Abstract

In the present work crosslinked methyl methacrylate-co-itaconic acid (MMA-co-IA) hydrogels were prepared by free radical copolymerization of methyl methacrylate (MMA) with itaconic acid (IA) using ethylene glycol dimethacrylate (EGDMA) and N, N methylene bisacrylamide (MBAAm) as crosslinkers and benzoyl peroxide as initiator. Prepared hydrogels were investigated for dynamic and equilibrium swelling studies. For swelling behaviour, effect of pH, monomeric compositions, degree of crosslinking and type of crosslinking agent were investigated. Swelling studies were performed in the USP phosphate buffer solutions of varying pH 1.2, 4.5, 5.5, 6.5 and 7.0. Results showed that swelling increased by increasing IA content in hydrogels structure. This may be due to the presence of more carboxylic groups available for ionization. Swelling was decreased with increase in crosslinking ratio owing to tighter hydrogel structure. Hydrogels were characterized by Fourier transform infrared (FTIR), and scanning electron microscope (SEM). Polymer-solvent interaction parameters (χ) of hydrogels were determined by using Flory–Rehner theory of equilibrium swelling values. The analysis of diffusion mechanism from gels using Peppas model showed that all monomeric compositions and degrees of crosslinking followed Fickian diffusion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogels are three dimentional polymeric networks which swell in the presence of water and aqueous solutions. In swollen state they are soft and rubbery and resemble with living tissues [1]. These gels respond to various external environmental conditions like temperature, pH and ionic strength. Among them pH sensitive hydrogels are extensively studied. These gels can be prepared by using one or more acidic monomers such as acrylic acid or methacrylic acid [2]. In recent years series of papers have been published on the copolymerization of itaconic acid (IA) with other monomers [3–5]. Authors showed that these hydrogels could be used as pH-sensitive drug carriers. Acidic gels can be used for colon specific drug delivery. Since these hydrogels have low equilibrium degree of swelling in acidic medium of stomach and their swelling increases as it passes down the GI tract due to increase in physiological pH. Therefore, these pH sensitive hydrogels protect the drug from the acidity of the stomach and gels releases its incorporated/loaded drug in the lower part of the gastrointestinal tract [6]. Various areas of hydrogel applications include [7]; (1) sustained release drug delivery systems, (2) topical applications i.e., wound dressings, (3) transdermal delivery systems, (4) dental applications, (5) injectable polymers, (6) implants (7) stimuli-responsive systems. One of the basic parameter determining applicability is the swelling and deswelling behaviour of the gels. The swelling behaviour of crosslinked hydrogels is influenced by numbers of factors, including monomeric composition, degree of crosslinking, molecular size of the monomers or crosslinking agent, nature of crosslinking agent, pH and ionic strength of the surrounding media. These parameters are extensively studied in order to modify swelling behaviors of various hydrogels. Ranjha and Doelker [8–10] showed that swelling characteristics of crosslinked hydrogels can be modified to desired extent by varying the monomeric compositions and degree of crosslinking.

In the present work novel pH-sensitive methyl methacrylate-co-itaconic acid (MMA-co-IA) hydrogels were developed. A series of samples with varying monomeric composition and degree of crosslinking were synthesized to investigate their influence on dynamic and equilibrium swelling. Two different types of crosslinking agents namely ethylene glycol dimethacrylate (EGDMA) and N, N methylene bisacrylamide (MBAAm) were used to study the influence of nature of crosslinking agent on the swelling behaviour. Hydrogel samples were characterized by FTIR and SEM to investigate their structure and surface morphology respectively and Flory–Rehner theory was used to determine polymer-solvent interaction parameters (χ). Swelling data were analysed using Peppas model for penetrant diffusion [11].

Materials and methods

Materials

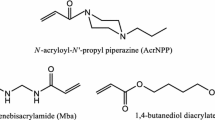

The comonomers used were methyl methacrylate (MMA) and itaconic acid (IA) (Fluka, Buchs, Switzerland). Ethylene glycol dimethacrylate and N, N methylene bisacrylamide (EGDMA and MBAAm, Merck, Darmstadt, Germany) were used as crosslinking agents.

Synthesis of crosslinked hydrogel

In the present work a series of crosslinked copolymers of MMA/IA with different monomeric composition and degree of crosslinking were synthesized after modification of the procedure reported earlier [12]. Procedure used for the synthesis of hydrogels is briefly described as, IA was dissolved in ethanol, benzoyl peroxide was dissolved in MMA at a concentration of 0.5 wt.% of the total monomers. After mixing the monomers and crosslinking agent, the solution polymerization was carried out after dilution using ethanol. The ratio of ethanol and monomers was 1:1 by volume. The theoretical crosslinking ratio of EGDMA or MBAAm was calculated as:

After adding required quantity of crosslinking agent, these solutions were poured into polyethylene tubes having 16 mm internal diameter and 150 mm length. The air above the solution in the tubes or/any dissolved oxygen was removed with nitrogen and it was bubbled through the reaction mixture for 15–20 min, which acted as free radical scavenger. The capped tubes were placed in the water bath and the temperature was gradually increased to avoid bubble formation. The temperature programme was 45°C for 1 h, 50°C for 2 h, 55°C for 3 h, 60°C for 4 h, 65°C for 24 h. After cooling to room temperature, cylinders were removed from the tubes and were cut into 8 mm thick discs with a razor blade. The cylinders of MMA/IA were washed in 50% v/v ethanol water for 1–2 weeks, for complete removal of the unreacted monomers, during this period the solvent was changed daily. These gels discs were thoroughly washed until the pH of the washing was same as that of ethanol water mixture before washing. Then disks were dried, at first at room temperature and then in oven at 40–45°C for 1 week. One sample of noncrosslinked MMA/IA was prepared using same procedure as for crosslinked polymer but without the addition of the crosslinking agent. Presumtive structure of hydrogel using EGDMA is presented in Fig. 1. Table 1 shows the samples feed monomeric compositions, degree of crosslinking and crosslinking agents used for the preparation of hydrogels.

Scanning electron microscopy (SEM)

The morphology of the hydrogel sample was investigated using, scanning electron microscope S3400-N (Hitachi). The hydrogels were scanned using two magnifications i.e., 3,000 and 5,000.

FT-IR spectroscopic studies and chemical analysis

Non-crosslinked hydrogel sample was crushed with pestle in an agate mortar. The crushed material was mixed with potassium bromide (Merck IR spectroscopy grade) in 1:100 proportions and dried at 40°C. The mixture was compressed to a 12 mm semitransparent disk by applying a pressure of 65 kN (Pressure gauge, Shimadzu) for 2 min. The FTIR spectrum over the wavelength range 4,000–400 cm−1 were recorded using FTIR spectrometer (FT-IR 8400 S, Shimadzu).

Acid value (AV) and percentage of carboxyl groups

A dried sample weighing 0.5 g was taken. It was dissolved in 50 ml acetone, which was selected on the basis of solubility of the polymers. After adding 0.5 ml of a phenolphthalein indicator solution, the solution was titrated against 0.1 N KOH methanolic solution, until a slight pink colour appeared, acid value was calculated by the following formula:

where v is the volume of 0.1 N KOH solution used and w is the weight in grams of the polymer taken.

The percentage of carboxyl groups was calculated by the following expression:

where v is the volume in ml of the KOH solution used, N is the normality of the KOH solution, w is the weight in mg of the polymer taken, and 45.02 is the molecular weight of the carboxylic acid group.

Saponification value (SV)

A completely vacuum oven dried copolymer was dissolved in methanol. A known volume of 0.5 N KOH aqueous solution was added. When the polymer precipitated upon the addition of KOH solution, a small amount of water was added to dissolve the polymer. Then this solution was refluxed on a steam bath for two hrs using a suitable condenser. During this period, the content of the flask was frequently rotated. Excess KOH was titrated while the solution was still hot, using 1 ml of phenolphthlein solution as indicator. One blank sample (without the polymer) was run similarly. The saponification value was determined by the following expression:

where v is the difference, in ml, between titrations, and w is the weight in grams of the polymer taken.

Ester value (EV), percentage of acetyl groups

Ester value was determined by subtracting the acid value from the saponification value as:

Percentage of acetyl groups can be determined by calculating the volume of KOH reacted with acetic acid which was liberated by the hydrolysis of acetyl groups according to:

where v is the difference in volume of KOH used for saponification and for acid value, and w is the weight of the polymer taken in grams.

Swelling characterization

Dynamic swelling studies

The dynamic swelling experiments were carried out in 100 ml solution at 37°C. Two types of solutions were used for the swelling experiments 0.l M HCI as simulated gastric fluid (pH 1.2) and USP phosphate buffer solutions. Dry discs were weighed and immersed in a USP phosphate buffer solution of pH 1.2, 4.5, 5.5, 6.5, and 7.0. The concentration of the buffering agent was 0.05 M. The pH of these solutions was adjusted by adding HCl or NaOH solution. Samples were taken out at regular intervals of time and weighed after removing the excess surface water by blotting using laboratory tissue.

Equilibrium swelling studies

After the completion of dynamic swelling up to 8 h same samples were used for equilibrium swelling experiments in flask containing 100 ml solution. Swelling was considered at equilibrium after reaching constant weight (2–4 weeks). The equilibrium weight swelling ratio q was calculated using following equation [13];

where W h and W d are the weights of the swollen and of dry gel, respectively.

Swelling mechanism

In order to understand the solvent transport mechanisms, the results were analyzed using a semi empirical equation [11];

where M t/M ∞ is the fractional solvent transport at time t, k the constant related to the structural and geometric characteristics of the device and n is the swelling exponent.

Diffusion coefficient

Diffusion coefficient is a kinetic parameter which depends on the polymer segmental mobility. This was determined by using the relation [14, 15]:

where Q eq is the swelling of the gel at equilibrium, θ is the slop of the linear part of the swelling curves and h is the initial sample thickness before swelling.

Determination of solvent interaction parameters

The volume fraction of the polymer v 2m , and equilibrium volume swelling ratio, (V/V 0) of the gel in a given gel sample swollen to equilibrium in phosphate buffer solution is calculated using following equation:

Where V is the volume of swollen gel, and V 0 is the volume after dry gel, and m s is the mass of the swollen hydrogel at the equilibrium state, m d is the mass of the dry gel, ρ 2 and ρ 1 are the densities of dry gel and solvent respectively. The values of ρ 2 and ρ 1 used were 1.26 and 1.0 g/ml. The dry gel density was determined by a pycnometer using acetone as non-solvent. The density value of the hydrogels did not change with IA content.

Results and discussions

Scanning electron microscopy (SEM)

MMA/IA 70/30 samples became translucent or turbid. After swelling they became flexible. Their flexibility and rigidity were found to be dependent on the mol% of the IA added. As the mole% of the IA was increased, the flexibility of hydrogels increased.

Scanning electron microscopy (SEM) was performed to study the internal structure of the hydrogels. Figure 2 shows fractured surface morphology of MMA/IA hydrgels at two different magnifications (×3,000 and ×5,000). Large voids are observed in the surface which could facilitate the incorporation of the larger drug particles. Dense structure is observed since the scanning was performed on dry hydrogels. On swelling the same structure will become more flexible and porous. Similar network structure was observed and reported by Chen et al. [16].

FT-IR spectroscopic studies and chemical analysis

Figure 3 shows the FTIR spectrum of MMA/IA hydrogels. The spectrum shows the four characteristics signal for methyl methacrylate-co-itaconic acid hydrogels. The carbonyl absorption of the samples were observed at 1,790–1,715 cm−1.

Other characteristics peaks of MMA/IA hydrogels were observed at 3,400 cm−1 for –OH stretching vibration, at 2,990–2,950 cm−1 for –CH-stretching, at 1,090 cm−1 for CH–O bending.

Copolymers with MMA/IA (70:30) non-crosslinked were used for determining the acid values and ester values. The acid value was 203.75 and ester value was 1176.31. The % COOH and % CH3 CO– groups were 16.35 and 11.076 respectively.

Determination of solvent interaction parameters

The Flory–Huggins theory was used in order to obtain solvent interaction parameters, (χ) [17]. The χ values were calculated by using the following equations:

where v 2m is the volume fraction of the swollen gel in the equilibrium state. It was determined from polymer swelling studies which were used in swelling analysis. The χ parameters of the hydrogels can also be obtained experimentally via expression [18]:

The values of χ obtained by using the values of v 2m are given in Table 2. χ parameters of the hydrogels were found in the range of 0.515–0.565, depending on the amounts of IA. In the present work it was assumed that all EGDMA molecules used in the hydrogel synthesis participate in forming effective crosslink, therefore only theoretical Mc values of the hydrogels were calculated by the following equation:

The theoretical number average molecular weight between crosslinks for a polymer network, M c,th was calculated from the knowledge of the mole fraction of each monomer x i, the molecular weight of he repeating units of each monomer M r,i, and the molar crosslinking ratio X. For a copolymer of two monomers, the value of M c,th was calculated using above equation. The theoretical parameters of the hydrogels are given in Table 2.

From molecular weights between crosslinks, the number of links between two crosslinks n is calculated as:

where M r is the average molecular weight of the repeating units and results are given in Table 2. Results show that value n decreased with increase in crosslinking ratio, however it was increased with increase in IA content in the copolymer.

Effect of itaconic acid content on swelling behaviour

To study the effect of monomeric composition on dynamic and equilibrium swelling two series of copolymer were synthesized, in first series seven samples of MMA/IA 100:0, 90:10, 80:20, 70:30, 60:40, 50:50 and 0:100 were synthesized using EGDMA as crosslinking agent, keeping the degree of crosslinking constant i.e., x = 0.30 mol%. In second series MMA/IA i.e., 100:0, 90:10, 85:15, 80:20, 75:25 samples were synthesized using MBAAm as crosslinking agent at x = 0.30 mol%.

It was observed that by increasing the IA component in the hydrogel, from 0 to 40 mol% at fixed crosslinking ratio (x = 0.30 mol% EGDMA) swelling increases. This phenomenon was seen in both dynamic and equilibrium swelling. The results indicate that under acidic conditions, anionic carboxylate groups are protonated, and the hydrogel remain intact. At basic pH values, the concentration of anionic groups in the polymer network increases. This results in increased degree of swelling of hydrogels with an increase in ionizable constituent.

Hydrogels prepared from MMA/IA molar feed ratio of 50:50 and 60:40 (x = 0.30 mol% EGDMA) are rich in IA and contains more ionizable carboxylic groups. Therefore, these samples showed higher swelling compared with samples with comparatively low molar feed ratio of IA i.e., 70:30 and 80:20. Hydrogel samples containing 50:50 MMA/IA (x = 0.30 mol% EGDMA) broke at higher pH values before attaining the equilibrium values due to excessive swelling while their dynamic swelling behaviour is presented in Fig. 4. Therefore, no samples were prepared containing IA more than 50 mol%. Similar increase in the swelling behaviour was observed with increase in IA content in the hydrogels when various compositions were synthesized using MBAAm at fixed degree of crosslinking. Table 3 shows the equilibrium swelling coefficient of MMA/IA x = 0.30 mol% using MBAAm as crosslinking agent as a function of monomer ratio and pH. Caykara et al. [19] reported similar findings that swelling and shrinking properties of IA based hydrogels are dependent on the composition of the hydrogel and the pH of the buffer solution. The equilibrium swelling (q e ) of copolymeric hydrogels slightly increases with increasing pH value. Change in pH leads to gain in q e due to ionization of itaconic acid first carboxylic group. The first and second dissociation constants of IA are pKa1 = 3.85, pKa2 = 5.45, respectively. In all compositions, maximum extents of swelling were reached at pH 7.0, this being due to the complete dissociation of acidic groups of IA at this pH value [4]. Chen et al. [16] prepared crosslinked hydrogels of N-vinyl 2-pyrrolidone and itaconic acid. They observed that swelling increased by increasing the pH of the solution and this effect was significant in those samples containing high IA content.

To investigate the properties of pure poly(itaconic acid) hydrogels, sample containing MMA/IA 0:100 (x = 0.30 mol% EGDMA), was also tried. However, the sample fails to polymerize. Similar results were also observed by Sen and Yakar [20].

Regarding swelling of MMA/IA 80:20, 90:10 and 100:0 (x = 0.30 mol% EGDMA) samples, neither composition showed any substantial swelling at any pH values. The reason for this is the extensive anhydride formation with 20% itaconic acid containing copolymer and occurred at lower temperature, moreover intermolecular crosslinking also occurs during polymerization of itaconic acid copolymers as does with methacrylic acid copolymers (The methacrylic acid-methacrylate copolymers form intermolecular crosslinks as well as a six-membered anhydride ring between adjacent monomer units upon synthesis [21]). The results of Table 3 indicate that these compositions are unsuitable for targeted drug delivery. Likewise the samples prepared with such a low content of IA (100:0, 90:10, 85:15, 80:20 and x = 0.30 mol% MBAAm) were also unable to show significant swelling. The swelling ratios of these samples were almost negligible as expected because the methyl groups of MMA make the polymer more hydrophobic. Moreover due to high reactivity ratio, MMA content in the gel tends to rise [22]. In the samples of MMA/IA 100:0, 90:10, 80:20 x = 0.30 mol% EGDMA and 100:0, 90:10, 85:15 x = 0.30 mol% MBAAm, the solvent front faces two types of hindrance, firstly; the samples were very hard and glassy and secondly; the presence of methyl groups imparts hydrophobicity to the gels [22]. It is suggested that the final swelling equilibrium greatly decreased as MMA content increases. Siegel [23] reported the similar decrease in swelling with increase in MMA content in the gels.

Effect of degree and nature of crosslinking agent on swelling behaviour

Swelling behaviour of the hydrogels can be modulated not only by changing the monomeric composition in the hydrogel structure but also by changing the degree of crosslinking. Figure 5 shows the effect of degree of crosslinking on the equilibrium swelling behaviour at fixed monomeric composition of MMA/IA 70:30 using EGDMA as crosslinking agent. The effect of degree of crosslinking was not significant at 0.25 and 0.35 as it is in 0.15 ratios. To better visualize the effect of degree of crosslinking on swelling behaviour at fixed monomeric composition of MMA/IA 80:20 three different crosslinking ratios (x = 0.15, 0.30 and 0.45) were studied by using MBAAm as crosslinking agent. Effect of degree of crosslinking ratio was again not significant. To investigate the influence of nature of crosslinking agent two types of crosslinking agents were used namely EGDMA and MBAAm. For each crosslinking agent different crosslinking ratios were studied. It was observed that at same monomeric composition and degree of crosslinking swelling was more pronounced using MBAAm as compared to EGDMA. This may be due to the presence of CO-NH-R group that makes it more hydrophilic as compared to EGDMA. These findings are correlated with the results reported by Karadag [24] who prepared superwater absorbent acrylamide/sodium acrylate (AAm/SA) hydrogels by free radical polymerization in aqueous solutions of AAm and of AAm with SA as comonomer. For each copolymerization they used nine different compositions and in all systems a concentration of a multifunctional crosslinker such as trimethylolpropane triacrylate (TMPTA), ethylene glycol dimethacrylate (EGDMA), 1, 4-Butanediol dimethacrylate (BDMA) and N, N methylene bisacrylamide (MBAAm) were employed. It was reported that the samples containing MBAAm crosslinking agent showed more swelling than those samples having EGDMA as crosslinking agent.

Equilibrium swelling coefficient of MMA/IA 70:30 copolymer (x = 0.30 mol% EGDMA) in various solutions of different pH at 37°C as a function of degree of crosslinking. The pH values are: pH 1.2 (open circle), pH 4.5 (filled circle), pH 5.5 (open square), pH 6.5 (filled square), pH 7.0 (open triangle)

Mechanism of penetrant transport and diffusion coefficient

It is very important to analyze the swelling kinetics of the hydrogels for knowing the mechanism of penetrant absorption. The n value provides information on the mechanism of penetrant transport. When n = 0.5 Fickian absorption is observed, n = 1 corresponds to case II transport, while 0.5 < n < 1 the diffusional mechanism is non-Fickian. No n values were calculated when no significant penetrant transport was observed.

For MMA/IA 50:50 to 100:0 (x = 0.30 mol% EGDMA) at all investigated monomeric compositions the value of n was less than 0.5 indicating Fickian diffusion mechanism. Table 4 shows that the highest value of n for MMA/IA 60:40 sample which was 0.48 indicating Fickian transport mechanisms. These results of n values can also be related to the work of Tomic et al. [4] who prepared crosslinked copolymer of 2-hydroxyethyl methacrylate and itaconic acid with varying monomeric compositions. They observed Fickian diffusion in all monomeric compositions. The values of n for penetrant uptake mechanism calculated for MMA/IA 70:30 samples with varying crosslinking ratios of EGDMA are also given in Table 4. All these crosslinking ratios followed Fickian diffusion. Similarly the results in Table 4 suggest that dominant mechanism was Fickian for MMA/IA 80:20 samples at different crosslinking ratios using MBAAm as crosslinking agent.

The penetrant transport from a matrix system is usually governed by diffusion, so determining the diffusion coefficient of hydrogel is essential. The diffusion coefficient of the hydrogel was determined by using Eq. (9) and results are presented in Table 5 which indicates a significant difference in the values, the difference may be due to difference in crosslinking ratios, monomeric composition and pH of the swelling medium.

Conclusion

The present study is aimed at developing oral controlled release pH sensitive drug delivery system for water soluble drugs using MMA-co-IA as a carrier. Hydrogels were synthesized by free radical polymerization method using two types of crosslinking agents namely EGDMA and MBAAm. For studying the effect of pH USP phosphate buffers solutions of varying pH 1.2, 4.5, 5.5, 6.5, and 7.0 were used. Swelling ratio of crosslinked hydrogels was increased with increase in IA content in hydrogel structure and it was also increased with increase in the pH of the surrounding media. This was due to increase in the availability of the percentage of ionizable carboxylic groups. The presence of IA in hydrogel was confirmed by FTIR spectroscopy. The equilibrium swelling of MMA-co-IA copolymer hydrogels decreased with increasing cross-linking ratio. The SEM revealed the surface with large, open, channel like appearance and highly porous structure. For all monomeric composition and degree of crosslinking Fickian diffusion was observed. In conclusion MMA/IA hydrogels can be used for carrying some pharmaceutical substances including water soluble drugs for drug delivery applications.

References

Peppas NA, Buri P, Leobandung W, Ichikawa H (1992) Eur J Pharm Biopharm 20:27–46

Brondsted H, Kopecek J (1992) pH-sensitive hydrogels. American Chemical society, Washington, DC, pp 285–305

Tomic SL, Suljovrujic EH, Filipovic JM (2006) Polym Bull 57:691–702

Tomic SLJ, Micic MM, Filipovic JM, Suljovrujic EH (2007) Radiat Phys Chem 76:801–810

Tomic SLJ, Micic MM, Filipovic JM, Suljovrujic EH (2007) Radiat Phys Chem 76:1390–1394

Brondsted H, Kopecek J (1991) Biomat 12:584–592

Peppas NA, Mikos AG (1986) Hydrogels in medicine and pharmacy, Vol 1. CRC Press, Boca Raton, FL

Ranjha NM, Doelker E (1999a) Saudi Pharm J 7:137–143

Ranjha NM, Doelker E (1999b) STP Pharm Sci 9(4):335–340

Ranjha NM, Doelker E (1999c) STP Pharm Sci 9(4):341–349

Peppas NA (1985) Pharm Acta Helv 60:110–111

Kare AR, Peppas NA (1995) Biomat 16:559–567

Peppas NA, Barr-Howell BD (1987) Hydrogels in medicine and pharmacy. CRC Press, Boca Raton, p 27

Crank J (1975) In The mathematics of diffusin, 2nd edn. Oxford, Clarendon Press, p 244

Britton LN, Ashman RB, Aminabhavi TM, Cassidy PE (1988) J Chem Educ 65:368

Chen KS, Ku Yuan YA, Lin HR, Yan TR, Sheu DC, Chen TM, Lin FH (2005) Mater Chem Phys 91:484–489

Flory PJ (1953) Principles of Polymer Chemistry. Cornell University, Ithaca, NY

Xue W, Champ S, Huglin MB (2001) Polymer 42:3665

Caykara T, Dogmus M, Kantogluo O (2004) J Polym Sci B Polym Phy 42(13):2586–2594

Sen M, Yakar A (2005) Nucl Instrum Methods Phy Res B 234:226–234

Moreau W, Merritt D, Moyer W, Hatzakis M, Johnson D, Pederson L (1979) J Vac Sci Technol 16:1989

Soykan C, Erol I (2004) J Polym Res 11:53–63

Siegel RA, Firestone BA (1988) Macromol 21:3254

Karadag E (2002) Turk J Chem 26:863–875

Acknowledgement

We thank the Ministry of Health, Government of Pakistan for funding this research project. We thank the Faculty of Pharmacy B.Z. University for providing laboratory facilities. Director Centralized Resource Laboratory, Department of Physics University of the Peshawar, and Centre of Excellence in Solid State Physics, University of the Punjab, Lahore for providing us the facility of SEM is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mudassir, J., Ranjha, N.M. Dynamic and equilibrium swelling studies: crosslinked pH sensitive methyl methacrylate-co-itaconic acid (MMA-co-IA) hydrogels. J Polym Res 15, 195–203 (2008). https://doi.org/10.1007/s10965-007-9159-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-007-9159-x