Abstract

Starting from the natural α-amino-acid L-tyrosine, a potentially bioactive diphenolic molecule, N,N′-(pyromellitoyl)-bis-L-tyrosine dimethyl ester (8), was prepared in three steps using protecting groups to block the NH2 and COOH of tyrosine. A facile and rapid polycondensation reaction of diol 8 with several optically active diacid chlorides such as N,N′-(pyromellitoyl)-bis-(L-α-amino) diacid chlorides derived from L-phenyalanine, L-leucine, L-methionine, L-valine and L-alanin was developed under microwave irradiation. The polymerization reactions proceeded rapidly and was completed within 12 min, producing a series of novel poly(ester-imide)s (PEI)s in good yields and moderate inherent viscosities of 0.41–0.51 dL/g. The obtained polymers were characterized by means of FT-IR, 1H-NMR, elemental and thermogravimetric analysis techniques. In addition, in vitro toxicity test and biodegradability behavior of the diphenolic 8 and obtained PEIs were investigated in culture media and soil burial degradation. The outcome showed that synthesized diol 8 and its derived polymers are biologically active and biodegradable under natural environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since poly(α-amino acid)s PAAs are structurally related to natural proteins, the synthesis of amino-acid-based polymers was investigated as a potential source of new biomaterials. Starting from 1970, the use of both homo and copolymers of amino acids was studied for a variety of biomedical applications [1–4]. Materials that incorporate α-amino acids have generated significant interest because they offer certain advantages over conventional polymer systems. They are structurally sundry, relatively nontoxic, tissue-compatible, and the degradation products may be nontoxic and easily metabolized by living tissues [5]. The early studies revealed that a good number of PAAs could not be considered as potential biomaterials due to their unfavorable mechanical and thermal properties. So far, only a small number of poly(γ-substituted glutamates) and their copolymers have been identified as promising candidate materials for biomedical applications [6–8]. To improve the poor physicomechanical properties of most PAAs, amino acids have been used as monomeric building blocks in polymers that do not have the conventional backbone structure found in peptides. Collectively, these materials are referred to as ‘non-peptide amino-acid- based polymers’ or as ‘amino-acid-derived polymers with modified backbones. These materials have previously been classified into four major groups by Kenmitzer and Kohn [9]. For example, one group is pseudo-PAAs which in their structures, naturally occurring amino acids are linked by non-amide bonds, such as, iminocarbonate, ester and carbonate bonds. The resulting polymers contain the same monomeric building blocks as conventional PAAs, but do not have a peptide-like backbone structure which they were first described in 1984 [10, 11]. Several L-tyrosine based pseudo-PAAs were introduced as a new class of polymeric biomaterials by Kohn and Langer in 1984 [12–14]. The aromatic amino acid L-tyrosine is itself used as a common dietary supplement, primarily because of anecdotal reports of ability to excite brain activity for improved memory and mental awareness. It also could act as an appetite suppressant, control depression and anxiety and enhance physical performance. It has promise a valuable precursor compound for various industrial and pharmaceutical applications [15, 16]. Langer and coworker studied the synthesis and characterization of a family of biodegradable polymers based on dityrosine imitatives, due to the inherent ability of L-tyrosine and many of its derivatives to stimulate a potent immune response to adsorbed antigens [17–20].

In recent years microwave irradiation has received growing applications in the field of chemistry for improving reaction rates, yields and selectivity of a wide variety of chemical reactions [21, 22]. Recently we have used microwave irradiation for the synthesis of different kind of macromolecules [23].

In our previous reports we described an approach to incorporate α-amino acids into different types of polymeric structure via imide linkage for improving their poor thermal possessions, because imide bonds are known to show excellent mechanical and thermal properties [24–29]. In connection with our interest in preparing optically active and thermally stable modified polymers having only one type of amino acid in main chain or side chain, herein we wish to report for the first time the synthesis and characterization of novel poly(ester-imide) (PEI)s which have two different types of amino acid linkages in the main chain. Step growth polymerization reactions of N,N′-(pyromellitoyl)-bis-dimethyl ester tyrosine as a novel diphenolic monomer 8 with different chiral diacid chloride monomers derived from L-phenylalanine, L-leucine, L-methionine, L-valine and L-alanin were performed under microwave irradiation. Furthermore, by incorporating various linkages such as ester and imide bonds combining with two amino acids the resulting polymeric materials could demonstrate good solubility, better thermal stability and processability. In vitro toxicity and soil biodegradability of synthetic aromatic diol 8 as well as obtained novel PEIs were also investigated using Petri plate containing Potato Dextrose Agar (PDA) and soil burial, respectively.

Experimental

Materials

All chemicals were purchased from Fluka Chemical Co. (Buchs, Switzerland), Aldrich Chemical Co. (Milwaukee, WI), Riedel-deHaen AG (Seelze, Germany). Pyromellitic dianhydride (benzene-1,2,4,5-tetracarboxylic dianhydride) (4) (from Merck Chemical Co) was purified by recrystallization from a mixture of acetic anhydride and acetic acid (1:4). N,N′-Dimethylformamide (DMF) was dried over BaO and then was distilled under reduced pressure.

Techniques

The microwave apparatus used for the polycondensation was a Samsung (South Korea) microwave oven (2,450 MHz, 900 W). All of the polymerization reactions were performed in a hood with strong ventilation. Proton Nuclear Magnetic Resonance (1H-NMR, 500 MHz) spectra were recorded in DMSO-d6 solution using a Bruker (Germany) Avance 500 instrument, and also Carbon Nuclear Magnetic Resonance (13C-NMR, 125 MHz) spectrum was recorded on a Bruker (Germany) advance 500 instrument at Sharif University of Technology, Tehran, Iran. Proton resonances are designated as singlet (s), doublet (d), doublet of doublet (dd) and multiplet (m). FT-IR spectra were recorded on (Jasco-680, Japan) spectrophotometer. The spectra of solids were obtained using KBr pellets. The vibrational transition frequencies are reported in wavenumbers (cm−1). Band intensities are assigned as weak (w), medium (m), strong (s) and broad (br). Solubility of the polymers was tested in various polar and non-polar solvents. 5 mg of the polymer was added to 1 ml of different solvents. Inherent viscosities were measured by using a Cannon-Fenske Routine Viscometer (Germany) at concentration of 0.5 g dL−1 at 25 °C. Specific rotations were measured by a Jasco Polarimeter (Japan). Thermal Gravimetric Analysis (TGA) data for polymers were taken on Perkin Elmer in nitrogen atmosphere at a rate of 10 °C min−1 and differential scanning calorimetry (DSC) data were recorded on a rate of 20 °C min−1. Elemental analyses were performed by the Iran Polymer and Petrochemical Research Institute, Tehran, Iran. Cultured sample images in Petri plate were captured using a binocular equipped with a digital canon (DS126181, Japan) camera.

Monomer synthesis

N,N′-(Pyromellitoyl)-bis-L-α-amino acids (3a–3e) and N,N′-(pyromellitoyl)-bis-L-α-amino diacid chloride (4a–4e) were prepared according to our previous works [23, 25–29].

N,N′-(Pyromellitoyl)-bis-L-tyrosine dimethyl ester (8) was introduced for the first time and was used of a new membrane selective electrode based on the potentiometric method for the determination of phenazopyridine as a drug [30]. The preparation of this diol was reported briefly and here its synthesis and characterization are reported in detail.

Synthesis of L-tyrosine methyl ester hydrochloride (6)

L-Tyrosine (3 g, 1.65 × 10−2 mol) was added to a methanol solution (15 mL) containing thionyl chloride (3.6 mL, 4.95 × 10−2 mol) at −10 °C. The solution was stirred at room temperature for 12 h and then the solvent was removed under reduced pressure, finally residual mass was washed several times with petroleum ether (15 mL) to obtain white, powdery, L-tyrosine methyl ester hydrochloride, which was used for the next step without further purification. Yield: 3.73 g (98%); mp 193 °C, Lit: 194–195 °C [31, 32].

Synthesis of L-tyrosine methyl ester (7)

Triethylamine (1.31 mL, 1.93 × 10−2 mol) was added slowly to a suspension of L-tyrosine methyl ester hydrochloride (3 g, 1.29 × 10−2 mol) in 20 mL of CH2Cl2, and the suspension was stirred for 3 h at 0 °C under nitrogen. The solvent was removed under reduced pressure, then the residual mass was washed with H2O (100 mL), followed by recrystallization from DMF to obtain a colorless solid, L-tyrosine methyl ester. Yield: 1.5 g (60%); mp: 135 °C Lit: 135–136 °C, \( \left[ \alpha \right]_{\rm{D}}^{25} = + 23^\circ \;{\hbox{Lit}}: + 26^\circ \) (c = 2.4 g/dL, methanol) [31, 32].

N,N′-(Pyromellitoyl)-bis-L-tyrosine dimethyl ester (8)

Into a 25 mL round-bottomed flask, 0.50 g (2.29 × 10−3 mol) of pyromellitic dianhydride (1), 0.60 g (4.58 × 10−3 mol) of L-tyrosine methyl ester (7), 8.0 mL of DMF and a stirring bar were placed. The mixture was stirred at room temperature for 6 h under nitrogen, then heated for 8 h at 80 °C and finally was refluxed 2 h at 120 °C. The yellow solution was distilled-off under reduced pressure, then the mixture was poured into a mixture of 50 mL/5 mL of cold distilled water/concentrated HCl. The yellow precipitates was collected by filtration and washed thoroughly with water and dried at 70 °C for 8 h, to yield 1.20 g (92%) of diol 8. mp: 168 °C, \( \left[ \alpha \right]_{\rm{D}}^{25} = - 16.81 \) (0.050 g in 10 mL of absolute ethanol).

FT-IR (KBr): 3436 (m, br), 2955 (w), 1775 (m), 1724 (s), 1614 (w), 1595 (w), 1516 (s), 1439 (m), 1383 (s), 1364 (s, br), 1259 (m), 1115 (m), 1016 (m), 833 (m), 802 (m), 734 (m) cm−1.

1H-NMR (500 MHz, DMSO-d6): δ 3.15–3.20 (dd, 2H, J 1 = 13.72 Hz, J 2 = 11.55 Hz,), 3.37–3.41 (dd, 2H, J 1 = 14.10 Hz, J 2 = 4.64 Hz), 3.69 (s, 6H), 5.18–5.22 (dd, 2H, J 1 = 11.14 Hz, J 2 = 4.86 Hz), 6.53–6.55 (d, 4H, Ar-H, J = 8.5 Hz), 6.92–6.94 (d, 4H, Ar-H, J = 8.5), 8.25 (s, 2H, Ar-H), 9.17 (s, 2H, OH) ppm.

13C-NMR (125 MHz, DMSO-d6): 33.93(CH2), 53.61 (CH, chiral center), 54.35 (CH3-O), 115.95 (4CH, aromatic), 119.08 (2CH, aromatic), 128.12 (2CH, aromatic), 130.32 (4C, aromatic), 136.95 (4C, aromatic), 155.08 (2C, aromatic), 165.74 (4C=O, imidic), 169.74 (2 C=O, ester) ppm.

Elemental analysis calculated for (C30H24N2O10)n(572.51 g/mol): C, 62.94%; H, 4.23%; N, 4.89%; Found: C, 62.16%; H, 4.28%; N, 4.95%.

Polymer synthesis

The PEI9a–PEI9e were prepared by the following procedure (using polymer PEI9a as an example). Into a porcelain dish 0.05 g (4.58 × 10−4 mol) of diacid chloride (4a) was placed then 0.039 g (4.58 × 10−4 mol) of phenolic diol 8 was added and the mixture was ground for 5 min. Then 0.40 mL of o-cresol as a solvent was added, the mixture was ground for 2 min. The reaction mixture was irradiated in the microwave oven for 12 min at 100% (900 W) of its power level. The resulting homogenous glassy polymer film was isolated by adding methanol and triturating, followed by filtration. Powdered polymer was dried at 80 °C for 5 h under vacuum to leave 0.085 g (94%) of white solid PEI9a.

-

PEI9a: white solid; FT-IR (KBr): 3031 (w), 1776 (m), 1725 (s), 1605 (w), 1508 (m, sh), 1455 (m), 1383 (s), 1363 (s), 1195 (m, br), 1113 (m), 917 (w), 728 (m), 1113 (m), 701 (m) cm−1.

1H-NMR (500 MHz, DMSO-d6, TMS): 3.20–3.23 (m, 8H), 3.68 (s, 6H), 5.28–5.29 (dd, 2H, J 1 = 10.73 Hz, J 2 = 3.77 Hz), 5.54–5.58 (dd, 2H, J 1 = 10.73 Hz, J 2 = 4.80 Hz), 6.80–6.82 (m, 2H, Ar-H), 6.90 (s, 4H, Ar-H), 7.14–7.24 (m, 12H, Ar-H), 8.19 (s, 4H, Ar-H) ppm.

-

PEI9b: Off white solid; FT-IR (KBr): 2959 (m), 1777 (m), 1725 (s), 1508 (m), 1456 (w), 1382 (s), 1362 (s), 1198 (m, br), 1114 (w), 1018 (m), 917 (w), 728 (m) cm−1.

1H-NMR (500 MHz, DMSO-d6, TMS): 0.85–0.90 (s, 6H), 0.95–0.97 (s, 6H), 1.51 (s, 2H), 1.93 (s, 2H), 2.11 (s, 2H), 3.31 (s, 4H), 3.66 (s, 6H), 5.25 (s, 4H), 6.86 (s, 4H, Ar-H), 7.17 (s, 4H, Ar-H), 8.15 (s, 2H, Ar-H), 8.30 (s, 2H, Ar-H) ppm.

-

PEI9c: Off white solid; FT-IR (KBr): 2959 (m), 1777 (s), 1725 (s), 1508 (m), 1456 (w), 1382 (s), 1362 (m), 1198 (m, br), 1114 (w), 1018 (m), 917 (w), 728 (m) cm−1.

1H-NMR (500 MHz, DMSO-d6, TMS): 1.99–2.04 (m, 10H), 2.37–2.58 (m, 4H), 3.31 (s, 4H), 3.66 (s, 6H), 5.25 (s, 2H), 5.37–5.38 (m, 2H), 6.84 (s, 4H, Ar-H), 7.18 (s, 4H, Ar-H), 8.16(s, 2H, Ar-H), 8.33 (s, 2H, Ar-H) ppm.

-

PEI9d: Off white solid; FT-IR (KBr): 3020 (m), 1777 (s), 1725 (s), 1508 (m), 1458 (w), 1382 (s), 1362 (s), 1198 (m, br), 1114 (w, s), 1018 (m), 917 (w), 728 (m) cm−1.

-

PEI9e: Off white solid; FT-IR (KBr): 3031 (w), 1776 (m), 1725 (s), 1605 (w), 1508 (m), 1455 (m), 1383 (s), 1363 (s), 1195 (m, br), 1113 (m), 917 (w), 728 (m), 1113 (m), 701 (m) cm−1.

Bacterial biodegradation

In vitro assessment is a rapid, cost effective and reliable test for toxicity studies [33, 34]. In vitro toxicity of bisphenol-A (BPA, 2,2-bis(4-hydroxydiphenyl)propane) as a reference, aromatic diol 8 and PEI9c were evaluated based on the growth of air-born bacterial saprophytes on culture media. For this purpose, BPA, aromatic diol 8, PEI9c and air-born spores were co-cultivated on the same Petri plates containing Potato Dextrose Agar (PDA) in three replications. Plates were incubated at 23–25 °C, for 4 weeks. Then colonial growth of bacterial saprophytes were noted and visually observed on each Petri plate.

Soil biodegradability test

Soil degradation of biologically active materials is an important characteristic that define their performance, safety, and storage conditions. The soil burial degradation test of segmented BPA as a reference, novel diol 8 and obtained polymers was conducted in aerobic soil condition in the presence of natural microorganisms. A sample of clay loam soil was conditioned for 2 weeks before it was used for the actual test. Materials were buried in the soil (pH = 7.5) in which the relative humidity maintained was 60–70% by spraying water and the temperature was thermostated at 28–30 °C in a humidity chamber (Ogawa Co., Japan). The buried compounds were monitored for 3 months at regular interval of 10 days. Material invasion by soil microbial fauna was checked during this period by digital DS126181 camera Canon and the time of disappearance of materials was recorded.

Results and discussion

Monomer synthesis

N,N′-(Pyromellitoyl)-bis-L-α-amino diacids (3a–3e) and N,N′-(pyromellitoyl)-bis-L-α-amino diacid chlorides (4a–4e) were prepared according to our previous work (Scheme 1) [23, 25–29]. The FT-IR spectrum of N,N′-(pyromellitoyl)-bis-L-phenylalanine as chiral synthesized diacid showed a broad and strong peak at 2354–3463 cm−1, which was assigned to the COOH groups of this diacid monomer. The characteristic absorptions of imide groups occurred around 1766, 1720 cm−1, peculiar to carbonyl stretching of imides (Fig. 1a). N,N′-(Pyromellitoyl)-bis-L-tyrosine dimethyl ester was synthesized as procedure that described below, and is shown in Scheme 2.

L-Tyrosine was added to a methanol solution containing thionyl chloride to obtain white, powdery, L-tyrosine methyl ester hydrochloride which deprotected with triethylamine to obtain L-tyrosine methyl ester. In addition L-tyrosine methyl ester was reacted with pyromellitic dianhydride in DMF at room temperature. In this reaction, the intermediate amic acid was not isolated and ring closure for the formation of imide ring was performed under refluxing conditions to obtain monomer 8.

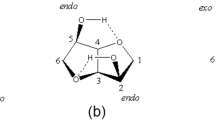

The chemical structure and purity of the compounds 8 were proved using thin layer chromatography, elemental analysis, FT-IR, 1H-NMR, 13C-NMR spectroscopic techniques and specific rotation measurements. The FT-IR spectrum of compound 8 showed a broad and strong peak at 3436 cm−1, which was assigned to the OH group of phenolic diol and two absorption bands at 1775 and 1725 cm−1 due to the symmetrical and asymmetrical imides carbonyl stretching vibrations (Fig. 1b). The 1H-NMR spectrum (500 MHz) of compound 8 is shown in Fig. 2.The 1H-NMR of this diol shows the characteristic resonance of C–H chiral center doblet of doublt at 5.18–5.22 ppm, peaks at 3.15–3.20 and 3.37–3.41 ppm are assigned to diastereotopic CH2 protons bonded to chiral center respectively. Singlet peak at 3.69 ppm was assigned to the CH3 protons of methoxy group. Figure 3 shows 13C-NMR spectrum (125 MHz) of monomer 8. It shows carbons for diastereotopic CH at 53.64 ppm. In addition the presence of different aromatic carbons and six carbons for carbonyl groups in this spectrum confirm the structure of monomer 8.

The purity of compounds 8 was checked by thin-layer chromatography, which showed one spot in an ethylacetate/cyclohexane mixture (50:50) with Rf = 0.80.

Polymer synthesis

A series of new macromolecules PEI9a–PEI9e were prepared from an equimolar mixture of monomer 8 with five different diacide chlorides derived from L-phenyalanine, L-leucine, L-methionine, L-valine and L-alanin (4a–4e) under microwave irradiation (Scheme 3). Microwave radiation energy is very useful for high efficiency utilization of heat energy. So the application of this technique produces polymers with quantitative yields and high inherent viscosities in a short time. The heating effect utilized in microwave-assisted organic transformations is due to dielectric constant (ε) of materials. It is particularly convenient that qualitatively, the larger the dielectric constant, the greater the coupling with microwave irradiation. Thus the use of small amount of a polar solvent, which is heated when irradiated in a microwave oven, acts: 1. as a primary absorber, and 2. as a solvent for both the starting and resulting materials. Therefore, the solvent allows induction of effective homogeneous heating to convert the monomers to polymers. Here we have used o-cresol as solvent. According to previous observations, we found that by increasing the dielectric constant and boiling point and polarity of the solvents, the inherent viscosities of final polymers will be increased [29]. Therefore, the polymers were synthesized in o-cresol. To optimize the influence of the amount of o-cresol on the inherent viscosity, the different values of solvent were added to the sample cell. For this purpose, diacid chloride 4a with one equimolar diol 8 was irradiated at a constant time (7 min). Figure 4 exhibits that, by increasing the solvent volume from 0.1 to 0.4 mL at a constant irradiation time, the inherent viscosities increased from approximately 0.29 to 0.38 dL/g, and after that by increasing the solvent volume, the inherent viscosities decreased. Thus, after optimizing the reaction solution concentration, the favored reaction time was obtained by changing microwave irradiation time in the presence of known amount of o-cresol and measuring the viscosity values. Figure 5 shows that by increasing the irradiation time up to 12 min, the inherent viscosity has increased sharply and above this time its value decreased to zero because the solution was burned. According to these results the optimum condition was selected for the synthesis of the other PEIs. Thus one equimolar of diol 8 with one equimolar of diacid chlorides (4b–4e) in o-cresol were irradiated for 12 min at 100% (900 W) of its power level and the resulting mixture was precipitated in methanol to obtain polymers with high yields. The synthesis and some physical properties of obtained novel PEI9a–PEI9e are listed in Table 1. All of the polymers were obtained in good yields with moderate inherent viscosities of 0.41–0.54 dl/g (Table 1). With respect to the straight relation between inherent viscosity and the molecular weight of structurally similar polymers, it is possible to judge about the molecular weight of PEIs. They are estimated to be in the ranges of roughly 3.4 × 104–4.3 × 104 g/mol [35, 36].

Polymer characterization

The resulting polymers were characterized by FT-IR, 1H-NMR spectroscopy techniques and elemental analyses. The FT-IR spectrum of PEIs showed the characteristic absorptions of imide and ester groups occurred around 1766, 1725 cm−1, peculiar to carbonyl stretching of imides and esters, respectively. All of these PEIs exhibited absorption at 1,383 cm−1 and 711–747 cm−1 that show the presence of the imide heterocycle in these polymers (Fig. 1c). The 1H-NMR spectrum (500 MHz) of PEI9a is shown in Fig. 6a. In the 1H-NMR spectrum of this polymer, appearances of the methoxy protons (OCH3) at 3.67 ppm as single peak indicates the presence of ester groups in the polymers side chain. The protons of the two chiral centers appeared as doublet of doublet in the range of 5.28–5.29 and 5.54–5.58 ppm respectively. The resonance of the diastereotopic hydrogen’s bonded to neighbor carbon of chiral centers appeared in the 3.20–3.23 ppm. The resonance of aromatic protons appeared in the range of 6.80–8.19 ppm. The 1H-NMR spectrum (500 MHz) PEI9b is shown in Fig. 6b. Elemental analysis values of the resulting polymers are also in good agreement with calculated values of carbon, hydrogen and nitrogen in the polymers (Table 2).

Solubility of PEIs

The solubility properties of PEIs were studied in different solvents. The presence of ester groups in the side chain as well as main chain (as pendant and polar groups) in obtained polymers give as effective way for improving solubility in common solvent, also polymers are soluble in organic polar solvents such as DMF, N-methyl pyrolidine (NMP), and in sulfuric acid at R.T, and are insoluble in solvents such as chloroform, methylene chloride, acetone, cyclohexane, tetrahyrofuran and water. These polymers show good solubility.

Thermal properties

The thermal properties of some PEIs were evaluated by means of TGA in a nitrogen atmosphere at a heating rate of 10 °C/min. Thermal stabilities of the polymers were studied based on 5 and 10% weight loss (T5, T10) of the polymers and residue at 800 °C (char yield). In addition, TGA data reveal that PEIs are thermally stable up to 320 °C. The thermoanalysis data of these polymers are summarized in Table 3. The temperature of 10% weight loss for PEI9a and PEI9b are 390 °C, 341 °C respectively. Char yield can be used as criteria for evaluating limiting oxygen index (LOI) of the polymers in accordance with Van Krevelen and Hoftyzer equation [37]. LOI = 17.5 + 0.4 CR where CR = char yield. All of the polymers had LOI values calculated based on their char yield at 800 °C was higher than 20. LOI values for PEI9a is 29.5. On the basis of LOI values, such macromolecules can be classified as self-extinguishing polymers. According to Table 3, it is clear that the PEI9a (based on L-phenylalanine as chiral moiety diacid chloride monomer) has higher thermal stability than PEI9b (based on L-leucine) (Fig. 7). It could be pertained to aromatic, rigid structure of phenylalanine for PEI9a compare to aliphatic, flexible structure of L-leucine for PEI9b. According to thermal data for PEI9a and PEI9b, it can be concluded that the resulting polymers are more thermally stable than similar structures of PEIs which were obtained with diacid chloride monomers (4a and 4b) with industrially used diphenols in previous works (Table 3) [25, 26]. The differential scanning calorimetry (DSC) technique was used to determine the Tg of the polymers. The heating rate was kept at 20 °C/min under a flow of nitrogen. These polymers showed Tg values in the range of 86 and 116 °C, respectively (Table 3).

Toxicity test

Bacteria growth profiles of BPA as a blank, diol 8 and its polymers in Petri plate containing culture media are shown in Fig. 8a, b and c after a period of two, three and 4 weeks, respectively. Figure 8e and h on culture media PDA show synthetic aromatic diol 8 was almost completely covered and colonized by saprophytic bacteria and they formed densely populated areas after 2 and 4 weeks, respectively. As shown in Fig. 8f and i, PEI9c was wholly colonized by saprophytic bacteria similar to diol 8 after 2 and 4 weeks, respectively. In contrast, BPA on the media was not invaded after 2 and 4 weeks (Fig. 8d and g, respectively). It seems that BPA has toxic properties for mentioned bacterial growth than synthetic diol 8 at the period of experimental time and it may have lower degradation rate under the soil burial conditions.

Whole Petri plates containing diol 8, PEI9c and BPA cultivated and incubated with saprophytic bacteria at 23–25 °C after one (a), two (b) and 4 weeks (c), respectively. Also inhibited growth of saprophytic bacteria incubated with BPA (d and g) versus their colonial growth around synthetic aromatic diol 8 (e and h) and PEI9c (f and i) at 23–25 °C, after 2 and 4 weeks in Petri plates, respectively

Soil biodegradability

Degradation profiles of BPA as a reference, diol 8 and its polymers in Petri plate under soil burial are shown in Fig. 9. The diol 8, PEI9a and PEI9c were initiated to decompose after 1 month (Fig. 9a–c, respectively) but BPA was remained intact (Fig. 9d). After 3 months, diol 8 and its polymers were almost disappeared under soil burial conditions (Fig. 9a′–c′, respectively) but BPA was not visibly changed during this period (Fig. 9d′). It could be concluded that diol 8 and obtained polymers are biologically active and biodegradable under soil burial test due to microbial invasion compared with commercial BPA.

Disappearance of diol 8 (a and a′), PEI9a (b and b′) and PEI9c (c and c′) under soil burial in Petri plates after one and 3 months, respectively, due to their biodegradability compared with non-disappeared BPA owing to its non-biodegradability under the same condition after one (d) and 3 months (d′)

Conclusions

In this report, a derivative of L-tyrosine, diol 8 was synthesized in three steps. This new diphenolic monomer can be regarded as a novel, potentially nontoxic and thermally stable monomer compare to the industrially used diphenols such as BPA [38, 39]. Based on captured photographs of culture media PDA, rapid bacterial colonization of synthetic diol 8 was observed on the media but BPA was not colonized possibly for its toxic properties growth. The incorporation of this diol into the backbone of different polymer systems results in versatile polymers with interesting properties, such as thermal stability, solubility and biodegradability. Thus, a series of new optically active PEIs having inherent viscosities of 0.41–0.54 dL/g were synthesized by microwave-assisted polycondensation reactions of the diol 8 with five different amino acid containing diacid chlorides 4a–4e. This approach allows the insertion of some of the natural amino acids into the polymer backbone and creation of a new class of bioactive polymers. Furthermore, degradation of polymeric products under soil burial showed that they may not hinder microbial growth at low and high concentration and therefore are favorable candidates as biodegradable and biologically active polymers. The above results also demonstrate that microwave heating is an efficient method (shorter reaction time and high energy efficiency) for polycondensation reactions.

References

Lescure F, Gurny R, Doelker E, Pelaprat ML, Bichon D, Anderson JM (1989) J Biomed Mater Res 23:1299–1313

Pulapura S, Kohn I (1992) Biopolymers 32:411–417

Anderson JM, Spilizewski KL, Hiltner A (1985) Poly-α amino acids as biomedical polymers. In: Williams DF (ed) Biocompatibility of tissue analogs vol. 1. CRC, Boca Raton, pp 67–88

Lyman DJ (1983) Polymers in medicine, biomedical and pharmacological applications. Plenum, New York, pp 215–218

Nair L, Laurencin CT (2007) Prog Polym Sci 32:762–798

Fasman GD (1987) Biopolymers 26:S59–S79

Sidman KR, Steber WD, Schwope AD, Schnaper GR (1983) Biopolymers 22:547–556

Bhaska RK, Sparer RV, Himmelstein KJ (1985) J Membr Sci 24:83–96

Kemnitzer J, Kohn J (1997) Degradable polymers derived from the amino acid L-tyrosine. Drug targeting and delivery. Handbook of biodegradable polymers, vol. 7. Harwood Academic, Amsterdam, pp 251–272

Kohn J, Langer R (1987) J Am Chem Soc 109:817–820

Kohn J, Langer R (1984) A new approach to the development of bioerodible polymers for controlled release applications employing naturally occurring amino acids. In: Polymeric materials, science and engineering, vol. 51, American Chemical Society, Washington, DC, pp 119–121

Kohn J, Langer R (1984) Polym Mater Sci Eng 51:119–121

Kohn J, Langer R (1986) Biomaterials 7:176–182

Bourke SL, Kohn J (2003) Adv Drug Deliv Rev 55:447–466

Deijen JB, Orlebeke JF (1994) Brain Res Bull 33:319–323

Eversloh TL, Nicole Ch, Santos S, Stephanopoulos G (2007) Appl Microbiol Biotechnol 77:751–762

Staubli A, Ron E, Langer R (1990) J Am Chem Soc 112:4419–4424

Hanes J, Chiba M, Langer R (1996) Macromolecules 29:5279–5287

Penney C (1995) In: Powell MF, Newman MJ (eds) Vaccine design: the subunit and adjuvant approach stearyl tyrosine: an organic equivalent of aluminum-based immunoadjuvants. Plenum, New York, p 611

Hanes J, Chiba M, Langer R (1998) Biomaterials 19:163–172

Wiesbrock F, Hoogenboom R, Schubert US (2004) Macromol Rapid Commun 25:1739–1764

Borriello A, Nicolais L, Fang X, Huang SJ, Scola DA (2007) J Appl Polym Sci 103:1952–1958

Mallakpour S, Rafiee Z (2008) Iranian Polym J 17:907–935

Mallakpour S, Taghavi M (2008) Eur Polym J 44:87–97

Mallakpour S, Hajipour AR, Habibi S (2002) J Appl Polym Sci 86:2211–2216

Mallakpour S, Habibi S (2003) Eur Polym J 39:1823–1829

Faghihi K, Foroughifar N, Mallakpour S (2004) Iranian Polym J 13:93–99

Mallakpour S, Shahmohammadi MH (2005) Iranian Polym J 14:473–483

Mallakpour S, Hajipour AR, Khoee S (2000) J Appl Polym Sci 77:3003–3009

Ensafi AA, Mallakpour S, Doozandeh F, Allafchian AR, Tirgir F. Anal Lett, Accepted for publication

Kudo H, Nagai A, Ishikawa J, Endo T (2001) Macromolecules 34:5355–5357

Nagai A, Ishikawa J, Kudo H, Endo T (2004) J Polym Sci Part A: Polym Chem 42:1143–1153

Hayes A, Bakand S, Winder C (2007) Novel in-vitro exposure techniques for toxicity testing and biomonitoring of airborne contaminants. In: Marx U, Sandig V (eds) Drug testing in vitro: breakthroughs and treands in cell culture technology. Wiley-VCH, Berlin, pp 103–124

El-Mohdy HLA, Ghanem S (2009) J Polym Res 16:1–10

Liaw DJ, Huang CC, Chen WH (2006) Polymer 47:2337–2348

Hsiao SH, Chang YH (2004) Eur Polym J 40:1749–1757

Vankrevelen D, Hoftyzer P (1976) Properties of polymer. Elsevier Scientific Publishing Company, New York

Chen MY, Ike M, Fujita M (2002) Environ Toxicol 17:80–86

Nakagawa Y, Tayama S (2000) Arch Toxicol 74:99–105

Acknowledgments

We wish to express our gratitude to the Research Affairs Division, Isfahan University of Technology (IUT), for partial financial support. Further financial support from National Elite Foundation (NEF) and Center of Excellency in Sensors and Green Research (IUT) is gratefully acknowledged. We also extend our thanks to Mr. M. Dinari and Mr. H. Seyedjamali for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mallakpour, S., Tirgir, F. & Sabzalian, M.R. Synthesis and structural characterization of novel biologically active and thermally stable poly(ester-imide)s containing different natural amino acids linkages. J Polym Res 18, 373–384 (2011). https://doi.org/10.1007/s10965-010-9427-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9427-z