC, AIBN and ODA at 0.282 g, 22.6 mg and 0.25 g respectively. And the mass of NIPAAm in B0.5mA8mB0.5m, B0.5mA12mB0.5m, B0.5mA24mB0.5m, B0.5mA28mB0.5m, B0.5mA32mB0.5m, B0.5mA42mB0.5m was 2.0 g, 3.0 g, 6.0 g, 7.0 g, 8.0 g, 10.5 g, respectively.

Critical micellization concentration (CMC)

The critical micellization concentration (CMC) value was an important parameter for amphiphilic molecules. Using the automatic surface tension meter, the surface tensions of a series of solutions of the block copolymers were measured at 25 °C. Figure 1 showed the changes of surface tensions of amphiphilic block copolymer with increasing copolymer concentration. At values of the copolymer concentration below the CMC, free copolymer molecules remained dissolved, no micelles existed, and the surface tension decreased with increasing concentration. At concentrations above CMC, micelles appeared, the concentration of free molecules remained near CMC, and saturated to a constant value, illustrating the expected surfactant-like behavior of the copolymer. The CMC value of B0.5mA32mB0.5m in the illustration of Fig. 1 was 7.82 mg/L, as an example of the CMC of the block copolymers. The CMC values of B0.5mA8mB0.5m, B0.5mA12mB0.5m, B0.5mA24mB0.5m, B0.5mA28mB0.5m, B0.5mA32mB0.5m, B0.5mA42mB0.5m were 6.11, 6.39, 6.40, 6.66, 7.82, 7.91 mg/L, respectively. The surfactivity could be ascribed to the flower-like structure of BAB copolymer as shown in Fig. 2, BAB-type block copolymer chains initially aggregated and formed flower-like microstructures with PODA sequences buried inside and stabilized by PNIPAAm sequences at the periphery. The process was spontaneous because the conformational entropy was increased in the micellization. And the longer the hydrophilic chain was, the higher the CMC would be, which was mainly attributed to the extended NIPAAm hydrophilic chains, formed hydrogen bonding with water, leading to improved hydrophilicity. The tendency was contrary to which in the literature [17]. And the CMC values of BAB are all lower than those of ABA’s which had the same ratio of NIPAAm and ODA. This could be ascribed to the structure of the two micelles. The structure of BAB type block copolymer was more stable than ABA’s and was easier to micellize, because the repulsion of flower-like micelle with bended PNIPAAm chain was greater than that of dendritic micelle, which was easier to aggregate.

Lower critical solution temperature (LCST)

It was known that the lower critical solution temperature (LCST) of thermo-sensitive copolymers could be changed to some extent by copolymerizing with a hydrophilic or hydrophobic monomer. The LCST of the block copolymers was investigated by ultraviolet/visible (UV-Vis) spectrophotometer measurements using deionized water as reference. The transmittance of the BAB block copolymers as a function of temperature was shown in Fig. 3 (using the sharply decreasing point of transmittance as the LCST value). As shown in Fig. 3, the LCST of PNIPAAm-TTC was 36 °C, which was higher than that of pure PNIPAAm(32 °C) [15] due to the effect of the two carboxyls of TTC shown in Scheme 1. All the BAB block copolymers had undergone a sudden decrease of light transmittance with the increasing of the temperature, which indicated that the addition of PODA had no obvious effect on the thermo-sensitivity of micelle and all the block copolymers distributed double thermo-sensitivity. The first LCSTs of B0.5mA12mB0.5m, B0.5mA20mB0.5m, B0.5mA24mB0.5m, B0.5mA32mB0.5m, B0.5mA42mB0.5m block copolymers were 21, 25, 26, 28, 29 °C, and the second were 27、33、35、36、37 °C, respectively. Compared with the PNIPAAm-TTC, the first LCST was because the PODA chain contracted, and the second due to the collapsed PNIPAAm chains. The copolymerization of PNIPAAm with hydrophobic functional groups had the potential to reduce the LCST below that of pure PNIPAAm, and vice versa for hydrophilic functional groups, due to the change in the overall hydrophilicity of the copolymer [16]. Decreasing the mass ratio of the PNIPAAm and PODA caused the copolymer to become more hydrophobic, and hence the LCST was expected to decrease. On the other hand, the decreasing conformational entropy resulted in the regularity of the molecule, leading to the decrease of transmittance. Therefore, the increasing mass ratio of the PNIPAAm and PODA caused the LCST to increase. At the temperature below its LCST, the block copolymer was soluble due to the intermolecular hydrogen bonding between the PNIPAAm chains and water molecules. When the temperature reached or was above its LCST, intermolecular hydrogen bonding was destroyed and the flower-like shell of PNIPAAm was contracted, leading to the decrease of transmittance. Compared with ABA type block copolymer [17], the total amount of decreasing transmittance of BAB is smaller than that of ABA’s. This could be interpreted by the geometry of the two block copolymers. ABA block copolymer was dendritic, while BAB was flower-like, therefore, BAB type micelle was more stable, leading to the larger amount of decreasing transmittance.

Dynamic light scattering (DLS)

The hydrodynamic radius (R h ) and polydispersity index (PdI) were investigated by dynamic light scattering (DLS). A single peak exhibited in the distribution curves of hydrodynamic radius of the B0.5mA24mB0.5m micelles at all the studied concentrations suggested the formation of one kind of micelle. What’s more, as shown in Fig. 4, BAB-type block copolymer micelle had R h values ranging from 40 to 100 nm. At the temperature below LCST (26 °C), the average R h remained at about 100 nm and not changed with the temperature increased. When the temperature reached the LCST (which was in accordance with the LCST measured by transmittance), R h decreased sharply to about 42 nm. Above 29 °C, the average R h remained at about 42 nm and not changed with the temperature increased. The PdI of block copolymers was about 0.55 below LCST, when reaching LCST, it decreased to 0.1 and kept constant even at higher temperature. The broken intermolecular hydrogen bonding between the PNIPAAm chains and water molecules and the contraction of the block copolymer led to the decline of R h . Importantly, the average R h didn’t increase, suggesting the non-aggregation of block copolymers above LCST. However, the ABA type block copolymer micelle [17] aggregated, because both the particle size and PdI decreased when the temperature reached at LCST, but increased to three times bigger than that before LCST sharply. This was mainly because the structure of ABA micelle was dendritic, which was easy to aggregate. The small PdI value also demonstrated the narrow micelles size distribution and homogeneity. Additionally, the entropy loss of BAB copolymer chains due to the looping geometry of the PNIPAAm block also led to the formation of the micelles at higher temperature. Therefore, as shown in Fig. 2, the coil-looping microstructure above LCST also led to the stability and homogeneity.

Drugs loading efficiency

The core-shell structure could provide amphiphilic copolymer micelle nano particles with the potential as drug delivery vehicles in that the hydrophobic core could create a microenvironment for the incorporation of lipophilic drugs, while the hydrophilic shell provided a stable interface between the hydrophobic core and the aqueous medium, which enhanced dispersion and inhibited aggregation. Sudan Red IV was used as a model drug because of its hydrophobic group and the fresh red color could be observed obviously, the drug encapsulation efficiency could be investigated qualitatively. The drug encapsulation efficiency in different block copolymers was shown in Fig. 5, qualitatively. As could be seen in Fig. 5, B0.5mA24mB0.5m had the largest encapsulation efficiency and was used as a typical model for characterization. The particle size was 121 nm (PdI = 0.341) before drugs loading while it was 199 nm (PdI = 0.394) afterwards, determined with the Nano-ZS 90 Malvern instrument. The micelles size was larger after loading drugs obviously, indicating that the drug was encapsulated into the micelles. As shown in Fig. 2, the physical encapsulation of hydrophobic drugs in polymeric micelles was mainly driven by the hydrophobic interactions between drug and hydrophobic segments of copolymer. The drug loading capacity was investigated quantificationally and the drug loading capacity and loading efficiency were shown in Table 1. We could see from Table 1 that B0.5mA 24mB0.5m had the largest capacity to encapsulate drugs. This could be ascribed to the appropriate ratio of hydrophilic and hydrophobic chain. Inappropriate ratio resulted in too compact or too loose packing of PNIPAAm chains in copolymer micelles which prevented the penetration and diffusion of drugs, which showed relatively lower drug loading efficiency.

Conclusion

A series of thermo-sensitive block copolymers PODAx-PNIPAAmy-PODAx (BAB type) were prepared successfully based on a chain transfer agent (TTC) via RAFT polymerization. It was found that the block copolymers could self-assemble into nano-micelles due to the hydrophilic PNIPAAm and hydrophobic PODA and the characterizations of nano-micelles were demonstrated by surface tension technique, UV-Vis and DLS measurements. The measurement results showed that the longer the hydrophilic chain was, the higher the CMC would be, and the lower the mass ratio of the PNIPAAm and PODA was, the lower the LCST would be. The average R h remained at about 100 nm below LCST, but R h decreased sharply to about 42 nm and kept constant when reaching and above LCST, which meant the non-aggregation of BAB type block copolymers. The micelle was homogeneous with the small PdI within the range of research. Drug delivery for Sudan Red IV research indicated that B0.5mA 24mB0.5m had the largest capacity to encapsulate drugs and the drug loading efficiency was 9.76%.

References

Li CM, Madsen J, Armes SP, Lewis AL (2006) A new class of biochemically degradable, stimulus-responsive triblock copolymer gelators. Angew Chem Int Ed 45:3510–3513

Ma YH, Tang YQ, Billingham NC, Armes SP (2003) Synthesis of biocompatible, stimuli-responsive, physical gels based on ABA triblock copolymers. Biomacromolecules 4:864–868

Peng Z, Li G, Liu X, Tong Z (2008) Synthesis, pH-and temperature-induced micellization and gelation of doubly hydrophilic triblock copolymer of poly (N,N-dimethylamino-2-ethyl methacrylate)-b-poly (ethylene glycol)-b-poly (NN-dimethylamino-2-ethyl methacrylate) in aqueous solutions. Polym Sci Part A: Polym Chem 46:5869–5878

Andrew PV, Brent SS (2009) Temperature and redox responsive hydrogels from ABA triblock copolymers prepared by RAFT polymerization. Soft Matter 5:2347–2351

Ma CL, Pan PJ, Shan GR, Bao YZ, Fujita M, Maeda M (2015) Core–Shell structure, biodegradation, and drug release behavior of poly (lactic acid)/poly (ethylene glycol) block copolymer micelles tuned by macromolecular Stereostructure. Langmuir 31:1527–1536

Kataoka K, Harada A, Nagasaki Y (2012) Block copolymer micelles for drug delivery: design, characterization and biological significance. Adv Drug Deliv Rev 64:37–48

Winnik FM (1990) Fluorescence studies of aqueous solutions of poly (N-isopropylacrylamide) below and above their LCST. Macromolecules 23:233

Aoshima S, Kanaoka S (2008) Synthesis of stimuli-responsive polymers by living polymerization: poly (N-isopropylacrylamide) and poly (vinyl ether)s. Adv Polym Sci 210:169–208

Wiktor S, Richard H, Helmut K, Martin (2010) Copolymerization of 2-Hydroxyethyl acrylate and 2-Methoxyethyl acrylate via RAFT: kinetics and Thermoresponsive properties. Macromolecules 43:7041–7047

Zhou C, Hillmyer MA, Lodge TP (2012) Efficient formation of Multicompartment hydrogels by stepwise self-assembly of Thermoresponsive ABC triblock Terpolymers. J Am Chem Soc 134:10365

Nicholas JW, Oleksandr OM, Daniel M, Anthony JR, Steven PA (2014) RAFT aqueous dispersion polymerization yields poly (ethylene glycol)-based Diblock copolymer Nano-objects with predictable single phase morphologies. J Am Chem Soc 136:1023–1033

Nicholas JW, Steven PA (2014) Polymerization-induced self-assembly of block copolymer Nano objects via RAFT aqueous dispersion polymerization. J Am Chem Soc 136:10174–10185

Yu YQ, Hong D, Liu Z, Jia FJ, Zhou YM, Leng CF (2013) Controllable preparation and characterization of the thermosensitive block polymers. J Polym Res 20:235

John TL, Debby F, Ronald S (2002) Functional polymers from novel carboxyl-terminated Trithiocarbonates as highly efficient RAFT agents. Macromolecules 35:6754–6756

Maeda Y, Higuchi T, Ikeda I (2000) Change in the hydration state during the coil-globule transition of aqueous solution of poly (Nisopropylacrylamide) as evidence by FTIR spectroscopy. Langmuir 16:7503–7509

Feil H, Bae YH, Feijen J, Kim SW (1993) Effect of comonomer hydrophilicity and ionization on the lower critical solution temperature of N-isopropylacrylamide copolymers. Macromolecules 26:2496–2500

Wu J, Sun XJ, Zhang RL, Yuan SC, Wu ZM, Lu QL, Yu YQ (2016) RAFT preparation and self-assembly behavior of thermosensitive triblock PNIPAAm-b-PODA-b-PNIPAAm copolymers. Colloid Polym Sci 294:1989–1995

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 20876081), the Science Foundation of Shandong Province (ZR2012BM015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Y., Sun, X., Zhang, R. et al. Synthesis and properties of amphiphilic thermo-sensitive block copolymers. J Polym Res 24, 55 (2017). https://doi.org/10.1007/s10965-017-1219-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1219-2