Abstract

Polyaniline (PANI) has been blended with cellulose triacetate (CTA) to obtain both good mechanical properties and good electrical properties. The effects of PANI weight percentage on the optical, structural, morphological and electrical properties in the blend films of polyaniline and cellulose triacetate (PANI/CTA) have been investigated. The phenomenon of percolation was observed in these blend films. It is found that the electrical conductivity of the blend films increases with the increase of polyaniline content up to a value of 10−4 S cm−1 at 84 weight percentage of PANI. The experimental percolation threshold of the dried blend films is obtained at 9.5 wt% of polyaniline. The values of Mott’s temperature, density of states at the Fermi level [N (E f)], hopping distance (R hop), and barrier height (W hop) for PANI/CTA blend films are calculated. By applying Mott’s theory, it is found that the PANI/CTA blend films obey the three dimensional variable range hopping mechanism.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the discovery of polyacetylene as an electrical conductive polymer, many conjugated double-bond polymers have been investigated [1–4]. The conducting polymers based on aromatic or heterocyclic monomers like aniline, pyrrole, thiophene, and their derivatives have been attracted a great attention in recent years due to their good environmental stability [5–7]. Polyaniline (PANI) is now regarded as one of the most technologically promising electrically conductive polymers due to its ease of synthesis, low cost, high yield, and relatively stable electrical conductivity [8].

However, the major drawback of these conducting polymers is the unprocessability and intractability which has made their processing into the desired form is rather difficult. The discovery of counter-ion of functionalized doping acid strongly influences the solubility and consequently induced processability of the PANI [9]. Therefore PANI can be processed without altering its structure by blending it with some other conventional polymers. These blends are designed to combine the desired properties of both components, i.e. good electrical conductivity of PANI with processability and physical properties of the matrix polymer. In most studies of electrically conductive PANI blends, the blends are performed using solution technique where the two constituents of the blend (conductive and insulating) dissolve in a common solvent followed by evaporation of this solvent [10]. By proper selection of the functionalized doping acid, the solvent, and the insulating polymer, blends of PANI and insulating polymer have been made that posses excellent mechanical, optical and electrical properties. PANI-cellulose acetate blend films have been reported in many articles [11–14]. To the best of our knowledge, there were no previous studies on blended films prepared from PANI/CTA. CTA is known to have a better hydrolytic stability and a great resistance to free chlorine and biodegradation compared with cellulose diacetate. CTA have wide range of applications such as hemodialysis, reverse osmosis membrane, and liquid crystal displays [15]. In this article, optical, FTIR, morphological and electrical properties of PANI/CTA blend films are carried out. The conductivity measurement and conduction mechanism of these blend films at low temperature (70–300 K) are studied based on the Mott’s theory.

Experimental work

Materials and synthesis

Aniline (Loba Chemie, India) was purified by vacuum distillation before using. Cellulose triacetate was purchased from Aldrich. Dodecylbenzene sulfonic acid (DBSA) was obtained from Oil Extractor Company (Egypt). The chloroform, methanol, diethyl ether, and ammonium persulphate were bought from El-Gomhorrya Chemical Company (Egypt).

The chemical polymerization of aniline was carried out in an aqueous acidic solution where ammonium persulphate (54 g) was dissolved in 900 ml of 1.2 M HCl previously cooled to 0 °C. Aniline (80 ml) was also dissolved in 1000 ml of precooled 1.2 M HCl. Acidic solution of the ammonium persulphate (oxidant agent) was then slowly added to aniline solution to prevent the temperature from exceeding 5 °C. The mixture was then left for 3–4 h with continuous stirring at 5 °C. The precipitated polyaniline hydrochloride was filtrated and washed consecutively with distilled water, methanol, and diethyl ether. The polyaniline hydrochloride was dried at 50 °C for 48 h.

Ammonia solution (3%) was added to the polyaniline hydrochloride for 2 hour with continuous stirring in order to obtain the polyaniline base (EB). Deprotonated polyaniline was then separated, washed and dried.

Preparation of polyaniline/cellulose triacetate blend films

The polyaniline base (EB) was pasted with DBSA with 1:2.5 weight ratio and then dissolved in chloroform. The CTA also was dissolved in chloroform. The blend films of PANI/CTA with different weight percentage of polyaniline were casted at 60 °C in Petri dishes.

Characterization

For the FTIR measurements, pure PANI, pure CTA, and blended films of PANI/CTA were inserted onto KBr disks. Spectra were carried out in a (Shimadzu 8400S) FTIR spectrophotometer. UV-visible spectra were obtained using a LABOMED spectrophotometer. Optical micrographs of the prepared blend films were obtained at magnification of 500 using Olymus Bx61 microscope.

The DC conductivity was measured at different temperatures (70–300 K) using cryogenic system. The blend films painted with silver past were mounted between two copper electrodes for dc conductivity measurements. The bulk conductivity (σ m) was calculated using the following equation:

where ρ is the resistivity, R is the electrical resistance, A is the area of electrode, and d is the thickness of the sample.

Results and discussion

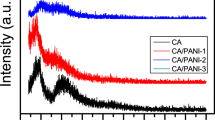

FTIR and UV-visible spectra

Figure 1 represents the FTIR spectra of pure PANI (a), pure CTA (b) and PANI-CTA blend films for 5.52 (c) and 9.5 (d) weight percentage of PANI. The characteristic broad band for O–H group of CTA appears around 3,500 cm−1 and a band around 2,950 cm−1 because of C–H presented in CH2OH group has been observed in Fig. 1a. The presence of C–O–C stretching vibration band can be detected at 1,232 cm−1, accompanied by weaker bands in the region 1,164–1,124 cm−1. The band corresponding to the ester carbonyl group (C = O) stretching vibration of the acetate appears around 1,735 cm−1 [16–18].

On the other hand, the bands around 3,235, 1,575, 1,487, and 806 cm−1 correspond to polyaniline in the blend films as shown in Fig. 1b and c. The band corresponding to out of plane bending vibration of C–H bond of p-substituted benzene ring appears at 806 cm−1. The bands corresponding to stretching vibrations of N–B–N and N=Q=N structures appear around 1487 and 1575 cm−1, respectively (where –B– and =Q= stand for benzenoid and quinoid moieties in the polyaniline backbone) [17, 19]. The peak detected at 3,235 cm−1 may be attributed to –NH– group.

Figure 2 shows the UV-visible spectra of pure PANI, pure CTA (transparent) and PANI/CTA blend films (1.75 and 9.5 weight percentage of PANI). The characteristics peak at 348 nm may be due to a π → π* transition of the benzenoid structure of PANI. The two peaks observed at 425 and 780 nm may be attributed to the formation of delocalized polarons [10].

Optical morphology

Figure 3 shows that optical micrographs of PANI/CTA blend films with different weight ratios of PANI with a magnification of 500×. The CTA image shows a regular smooth surface with granular structural. With the incorporation of PANI, the surface morphology is modified and the phase contrast is very distinct for the conductive PANI. With low weight percentage of PANI (9.5%), the PANI coagulated and the conduction is carried out between PANI granules by hopping. This interprets the percolated phenomena of PANI/CTA blend films. The percolation threshold is higher than those obtained from other works [20]. This may be due to the coagulation of PANI particles at low content of PANI. Further addition of PANI content in the blend films increases the number of conducting paths and PANI particle size becomes fine and dispersed in CTA matrix as shown in Fig. 3c, d.

DC conductivity at room temperature

The low value of percolation threshold is an important factor in the preparation of the conductive blend of polyaniline and insulating polymer because the desired mechanical properties of the host polymer can be retained with a small weight of PANI [11].

The dc electrical conductivity of the PANI/CTA blend films versus the weight percentage of PANI is plotted in Fig. 4a. In general, the conductivity behavior of the blend films can be explained using the morphology of the conductive phase. This behavior can be divided into two regions. When the conductive PANI phase is dispersed, the conductivity of the blend films is low. As the conductive PANI phase is modified from dispersive to the continuous phase, the blend conductivity increases abruptly. This sharp increase in the conductivity of the PANI/CTA blend films with the addition of PANI may be due to the formation of more elongated and connected domains. Once the conductive component forms a continuous phase, the addition of more PANI will has a small effect on the conductivity of the blend.

This type of dependence can be explained in terms of the percolation theory which predicts that, the conductivity of the composite materials obeys the following power-law equation [20]:

where σ h is the conductivity of the conductive filler, w is the weight percentage of the conductive filler, w c is the critical weight percentage of the conductive filler (percolation threshold), and t is the critical exponent.

These parameters can be determined by using linear regression analysis fit to the following straight line [21]:

The \( \sigma ^{{1 \mathord{\left/ {\vphantom {1 t}} \right. \kern-\nulldelimiterspace} t}}_{m} \) is plotted vs w as shown in Fig. 4b for different values of the critical exponent t and a linear regression analysis was applied to find the plot with the maximum value of the squared correlation coefficient, R 2. The maximum value of R 2 (i.e., 0.9762) was obtained for t equal to 3, and the corresponding value of w c was 1.5%. This value of w c obtained theoretically is significantly less than the experimental value (9.5 %) as shown in Fig. 4a. In general, w c depends on several factors, such as the shape of filler particles, the interaction between filler and host polymer and the spatial filler distribution [22].

The value of critical exponent (3) is higher than that predicted from percolation theory (t = 1 for two dimensions and t = 2 for three dimensions) [20, 23]. Therefore, the conductivity behavior of PANI/CTA blend films deviates from percolation law. This may be due to the formation of PANI granule structure and absence of fibril and network structures.

Temperature dependence dc conductivity studies

To investigate the conduction mechanisms in PANI/CTA blend films for different weight percentage of PANI, the temperature dependence of electrical conductivity is studied in the range 70–300 K as shown in Fig. 5. The conductivity increases with the increase of the temperature indicating a semiconducting behavior for all the blend films and at constant temperature, the conductivity also increases with increasing the PANI content [24].

For semiconductor, if the main conduction mechanism is due to the carriers excited beyond the mobility edge into nonlocalised or extended state, then the dc conductivity can be expressed using the following equation [24]:

where σ o is the conductivity at room temperature, T is the temperature, k is Boltzman constant, and E a is activation energy. The activation energy values are calculated from Fig. 6 and it is found that the activation energy is decreased with the decrease of temperature and the average value of activation energy at high temperatures is 0.45 eV whereas at low temperatures it has an average value of 0.15 eV.

The two regions of Ln σ vs 1/T curves, as shown in Fig. 6, indicate that PANI is in the doped state [24]. In the intrinsic region at high temperature, the conductivity curves can not represented by straight line, but shows a kin at 130 K. This may implies that near 130 K a transition from one conduction mechanism to another is carried out. It is suggested that, above 130 K the conduction associated with polaron transport in the extended state is at the mobility edge. With decreasing temperature, the probability of thermal release becomes rapidly low, so that at temperature below 130 K it is more likely that polaron hops to a neighboring localized state [25].

According to Mott’s theory in three dimensions, the conductivity due to hopping conduction in three dimensional localized states at the Fermi level corresponds to hopping between distant sites and is given by the following equation [24]:

where σ o is the dc conductivity at room temperature and T o is the Mott temperature. Here T 0 = 16/ [kN (E f) L 3], N(E f) is the density of states at the Fermi level, and L is the localization length. The density of states at Fermi level [N(E f)] is calculated by assuming localization length of aniline monomer unit of about 3 Å [26]. As shown in Fig. 7, PANI/CTA blend films at different weight percentage of PANI satisfy the hopping mechanism in three dimensions. The value of T 0 implies an effective energy separation between localized states. As T 0 decreases as shown in Table 1, the system becomes highly conducting.

The estimated values of N(E f) increase with increasing the amount of PANI in the PANI/CTA blend films. The increase of N(E f) enhances the hopping probability between the localized states. The average hopping distance between two sites R hop and the barrier height W hop are given by the following equations [23, 24]:

The localization length is an on chain property which depends on the morphology of the disorder regions, and it is larger for the rod-like morphologies compared to coil-like morphologies [27]. Both the hopping distance and barrier height decrease as the conductivity of PANI/CTA blend films increases may be attributed to the decreasing of the localization length. The closer approaches of hopping sites enhance the conductivity.

Conclusions

Blends of polyaniline doped with dodecylbenzene sulfonic acid and cellulose triacetate were successfully prepared using cosolvent method. The percolation phenomenon was observed in the conductivity curves in these blend films. Experimentally the critical threshold of this blend was 9.5 weight percentage of polyaniline while the theoretically value was 1.5 %. It was concluded that the conductivity behavior of these blend films deviates from the percolation law and the hopping mechanism in three dimensional is the dominant conduction mechanism.

Abbreviations

- PANI:

-

polyaniline

- CTA:

-

cellulose triacetate

- N (E f):

-

density of states at the Fermi level

- R hop :

-

hopping distance

- W hop :

-

barrier height

- EB:

-

polyaniline base

- DBSA:

-

dodecylbenzene sulfonic acid

- w :

-

weight percentage of polyaniline

- w c :

-

critical weight percentage of polyaniline

- σ o :

-

conductivity at room temperature

- T :

-

the temperature

- k :

-

Boltzman constant

- E a :

-

activation energy

- σ m :

-

the bulk conductivity

- ρ :

-

resistivity

- R :

-

electrical resistance

- A :

-

area of electrode

- d :

-

thickness of the sample

- σ h :

-

conductivity of the conductive filler

- t :

-

critical exponent

- T o :

-

Mott temperature

- L :

-

localization length

- R 2 :

-

squared correlation coefficient

References

Shirakawa H (2001) Curr Appl Phys 1:281–286

Peres R, De Paoli M, Torresi R (1992) Synth Met 48:259–270

Toyoshima R, Narita M, Akagi K, Shirakawa H (1995) Synth Met 69:289–290

MacDiarmid A, Chiang J, Halperm M, Huang W, Mu S, Somasiri N, Wu W, Yaniger S (1985) Mol Cryst Liq Cryst 121:173–180

Lux F (1994) Polymer 33:2915–2937

Killian J, Coffey B, Gao F, Poehler T, Searson P (1996) J Electrochem Soc 143(3):936–940

Goward G, Leroux F, Nezar L (1998) Electrochim Acta 43:1307–1313

Tabellout M, Fatyeyeva K, Baillif P, Bardeau J, Pud A (2005) J Non-Cryst Solids 351:2835–2841

Laska J, Pron A, Lefrant S (1995) J Polym Sci A 33:1437–1445

Zagorska M, Taler E, Kulszewicz-Bajer I, Pron A, Niziol J (1999) J Appl Polym Sci 73:1423–1426

Valente A, Burrows H, Lobo V (2006) Colloids Surf A Physicochem Eng Asp 275:221–227

Walter A, Banka E, Genoud F, Pron A, Nechtschein M (1997) Synth Met 84:753–754

Pronqb A, Zagorskab M, Nicolauc Y, Genoud F, Nechtschein M (1997) Synth Met 84:89–90

Cheguettine Y, Planes J, Banka E (1999) Synth Met 101:787–788

Kastelan-Kunst L, Dananic V, Kunst B, Kosutic K (1996) J Membr Sci 109:223–230

Valentea A, Burrowsa H, Polishchukb A, Dominguesa C, Borgesc O, Euse’bioa M, Mariaa T, Loboa, V, Monkmand A (2005) Polymer 46:5918–5928

Al-Ahmeda A, Mohammada F, Rahmanb M (2004) Synth Met 144:29–49

Rajini R, Venkateswarlu U, Rose C, Sastry T (2001) J Appl Polym Sci 82:847–853

Rodrigues P, Akcelrud L (2003) Polymer 44:6891–6899

Reghu M, Yoon C, Yang C, Moses D, Smith P, Heeger A, Cao Y (1994) Phys Rev B 50:13931–13941

Cruz-Estrada R, Folkes M (2002) J Mater Sci Lett 21:1427–1429

Mamunya Y, Muzychenko W, Pissis P, Lebedev E, Shut M (2002) Polym Eng Sci 42:90–100

Fournier J, Boiteux G, Seytre G, Marichy G (1997) Synth Met 84:839–840

Mott N, Davis E (1979) Electronic processes in non-crystalline materials. Oxford University Press, Oxford

Allen F, Walls R, Adkins C (1974) Conduction in randam arry of donor centers in germanium. In: Brening W (ed) Handbook of amorphous and liquid semicondcuors, vol 2. Taylor and Francis, New York

Saravanan S, Anantharaman M, Venkatachalam S (2006) Mater Sci Eng B 135:113–119

Nazeer K, Thamilselvan M, Mangalaraj D, Narayandass Sa K, Yi J (2006) J Polym Res 13:17–23

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebrahim, S.M., Kashyout, A.B. & Soliman, M.M. Electrical and structural properties of polyaniline/cellulose triacetate blend films. J Polym Res 14, 423–429 (2007). https://doi.org/10.1007/s10965-007-9125-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-007-9125-7