Abstract

In this paper, electrical and dielectric properties of multiwall carbon nanotubes (MWCNTs)/insulating polyaniline (PANI) composites were studied. A mixture of MWCNTs and insulating polyaniline was dispersed in an ethanol solution by ultrasonic process, subsequently dried, and was hot-pressed at 200 °C under 30 MPa. Electrical and dielectric properties of the composites were measured. The experimental results show that the dc conductivities of the composites exhibit a typical percolation behavior with a low percolation threshold of 5.85 wt.% MWCNTs content. The dielectric constant of the composites increases remarkably with the increasing MWCNTs concentration, when the MWCNTs concentration was close to percolation threshold. This may be attributed to the critical behavior of the dielectric constant near the percolation threshold as well as to the polarization effects between the clusters inside the composites.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The unique physical properties of carbon nanotubes (CNTs), which combine high strength and low weight, high electrical and thermal conductivity, have been of great interest for developing new classes of multifunctional composites that incorporate CNTs into polymers [1–5]. Kymakis et al. [2] reported the optoelectronic properties occurring in single-walled carbon nanotubes/poly(3-octylthiophene) composites, and found that the composite represents an alternative class of organic semiconducting material that is promising for organic photovoltaic cells with improved performance. Alexandrou [3] prepared the single-walled carbon nanotubes/poly(3-octylthiophene) composites and showed excellent field emission properties. Hughes [4] found that aligned multi-walled carbon nanotubes/polypyrrole (PPy) composite films offer an exciting combination of exceptional charge storage capacities (several times larger than that of either carbon nanotubes or PPy) and have potential applications in supercapacitors and secondary batteries. In particular, carbon nanotubes possess high flexibility, small diameter and large aspect ratio (100–1,000), make carbon nanotubes excellent candidates to substitute or complement the conventional nanofillers in the fabrication of multifunctional polymer nanocomposites. For example, as carbon nanotubes is dispersed in an insulating polymer matrix to make a composite, it is expected that the electrical properties of the composite can be greatly improved with a very low percolation threshold. Many experimental studies [6–10] have also verified the CNTs as conductive filler in polymer matrix resulting in very low percolation thresholds from 1 × 10−4 to 11 wt.% of CNTs concentration, which are much less than 16 vol.% of the theoretical value of percolation threshold derived from the percolation theory [11], and which suggest an advantage of small perturbations of bulk physical properties of polymer matrix, such as strength and lower cost. According to the percolation theory, the dielectric properties of the composites can be enhanced as the conductive CNTs concentration is close to the percolation threshold, which suggest the potential applications for the composites.

It has been known that polyaniline (PANI) can be applied for many practical fields such as chemical sensor, supercapacitor, corrosion protection, battery and energy storage, and antistatic coating. Therefore, the preparation and properties of CNTs/polyaniline composites have also been investigated [12–15], however, the polyaniline in the composites are almost the conducting polyaniline, and the preparation and properties of CNTs/insulating polyaniline composite has few reported. In this work, we prepared MWCNTs/insulating polyaniline (PANI) composites and investigated systematically the behaviors of the dc electrical conductivity and dielectric properties at room-temperature, to explore some potential applications.

Experimental

The composites were prepared by solution blending and subsequently hot-pressing process. MWCNTs used in this study was prepared from chemical vapor deposition grown and treated by dilute nitric acid and fluorhydric acid by removing nickel and silica, respectively. It typically consists of eight to fifteen graphite layers wrapped around a hollow 20 nm core, and with typical average diameters 30 nm while lengths are between 0.05 and 1.0 μm. Insulating polyaniline used in this study was obtained from the Zheng Ji Company(Ji Lin, China). The starting materials of MWCNTs and PANI were mixed in different weight fraction of MWCNTs by ball milling, further ultrasonic dispersing and drying simultaneously in ethanol solution. Subsequently, the mixtures were molded by hot pressing at about 200 °C under 30 MPa. Disk-shaped samples (20 mm in diameter, 1 mm in thickness) were prepared for electrical testing. The ac conductivity and dielectric measurements were conducted using an impedance analyzer (Model HP4194A, Hewlett-Packard Corp. Palo Alto, CA) in the frequencies range from 100 Hz to 40 MHz at a bias voltage of 1.0 V. The dc conductivity was measured using the four-point probe method. The microstructure of the composites was observed by scanning electron microscopy (SEM, Jeol-6301F, Japan).

Results and discussion

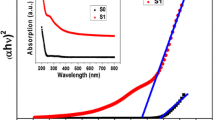

Figure 1 shows scanning electron microscopy (SEM) micrographs of fracture surface of the composites with 0.0, 3.0, and 5.0 wt.% MWCNTs content. The SEM micrographs show that the excellent dispersing of the MWCNTs in the PANI matrix. Figure 2a is the plot of dc conductivity measured at the room temperature of the composites versus mass fraction of MWCNTs. It can be observed that dc conductivity of the composites follows a typical percolative behavior, when the MWCNTs concentration is below 4 wt.%, it is only slightly elevated from the insulating PANI matrix, and with the increasing MWCNTs concentration is between 4 and 6 wt.%, it displays a dramatic increase. This behavior can be described by the following percolation theory [16–18]:

where σ m, σ c are the effective dc conductivity of the composites and conducting component, respectively, f is the weight fraction of the conducting component, f c is the critical weight fraction of the conducting component or percolation threshold. The t is the critical exponent. By using a least-squares fit, the percolation threshold f c and exponent t are determined to be f c = 0.0585 ± 0.0003, t = 2.20 ± 0.12. It should be noted that the value of critical exponent t is much close to the universal 3D lattice value (t ∼ 2) [19]. Depending on the polymer matrix and the processing technology as well as the characteristics of carbon nanotubes, such as aspect ratio, dispersion, and alignment, percolation thresholds between 1 × 10−4 and 11 wt.% have been observed experimentally for carbon nanotube/polymer composites. Kymakis et al. [6] reported a percolation threshold of 11 wt.% of multiwall carbon nanotube for carbon nanotube/poly(3-octylthiophene) composites. Sandler et al. [7] prepared aligned multiwall carbon nanotube/epoxy composites, and found that the composites exhibit a very low percolation threshold with 0.0025 wt.% of multiwall carbon nanotube, Seo et al. [20] found that the percolation threshold of multiwalled carbon nanotubes/polypropylene (PP) was between 1.0 and 1.5 wt.% of multiwall carbon nanotube. Long et al. [21] synthesized multiwalled carbon nanotube/polyaniline composite by an in situ chemical oxidative polymerization directed with cationic surfactant cetyltrimethylammonium bromide. They found that the conductivity of the composites increases by two orders of magnitude with increasing carbon nanotube loading from 0 to 24.8 wt.%. Comparatively, though our results shows the lower percolation threshold than that of Long’s result [21], however, it is higher than Sandler’s and Seo’s result [20], this may be attributed to the processing method of solution blending, in which multiwall carbon nanotubes tended to agglomerate during slow solvent evaporation, leading to inhomogeneous distribution of the nanotubes in the polymer matrix. Figure 2b is the plot of dielectric behavior of the composites measured at the room temperature versus mass fraction of MWCNTs. It can be seen that dielectric constant of the composites is enhanced when the MWCNTs concentration is close to the percolation threshold, according to the percolation theory, the following power law is given [16]:

where ɛ m, ɛ 0 are the dielectric constant of the composites and the matrix, respectively. The s is the critical exponent. The data for the composites with f c = 0.0585 ± 0.0003 (Fig. 1a) yield s = 0.81 ± 0.02. It is noted that the value of s is lower than the universal 3D lattice value (s ∼ 1), which can be attributed to effect of the large aspect ratio of MWCNTs fillers. In addition, it is seen that the dielectric constant of the composites remains increase above the percolation threshold but does not decrease as expected from Eq. 2. Such behavior has been reported earlier for polymer composites [22–25], and which was attributed to “micro capacitors” remaining in the sample above the percolation threshold. The “micro capacitors” are assumed to be formed by gaps between multiwall carbon nanotubes. Another possibility for formation of capacitances is parallel strength and free ends of the percolation structure.

According to the percolation theory, the frequency dependence of the dielectric constant and effective conductivity of the random mixture results from two important effects: (a) polarization effects between clusters inside the mixture and (b) anomalous diffusion within each cluster, and as considering only the polarization effects between clusters, many researchers have derived the following relation [26–29]:

where t, s are the critical exponent in the Eqs. 1 and 2, respectively. The x and y is the critical exponent, and Bergman derived the power law for the effective conductivity σ(2πν, f c) and dielectric constant ɛ(2πν, f c):

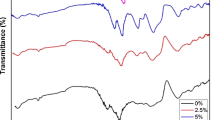

where f c and ν is the percolation threshold and frequency, respectively. Figure 3 shows the frequency dependence of the dielectric constant and ac conductivity of the composites. From Fig. 3a, it can be seen that the composites exhibited a typical dielectric behavior below the percolation threshold, i.e., ac conductivity increased linearly with the frequency. This may be explained by the polarization effects between the clusters, as the MWCNTs concentration is below the percolation threshold, due to a lack of percolating clusters, the polarization between the clusters and the motion of electrons in the finite cluster will determine ac conductivity of the composites, hence, the ac conductivity of the composites increases with the increasing of frequency. In addition, we can experimentally obtain the critical exponent x = 0.76 ± 0.03 from the ac conductivity of the composite with the MWCNTs concentration is just above the percolation threshold and 6 wt.%, which is much close to the universal 3D value (∼0.72) [30]. From the above determined critical exponent t and s, we can theoretically calculate critical exponent x = 0.74 ± 0.02 from the Eq. 4, which is much close to the experimentally obtain the critical exponent x, and which suggest that polarization effects between clusters inside the mixture play dominant part for the frequency dependence of the dielectric constant and effective ac conductivity of the composites. Subsequently, as the MWCNTs concentration is much above the percolation threshold, the ac conductivity of the composite is mainly determined by the many paths of the percolating clusters rather than the small effect of the capacitors, therefore, a finite conductivity led to a plateau at low frequency corresponding to the electrical response of the percolating network.

From Figure 3c, it is seen that the dielectric constant of composites are nearly frequency independent as the MWCNTs concentration is less than 4.0 wt.%, which follow the tendency of insulating PANI matrix, which is approximately frequency independent at room temperature. As the MWCNTs concentration is higher than 4.0 wt.%, the dielectric constant decrease with the increasing of frequency, which can be attributed to the MWCNTs become larger clusters, the dielectric relaxation become evident as the frequency of the electric field increases, results in the decrease of the dielectric constant. However, the dielectric constant of the composites is greatly enhanced by addition of MWCNTs toward low frequency, and a maximum value of the dielectric constant is achieved 650 at the frequency of 100 Hz, as the MWCNTs concentration is 8 wt.%, which suggests that it should be promising way for addition of MWCNTs to enhance the dielectric constant of materials.

Conclusions

MWCNTs/insulating PANI composites were prepared by solution blending and subsequently hot-pressing process. The electrical and dielectric behaviors of the composites were investigated. A low percolation threshold of 5.85 wt.% MWCNTs concentration in the system was determined by percolation theory. The dielectric constant of the composites can be greatly enhanced when the MWCNTs concentration is close to the percolation threshold, which may be attributed to the critical behavior of the dielectric constant near the percolation threshold as well as the polarization effects between clusters inside the composites. The electrical and dielectric behaviors of the MWCNTs/insulating PANI composites suggest that it should be attractive for some electrical applications.

References

Moniruzzaman M, Winey KI (2006) Macromolecules 39:5194 doi:10.1021/ma060733p

Kymakis E, Amaratunga GAJ (2002) Appl Phys Lett 80:112 doi:10.1063/1.1428416

Alexandrou I, Kymakis E, Amaratunga GAJ (2002) Appl Phys Lett 80:1435 doi:10.1063/1.1449537

Hughes M, Shaffer MSP, Renouf AC, Singh C, Chen GZ, Fray DJ, Windle AH (2002) Adv Mater 14:382 doi:10.1002/1521-4095(20020304)14:5<382::AID-ADMA382>3.0.CO;2-Y

Ago H, Pertritsch K, Shaffer MSP, Windle AH, Friend RH (1999) Adv Mater 11:1281 doi:10.1002/(SICI)1521-4095(199910)11:15<1281::AID-ADMA1281>3.0.CO;2-6

Kymakis E, Alexandou I, Amaratunga GAJ (2002) Synth Met 127:59 doi:10.1016/S0379-6779(01)00592-6

Sandler JKW, Kirk JE, Kinloch IA, Shaffer MSP, Windle AH (2003) Polymer (Guildf) 44:5893 doi:10.1016/S0032-3861(03)00539-1

Seoul C, Kim YT, Baek CK (2003) J Polym Sci Part B Polym Phys 41:1572 doi:10.1002/polb.10511

Ramasubramaniam R, Chen J, Liu HY (2003) Appl Phys Lett 83:2928 doi:10.1063/1.1616976

Bryning MB, Islam MF, Kikkawa JM, Yodh AG (2005) Adv Mater 17:1186 doi:10.1002/adma.200401649

Scher H, Zallen R (1970) J Chem Phys 53:3759 doi:10.1063/1.1674565

Zengin H, Zhou WS, Jin JY, Czerw R, Smith DW, Echegoyen JL, Carroll DL, Foulger SH, Ballato J (2002) Adv Mater 14:1480 doi:10.1002/1521-4095(20021016)14:20<1480::AID-ADMA1480>3.0.CO;2-O

Sainz R, Benito AM, Tmartínez M, Galindo JF, Sotres J, Baró AM, Corraze B, Chauvet O, Dalton AB, Baughman RH, Maser WK (2005) Nanotechnology 16:S150 doi:10.1088/0957-4484/16/5/003

Mottaghitalab V, Spinks GM, Wallace GG (2005) Synth Met 152:77 doi:10.1016/j.synthmet.2005.07.154

Wu TM, Lin YW (2006) Polymer (Guildf) 47:3576 doi:10.1016/j.polymer.2006.03.060

Nan CW (1993) Prog Mater Sci 37:1 doi:10.1016/0079-6425(93)90004-5

Bergman DJ (1980) Phys Rev Lett 44:1285 doi:10.1103/PhysRevLett.44.1285

Meir Y (1999) Phys Rev Lett 83:3506 doi:10.1103/PhysRevLett.83.3506

Clerc JP, Giraud G, Laugier JM, Luck JM (1990) Adv Phys 39:191 doi:10.1080/00018739000101501

Seo MK, Park SJ (2004) Chem Phys Lett 395:44 doi:10.1016/j.cplett.2004.07.047

Long YZ, Chen ZJ, Zhang XT, Zhang J, Liu ZF (2004) Appl Phys Lett 85:1796 doi:10.1063/1.1786370

Tchmutin IA, Ponomarenko AT, Shevchenko VG, Ryvkina NG, Klason C, McQueen DH (1998) J Polym Sci Part B Polym Phys 36:1847 doi:10.1002/(SICI)1099-0488(199808)36:11<1847::AID-POLB6>3.0.CO;2-N

Flandin L, Prasse T, Schueler R, Schulte K, Bauhofer W, Cavaille JY (1999) Phys Rev B 59:14349 doi:10.1103/PhysRevB.59.14349

McLachlan DS, Heaney MB (1999) Phys Rev B 60:12746 doi:10.1103/PhysRevB.60.12746

Pötschke P, Dudkin SM, Alig I (2003) Polymer (Guildf) 44:5023 doi:10.1016/S0032-3861(03)00451-8

Bergman DJ, Imry Y (1977) Phys Rev Lett 39:1222 doi:10.1103/PhysRevLett.39.1222

Efros AL, Shklovskii BI (1976) Phys Status Solidi B 76:475 doi:10.1002/pssb.2220760205

Stroud D, Bergman DJ (1982) Phys Rev B 25:2061 doi:10.1103/PhysRevB.25.2061

Wilkinson D, Langer JS, Sen PN (1983) Phys Rev B 28:1081 doi:10.1103/PhysRevB.28.1081

Song Y, Noh TW, Lee S-I, Gaines JR (1986) Phys Rev B 33:904 doi:10.1103/PhysRevB.33.904

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant no. 50572122).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, SL., Zhang, LZ. & Li, JS. Electrical and dielectric properties of multiwall carbon nanotube/polyaniline composites. J Polym Res 16, 395–399 (2009). https://doi.org/10.1007/s10965-008-9241-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-008-9241-z