Abstract

Blends of hydroxypropyl cellulose (HPC) in lyotropic phase have been prepared with a new epiclon- based poly(amic acid) (PAA) or its corresponding polyimide (PI). The flow behaviour of their mixed solutions in N,N-dimethylacetamide (DMAc) was investigated by means of shear viscometry and oscillatory shear tests. The effect of composition, temperature and shear rate on the rheological functions reflects the orientation or mobility of the chain segments in the shear field. Specific interactions, such as the hydrogen bonds between PAA and the liquid crystalline component, stabilized the resulted morphology. The band texture, typical for lyotropic HPC solutions, evidencing different intensities and dimensions is observed from atomic force microscopy images in PAA/HPC and PI/HPC blends. The paper pursues some aspects concerning the obtaining of mixed alignment layers used in display devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A successful alternative for the development of new polymeric materials is blending of the already existing polymers, to obtain a balance among the desired properties exhibited by the individual components. The development of the characterization techniques have led to an increased understanding of the mechanisms involved in polymers mixing, of their fundamental interactions, and of the manner in which these interactions affect their final properties. This link between molecular interactions and physical and engineering properties continues to be an important challenge for both scientific and industrial perspectives, due to the increasing economical impact of polymer blends and alloys in many domains affecting our everyday life. The morphology and rheology of polymer blends has been the subjects of many researches [1, 2]. It is well-known that the properties of blends depend on the rheology of components fluids, as well as on the interface properties. When a component becomes an anisotropic fluid, it is expected that the anisotropic interfacial properties would greatly affect the blends properties. Polymer/ liquid crystal polymer (LCP) blends have been intensively investigated as to their unique electrical, optical and mechanical properties and typical surface morphology [3]. The self-aligning nature of LC is used for enhancing the specific properties, important for obtaining organic polymer thin-film transistors (OP-TFTs) [4] for liquid crystal display devices [5].

Cellulose and some of its derivatives can form liquid crystalline solutions in a variety of solvents. Most of the lyotropic liquid crystalline phases formed by cellulose and its derivatives are cholesteric. The mesophases possess a unique helicoidal supramolecular structure in which the alignment of cellulosic molecules occurs at a small angle in one layer to another. Under a high shear rate flow, the chiral nematic structure changes to a flow-induced nematic-like phase. However, the shear-oriented phase is easy to disrupt after removing the shear force. This is generated by the driving force for the liquid crystalline solution forming the more thermodynamically stable helicoidal supramolecular structure [6]. One of the most common ethers of native cellulose, whose concentrated solutions display optical properties typical for cholesteric liquid crystals, is hydroxypropylcellulose (HPC). In the crystalline state, the HPC molecules are present in a helical arrangement. The structure is not dependent on the solvent alone, but also on the concentration [7]. Fundamental research on the formation of banded textures in thin-film samples from lyotropic HPC solutions subjected to shear is important, due to the large number of physical interactions involved [8, 9]. Moreover, the surface anisotropy of the mechanical and optical properties of the polymer films [10], together with their potential use as alignment layers for liquid crystal displays, make these systems particularly interesting and promising for new applications. Flow behavior is the most thoroughly studied rheological property. Onogi and Asada [11] hypothesized the universal existence of three shear flow regimes to describe the viscosity of polymer liquid crystals (PLC): a shear thinning regime at low shear rates (Region I), a Newtonian plateau at intermediate shear rates (Region II), and another shear thinning regime at high shear rates (Region III). Region I, observed at low shear rates, shows shear thinning, exhibiting a yield stress, as in some plastic materials. This region is characterized by distortional elasticity associated with spatial variation in the director field (average local molecular orientation). Region II is a Newtonian plateau, reflecting a “dispersed polydomain” structure and Region III is a shear thinning zone, showing viscoelastic behaviour. In Regions I and II the flow is not strong enough to affect molecular orientation, while in Region III the flow field is very strong, so that the shear induces molecular orientation. Literature [11, 12] shows that cellulose derivatives do not always cover the entire domain from Region I to Region III, because not every regime lies within the accessible shear rate range.

On the other hand, polyimides (PI) are the most commonly employed LC alignment layers [13]. Literature of the field is focused on wholly aromatic polyimides [14], because of their high-temperature resistance. However, they do not always provide optimum properties because of deficiencies in processability, solubility and transparency, as well as because of their relatively high dielectric constant. Incorporation of aliphatic units into the polyimide backbone facilitates fewer polymer-polymer interactions and enhances the solubility in organic solvents, offering a compromise between processability and thermal properties [15]. Therefore, utilization of aliphatic or cycloaliphatic monomers to form aliphatic polyimides can successfully counteract some of the shortcomings of the wholly aromatic ones [16]. Also, chain flexibility and conformation should satisfy specific requirements in various applications, so that a careful examination and control of polyimide solution properties, under the influence of some external factors, is of great importance [17]. The structural composites industry and the electronics business rely heavily upon rheological testing for product improvement, as well as for new product process development. During compounding, several factors influence the final morphology, including shear, solution concentration, solvent nature, specific interaction and, also rheological properties of the blend components.

The present work investigates a series of blends obtained from HPC in lyotropic phase, and a new partial aliphatic polyimide or its poly(amic acid) precursor (PAA), for which details of synthesis and properties were described in previous publications [18, 19]. The aim of the paper is to study the correlation between solution properties and solid film characteristics, providing insight on the interactions from the system, which lead to the stabilization of the resulting morphology. As a consequence, a good knowledge on the rheological properties of these solutions is important for their handling and formulation, and also for better understanding and controlling the process of polyimide coatings. In order to exploit the complex range of properties of HPC/PI or HPC/PAA blends, it is necessary to analyze the morphological and structure-rheological relationship, for investigating the origins of phase separation at different concentrations and shear rates, as well as for estimating segments orientation or mobility in the shear field.

Experimental part

Materials

Epiclon (5-(2,5-dioxotetrahydrofurfuryl)-3-methyl-3-cyclohexene-1,2-dicarboxylic acid anhydride), an asymmetrical flexible alicyclic dianhydride (Merk, 98% purity), has been used as a raw material for polyimide, to enhance its solubility and to render some new properties [20, 21]. The poly(amic acid) precursor was synthesized by the reaction of epiclon with 1,4-(p-aminophenoxy)benzene in N-methylpyrrolidinone (NMP) as solvent, under inert atmosphere. Concentration of the reaction mixture was adjusted to 20% total solids. The first step of this reaction, performed at 15–20 °C, led to the corresponding poly(amic acid). In the second step, the polymer solution was heated at 180–190 °C to perform cyclodehydration of the poly(amic acid) (PAA) to the corresponding polyimide structure (PI) [18, 19]. The number average molecular weight is 76,000 g/mol for PAA and 48,200 g/mol for PI, resulting from gel permeation chromatography (GPC) measurements in N,N-dimethylformamide (DMF), performed on a PL EMD-950 evaporative light scattering detector apparatus [22]. The investigated structures are presented in Scheme 1.

Hydroxypropylcellulose (HPC) (LF, Klucel™) was purchased from Aqualon Company, Hopewell, Virginia, USA. According to product specifications, HPC LF has a molecular mass of approximatively 100,000 g/mol and “moles of substitution” of 3.4.

Solution and film preparation

A standard procedure for preparing the sample solutions was used. First, the polymer powder (PAA, PI and HPC) was weighed and put into a jar (also weighed). HPC was then mixed with an appropriate amount of N,N-dimethylacetamide (DMAc), to obtain a 60 wt.-% concentration, where HPC is in liquid crystalline state. The jar was tightly sealed, covered with paper to stop the sample from being altered by light, and gently rolled for approximatively 4 weeks. After reaching the lyotropic phase, HPC was combined with PI (or PAA) 49 wt.-% solutions in DMAc, at different mixing ratios: 30/70 wt./wt, 50/50 wt./wt and 70/30 wt./wt. The resulting system was deposited onto a glass substrate. Films were cast and sheared simultaneously at room temperature, on a Teflon plate, by moving a Gardner casting knife at a controlled speed of 5 mm/s.

Rheology

The flow properties of the concentrated mixed solutions were determined on a Bohlin CS50 rheometer, manufactured by Malvern Instruments. The measuring system presents a cone-plate geometry with a cone angle of 4° and a diameter of 40 mm. Shear viscosities were registered over the 0.07–4582.40 s−1 shear rate domain for surprising all possible flow regimes, at several temperatures (25–40 °C). During the oscillatory shear tests, the frequency was varied between 0.1–150 Hz, and a shear stress of 30 Pa was applied.

Atomic force microscopy (AFM) measurements

Blends morphology was examined on a SPM SOLVER Pro-M instrument. A NSG10/Au Silicon tip with a 35 nm radius of curvature and 255 kHz oscillation mean frequency was used. The atomic force microscope was operated in semi-contact mode, over a 40 × 40 μm2 scan area, 256 × 256 scan point size images being thus obtained.

Results and discussion

Shear viscosity

The microstructure and polymer-solvent interactions of the lyotropic mesophases were derived from rheological studies. The shear experiments performed on lyotropic HPC solutions in DMAc reveal that the viscosity-shear rate dependence exhibit only Regions II and III (Fig. 1). The Newtonian plateau is smaller and it is shifted to lower shear rates as concentration increases. Viscosity versus concentration, from the small plot of Fig. 1, shows a maximum at/or near the critical concentration, in the 20–60 wt.-% concentration range, which designates the anisotropic phase formation. With increasing concentration the isotropic solutions show a monotonic increase in shear viscosity. Viscosity increases to a maximum when the isotropic to anisotropic transition is approached. The ordering of macromolecules in the HPC/DMAc system is associated with a viscosity lower than that of the isotropic solutions. In this context, one should mention that, below a certain critical shear rate, the isotropic solutions are Newtonian. The viscosity peak, observed for all lyotropic polymer solutions, is a decreasing function of shear rate, ascribed to several mechanisms. For example, Hermans [23] suggested a possible competition between the ordering induced by shear and that produced thermodynamically. However, Zugenmaier [24] found out that the correlation between the viscosity maximum and the anisotropic phase appearance is valid only when the shear rate is low (close to zero). Starting from this affirmation, at a constant shear rate of 0.76 s−1, the critical concentration of 45.71 wt.-% appears to be the concentration at which a distinct change in the rheological properties occurs. Therefore, the viscosity at high shear rates takes lower values than the viscosity of lower concentration solutions at equivalent shear rates. Based on the viscosity versus concentration relation for concentrations above 45.71 wt.-%, the solution is in a fully liquid-crystalline mesophase. Below this concentration, the solution is biphasic. Similar results were obtained by Ernst and Navard [25] for HPC aqueous solutions. Upon formation of the anisotropic phase, viscosity begins to decrease.

Logarithmic plot of viscosity as a function of shear rate for HPC in DMAc at different concentrations and temperatures. Logarithmic viscosity data points for 60 wt.-% are shifted upwards to 10 for better visualization. The small plot represents the dependence of shear viscosity on concentration at different shear rates

On the other hand, the PAA and PI solutions exhibit a constant viscosity region over the entire shear rates range, revealing a Newtonian behaviour (Figs. 2a and 3a). The working polymer concentrations were situated in the 21–49 wt.-% concentrated domain. The dependence of viscosity on concentration at a shear rate of 0.072 s−1 can be described by a power law η∝c x, with x in the 6.72–6.99 range for PAA, and 8.33–8.79 for PI, at different temperatures (Fig. 4). This dependence coincides with the theoretical prediction for concentrated polymer solutions in which entanglements between the macromolecules exist [26]. The interactions between the chain segments, which reflect the existence of polymer entanglements and hydrogen bonding, can be described by the activation energy, E a, evaluated with Eq. 1:

where η 0 is the zero-shear-rate viscosity, R is the universal gas constant and T is the absolute temperature.

The flow behaviour of the PAA/HPC and PI/HPC blends obtained from the highest concentration of the individual polymers taken into study, i.e. 49.29 wt.-%, 49.69 wt.-% and 60.01 wt.-% for PAA, PI and HPC, respectively, is presented in Figs. 2b and 3b. Introduction of a higher amount of HPC reduces the Newtonian regime. At these concentrations, the Newtonian behaviour is characteristic rather to PAA and PI than to HPC. Similarly with the case of individual components, the increasing of temperature leads to a decrease of shear viscosity and to a slight increase of the Newtonian domain.

Figure 5a shows the plot of lnη versus reciprocal temperature for HPC, PAA and PI samples. One can see that the solutions follow the Arrhenius expression (Eq. 1) and that the resulting flow activation energy is influenced by the chemical structures. At a close domain of the investigated concentrations, the slopes for all PAA solutions are slightly increasing with concentration, giving a mean activation energy of 44.75 ± 3 kJ/ mol, while the corresponding PI structure, which is a little more rigid, presents easily higher mean values: 46.86 ± 3 kJ/mol. The recurring anhydroglucose units reduce the flexibility of the HPC chain, resulting in highest mean activation energy values: 57.81 ± 3 kJ/mol, comparatively with the other two pure components. A smaller value of E a implies a lower energy barrier for the movement of an element in the fluid. In the case of the polymeric solutions here under analysis, this barrier can be related to the interaction between the chain segments and can be determined by polymer entanglements or by specific interactions, such as hydrogen bonding. Analysis of polymer entanglements may provide an interesting perspective. PAA may interact with DMAc through hydrogen bonding, due to the amidic groups. Also, it possesses higher chain flexibility comparatively to its corresponding PI. The results of these phenomena are reflected in the different values of E a. The corresponding PI in DMAc cannot form hydrogen bonds, yet it exhibits a higher rigidity, because of the imide rings.

Figure 5b shows the dependence of lnη on the reciprocal temperature, for PAA/HPC and PI/HPC blends. In this case, additional interactions may appear between the counterparts. The amidic and hydroxylic groups from the PAA/HPC system can also lead to the formation of hydrogen bonding. Therefore, at a mixing ratio of 30/70 wt./wt., where the liquid crystalline counterpart prevails, the activation energy slightly increases from 54.79 kJ/mol for PI/HPC, to 56.12 kJ/mol for PAA/HPC. As the HPC amount gets reduced at 70/30 wt./wt., the E a values decrease up to an equal value of 50.60 ± 0.4 kJ/mol for both blends. This value reflects the influence of the hydrogen bonding in PAA/HPC system, which increases rigidity.

Lyotropic HPC solutions and the corresponding blends with PAA or PI exhibit a typical pseudoplastic behavior and show a decrease in viscosity with increasing the shear rate. The dependence of shear stress, σ, on shear rate partly obeys the power law relationship described by Eq. 2

where n and K are the flow behavior and consistency indices, respectively.

For all samples, the shape of curves representing log shear stress versus log shear rate plots is different, as observed from Figs. 6a and 7, where two flow regimes were observed, comparatively with Fig. 6b and c, where only Newtonian behaviour exists. From this reason, the flow behavior and consistency indices were determined from the linear regression corresponding to Newtonian flow (Figs. 6a and 7—over a limited shear rate domain (0.07–100 s−1), or from the linear regression in Fig. 6b and c). The results listed in Table 1 show that the flow consistency index increases when increasing concentration and decreases when increasing temperature. Also, any increase in concentration is accompanied by an increase in pseudoplasticity, shown by a decrease in the values of the flow behavior index. The flow behavior index for PAA and PI solutions is approx. equal to the unity, as expected for a Newtonian fluid. The corresponding blends with HPC reveal a flow behavior index easily higher, comparatively with the pure liquid crystalline component, and a lower solution consistency.

Viscoelastic properties

The storage and loss moduli are plotted in Fig. 8 as a function of frequency, f, for the pure component solutions and the corresponding blends, at 25 °C. Over the low frequency regime, the loss modulus, G′′, is always higher than the storage modulus, G′, no plateau appearing in G′ versus f curves, which is a characteristic behavior for a viscoelastic fluid [27]. Generally, in this range, the storage modulus scales with frequency as \( G\prime \sim f{\text{ }}^2 \), while the viscous modulus is linear in frequency \( G\prime \prime \sim f \) [28]. This dependence is observed for both poly(amic acid) and polyimide solutions, where G′ and G′′ are proportional to f 2–2.4 and f 1–1.6, respectively. At higher values of f, the elastic modulus becomes higher than the viscous one, and the frequency corresponding to their overlapping increases with decreasing concentration. Similar results were also obtained for other epiclon-based poly(amic acid)s and polyimides [29]. For HPC solutions, the influence of concentration on the crossover frequency is more complex. Thus, increasing concentration from 20.01 wt.-% to 40.02 wt.-% leads to a decrease in crossover frequency. At higher concentration, of 60.01 wt.-%, when the liquid crystalline phase appears, the crossover frequency is higher comparatively with the case of the other two concentrations. Also, a similar dependence of the rheological moduli on frequency is observed, while the resulting slopes are smaller, i.e. \( G\prime \sim f^{{0.6 - 1.2}} \) and \( G\prime \prime \sim f^{{{\text{ }}0.6 - 0.9}} {\text{ }} \).

The different flexibility of PAA, PI and HPC is reflected in the G′, G′′, and G′ = G′′ values. Thus, the shear moduli values for PAA and PI are quite close, but lower than those of the HPC sample. The frequency corresponding to the crossover point, which delimits the viscous flow from the elastic flow, decreases with increasing the flexibility of the studied polymers, as shown in Table 2.

In the case of PAA/HPC or PI/HPC blends, the rheological moduli exhibit larger values by introducing a higher percent of HPC liquid crystal in the system. In the low frequency domain, the slopes are smaller comparatively to the pure components and decrease as the lyotropic phase becomes predominant. Also, the overlap frequency is influenced by the chemical structure of the components and by the blend composition. If the flexible counterpart (PAA or PI) is reduced, transition from the viscous to the elastic flow is delayed and the moduli crossover occurs at higher frequencies.

Investigation of the rheological properties of pure components and blends is essential for better understanding the morphology developed by PAA/HPC and PI/HPC blends. These combined studies contribute to the knowledge on the nature of the interactions in the system, and the relation between shear deformation and texture. AFM investigation of films prepared by shear casting of PAA/HPC and PI/HPC can reflect the influence of these interactions on the morphological properties.

Blends morphology

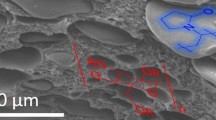

Literature shows that, under particular conditions, HPC liquid crystalline films subjected to shear exhibit a characteristic texture called “band texture” [30–32]; it consists of alternating bright and dark lines perpendicular to the shear direction, resulting from reorientation of the average molecular orientation (director), driven either by a prescribed mechanical deformation or by the relaxation of the elastic energy stored in the material during flow or deformation by shear [33]. After shear cessation, relaxation leads to the formation of the bands perpendicular to the flow direction, while the flow or deformation orthogonal to bulk orientation (or previous deformation direction) leads to bands parallel to the second deformation direction. Therefore, a primary set of “large” bands, perpendicular to the shear direction, and a smoother texture characterized by a secondary periodic structure containing “small” bands, can be distinguished for HPC. This particular behavior is useful for achieving ordered polymer films based on a liquid crystal template. By mixing HPC in lyotropic phase with PAA, which is anisotropic, the surface pattern is modified, yet the band texture is still discernible even at a high PAA content. Figure 9 shows the 2D topography image (40 × 40 μm 2) of the free surface of sheared PAA/HPC and PI/HPC films, prepared by mixing a 60 wt.-% HPC solution with a 49 wt.-% PAA or PI solution. Both sets of bands can be observed for the PAA/HPC system at a mixing ratio of 30/70 wt./wt. (Fig. 9a), where the resulting morphology is stabilized through the formation of hydrogen bonds between components or between them and the solvent. As the percent of the liquid crystalline counterpart decreases, the surface pattern is maintained, while its dimensions become higher and the “small” bands disappear (Fig. 9b). In PI/ HPC blends, hydrogen bonds appear only between HPC and DMAc, therefore the band texture is larger comparatively with PAA/HPC films, and also increases with decreasing the amount of HPC (Fig. 9c and d).

As a result of the symmetry properties of the HPC liquid crystal solution, large domains of well-oriented polymer chains are formed during shear flow, while the defects are squeezed into small regions. Shear accounts for an additional energy stored in the solution. There is a natural tendency for the semi-rigid segments of HPC to self-align into ordered domains, thus giving high performance properties to these materials [34]. It is well established that, for specific shear flow conditions, the cholesteric liquid crystalline cellulose derivatives exhibit unwinding of the cholesteric helix and a cholesteric-to-nematic transition [35]. When the shear is stopped, the system will first relax with a characteristic time to a transient state. In this state, the distortion energy is minimized, and the orientational order is maintained, resulting in a banded structure. The shear-induced anisotropy is affected by the inevitable relaxation of the chains, when the external field is removed. By introducing poly(amic acid) or polyimide into the HPC solution, relaxation will take place collectively, due to the fact that the highly concentrated and aligned polymers cannot individually relax and, therefore, the inner stress induces a periodical contraction in the whole liquid crystalline polymer and different packing modes are observed. Structural relaxation after cessation of shear depends on the shear history of the mixture and on the dominant mechanism of stress relaxation. The band morphology of the blend is influenced by precursor and polyimide solution composition, solvent evaporation rate, film thickness, rate and duration of shear [36, 37].

The effect of the chemical structure and composition on the viscoelastic properties is reflected on the orientation or mobility of segments in the shear field. The inherent long-range ordering tendencies of the LC itself—and specifically its pattern-forming properties open new perspectives to produce ordered polymer microstructures. The morphology of the ordered domains provides a means of “imaging”, respectively potentially novel aspects of the pattern-forming LC states. Pure and applied research related to the shear-induced morphology and structural relaxation after cessation of shear in polymer/LCP blends will become more and more important for developing high performance alignment layers used in display devices.

Conclusions

New data on the rheological properties of epiclon-based polyimide solutions, on their corresponding poly(amic acid), and hydroxypropylcellulose liquid crystalline solutions, as well as on PAA/HPC and PI/HPC blends are reported. Newtonian flow of the PAA and PI samples was observed over the entire studied shear rate range, while that of the HPC decreases with increasing concentration. Polymer concentration dependencies on shear viscosity at constant shear rate for PAA and PI samples can be described by a power law η∝c x, with x coefficients in the range corresponding to the theoretical prediction for concentrated polymer solutions. For the HPC sample, viscosity versus concentration shows a maximum at/or near the critical concentration, which designates the anisotropic phase formation. In the case of PAA/HPC and PI/HPC blends obtained at the highest studied concentrations, introduction of a higher amount of HPC reduces the Newtonian regime.

The activation energy determined from the dependence of viscosity on temperature shows that PAA, known as possessing a higher flexibility comparatively with PI and HPC, takes lower values, while the more rigid structures, resulting both from PI imidization and from the HPC recurring anhydroglucose units, increase the activation energy. On the other hand, the presence of hydrogen bonding, which enhances rigiditiy in the case of PAA/HPC systems, increases the activation energy, values closer to those for PI/HPC blends thus resulting.

For all studied samples, the flow consistency index increases when increasing concentration and decreases when increasing temperature. Also, a decrease in the values of the flow behavior index indicates an enhanced pseudoplasticity with increasing concentration. The corresponding blends with HPC reveal a slight decrease of pseudoplasticity, comparatively with the pure liquid crystalline component, and a lower solution consistency.

The storage and loss moduli for pure components (PAA, PI or HPC) exhibit the power law dependence on frequency, where the exponents are characteristic to viscoelastic fluids. Over the studied frequency range, these properties are strongly related to the chemical structure, reflecting the influence of flexibility and concentration. The frequency corresponding to shear moduli overlapping appears over the studied domain of frequency and increases with decreasing concentration. However, for HPC this conclusion is valid for concentrations smaller than 60 wt.-%, while at this concentration, when the liquid crystalline phase exists, the crossover frequency is higher. Introducing a higher percent of HPC liquid crystal in the PAA/HPC or PI/HPC blend determines higher values of the rheological moduli and an increase in the frequency of transition from the viscous to the elastic flow.

AFM investigations reveal the importance of the specific interactions on the type of hydrogen bonding in the occurrence of the band texture, one perpendicular to the shear direction, another parallel to the second deformation direction. Decrease of the HPC content reduces the hydrogen bonding in the blending system and thus increases the dimension of the bands.

Knowledge on the rheological properties in correlation with morphological aspects lies at the basis for future investigation concerning high performance mixed alignment layers used in display devices.

References

El-Zaher NA, Osiris WG (2005) J Appl Polym Sci 96:1914–1923

Ulcnik-Krump M (2006) J Appl Polym Sci 100:2303–2316

Dutta D, Fruitwala H, Kolhi A, Weiss RA (1990) Polym Eng Sci 30:1005–1018

Kinder L, Kanickia J, Petroffa P (2004) Synth Met 146:181–185

Chae B, Lee SW, Lee B, Choi W, Kim SB, Jung YM, Jung JC, Lee KH, Ree M (2003) Langmuir 19:9459–9465

Dai Q, Khan SA, Kadla JF (2006) Cellulose 13:213–223

Roschinski C, Kulicke WM (2000) Macromol Chem Phys 201:2031–2040

Israelachvili JN (1985) Intermolecular and surface forces with applications to colloidal and biological systems. Academic, London

Godinho MH, Fonseca JG, Ribeiro AC, Melo LV, Brogueira P (2002) Macromolecules 35:5932–5936

Wang J, Labes MM (1992) Macromolecules 25:5790–5793

Onogi S, Asada T (1980) In: Astarita G, Marucci G, Nicolais L (eds) Rheology. Plenum, New York

Navard P, Haudin JM (1986) J Polym Sci 4:189–227

Andrienko D, Kurioz Y, Nishikawa M, Reznikov Y, West JL (2000) Jpn Appl Phys 39:1217–1220

Goyal M, Inoue M, Kakimoto T, Imai M (1998) J Polym Sci Part A 26:39–47

Matsumoto T, Kawabata S, Takahashi R (2006) High Perform Polym 18:719–730

Hajipour AR, Zahmatkesh S, Ruoho AE (2007) e-Polymers 88:1–13

Siddiq M, Wu C (2001) J Appl Polym Sci 81:1670–1674

Hamciuc E, Lungu R, Hulubei C, Bruma M (2006) J Macromol Sci Part A 43:247–258

Hulubei C, Hamciuc E, Bruma M (2007) Rev Roum Chim 52:1057–1062

Kim IC, Tak TM (1999) J Appl Polym Sci 74:272–277

Mallakpour S, Hajipour AR, Zamanlou MR (2003) J Polym Sci Part A 41:1077–1090

Macocinschi D, Taranu A, Hulubei C, Ioan S (2006) Rev Roum Chim 51:1001–1009

Hermans J (1962) J Colloid Sci 17:48–638

Zugenmaier P (1994) In: Gilbert RD (ed) Cellulosic polymers, blends and composites. Hanser, Munich

Ernst B, Navard P (1989) Macromolecules 22:1419–1422

Grigorescu G, Kulicke WM (2000) Adv Polym Sci 152:1–40

Ferry JD (1980) Viscoelastic properties of polymers. Wiley-Interscience, New York

Liu X, Qian L, Shu T, Tong Z (2003) Polymer 44:407–412

Cosutchi AI, Hulubei C, Ioan S (2007) J Macromol Sci Part B 46:1003–1012

Peuvrel E, Navard P (1991) Macromolecules 24:5683–5686

Walker LM, Kernick WA, Wagner NJ (1997) Macromolecules 30:508–514

Patnaik SS, Bunning TJ, Adams WW (1995) Macromolecules 28:393–395

Fried F, Sixou P (1988) Mol Cryst Liq Cryst 158B:163–184

Yasushi K, Takashi K, Atsushi K, Shigeru T, Ryuichi A (2008) Jpn J Appl Phys 47:7941–7942

Andresen EM, Mitchell GR (1998) Europhys Lett 43:296–301

Yan L, Zhu Q, Ikeda T (2003) Polym Int 52:265–268

Riti JB, Cidade MT, Godinho MH, Martins AF, Navard P (1997) J Rheol 41:1247–1260

Acknowledgements

The authors are indebted to the Romanian National Council for Scientific Research in Higher Education (Project TD-547/2007), for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cosutchi, A.I., Hulubei, C., Stoica, I. et al. Morphological and structural-rheological relationship in epiclon-based polyimide/hydroxypropylcellulose blend systems. J Polym Res 17, 541–550 (2010). https://doi.org/10.1007/s10965-009-9342-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-009-9342-3