Abstract

Barium hexagonal ferrites doped with La3+, Ba1−x La x CoTiFe10O19 (x = 0.10, 0.15, 0.20), were prepared by sol-gel combustion method. The structure, magnetic properties, and microwave absorption of the samples were investigated. The X-ray diffraction patterns of the doped ferrites confirmed the formation of the M-type barium ferrite, and no other impurities could be found. The electromagnetic parameter spectra showed that The La3+ ions doped in the ferrite improved complex permittivity and permeability so that microwave absorption was enhanced. The minimum reflection loss of −39.15 dB was obtained for sample x = 0.20 with thickness of 2.4 mm, and the maximum bandwidth of RL <−10 dB can reach to 11.5 GHz when the thickness is 2.0 mm.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rapid developments of electrical and electronic devices cause a growing request in microwave absorbing materials, which could be used extensively in commerce, industry, and defense applications [1–6]. Due to their strong absorption of electromagnetic (EM) wave, the microwave absorbers can minimize various EM radiations and interferences. In this way, an appropriate microwave absorber can eliminate the excessive electromagnetic waves to ensure the people’s health and the undisturbed functioning of equipment. Moreover, the appropriate absorbers can help military aircrafts and vehicles to avoid detection by the radar in defense and aerospace industries, as the application of microwave absorbing coating on the exterior surfaces of military equipments. However, owing to the advancing technology, the EM wave absorbing materials are expected to have broad bandwidth, minimum reflection loss (RL), and light weight (or small thickness) in recent years [7]. Therefore, broadening bandwidth and minimizing reflection loss have been the vital problem for microwave absorbers.

Among the microwave absorbing materials, M-type barium hexagonal ferrite (BaFe12O19, BaM) has generated considerable recent research interests because of its low cost, good stability, large magnetocrystalline anisotropy, high natural resonance frequency (about 47.6 GHz), and excellent magnetic loss [7–10]. At the microwave band, the microwave attenuation properties of BaM are closely related to the magnetic losses which result mainly from the resonance absorption of moving magnetic domains in lower frequency and the spin relaxation of magnetization in higher frequency. It has been known that the microwave absorption performance can be improved by choosing suitable cations to substitute the Fe3+ in BaM. M. K. Tehrani et al. [11] have confirmed that the bandwidth of EM wave absorption for BaM can be broadened when the Fe3+ was partially replaced by metal cations (Mg2+, Mn2+, Co2+) and Ti4+. C. S. Dong et al. [12] have demonstrated that the minimum reflection loss of BaCo0.3Ti0.3 Fe11.4O19 can reach −47 dB at the thickness of 0.8 mm. X. Tang and his co-workers [13] have reported that the non-stoichiometric Ni2+-Ti4+ can improve the absorption performance of BaM and the natural resonance frequency of the doped ferrite shift to X-band (8–12 GHz). Thus, using the right cations to substitute BaM is significant for the excellent microwave absorption properties of the absorbing materials. However, influence of substituting Ba2+ on properties of barium hexaferrite has been rarely reported.

In the current work, the La3+-doped ferrites Ba1−x La x CoTiFe10O19 were synthesized and the phase composition was confirmed. Moreover, the magnetic and microwave absorption properties were investigated in the frequency range of 2–18 GHz.

2 Experimental

The powders of Ba1−xLaxCoTiFe10O19 (x=0.10, 0.15, 0.20) were synthesized via the sol-gel combustion method. As starting materials, stoichiometric amount of Fe(NO3)3⋅9H2O, Ba(NO3)2, Co(NO3)2⋅6H2O, Ti(OC4 H 9)4, and La(NO3)3⋅6H2O were dissolved in deionized water by stirring it constantly using a magnetic stirrer. After dissolved completely, appropriate citric acid solution was added into the solution, and then ammonia solution was added dropwise with vigorous stirring to maintain the pH value of the solution at 7. Subsequently, the neutralized solution was heated at 100∘C with continuous magnetic stirring to obtain the dried gel. With further heating, the dried gel would burn up in a self-propagating combustion manner, and some brown precursors could be obtained. Finally, the precursors were pre-heated at 450∘C for 2 h and then calcined at 1100∘C for 4 h to obtain the ferrite powders.

The phase composition of ferrites was identified by the X-ray diffractometer (XRD; PANalytical X’Pert PRO), with Cu K α radiation (λ = 1.540598 Å) in the range of 20∘–75∘. The morphology was observed by using the field emission scanning electron microscopy (FE-SEM; Zeiss Ultra 55). The vibrating sample magnetometer (VSM) was used to measure magnetic properties of the ferrites at room temperature. The resulting ferrite powders were mixed with paraffin wax at ratio of 6:1 and then compacted into a circular cylinder with the inner diameter of 3.04 mm, the outer diameter of 7.0 mm. The electromagnetic parameters of composite samples in the frequency range of 1–18 GHz were measured by network analyzer (Agilent Technologies, E8363A) using a coaxial method.

3 Results and Discussion

The X-ray diffraction patterns of Ba1−x La x CoTiFe10O19 (x=0.10, 0.15, 0.20) are presented in Fig. 1. The results show that all the samples have similar diffraction patterns representing a single phase with hexagonal crystal structure and no second phase can be found, indicating that the La3+ can enter the lattice and do not affect the crystal structure of hexagonal barium ferrite. However, the substitution of Ba2+ with La3+ results in a slight change of diffraction peak position due to the slight change in lattice parameters of the respective compounds. The lattice parameters (a and c) are tabulated in Table 1 and which were calculated by the following formula:

where (h k l) is the Miller indices, and d is the crystal face distance. It can be seen that the value of a decreases little, the value of c decreases from 23.423 to 23.136 Å and the ratio of c/a decreases from 3.954 to 3.913 with increasing x. The variations of lattice parameters can be attributed to partial replacement of Ba2+ (ionic radius 149 pm) with the smaller La3+ (ionic radius 117 pm) ions.

A representative scanning electron micrograph (SEM) for Ba0.8La0.2CoTiFe10O19 is shown in Fig. 2. The micrograph clearly illustrates hexagonal structure. From the image, it can be seen that the particles appear fine grain growth with the grains size varying from 100 to 300 nm. The micrographs of other samples also show similar features and no obvious microstructure change is seen with La3+ substitution.

The magnetic hysteresis loops for Ba1−x La x CoTiFe10O19 with different values of x are shown in Fig. 3. The saturation magnetization M sand coercivity H c are plotted in Fig. 4 as a function of La3+ substitution. The hysteresis loops show that all the samples exhibit typical characteristics of soft magnetic materials. The value of M s increases from 57 to 66 emu/g with increasing La3+ amount as revealed in Fig. 4. On the contrary, the value of H cdecreases with increasing x. These can be explained by the ferromagnetic theory of ferrite. The increase of M s is ascribed to the occupation of La3+ in the lattice site of Ba2+ enhancing molecular magnetic moment, and the decease of H c is due to the weakened uniaxial magnetocrystalline anisotropy of the barium ferrite for La3+ substitution being consistent with variation of lattice parameter c/a.

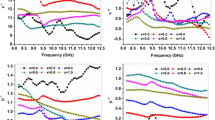

In order to understand the possible microwave absorption mechanism, the complex permittivity (ε r = ε ′−j ε ″) and complex permeability (μ r = μ ′−j μ ″) were investigated. The complex permittivity and complex permeability can be used to represent the dielectric and dynamic magnetic properties of materials. For microwave absorber, the real part of complex permittivity and permeability is proportional to storage capability of electric and magnetic energy when the material is under an applied electric or magnetic field. The imaginary part represents the loss of electric and magnetic energy.

Figure 5 shows the frequency dependence of the real and imaginary parts of the permittivity for Ba1−x LaxCoTiFe10O19 samples over the frequency range 1–18 GHz. From Fig. 5a, we can see that the real part (ε ′) of complex permittivity exhibits indistinctive variation with frequency for all compositions; this is a normal dielectric behavior of ferrites, which was consistent with reported before [14]. However, the value of ε ″ shows strong frequency dispersion, which can be attributed to intrinsic electric dipole polarization and interfacial polarization. Furthermore, with the amount of doped La3+ increasing, the average value of ε ′ and ε ″ rises continuously. In barium hexaferrites, Ba2+ are partially replaced when La3+ enter into the lattice, resulting in partial conversion of Fe3+ into Fe2+ in order to keeping charge equilibrium [15]. Since dielectric polarization mechanism is closely associated with electron hopping mechanism in ferrites, the greater electron hopping chance between Fe3+ and Fe2+ is the higher the permittivity would be [16]. As a result, the real part of complex permittivity and imaginary part increase with more addition of La3+ amount.

Figure 6 shows the frequency dependence of the real (μ ′) and imaginary (μ ″) parts of the permeability for Ba1−xLaxCoTiFe10O19. All curves of μ ″ vs. frequency had a broad peak corresponding to natural ferromagnetic resonance (f r), and the peak shift to lower frequency with increasing amount of doped La3+. This can be ascribed to weakening uniaxial magnetocrystalline anisotropy. Above f r, the real parts of permeability falls sharply to unity. As we mentioned above, the partial Fe3+ ions convert to Fe2+ ions with increase in La3+ content. It is well known that the static magnetic moment of Fe2+ (4 μ B) is lower than that of Fe3+ (5 μ B), resulting in overall magnetic interaction weakening in ferrites, thereby decreasing the values of μ ′ and μ ″ with increasing La3+ content. However, as shown in permeability spectra, the values of μ ′ and μ ″ increase slightly with increasing La3+ content instead of decreasing. According to Snoek’s law [17], a change in .μ due to variations in material structure is followed by an opposite change in resonance frequency (f r), i.e., (μ s−1)f r = (2/3)(γ4π M s), where 4 π M s is the saturation magnetization, γ is gyromagnetic ratio. As shown in hysteresis loops above, M s is enhanced with increasing La3+ content. Therefore, the value of μ ′ increases with more addition of La3+ amount below f r.

From the complex relative permittivity and the complex relative permeability, the microwave absorption performance of Ba1−x La x CoTiFe10O19 composites with paraffin wax was investigated. The reflection loss (RL) can be calculated from the relative complex permeability and permittivity with a given frequency range and a given absorber thickness (d) by the following equation [18]:

Z i n is determined as

where Z i n is the input impedance of absorber, ε rand μ r are complex permittivity and permeability of the composite, respectively, f is the microwave frequency, and c is the velocity of light in free space.

The frequency dependences of RL for all composition with different thicknesses are exhibited in Fig. 7. It is clear that the matching frequency decreases with increase in value of x. As shown in reflectivity curves, two absorption peaks with significantly different values and positions appear for samples with x= 0.15 and x=0.20 at all different thickness. This dispersion can be attributed to domain wall motion at the lower frequency and spin resonance at the higher frequency. However, there is only one absorption peak for composition x = 0.10 due to its peak from spin resonance beyond measuring frequency. For the sample x = 0.10, the matching frequencies are equal to 14.7 GHz with a minimum RL of −28.36 dB, and the corresponding matching thickness is 2.0 mm. For the sample x = 0.15, the RL values of −29.84 and −21.85 dB were achieved in the matching frequencies of 9.16 and 15.6 GHz, respectively. The corresponding value of matching thickness is 2.0 mm. Sample x=0.20 with matching thickness of 2.4 mm exhibits a minimum RL of −39.15 dB at 7.41 GHz. It is notable that the bandwidth of RL< −10 dB covers entirely X-band (8˜12 GHz) and Ku-band (12˜18 GHz) for sample x = 0.20 when matching thickness is 2.0 mm. The obtained results indicate that La3+ substituting not only enhance microwave attenuation of barium hexaferrites but also broaden its bandwidth.

4 Conclusions

In conclusion, Lanthanum ion-doped barium hexaferrites Ba1−x La x CoTiFe10O19 (x = 0.10, 0.15, 0.20) have been fabricated successfully by the sol-gel combustion method. The high-frequency magnetic and dielectric properties can be enhanced as addition of La3+. Increasing of La3+ content leads to a significant increase in complex permittivity and permeability, while the resonance frequency is shifted to low frequency. Thus, with the incorporation of La3+ the absorbing peak moved to the lower frequency and the microwave absorption performance is significantly improved. The sample Ba0.8La0.2CoTiFe10O19 has the best microwave absorption performance. The maximum RL of −39.15 dB can be achieved at 7.41 GHz when the matching thickness is 2.4 mm. Furthermore, the maximum bandwidth of RL< −10 dB can reach to 11.5 GHz (6.5˜18 GHz) when the matching thickness is 2.0 mm.

References

Yang, H., Cao, M.S., Y. L, Shi, H.L., Hou, Z.L., Fang, X.Y., Jin, H.B., Wan, W.Z., Yuan, J.: Enhanced dielectric properties and excellent microwave absorption of SiC powders driven with NiO nanorings. Advance Optical Materials 2, 214–219 (2014)

Wang, Y., Huang, Y., Ding, J.: Synthesis and enhanced electromagnetic absorption properties of polypyrrole–BaFe12 O19/Ni0.8Zn0.2Fe2O4 on graphene nanosheet. Synth. Met. 196, 125–130 (2014)

Singh, A.P., Mishra, M., Sambyal, P., Gupta, B.K., Singh, B.P., Chandrad, A., Dhawan, S. K.: Encapsulation of γ-Fe2O3 decorated reduced graphene oxide in polyaniline core–shell tubes as an exceptional tracker for electromagnetic environmental pollution. J. Mater. Chem. A 2, 3581–3593 (2014)

Baniasadi, A., Ghasemi, A., Nemati, A., Ghadikolaei, M.A., Paimozd, E.: Effect of Ti–Zn substitution on structural, magnetic and microwave absorption characteristics of strontium hexaferrite. J. Alloys Compd. 583, 325–328 (2014)

Wang, Y.M., Wang, L.D., Wu, H.J.: Enhanced microwave absorption properties of α-Fe2O3-filled ordered mesoporous carbon nanorods. Materials 6, 1520–1529 (2013)

Liu, P.B., Huang, Y., Wang, L., Zhang, W.: Preparation and excellent microwave absorption property of three component nanocomposites: polyaniline-reduced grapheme oxide-Co3O4 nanoparticles. Synth. Met. 177, 89–93 (2013)

Kong, L.B., Li, Z.W., Liu, L., Huang, R., Abshinova, M., Yang, Z.H., Tang, C.B., Tang, P.K., Deng, C.R., Matitsine, S.: Recent progress in some composite materials and structures for specific electromagnetic applications. Int. Mater. Rev. 58, 203–259 (2013)

Li, L.C., Chen, K.Y., Liu, H., Tong, G.X., Qian, H.S., Hao, B.: Attractive microwave-absorbing properties of M-BaFe12O19 ferrite. J. Alloys Compd. 557, 11–17 (2013)

Zhang, W.J., Bai, Y., Han, X., Wang, L., Lu, X.F., Qiao, L.J.: Magnetic properties of Co-Ti substituted barium hexaferrite. J. Alloys Compd. 546, 234–238 (2013)

Xu, F.F., Ma, L., Gan, M.Y., Tang, J.H., Li, Z.T., Zheng, J.Y., Zhang, J., Xie, S., Yin, H., Shen, X.Y., Hu, J.L., Zhang, F.: Preparation and characterization of chiral polyaniline/barium hexaferrite composite with enhanced microwave absorbing properties. J. Alloys Compd. 593, 24–29 (2014)

Tehrani, M. K., Ghasemi, A., Moradi, M., Alam, R. S.: Wideband electromagnetic wave absorber using doped barium hexaferrite in Ku-band. J. Alloys Compd. 509, 8398–8400 (2011)

Dong, C.S., Wang, X., Zhou, P.H., Liu, T., Xie, J.L., Deng, L.J.: Microwave magnetic and absorption properties of M-type ferrite BaCo x Ti x Fe12−2x O19 in the Ka band. J. Alloys Compd. 354, 340–344 (2014)

Tang, X., Yang, Y.G., Hu, K.: Structure and electromagnetic behavior of BaFe12−2x(Ni0.8Ti0.7)xO19−0.8x in the 2–12 GHz frequency range. J. Alloys Compd. 477, 488–492 (2009)

Meng, P.Y., Xiong, K., Wang, L., Li, S.N., Cheng, Y.K., Xu, G.L.: Tunable complex permeability and enhanced microwave absorption properties of BaNi x Co1−x TiFe10O19. J. Alloys Compd. 628, 75–80 (2015)

Meena, R.S., Bhattachrya, S., Chatterjee, R.: Complex permittivity, permeability and wide band microwave absorbing property of La3 + substituted U-type hexaferrite. J. Magn. Magn. Mater. 322, 1923–1928 (2010)

Xu, J.J., Yang, C.M., Zou, H.F., Song, Y.H., Gao, G.M., An, B.C., Gan, S.C.: Electromagnetic and microwave absorbing properties of Co2Z-type hexaferrites doped with La3 + . J. Magn. Magn. Mater. 321, 3231–3235 (2009)

Lagarkov, A.N., Rozanov, K.N.: High-frequency behavior of magnetic composites. J. Magn. Magn. Mater. 321, 2082–2092 (2009)

Ren, X., Xu, G.: Electromagnetic and microwave absorbing properties of NiCoZn-ferrites doped with La3+. J. Magn. Magn. Mater. 354, 44–48 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, Y., Ren, X. Enhanced Microwave Absorbing Properties of La3+ Substituting Barium Hexaferrite. J Supercond Nov Magn 29, 803–808 (2016). https://doi.org/10.1007/s10948-015-3355-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-015-3355-4