Abstract

Superconductivity and magnetism are mutually exclusive phenomena. This work was carried out to investigate the effect of ferrimagnetic Cr2S3 addition on YBa2Cu3O7−δ superconductor. The solid-state reaction method was used to prepare YBa2Cu3O7−δ (Cr2S3)x (x = 0 to 0.3 wt%). The samples were characterized by using the four-probe method to measure the electrical resistivity and AC susceptibility to measure the critical temperature, Tcχ and critical current density at the peak temperature Tp of the complex susceptibility, Jc(Tp). The x-ray diffraction (XRD) method was used to determine the phase and structure of the sample. Field emission electron microscopy (FESEM) was used to determine the microstructure. The x = 0.05 sample showed the highest onset transition temperature, Tc−onset (93 K), zero-resistance temperature, Tc−zero (89 K), Tcχ (93 K) and Tp (86 K). Addition of Cr2S3 did not affect the orthorhombic structure. However, the addition of Cr2S3 for x ≥ 0.10 showed some impurity peaks in the XRD patterns. The grain size decreased with Cr2S3 addition. Cr2S3 improved the intergrain coupling and flux pinning as indicated by the increase in Jc(Tp) and Tp. These results are compared with other magnetic and non-magnetic materials addition to YBa2Cu3O7−δ.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The interaction between magnetism and superconductivity is an interesting topic to study. There are several reports on the effect of magnetic impurities on the copper oxide-based high-temperature superconductor (HTSC). Nano-magnetic materials are reported to enhance the critical current density of high-temperature superconductors with a strong interaction between flux line network and magnetic texture [1, 2]. Addition of γ-Fe2O3, Fe3O4 and ZnO in Bi–Sr–Ca–Cu–O enhanced the critical current density [3,4,5]. GdBa2Cu3O7−δ containing α-Fe2O3 also exhibited enhanced critical current density [6]. Nano-sized PbO showed improvements in the superconducting properties of YBa2Cu3O7−δ [7]. However, addition of ferromagnetic Co3O4 decreased the transition temperature, Tc of YBa2Cu3O7−δ [8].

Apart from metal oxides, metal sulphides are an interesting substitution in YBa2Cu3O7−δ. Moreover, oxygen and sulphur belong to the same group (VI) in the periodic table. Metal fluorides such as antiferromagnetic FeF2 addition in YBa2Cu3O7−δ(FeF2)x showed the highest transition temperature and critical current density for x = 0.03 wt% [9]. Other compounds including Co3O4, CdTe, CoFe2O4, graphene and graphene oxide showed different effects on YBa2Cu3O7−δ depending on the magnetic property [8, 10,11,12,13].

Chromium sulphide (Cr2S3) is a ferrimagnetic semiconductor with Curie temperature of 120 K and energy gap of 1.1 eV [14, 15]. The melting point of Cr2S3 is 1350 ∘C and this is much higher than the formation temperature of YBa2Cu3O7−δ (∼ 900 ∘C). The transition temperature of YBa2Cu3O7−δ is around 92 K and this is well below the Curie temperature of Cr2S3. Hence, it is interesting to study the interaction of YBa2Cu3O7−δ superconductor with ferrimagnetic Cr2S3.

The objectives of this work were to study the properties of YBa2Cu3O7−δ as the amount of ferrimagnetic Cr2S3 is increased. The AC susceptibility and electrical resistivity of YBa2Cu3O7−δ(Cr2S3)x with x = 0 to 0.3 wt% as a function of temperature were measured. The structure, microstructure, and the chemical composition of the composite are also reported in this paper. The result from this work was compared with previous reports. Table 1 shows the effect of various compounds on the transition temperature of YBa2Cu3O7−δ from previous works as well as this work. In Table 1, samples with x = 0 showing the maximum Tc indicated that the transition temperature was suppressed for the respective additions. Antiferromagnetic material such as FeF2 [9], ferrimagnetic such as Cr2S3, and CdTe [10] which is diamagnetic [16, 17], enhanced Tc of YBa2Cu3O7−δ while ferromagnetic materials such as Co3O4 [8] and CoFe2O4 [11] suppressed the transition temperature.

2 Materials and Methods

The solid-state reaction method was used to prepare the samples. High purity (> 99.9 %) Y2O3, BaO or BaCO3 and CuO was mixed with starting chemical formula YBa2Cu3O7−δ and heated at 900 ∘C for over 24 h with intermittent grindings. Cr2S3 was then added to the resultant powders with chemical formula YBa2Cu3O7−δ(Cr2S3)x for x = 0, 0.05, 0.15, 0.2, and 0.3 wt%. The powders were pressed into pellets of about 12-mm diameter and 2-mm thickness and heated at 900 ∘C for 24 h.

The samples were characterized by x-ray diffraction (XRD) method to study the phase and structure using Bruker model D8 Advance diffractometer with CuKα source. The field emission scanning electron micrographs (FESEM) were recorded using a Merlin Gemini scanning electron microscope. The chemical composition of the samples was analysed by energy-dispersive x-ray analysis (EDX) using an Oxford Instrument analyser.

The dc electrical resistivity was measured using the four-probe method with silver paste contacts. A closed cycle refrigerator from CTI Cryogenics Model CSA 22 and a temperature controller from Lake Shore model 303 was used for low-temperature measurements. The onset transition temperature, Tc−onset, is the temperature where the resistivity starts to drop abruptly. The zero-resistance temperature, Tc−zero, is the temperature where the resistivity drops to zero.

An AC susceptometer from Cryo Industry model number REF-1808-AS was used to measure the complex susceptibility χ = χ′ + χ″. The frequency used was 295 Hz and applied magnetic field was H = 5 Oe. The Bean model was used to calculate the critical current density at the peak temperature Tp of χ” with formula Jc(Tp) = H/(lw)1/2, where H is the applied field and l and w are the dimensions of the cross section of the bar-shaped sample.

3 Results and Discussion

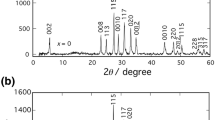

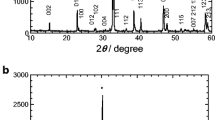

The XRD patterns of x = 0 and 0.05 wt% samples showed a single YBa2Cu3O7−δ phase with orthorhombic structure (Pmmm space group). The x = 0.1, 0.2 and 0.3 wt% samples showed the YBa2Cu3O7−δ phase as well as impurity peaks belonging to the Y2BaCuO5 (Y211) and Cr2S3 as indicated by (*) and (#), respectively in Fig. 1. Other unmarked peaks observed in the x = 0.1, 0.2 and 0.3 patterns (Fig. 1) may be due to unreacted starting materials. At least 15 peaks were used to calculate the lattice parameters. The lattice parameters a, b andc and the unit cell volume V did not show systematic change (Table 1). The lattice parameters of the non-added YBa2Cu3O7−δ are a = 3.829(1) Å, b = 3.881(1) Å and c = 11.696(2) Å. The ratio of the lattice parameter c/a and c/b indicates the internal lattice strain. The ratio of c/a ∼ 3.06 and c/b ∼ 3 for all samples. Hence, no changes in the internal lattice strain is expected in these samples.

The grain size of the samples decreased as Cr2S3 was added. Figure 2a shows the SEM micrograph of the non-added sample and Fig. 2b shows the micrograph for x = 0.05 sample. The x = 0 sample showed slightly elongated grains of more than 2 μ m and the x = 0.05 sample showed irregular grains of around 1 μ m with vivid grain boundaries. Hence, Cr2S3 reduced the grain size of YBa2Cu3O7−δ. Figure 3 shows the EDX spectra of the x = 0 and 0.05 samples with approximate elemental weight percent of the related elements. The presence of Cr and S with the approximate weight percent are shown in the EDX spectrum (Fig. 3b).

The electrical resistivity versus temperature curves of all samples are shown in Fig. 4a, b. The x = 0 and 0.05 samples showed metallic normal state behaviour with Tc−onset = 92 and 93 K, respectively. The x = 0.1, 0.2 and 0.3 samples showed a semiconducting-like normal-state behaviour. Tc−onset for the x = 0.1, 0.2 and 0.3 samples was 93, 92 and 89 K, respectively. Among all samples, the x = 0.05 showed the highest Tc−onset (93 K) and Tc−zero (89 K). Tc−zero does not show systematic change; however, all samples showed a consistent and systematic change in Tc−onset with Cr2S3 content. The transition width ΔTc is 4 K for x = 0.05 sample and 32 K for x = 0.2 sample. The large ΔTc in the x = 0.2 sample was probably specific to this sample and may be due to the large variation of the transition temperature of individual superconducting grains as Cr2S3 was increased. The room-temperature resistivity decreased for x = 0.05 sample and then increased with further Cr2S3 additions. Sample with x = 0.3 wt% showed the highest room-temperature resistivity which was 8.1 × 10− 5 Ω m. The increase in electrical resistivity indicated a decrease in the carrier concentration in the samples. The x = 0.05 sample showed the lowest electrical resistivity (i.e., the highest carrier concentration) resulting in the highest transition temperature which is probably due to the optimization of the oxygen content in this sample. The electrical resistivity at room temperature, Tc−onset and Tc−zero are shown in Table 2.

The AC susceptibility versus temperature curves for the x = 0, 0.05 and 0.1 samples are shown in Fig. 5a, b. The sudden decrease in the real part χ′ of the complex susceptibility (χ = χ′ + iχ″) is the transition temperature, Tcχ’ which is due to diamagnetic shielding and can be identified as the onset of bulk superconductivity. The peak temperature (Tp) in the imaginary part of the susceptibility χ” represents AC losses. The weaker the pinning, the larger Tp shift to lower temperature. Below Tp the amplitude of χ″ falls due to the decrease in flux penetration. The x = 0 and 0.05 samples showed the highest \(T_{\mathrm {c}\chi ^{\prime }}\) which was 93 K. The x = 0.1, 0.2 and 0.3 samples showed \(T_{\mathrm {c}\chi ^{\prime }}= 90\), 84 and 86 K, respectively. Tp was highest for x = 0.05 indicating that Cr2S3 improved the flux pinning for lower value of x. Higher Cr2S3 content decreased Tp severely to 53–58 K in the x = 0.1, 0.2 and 0.3 samples indicating flux penetration only occurred at lower temperatures The transport critical current density at the peak temperature Jc(Tp) was around 18–22 A/cm2. Table 2 shows the values for \(T_{\mathrm {c}\chi ^{\prime }}\), Tp and Jc(Tp).

Figure 6 shows Tc−onset, Tp and room-temperature electrical resistivity versus Cr2S3 content. This graph shows that the optimal superconducting properties in terms of Tc−onset,Tp and room temperature resistivity were observed for the x = 0.05 sample. This sample also showed the lowest electrical resistivity and narrowest transition width (ΔTc = 4 K) compared to other samples. This work showed that a small amount of ferrimagnetic Cr2S3 addition improved the superconducting properties. This result is similar to the work reported on YBa2Cu3O7−δ added with antiferromagnetic FeF2 where the optimal addition is for x = 0.03 wt%. Changes in the transition temperature of our samples are not due to variation in the internal lattice strain because the lattice ratio (c/a ∼ 3.06 and c/b ∼ 3) did not change with Cr2S3 addition.

In Table 1, the suppression of transition temperature with ferromagnetic-added sample was due to the exclusive nature of superconductivity and magnetism. Ferromagnetic materials such as CoFe2O4 [11] and Co3O4 [8] may act as effective pair breaking centre leading to the suppression of the transition temperature. However in ferrimagnetic (this work), antiferromagnetic [9] and diamagnetic [10] material-added samples, the enhancement of Tc−onset and Jc was due to the improved grain coupling and carrier density and these materials may not be as effective pair breaking centre as ferromagnetic materials.

In conclusion, the effects of Cr2S3 on YBa2Cu3O7−δ have been investigated. Ferrimagnetic Cr2S3 enhanced the transition temperature for low addition level (x = 0.05). The peak temperature of χ” (Tp) and critical current density Jc(Tp) increased as Cr2S3 was added (x = 0.05) indicating improved flux pinning and enhanced intergrain coupling. The grain size was reduced as Cr2S3 was added. The presence of Cr2S3 peaks in the XRD patterns showed that it exists as a separate phase and did not enter the YBa2Cu3O7−δ lattice. By comparing with previous works, in general, ferromagnetic materials suppressed Tc but ferrimagnetic, antiferromagnetic and diamagnetic materials enhanced Tc for low-level addition. These results can be useful in determining the appropriate addition to improve the superconducting properties of YBa2Cu3O7−δ. Further works on other materials can be useful in determining the effects of magnetism on HTSC in general.

References

Lyuksyutov, I.F., Naugle, D.G.: Mod. Phys. Lett. B 13, 491 (1999)

Lyuksyutov, I.F., Naugle, D.G.: Proceeding of SPIE,, p. 376 (2000)

Lau, K.T., Yahya, S.Y., Abd-Shukor, R.: J. Appl. Phys. 99, 123904 (2006)

Kong, W., Abd-Shukor, R.: J. Supercond. Nov. Magn. 23, 257 (2010)

Agail, A., Abd-Shukor, R.: Appl. Phys. A 112, 501 (2013)

Zhang, Y.F., Izumi, M., Xu, Y., Gao, T., Kimura, Y.: J. Phys.: Conf. Ser. 234, 012052 (2010)

Al-Sharabi, A., Tajuddin, S.Y., Saffiey, A.D.F.W., Jasman, S., Alwi, H.A., Jumali, M.H., Abd-Shukor, R.: Sains Malaysiana 45, 1959 (2016)

Salama, A.H., El-Hofy, M., Rammah, Y.S., Elkhatib, M.: Adv. Nat. Sci.: Nanosci. Nanotechnol. 7, 015011 (2016)

Abd-Shukor, R., Kong, I., Lim, E.L., Mizan, N.A., Alwi, H.A., Jumali, M.H., Kong, W.: J. Supercond. Nov. Magn. 25, 957 (2012)

Nur-Akasyah, J., Nur-Shamimie, N.H., Abd-Shukor, R.: J. Supercond. Nov. Magn. 30, 3361 (2017)

Sahoo, M., Behera, D.: J. Material Sci. Eng. 1, 115 (2012)

Wei, K., Ing, K., Hamdan, M.S., Radiman, S., Abd-Shukor, R.: J. Supercond. Nov. Magn. https://doi.org/10.1007/s10948-017-4536-0 (2018)

Dadras, S., Dehghani, S., Davoudiniya, M., Falahati, S.: Mater. Chem. Phys. 193, 496 (2017)

van Bruggen, C., Vellinga, M.B., Haas, C.: J. Solid State Chem. 2, 303 (1970)

Maignan, A., Guilmeau, E., Gascoin, F., Bréard, Y., Hardy, V.: Sci. Technol. Adv. Mat. 13, 053003 (2012)

Begam, M.R., Rao, N.M., Joshi, G.M., Kaleemulla, S., Shobana, M., Krishna, N.S., Kuppan, M.: Adv. Condens. Matter Phys. 2013, 218659 (2013)

Shaldin, Yu.V.: Inorg. Mater. 37, 560 (2001)

Acknowledgements

This research was supported by Universiti Kebangsaan Malaysia under grant number AP-2015-006 and the Ministry of Higher Education of Malaysia under grant no. FRGS/1/2017/STG02/UKM/01/1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nur-Syazwani, A.C.A., Abd-Shukor, R. Effect of Ferrimagnetic Cr2S3 on AC Susceptibility and Superconducting Properties of YBa2Cu3O7−δ. J Supercond Nov Magn 32, 863–868 (2019). https://doi.org/10.1007/s10948-018-4801-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-018-4801-x