Abstract

With a constant poly(ethylene glycol) (PEG) block length while adjusting the block length of poly(L-lactide) (PLLA), two types of PLLA-PEG-PLLA copolymers were synthesized, and their crystallization under shear flow using high-temperature shear stage was investigated. Wide angle X-ray diffraction (WAXD) results show that PEG is noncrystalline due to its short chain length and confined crystallization by the presence of the PLLA microstructure. From the results calculated by Scherrer equation, the crystallite size of dynamic sample increased comparing to those of the quiescent sample. It could be concluded that the application of shear has a positive effect on the crystallization of long chain series and crystal size. Differential scanning calorimetry (DSC) measurement shows that shear reduces the double melting peak phenomenon and leads to much more uniform of the crystals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, growing attention has been paid to a new class of biomaterials, double crystalline block copolymers [1–8]. The multicomponent nature of these systems provides the versatility in terms of mechanical properties, biodegradability as well as biocompatibility. The copolymerization of poly(ethylene glycol) (PEG) with lactides has raised interests because it combines the hydrophilicity of PEG and the advantage of the proven usefulness of biodegradable poly(L-lactides) (PLLA).

So far, most works have been focused on the crystallization of PLLA-PEG-PLLA copolymers which can be modulated by adjusting chemical structure (diblock, triblock and multiblock) or copolymer composition. Multiblock copolymer presents lower crystallinity and better miscibility between the two components compared to its diblock or triblock counterparts [9]. Other experimental results indicate that the crystalline property could be tailored by altering the ratio of PEG to PLA segments [9–11]. Generally, the longer the segment length of one component, the higher its crystallinity, and the lower the crystallinity of the other component is.

By analyzing all of these investigations mentioned herein, such a noticeable conclusion can be drawn definitely, that is, the previous researches are mainly performed under quiescent condition, the shear-induced crystallization of PLLA-PEG-PLLA remains largely unexplored. However, in most polymer processing operations, such as extrusion, injection molding, fiber spinning, etc., the molten polymer is inevitably exposed to various levels of flow fields (elongation, shear, or mixed) [12]. These flow fields introduce different degrees of anisotropy to the polymer melt, which modify the nucleation and crystallization behavior [13, 14] and determine the final structure and properties [15, 16] of the polymer. This scientific background also forms the motivation for this work and inspires us to introduce shear flow to the PLLA-PEG-PLLA copolymer.

In this work, a series of experiments were elaborately conducted with different block lengths at different shear rates by means of wide angle X-ray diffraction (WAXD) as well as differential scanning calorimetry (DSC), which represent the experimental validation of the effect of shear on the crystallization of PLLA-PEG-PLLA. These results are instructive for practical applications of PLLA-PEG-PLLA in the biomedical field.

Experimental

Materials

L-lactic acid (L-LA) was purchased from Aldrich Co. (Germany), Cat. 36, 704-4. Poly(ethylene glycol) (PEG) was the products of Kelong chemical industry corporation (Chengdu, China). Diethyl ether was obtained from Bodi chemical industry Co. (Tianjin, China), and stannous octoate was purchased from Aldrich (Germany) and distilled before used.

Preparation of block copolymer samples

PLLA-PEG-PLLA triblock copolymers were prepared by polymerization of prescribed amounts of L-LA and PEG in the presence of a catalyst, stannous octoate. The reaction was carried out under vacuum at 130 °C for 48 h in an oil bath. Subsequently, the reaction product was dissolved in chloroform and precipitated into a large amount of diethyl ether. Finally, the white precipitates were filtered and dried under vacuum at room temperature for 2 days. Two series of copolymers have been synthesized, 1H NMR spectra were recorded on a Bruker DMX-300 spectrometer working at 300.130 MHz to confirm the synthesized structure. The one which is composed of 1 × 104 (10 k, \( \overline {{M_n}} \)) PLLA at both sides and 1 × 103 PEG (1 k, \( \overline {{M_n}} \)) in the center is denoted as 10TRI1, while the other series is given the name of 30TRI1, with 3 × 104 PLLA (30 k, \( \overline {{M_n}} \)) at both ends and 1 × 103 PEG (1 k, \( \overline {{M_n}} \)) in the middle.

Measurements

The as-synthesized polymers were dissolved to form film with a thickness of ca. 0.5 mm. Linkam CSS-450 high-temperature shear stage was employed to provide shear. The film samples were first heated to 200 °C at 50 °C/min and held for 5 min to diminish any thermal history, and then cooled to isothermal crystallization temperature (125 °C) at 5 °C/min. Different levels of shear were applied for 10 min in course of the initial cooling stage (from 200 to 150 °C). After the crystallization of PLLA block completed, the samples were cooled to ambient temperature. Samples isothermally crystallized at 125 °C under static and shear conditions were measured by wide angle X-ray diffraction (Rigaku D/max-A, Japan) at room temperature. The profile of 2θ was 10–40°. The crystallite size (L) was estimated on a relative scale with the Scherrer equation (Eq. 1), relating crystallite dimensions to the width of the reflections [17].

where L is the crystallite size perpendicular to the reflecting plane, λ is the wavelength of Cu Kα source (λ = 0.154 nm). 2θ is the scattering angle of the diffraction peak, ΔB is the observed peak width at half-maximum intensity, and ΔB 0 is the instrumental line width, which depends on the sample thickness, wavelength and collimation, here ΔB 0 = 0.125°.

A Linkham CSS-450 high-temperature optical shear stage equipped with video camera coupled to an optical polarizing microscope (POM), Olympus BX51 model, was employed for the observation of the crystallization process under quiescent condition. The samples for POM observation underwent the same thermal history with those for WAXD characterization.

The samples were also used for melting behavior testing by differential scanning calorimetry (Perkin Elmer DSC-7) under nitrogen atmosphere. The samples all within 5–10 mg were scanned from room temperature to 200 °C at a heating rate of 10 °C/min.

Results and discussion

Influence of block length on the crystallization of PLLA-PEG-PLLA copolymer

Figure 1 shows the WAXD curves of 10TRI1 and 30TRI1 samples obtained in static state. The characteristic diffraction peaks of PLLA should appear at 14.8, 16.8, 19.1 and 22.28°, corresponding to planes of (011), (110) or (200), (113) or (203), and (210), respectively. And those for PEG crystallites should be observed at 15, 19.1 and 23.28°, according to the reported planes of (110), (120) and (032) [18]. Regardless of the structure and the molecular weight of the PLLA block, all the diffraction peaks in Fig. 1 are remarkably consistent with the characteristic peaks of PLLA. However, those of PEG cannot be observed in the diagram, or a diffraction peak will show up right beside the peak at 22.28°, where double peaks emerge [18]. It was reported that in PLLA-PEG diblock, triblock and multiblock copolymers, the crystallization behavior of one block was greatly influenced by the presence of the other block, in particular by the block length of the other block [18, 19]. In the case of PLLA-PEG diblock copolymers, with increasing the PLLA block length, the crystallization temperature (Tc) and melting temperature (Tm) of the PEG block in the copolymers decreased. It was indicated that the crystallization of PEG was restricted by the earlier crystallization of PLLA due to their different Tc [10]. So these conclusions could also explain our experimental results. With the temperature falling, PLLA block crystallizes first, and the crystallization of PEG block occurs later which is confined by the presence of the PLLA microstructure intensively. That is, after the PLLA block has crystallized, there is little room left between the crystals and amorphous parts of the PLLA block in which the PEG block can crystallize, hence, the crystallization of PEG is restricted. Additionally, the PEG block lengths in 10TRI1 and 30TRI1 are really short compared with those of PLLA (1/10 and 1/30 that of PLLA), so the crystallization of the PEG block requires a larger degree of supercooling (generally below 0 °C). But the samples were only cooled to room temperature in this work, which also constrained the crystallization of PEG block. This is very similar to the result that the crystallization of PEG block was suppressed in PLLA-PEG multiblock copolymer, depending on their block length ratio [10]. Consequently, it is believed that PEG remains the amorphous state in this triblock copolymer, and acts as a noncrystalline diluent.

Comparing the two curves in Fig. 1, it is noticeable that the peak width at half-maximum intensity (HMW) of PLLA changes with its block length, which is also shown in Table 1. According to Scherrer equation (Eq. 1), the crystallite size (L) of PLLA in the triblock can be estimated using the diffraction peak at 2θ = 16.5°. The L for 30TRI1 under quiescent state is 22.7 nm, while the L for 10TRI1 is 24 nm. One can find with the length of PLLA block increasing, the crystallite size of it in the triblock copolymer decreases. It differs from the reported results [9, 20] that the length of one block increasing would generally promote its crystallization. Here, on the contrary, the crystallization of PLLA block becomes poorer for 30 k block length. But it could be found that the reported block lengths are not as long as these in our experiment, thus, the corresponding increase of entanglements and the consequently increased viscosity of the system should be taken into consideration. The longer polymer chains are, the more entanglements per chain with the adjacent ones have. Those physical entanglements profoundly deteriorate the chain mobility and restrict polymer chains from arranging into crystalline regions. The overall increase of the viscosity will again reduce the chain mobility. Therefore, the reduced crystallite size is the result of the increase in the entanglements and viscosity causing by the increased long molecular chains.

Influence of shear on the crystallization of PLLA-PEG-PLLA copolymer

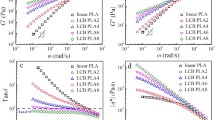

The WAXD curves of isothermally crystallized 30TRI1 and 10TRI1 under shear flow at shear rates of 0.1, 1 and 10 s−1 are depicted in Fig. 2(a) and (b). The locations of characteristic crystalline peaks of both PLLA and PEG hardly change, which implies that there is no new modification of PLA crystal formed after applying shear. It can be found that the application of shear decreases HMW, and HMW at other locations has similar results. Since HMW is inversely proportional to L according to the Scherrer equation, Eq. 1, the reduction of HMW means the increase of the crystallite size as shown in Table 1. The consistent result has been reported by Zhong et al. [21] who investigated the crystalline morphology in injection molding samples, and found out that long period in the skin layer is larger than that in the interior region because of shear. Thus, compared the samples crystallized under static, shear could promote the crystallite size perpendicular to the reflecting plane. Hence, it indicates that shear has positive effects on the crystallization of PLLA. This is because shear flow induces higher chain mobility and causes extension and orientation of polymer chains, which leads to the formation of crystallization precursor structures [22, 23].

Furthermore, when both triblock copolymers were under the same shear rate (except at 10−1 s), the crystallite size of 30TRI1 is larger than that of 10TRI1. Since the relaxation time is proportional to the molecular weight, flow-induced orientation decays much more slowly for long chains than for short chains. So, after the cessation of shear, long polymer chains may not have sufficient time to relax back to the random coiled state and will remain in the stretched state. The increased molecular weight results in enhanced stability and increased concentration of the shear-induced oriented microstructure. It can be summarized that the application of shear is more effective on the crystallization of long chain systems. However, at the higher shear rate (10−1 s), both long and short PLLA chains corresponding to 30TRI1 and 10TRI1 may be well oriented which makes the chain relaxation difficult. The effect of the viscosity may manifest again. So the L of PLLA for 10TRI1-10−1(35.8 nm) is larger than that for 30TRI1-10−1(34.9 nm), although the proportion of amorphous PEG for 10TRI1 increases which may restrain the crystallization of PLLA.

The DSC analysis has also been carried out to clarify the effect of shear on the microstructure of PLLA blocks. Figure 3 illustrates the DSC curves for the 30TRI1 copolymer at different shear rates and their melting temperatures where their endothermic rates reach the maximum are summarized in Table 2. It can be found that the main melting peak ranging from 115 to 140 °C belongs to the PLLA crystals in each of the individual curves [24]. It shifts to lower temperatures compared to the previous study of neat PLLA [25], which provides the evidence of the confined crystallization of PLLA in the copolymers. The absence of the melting peak of PEG block indicates that the crystallization of PLLA blocks is dominant while that of the PEG block is very limited, which is in accordance with WAXD results.

A shoulder peak (135 °C) appears at lower shear rate (0.1 s−1), then it weakens towards higher shear rate and totally disappears when the shear rate reaches 10 s−1. It is believed that the presence of shoulder peak mainly refers to the melting of crystals with different crystal perfection due to the large distribution of segments location [9, 26]. For instance, in 30TRI1, because the Tc of PLLA is higher than that of PEG, the PEG block might remain in the molten state when PLLA block was isothermally crystallized at 125 °C. This may lead to the difference in mobility between PLLA block and PEG block. So the crystallization of PLLA block could be affected in the region where the segments of PLLA block is chemically connected the PEG block, resulting in the imperfect crystals formed. According to theory proposed by Hoffman [27], the small and imperfect crystalline lamellae formed from more restricted segments begin to melt first, and then they continue to melt as the temperature increases. At higher temperature, the thicker and bigger lamellae start to melt gradually, where a shoulder peak shows. However, shear affords mobility to molecular chains, reducing the segments mobility discrepancy within one individual chain, which leads to much more uniform crystalline structures. While at the same time, the whole weakening process of shoulder peak is accompanied with the shifting of peak location to higher temperature, which shows the overall number of more perfect crystals increases.

We attempted to observe in-situ the crystal morphology of the copolymers during shear-induced crystallization. However, we faced practical difficulties. While preparing the samples for WAXD measurement, they were too thick (0.5 μm) to discern the crystallites. It was excepted that the thickness of film samples was reduced to the degree that polarized optical microscope (POM) can easily detect, unexpectedly, they were quite fragile under shear, and the crystalline morphology could not be available. So only the optical images of the crystals under quiescent condition were taken, as shown in Fig. 4, which clearly show the typical spherulitic morphology for both block copolymers.

Conclusions

PEG is noncrystalline dilute in the triblock copolymers due to its short chain length and confined crystallization by the presence of the PLLA microstructure. But the application of shear improves the crystallization of long chain series, because shear induces the extension and orientation of polymer chains and the orientation decays much more slowly for long chains after the cessation of shear, so the crystallization of the PLLA block in 10TRI1 is more influenced compared with that in 30TRI. Shear also reduces the half-maximum intensity peak widths, which means the increase of crystal size. Differential scanning calorimetry shows that increased shear rate reduces the double melting peak phenomenon as a result of large distribution of segments locations and leads to much more uniform crystals. The experimental validation of the effect of shear on the crystallization of PLLA-PEG-PLLA is presented, which is instructive for practical applications of PLLA copolymers in the biomedical field. Further issues will be addressed to probe the influence of shear duration time, higher shear rates, different crystallization temperature on the crystallization of PLLA-PEG-PLLA.

References

Fujiwara T, Miyamoto M, Kimura Y (2000) Crystallization-induced morphological changes of a poly(L-lactide)/poly(oxyethylene) diblock copolymer from sphere to band via disk: a novel macromolecular self-organization process from core-Shell nanoparticles on surface. Macromolecules 33:2782–2785

Hu X, An HN, Li ZM, Geng Y, Li LB, Yang CL (2009) Origin of carbon nanotubes induced Poly(L-lactide) crystallization: surface induced conformational order. Macromolecules 42:3215–3218

Xu JZ, Chen T, Yang CL, Li ZM, Mao YM, Zeng BQ, Hsiao BS (2010) Isothermal crystallization of poly(L-lactide) induced by graphene nanosheets and carbon nanotubes: a comparative study. Macromolecules 43:5000–5008

Shin D, Shin K, Aamer KA, Tew GN, Russell TP (2005) A morphological study of a semicrystalline poly(L-lactic acid-b-ethylene oxide-b-L-lactic acid) triblock copolymer. Macromolecules 38:104–109

Hamley IW, Castelletto V, Castillo RV, Müller AJ, Martin CM, Pollet E, Dubois P (2005) Crystallization in poly(L-lactide)-b-poly(ε-caprolactone) double crystalline diblock copolymers: a study using X-ray scattering, differential scanning calorimetry, and polarized optical microscopy. Macromolecules 38:463–472

Kim JK, Park DJ, Lee MS, Ihn KJ (2001) Synthesis and crystallization behavior of poly(L-lactide)-block-poly(ε-caprolactone) copolymer. Polymer 42:7429–7441

Reiter G, Strobl GR (2007) Progress in understanding of polymer crystallization. Lecture Notes in Physics 714, Springer

Castillo RV, Müller AJ (2009) Crystallization and morphology of biodegradable or biostable single and double crystalline block copolymers. Prog Polym Sci 34:516–560

Luo WJ, Li SM, Bei JZ, Wang SG (2002) Synthesis and characterization of poly(L-lactide)-poly(ethylene glycol) multiblock copolymers. J Appl Polym Sci 84:1729–1736

Lee S, Chin I, Jung J (1999) Crystallization behavior of poly(L-lactide)-poly(ethylene glycol) multiblock copolymers. Eur Polym J 35:2147–2153

Zhu KJ, Lin XZ, Yang SL (1990) Preparation, characterization, and properties of polylactide (PLA)-poly(ethylene glycol) (PEG) copolymers: a potential drug carrier. J Appl Polym Sci 39:1–9

Lee O, Kamal MR (1999) Experimental study of post-shear crystallization of polypropylene melts. Polym Eng Sci 39:236–248

Abuzaina FM, Fitz BD, Andjelić S, Jamiolkowski DD (2002) Time resolved study of shear-induced crystallization of poly(p-dioxanone) polymers under low-shear, nucleation-enhancing shear conditions by small angle light scattering and optical microscopy. Polymer 43:4699–4708

Kumaraswamy G, Issaian AM, Komfield JA (1999) Shear-enhanced crystallization in isotactic polypropylene. 1. correspondence between in situ rheo-optics and ex situ structure determination. Macromolecules 32:7537–7547

Varga J, Karger-Kocsis J (1996) Rules of supermolecular structure formation in sheared isotactic polypropylene melts. J Polym Sci Polym Phys 34:657–670

Wu CM, Chen M, Karger-Kocsis J (1999) The role of metastability in the micromorphologic features of sheared isotactic polypropylene melts. Polymer 40:4195–4203

Klug HP, Alexander LE (1974) X-ray diffraction procedures for polycrystalline and amorphous materials. Wiley, New York

Yang JL, Zhao T, Cui JJ, Liu LJ, Zhou YC, Li G, Zhou EL, Chen XS (2006) Nonisothermal crystallization behavior of the poly(ethylene glycol) block in poly(L-lactide)-poly(ethylene glycol) diblock copolymers: effect of the poly(L-lactide) block length. J Polym Sci Polym Phys 44:3215–3226

Sun JR, Hong ZK, Yang LX, Tang ZH, Chen XS, Jing XB (2004) Study on crystalline morphology of poly(L-lactide)-poly(ethylene glycol) diblock copolymer. Polymer 45:5969–5977

Kim KS, Chung S, Chin IJ, Kim MN, Yoon JS (1999) Crystallization behavior of biodegradable amphiphilic poly(ethylene glycol)-poly(L-lactide) block copolymers. J Appl Polym Sci 72:341–348

Zhong GJ, Li ZM, Li LB, Mendes E (2007) Crystalline morphology of isotactic polypropylene (iPP) in injection molded poly(ethylene terephthalate) (PET)/iPP microfibrillar blends. Polymer 48:1729–1740

Yang L, Somani RH, Sics I, Hsiao BS, Kolb R, Lohse D (2006) The role of high molecular weight chains in flow-induced crystallization precursor structures. J Phys Condens Matter 18:S2421–S2436

Vilgis T, Halperin A (1991) Aggregation of coil-crystalline block copolymers: equilibrium crystallization. Macromolecules 24:2090–2095

Cohn D, Salomon AH (2005) Biodegradable multiblock PEO/PLA thermoplastic elastomers: molecular design and properties. Polymer 46:2068–2075

Hu X, Xu HS, Li ZM (2007) Morphology and properties of poly(L-lactide) (PLLA) filled with hollow glass beads. Macromol Mater Eng 292:646–654

Liu MY, Zhao QX, Wang YD, Zhang CG, Mo ZS, Cao SK (2003) Melting behaviors, isothermal and non-isothermal crystallization kinetics of nylon 1212. Polymer 44:2537–2545

Hoffman JD, Miller RL (1988) Test of the reptation concept: crystal growth rate as a function of molecular weight in polyethylene crystallized from the melt. Macromolecules 21:3038–3051

Acknowledgement

The authors gratefully acknowledge the financial support of this work by National Outstanding Youth Foundation of China (Grant No. 50925311).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Hu, X., Xu, JZ., Zhong, GJ. et al. Shear induced crystallization of poly(L-lactide) and poly(ethylene glycol) (PLLA-PEG-PLLA) copolymers with different block length. J Polym Res 18, 675–680 (2011). https://doi.org/10.1007/s10965-010-9463-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9463-8