Abstract

Modified screen printed (SPE) and carbon paste electrodes (CPE) with phenanthroline–tetraphenyl borate ionophore [Phen:TPB] were fabricated for the determination of copper(II). The modified electrodes have linear responses over a wide concentration range (1 × 10−6–1 × 10−2 mol·L−1) of copper(II) ion at 25 °C with divalent cationic slopes of 29.85 ± 0.58 and 29.45 ± 0.81 mV·decade−1 and exhibit a detection limit of 1 × 10−6 mol·L−1 for SPE and CPE. The selectivity coefficient was measured using the match potential method in acetate buffer of pH = 4.2. The modified SPE and CPE sensors show high selectivity and sensitivity for determination of copper(II) and also show stable and reproducible response over a period of five and three months for SPE and CPE sensors, respectively. This method can be used for determination of copper(II) in water, soil, plant and fish tissue samples and the results obtained agreed with those obtained with atomic absorption spectrometer (AAS).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Ion selective electrodes, especially solid state and screen printed electrodes (SPEs), are still attracting the interest of the scientific community. Potentiometric detection based on ISEs is a simple method that offers several advantages such as fast and easy preparation procedures, simple instrumentation, relatively fast response time, wide concentration range, reasonable selectivity, low cost and may also be suitable for online analysis [1–12].

Copper is an essential trace element in biological systems [13] where it serves as a cofactor in at least 30 important enzymes [14] and is known to exhibit a strong affinity for natural carriers [15, 16]. It is also toxic at high concentration. Reactivity and biological uptake of copper are strongly influenced by its free ion concentration. Potentiometric measurements with a copper selective electrode allow direct determination of copper ion concentrations in water [17] and soil samples [18]. For this reason researchers have attempted to develop sensors for its determination with high selectivity and sensitivity, for example solid membrane electrodes with electroactive material such as quaternary thiospinel [19], ion exchangers [20] and 1-phenyl-2-(2-hydroxyphenylhydrazo)-butane-1,3-dione [21], N,N′-(2,2-dimethylpropane-1,3-diyl)-bis(dihydroxyacetophenone) [22] and phenanthroline tetraphenyl borate [23].

The determination of free copper(II) concentrations in natural matrices is critical for the evaluation of copper toxicity [24]. Due to the vital importance of determining copper in many biological systems [25] and industry [26], some copper sensors were prepared based on alkyl thioglycolic acid [27, 28], crown ethers [29], calixarenes [30], Schiff bases [31–33] and neutral ionophores [34, 35].

The purpose of the present work is to obtain a better modified screen printed and carbon paste electrodes (CPE) with the [Phen:TPB] ionophore to make a highly selective and sensitive electrodes for potentiometric determination of copper by titration with 1,10-phenanthroline monohydrate [Phen] solution in the presence of potassium thiocyanate (KSCN) and acetate buffer. This work provides a simple, low cost, highly sensitive and selective method in the presence of large number of metal ions with minimum interference for determination of copper over a wide concentration range.

2 Experimental

2.1 Reagents and Chemicals

Analytical grade reagents are used in this study. Distillated water was used throughout all experiments. Copper sulfate [CuSO4·5H2O, 99 %] was supplied by Merck. 1,10-Phenanthroline monohydrate [Phen, 98 %] and o-nitrophenyloctylether (o-NPOE, 100 %) were supplied by Fluka. Dioctylphthalate (DOP, 99 %), dibutylphthalate (DBP, 99 %) and dioctylsebacate (DOS, 99 %) were supplied by BDH. Tricresylphosphate (TCP), PVC (relative high molecular weight) and graphite powder (synthetic 1–2 μm) were supplied by Aldrich. Sodium tetraphenylborate (NaTPB, 99 %) was purchased from Fluka. Potassium fluoride and sodium hydroxide were supplied by BDH; hydrogen peroxide was supplied by Koch Light. Chloride salts of iron, magnesium, cadmium, strontium, zinc, nickel, calcium, potassium, manganese, lead, barium, cobalt, sodium and aluminum are used as interfering materials.

2.2 Apparatus

Laboratory potential measurements were performed using a Jenway 3505 pH-meter. Silver–silver chloride double-junction reference electrode (Metrohm 6.0726.100) was used in conjugation with different ion selective electrodes. A digital Burette was used for the field measurement of the Cu(II) ion under investigation. pH measurements were done using a Thermo-Orion, model Orion 3 stars, USA. Prior to analysis, all glassware used were washed carefully with distilled water and dried in the oven before use.

2.3 Preparation of Phenanthroline–Tetraphenyl Borate [Phen:TPB] Ionophore

Phenanthroline–tetraphenyl borate ionophore was synthesized by adding equal volumes of 10−2 mol·L−1 of 1,10-phenanthroline monohydrate and 10−2 mol·L−1 of sodium tetraphenyl borate, mixed for 5 min; the precipitate was filtrated using Whatman filter paper No. 42, washed several times with distillated water and dried for 24 h at room temperature [23].

2.4 Preparation of the Modified Screen Printed Electrode

The SPE was prepared by using a manual screen printer. An array of 12 electrodes was printed on a flexible X-ray film by forcing the prepared conductive ink to penetrate through the mesh of a screen stencil. A screen consisting of a heavy duty polyester fabric (I 003M Sefar Pet 1000 with mesh count of 36) was pre-tensioned to a 30 × 40 cm wooden frame. For the stainless steel template, a steel sheet were pre-tensioned to a steel frame and contains grooves with the same electrode dimensions [36–43]. The homemade printing ink was prepared by thoroughly mixing a cyclohexanone–acetone mixture 1:1, as a solvent for the binding material with 450 mg of o-NPOE, 1.25 mg polyvinyl chloride, 0.75 mg of the carbon powder and then 7.5 mg of [Phen:TPB] was added after stirring for 15 min; the ink was sonicated and applied for printing of the electrodes [36–43]. The influence of the plasticizer choice on the electrode performances has been studied as the electrode plasticized with o-NPOE was compared with those plasticized with DBP, DOP, DOS and TCP. The SPEs were stored in a dry state at room temperature [36–43].

2.5 Preparation of Modified Carbon Paste Electrode

A 500 mg sample of pure graphite powder and 10 mg [Phen:TPB] ionophore were transferred to a mortar and mixed well with plasticizer (0.2 mL of DOP, TCP, DBP, DOS or o-NPOE). The modified paste was filled into the electrode body and kept in distillated water for 24 h before use [36–43]. A fresh surface was obtained by gently pushing the stainless-steel screw forward and polishing the new carbon-paste surface with filter paper to obtain a shiny new surface.

2.6 Preparation of Sample Solutions

1.5 mL of 10−2 mol·L−1 Cu(II) was mixed with 2 mL of 0.1 mol·L−1 KSCN and 1 mL of 0.5 mol·L−1 acetate buffer. The mixture was diluted to 10 mL with distilled water and the pH of the solution was adjusted to 4.2 using hydrochloric acid (0.1 mol·L−1) and/or sodium hydroxide (0.1 mol·L−1).

2.7 Potentiometric Determination of Copper

The double junction Ag/AgCl reference electrode and the modified SPE or CPE sensors were conjugated and immersed in a 50 mL beaker containing the prepared sample solution and then titrated using the Phen solution.

2.8 Determination of Copper in Water Samples

Add 2 mL of water samples (Table 1), 2 mL of KSCN, 1 mL acetate buffer, dilute to 10 mL with bidistilled water, mix well and adjust pH to 4.2. Copper(II) is determined potentiometrically as described above.

2.9 Determination of Cu(II) in Soil Samples

About 10 gm of aerobically dried soil samples (Table 1) are treated with diethylene triamine pentaacetic acid [DTPA] solution, stirred for 2 h, filtered with Whatman filter paper No. 42 [44]. Take 2 mL of the prepared soil solution, treat it as described above. Copper is measured by potentiometric titration with Phen solution.

2.10 Determination of Copper in Plant Samples

Plant samples (Table 1) are prepared according to Rashid`s (1986) method [45–47]. 2 mL KSCN and 1 mL acetate buffer were added to 2 mL of the prepared plant samples and the pH was readjusted to 4.2. Copper is determined in plant samples potentiometrically as described above.

2.11 Determination of Copper in Fish Tissue Samples

Copper is determined in fish tissue samples (Table 1) after their preparation and digestion according to the previously reported method [48]. A 2 mL sample is transferred to 50 mL beaker and treated with 2 mL KSCN, 1 mL acetate buffer and readjust the pH to 4.2. Copper is determined by potentiometric titration with Phen solution as described above.

3 Results and Discussion

The process of preparing the electrodes is one in which the Phen solution reacts with sodium tetraphenyl borate [Na-TPB] to form a water insoluble complex [Phen:TPB] which can then be mixed with graphite powder, o-NPOE and PVC to form a modified SPE, and mixed with graphite powder and o-NPOE to form a modified CPE for potentiometric determination of copper(II) by using Phen solution as titrant in the presence of KSCN and acetate buffer at pH = 4.2.

To test the performance of the modified SPEs and CPEs, various operational parameters, including: selectivity, working range, pH of the media and life time of electrodes are usually determined. The electrodes were found to have a linear response over a wide concentration range of 1 × 10−6–1 × 10−2 mol·L−1 of Cu(II) with divalent cationic slopes of 29.85 ± 0.58 and 29.45 ± 0.81 mV·decade−1 and a detection limit of 1 × 10−6 mol·L−1 for SPE and CPE sensors, respectively (Fig. 1). The electrodes show stable and reproducible potentials over a period of 5 and 3 months for SPE and CPE, respectively. The selectivity of the modified SPE and CPE potentiometric sensors has been studied and the results show that the electrodes are highly selective for determination of Cu(II) (Table 2). The SPE and CPE sensors show an advantage over the previously reported PVC electrode [23] with respect to linear range, life time and limit of detection. The reproducibility and stability of the sensor potential over a period of 6 weeks was within ±2 mV [23].

3.1 Effect of Ionophore Content

It is known that the sensitivity and linearity of a given electrode depend significantly on the amount of ionophore in the electrode composition. Thus, five SPEs and five CPEs were prepared to determine the best electrode contents. The proportions of [Phen:TPB] ionophore were varied as 2.5, 5, 7.5, 10 and 12.5 mg (w/w)%. The potentiometric titration was carried out for each electrode and the resulting potential breaks at the end point were found to be 205, 234, 280, 253 and 221 mV·mL−1 and 138, 197, 143, 130 and 125 mV·mL−1 for modified SPE and CPE sensors, respectively. These electrodes give a sharp and reproducible inflection at the end point (280 and 197 mV·mL−1 for modified SPE and CPE sensors, respectively) in comparison with the previously reported PVC membrane (180 mV) [23]. This corresponds to the formation of a Cu(II):SCN−:Phen complex with composition 1:2:1 [23]. These results indicate that the highest potential break at the end point was achieved using 7.5 and 5 mg of [Phen:TPB] ionophore for SPE and CPE sensors, respectively. But when increasing the amount of ionophore over 7.5 and 5 mg, the total potential change decreased as shown in Fig. 2 and Table 3.

It is found that no inflection breaks are observed in the absence of SCN−, and also the citrate buffer (pH = 4.2) is not suitable for this study due to its strong interaction with Cu(II). This finding is in accordance with the previously published data [23].

3.2 Effect of Plasticizer Type

The behaviors of SPEs and CPEs are greatly influenced by the plasticizer type since they improve the solubility of the sensing material and lower the overall bulk resistance of the electrode due to their polarity characteristics. The influence of plasticizer choice on the electrode performance has been studied; five plasticizers were used (o-NPOE, TCP, DBP, DOP and DOS) and the potential break at the end point of the electrode was measured and found to be 297, 280, 268, 250 and 239 mV·mL−1 and 210, 199, 193, 177 and 165 mV·mL−1 for SPEs and CPEs, respectively. The results show that the best performance is for the electrodes which are prepared using o-NPOE, which has the highest dielectric constant (Fig. 3).

3.3 Effect of Soaking Time

The effect of soaking time on the electrode performance was evaluated by soaking freshly prepared electrodes in [Cu:phen] for 0, 5, 10, 15, 30 and 45 min and 1, 6 and 24 h to form a thin gel layer at which the ion exchange occurs. The optimum soaking time was found to be 0 min, where the highest total potential change and the potential break at the end point are obtained at 25 °C. They decreased with increasing soaking time (Table 4).

3.4 Effect of PH

The behavior of the modified SPEs and CPEs was studied at pHs from ranging 2 to 8. The pH value was adjusted by adding very small volumes of HCl (0.1 mol·L−1) and/or NaOH (0.1 mol·L−1) solution in which the potential response was measured at 10−4 and 10−2 mol·L−1 copper(II). The potential change at each pH value was reported. It was obvious that in pH range from 3.8 to 5, the potentials of the SPEs and CPEs are practically independent of pH as is shown in Fig. 4. At lower or higher pHs, a drift is observed which could be due to the formation of some hydroxyl complexes of copper(II) and the formation of doubly charged [PhenH2]2+ and neutral [Phen] species, so all potentiometric titrations were carried out at pH = 4.2 using acetate buffer. Also, previous studies showed that the pH range for PVC electrode is 3.8–4.5 [23].

3.5 Effect of Temperature

The effect of temperature on the performance of the electrodes was studied at different temperatures ranges from 10 to 60 °C. A straight-line plot is obtained according to the following equation [49]:

where E 0(25) is the standard electrode potential at 25 °C. The slope of the straight-line obtained represents the isothermal coefficient of the electrode. The isothermal coefficients were found to be 0.0125 and 0.0154 mV·°C−1 for the SPE and CPE sensors, respectively, as shown in Fig. 5. The values of the isothermal coefficients of the electrodes indicate that SPE and CPE have a fairly high thermal stability within the investigated temperature range. The investigated electrodes were found to be usable up to 60 °C without noticeable deviations from Nernstian behavior.

3.6 Response Time

For analytical applications, the response time of a sensor is of critical importance. The SPE and CPE sensors showed very fast response times (Fig. 6) (8 s for 10−3 mol·L−1 and 11 s for lower concentrations) which are shorter than for previously reported copper(II) sensors [36, 40, 50, 51] and the equilibrium potentials essentially remained constant for 7 min.

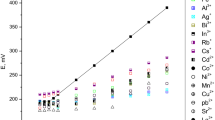

3.7 Selectivity and Interference

The selectivity coefficient of the modified SPEs and CPEs were evaluated by using the match potential method (MPM). A 10−3 mol·L−1 Cu(II) activity was used as reference solution. In this method, the potentiometric selectivity coefficient is defined as the activity ratio of primary and interfering ions that give the same potential change under identical conditions. The selectivity coefficient was calculated from the activities of the interfering ions and copper(II) ion, which induced the same potential change using the following formula:

where a Cu is the Cu(II) activity of the reference solution (10−3 mol·L−1), a \Cu is the Cu(II) activity of the solution after addition of Cu(II), a B is the activity of B, the interfering ion, in the solution after addition of B ions into the reference solution to reach the same potential change. The log10 K Cu,B values obtained by the MPM are summarized in Table 5. The results summarized in Table 5 indicate that the modified SPE and CPE sensors are highly selective for Cu(II) ion and there is no interference from the studied cations except iron, which showed a high selectivity coefficient. The interference of excess ferric ion can be eliminated by adding 0.5 g of KF to each titration but excess ferrous ions are oxidized to ferric ion by acidified hydrogen peroxide followed by heating to remove excess hydrogen peroxide [23, 52].

3.8 Analytical Applications

The modified SPE and CPE potentiometric sensors were also successfully applied for the determination of copper(II) in different samples such as water, soil, plant and fish tissue samples. The copper(II) contents were determined with the modified SPE, CPE and atomic absorption spectrometric methods (AAS). The results obtained are summarized in Table 6. The results obtained for copper determination in water, soil, plant and fish tissue samples using the modified SPE and CPE sensors are very close to those obtained using the recommended AAS method. As can be seen, the electrodes give acceptable standard deviations (SD) and relative standard deviation (RSD) values for copper(II) ion determination, which are also in satisfactory agreement with those obtained by the AAS method.

3.9 Precision and Accuracy

In order to determine the precision of the proposed potentiometric method, three different concentrations of pure Cu(II) solution, different water and soil samples (Table 7) and five different titration runs of 1.5 mL of 10−2 mol·L−1 Cu(II) with 10−2 mol·L−1 Phen solution (Table 8) were performed to evaluate the reproducibility of the results obtained. Tables 7 and 8 give a statistical summary of each of the titration series using the modified SPE and CPE sensors. RSD and SD values were obtained within the same day to evaluate repeatability (intra-day precision) and over 5 days to evaluate intermediate precision (inter-day precision). The low values of the RSD and SD also indicate the high precision and the good accuracy of the proposed method.

4 Conclusions

Screen printed and CPE modified with [Phen:TPB] were synthesized for potentiometric determination of copper(II) at pH = 4.2 by titration with Phen solution in the presence of KSCN and acetate buffer. It was found that SPE has high performance and more selectivity than CPE. The proposed SPE and CPE sensors show more advantages over other methods as high performance, selectivity, sensitivity in a wide range of Cu(II) activities, long-term stability (5 and 3 months for SPE and CPE, respectively), wide pH range and higher calibration graph slope [23]. This method can be used for determination of copper ion in water, soil, plant and fish tissue samples.

References

Khan, A.A., Baig, U.: Polyacrylonitrile-based organic–inorganic composite anion exchange membranes: preparation, characterization and its application in making ion-selective membrane electrode for determination of As(V). Desalination 289, 21–26 (2012)

Osakai, T., Sato, Y., Imoto, M., Sakaki, T.: Interpretation of the potential response of PVC membrane ion-selective electrodes based on the mixed potential theory. J. Electroanal. Chem. 668, 107–112 (2012)

Zamani, H.A., Ganjali, M.R., Faridbod, F., Salavati-Niasari, M.: Heptadentate Schiff-base based PVC membrane sensor for Fe(III) ion determination in water samples. Mater. Sci. Eng. C 32, 564–568 (2012)

Zamani, H.A., Zabihi, M.S., Rohani, M., Zangeneh-Asadabadi, A., Ganjali, M.R., Faridbod, F., Meghdadi, S.: Quantitative monitoring of terbium ion by a Tb3+ selective electrode based on a new Schiff’s base. Mater. Sci. Eng. C 31, 409–413 (2011)

Moriuchi-Kawakami, T., Yamamoto, H., Shibutani, Y.: Ion selective electrodes based on l-tryptophan and l-tyrosine. Talanta 94, 99–103 (2012)

Ramanjaneyulu, P.S., Kumar, A.N., Sayi, Y.S., Ramakumar, K.L., Nayak, S.K., Chattopadhyay, S.: A new ion selective electrode for cesium(I) based on calix[4]arene-crown-6 compounds. J. Hazard. Mater. 205–206, 81–88 (2012)

El-Nashar, R.M., Abdel Ghani, N.T., Hassan, S.M.: Construction and performance characteristics of new ion selective electrodes based on carbon nanotubes for determination of meclofenoxate hydrochloride. Anal. Chim. Acta 730, 99–111 (2012)

Bolger, F.B., McHugh, S.B., Bennetta, R., Li, J., Ishiwaria, K., Francoisc, J., Conwayc, M.W., Gilmourc, G., Bannermanb, D.M., Fillenz, M., Tricklebankc, M., Lowrya, J.P.: Characterization of carbon paste electrodes for real-time amperometric monitoring of brain tissue oxygen. J. Neurosci. Method. 195, 135–142 (2011)

Bergamini, M.F., Santos, D.P., Valnice, M., Zanoni, B.: Determination of isoniazid in human urine using screen-printed carbon electrode modified with poly-l-histidine. Bioelectrochemistry 77, 133–138 (2010)

Ojani, R., Raoof, J.B., Zamani, S.: A novel voltammetric sensor for amoxicillin based on nickel–curcumin complex modified carbon paste electrode. Bioelectrochemistry 85, 44–49 (2012)

Eghbalnia, M., Dixon, D.G.: Electrochemical study of leached chalcopyrite using solid paraffin-based carbon paste electrodes. Hydrometallurgy 110, 1–12 (2011)

Flores-Álvarez, J.M., González, I., García-de la Rosa, L.A., Mancilla-Peña, F., Reyes-Gómez, J.: Carbon paste electrodes modified with biosolids, soils and biocomposites utilized to study the interaction between organic matter and copper. J. Environ. Manag. 92, 448–456 (2011)

Abbasi, S., Khani, H., Tabaraki, R.: Determination of ultra trace levels of copper in food samples by a highly sensitive absorptive stripping voltametric method. Food Chem. 123, 507–512 (2010)

Honeychurch, K.C., Hawkins, D.M., Hart, J.P., Cowell, D.C.: Voltammetric behaviour and trace determination of copper at a mercury-free screen-printed carbon electrode. Talanta 57, 565–574 (2002)

Marques de Oliveira, I.A., Pla-Roca, M., Escriche, L., Casabó, J., Zine, N., Bausells, J., Samitiera, J., Errachid, A.: New membrane for copper-selective electrode incorporating a new thiophosphoril-containing macrocycle as neutral carrier. Mater. Sci. Eng. C 26, 394–398 (2006)

Chai, Y., Dai, J., Yuan, R., Zhong, X., Liu, Y., Tang, D.: Highly thiocyanate-selective membrane electrodes based on the N,N′-bis-(benzaldehyde)–glycine copper(II) complex as a neutral carrier. Desalination 180, 207–215 (2005)

Fathi, S.A.M., Yaftian, M.R.: Enrichment of trace amounts of copper(II) ions in water samples using octadecyl silica disks modified by a Schiff base ionophore prior to flame atomic absorption spectrometric determination. J. Hazard. Mater. 164, 133–137 (2009)

Luo, X., Zhou, D., Wang, Y.: Free cupric ions in contaminated agricultural soils around a copper mine in eastern Nanjing City. China. J. Environ. Sci. 18, 927–931 (2006)

Laganovskya, V., Kormosha, Zh.O., Sachanyukb, V.P., Parasyukb, O.V.: Quaternary thiospinel CuCrTiS4 as an electroactive material for copper(II)-sensitive and selective electrode. Mater. Sci. Eng. C 28, 1112–1116 (2008)

Gupta, K.C., D’Arc, M.J.: Effect of concentration of ion exchanger, plasticizer and molecular weight of cyanocopolymers on selectivity and sensitivity of Cu(II) ion selective electrodes. Anal. Chim. Acta 437, 199–216 (2001)

Kopylovich, M.N., Mahmudov, K.T., Pombeiro, A.J.L.: Poly(vinyl) chloride membrane copper-selective electrode based on 1-phenyl-2-hydroxyphenylhydrazo) butane-1,3-dione. J. Hazard. Mater. 186, 1154–1162 (2011)

Ghanei-Motlagh, M., Taher, M.A., Saheb, V., Fayazi, M., Sheikhshoaie, I.: Theoretical and practical investigations of copper ion selective electrode with polymeric membrane based on N,N′-(2,2-dimethylpropane-1,3-diyl) bis(dihydroxyacetophenone). Electrochim. Acta 56, 5376–5385 (2011)

Marzouk, S., Al-Ariqui, W., Hassan, S.: A novel 1,10-phenanthroline-sensitive membrane sensor for potentiometric determination of Hg(II) and Cu(II) cations. Anal. Bioanal. Chem. 375, 1186–1192 (2003)

Rachou, J., Gagnon, C., Sauvé, S.: Use of an ion-selective electrode for free copper measurements in low salinity and low ionic strength matrices. Environ. Chem. 4, 90–97 (2007)

Saumya, V., Prathish, K.P., Rao, T.P.: In situ copper oxide modified molecularly imprinted polypyrrole film based voltammetric sensor for selective recognition of tyrosine. Talanta 85, 1056–1062 (2011)

Dadfarnia, S., Shamsipur, M.: Specific membrane transport of copper(II) ion by a cooperative carrier composed of 1,7-diaza-15-crown-5 and palmitic acid. J. Membr. Sci. 75, 61–68 (1992)

Rechnitz, G.A., Lin, Z.F.: Complex formation studies with cupric ion-selective membrane electrodes. Anal. Lett. 1, 23–26 (1967)

Moody, G.J., Thomas, J.D.R.: Selective ion-sensitive electrodes. Sel. Annu. Rev. Anal. 3, 59–138 (1973)

Shamsipur, M., Javanbakht, M., Mousavi, M.F., Ganjali, M.R., Lippolis, V., Garau, A., Te, L.: Copper(II)-selective membrane electrodes based on some recently synthesized mixed aza-thioether crowns containing a 1,10-phenanthroline sub-unit. Talanta 55, 1047–1054 (2001)

Cobben, P.L.H., Egbernik, R.J.M., Bomer, J.B., Bergveld, P., Verboom, W., Reinhoudt, N.: Transduction of selective recognition of heavy metal ions by chemically modified field effect transistors (CHEMFETs). J. Am. Chem. Soc. 114, 10573–10582 (1992)

Shokrollahi, A., Abbaspour, A., Ghaedi, M., Ghaedi, A.N., Kianfar, X.A.H., Ranjbar, M.: Construction of a new Cu2+ coated wire ion selective electrode based on 2-((2-(2-(2-(2-hydroxy-5-methoxybenzylideneamino)phenyl)disufanyl)phenylimino)methyl)-methoxyphenol Schiff base. Talanta 84, 34–41 (2011)

Hassouna, M.E.M., Elsuccary, S.A.A., Graham, J.P.: N,N′-Bis(3-methyl-1-phenyl-4-benzylidine-5-pyrazolone)propylenediamine Schiff base as a neutral carrier for silver(I) ion-selective electrodes. Sens. Actuators B 146, 79–90 (2010)

Ghiaci, M., Rezaei, B., Arshadi, M.: Characterization of modified carbon paste electrode by using Salen Schiff base ligand immobilized on SiO2–Al2O3 as a highly sensitive sensor for anodic stripping voltammetric determination of copper(II). Sens. Actuators B 139, 494–500 (2009)

Fathi, S.A.M., Parinejad, M., Yaftian, M.R.: Multidentate nitrogen/oxygen donor ionophores; their use as selective extracting and mobile-carrier agents for copper(II) ions. Sep. Purif. Technol. 64, 1–7 (2008)

Mittal, S.K., SK, A., Gupta, N., Kaur, S., Kumar, S.: 8-Hydroxyquinoline based neutral tripodal ionophore as a copper(II) selective electrode and the effect of remote substituents on electrode properties. Anal. Chim. Acta 585, 161–170 (2007)

Mohamed, G.G., Ali, T.A., El-Shahat, M.F., Al-Sabagh, A.M., Migahed, M.A., Khaled, E.: Potentiometric determination of cetylpyridinium chloride using a new type of screen-printed ion selective electrodes. Anal. Chim. Acta 673, 79–87 (2010)

Frag, E.Y.Z., Ali, T.A., Mohamed, G.G., Awad, Y.H.H.: Construction of different types of ion-selective electrodes. Characteristic performances and validation for direct potentiometric determination of orphenadrine citrate. Int. J. Electrochem. Sci. 7, 4443–4464 (2012)

Frag, E.Y.Z., Mohamed, G.G., El-Sayed, W.G.: Potentiometric determination of antihistaminic diphenhydramine hydrochloride in pharmaceutical preparations and biological fluids using screen-printed electrode. Bioelectrochemistry 82, 79–86 (2011)

Frag, E.Y.Z., Mohamed, G.G., Nour El-Dien, F.A., Mohamed, M.E.: Construction and performance characterization of screen printed and carbon paste ion selective electrodes for potentiometric determination of naphazoline hydrochloride in pharmaceutical preparations. Analyst 136, 332–339 (2011)

Mohamed, G.G., El-Shahat, M.F., Al-Sabagh, A.M., Migahed, M.A., Ali, T.A.: Septonex–tetraphenylborate screen-printed ion selective electrode for the potentiometric determination of Septonex in pharmaceutical preparations. Analyst 136, 1488–1495 (2011)

Mohamed, G.G., Ali, T.A., El-Shahat, M.F., Al-Sabagh, A.M., Migahed, M.A.: New screen-printed ion-selective electrodes for potentiometric titration of cetyltrimethylammonium bromide in different civilic media. Electroanalysis 22, 2587–2599 (2010)

Khaled, E., Mohamed, G.G., Awad, T.: Disposal screen-printed carbon paste electrodes for the potentiometric titration of surfactants. Sens. Actuators B 135, 74–80 (2008)

Mohamed, G.G., Ali, T.A., El-Shahat, M.F., Migahed, M.A., Al-Sabagh, A.M.: Novel screen-printed electrode for the determination of dodecyltrimethyl–ammonium bromide in water samples. Drug Test Anal. 4, 1009–1013 (2012)

Lindasy, W., Norvell, W.A.: Development of a DTPA soil test for zinc, iron, manganese, and copper. Soil Sci. Soc. Am. J. 42, 421–428 (1978)

Reuter, D., Robinson, J. (eds.): Plant Analysis: An Interpretation Manual. Inkata Press, Melbourne (1986)

Reuter, D.J., Robinson, J.B.: Plant Analysis. An Interpretation Manual, 2nd edn. CSIRO Publishing, Melbourne (1997)

Peverill, K.I., Sparrow, L.A., Reuter, D.J. (eds.): Soil Analysis: An Interpretation Manual. CSIRO Publishing, Collingwood (1999)

Finerty, M.W., Madden, J.D., Feagly, S.H., Grodner, R.M.: Effect of environmental and seasonality on metal residues in tissues of wild and pond raised cray fish in southern Louisiaana. Arch. Environ. Contam. Toxicol. 19, 94–100 (1990)

Bauer, H.H., Christian, G.D., O’Reilly, J.E.: Instrumental Analysis, pp. 750–757. Allyn and Bacon, Boston (1978)

Mashhadizadeh, M.H., Ramezani, S., Ebrahimi, S.: Potentiometric determination of nanomolar concentration of Cu(II) using a carbon paste electrode modified by a self-assembled mercapto compound on gold nanoparticles. Sens. Actuators B 169, 305–311 (2012)

Gismera, M.J., Hueso, D., Procopio, J.R., Sevilla, M.T.: Ion-selective carbon paste electrode based on tetraethyl thiuram disulfide for copper(II) and mercury(II). Anal. Chim. Acta 524, 347–353 (2004)

Svehla, G.: Chap. VI: semimicro qualitative inorganic analysis. In: Vogel’s Textbook of Macro and Semimicro Qualitative Inorganic Analysis, 5th edn, pp. 461–500. Longman, England (1987)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, T.A., Mohamed, G.G., El-Dessouky, M.M.I. et al. Modified Screen-Printed Electrode for Potentiometric Determination of Copper(II) in Water Samples. J Solution Chem 42, 1336–1354 (2013). https://doi.org/10.1007/s10953-013-0030-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10953-013-0030-x