Abstract

We report on magnetic behavior of Y 1−xLu xBa 2 Ca 3 O 7−δ (x= 0, 0.5) samples synthesized by a modified melt powder melt growth (MPMG) method at three different sintering temperatures (920, 930, 940 ∘C). Isothermal magnetization measurements were done as a function of magnetic field at 20 and 77 K upon zero-field cooling (ZFC) process. The critical current densities as a function of magnetic field have been estimated from M–H hysteresis loop. Partial Lu substitution for Y on YBCO superconductors improved significantly the bulk critical current density, which is confirmed by field-cooled magnetization and AC susceptibility measurements. Magnetic relaxation measurement has been carried out in remanent magnetization regime. AC susceptibility measurements have been performed as a function of temperature to determine the transition temperature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the discovery of Y–Ba–Cu–O compound system, it has been widely studied for improving the superconducting properties by many researchers. A great number of papers have been published on adding elements in Y123 system for increasing the critical temperature (T c) and critical current density (J c) values of YBCO samples. It was found that Y can be replaced with various rare earth elements (Re) [1–16], including Lu [1–4, 16–18] without any significant change in T c for Re–Ba–Cu–O (123) system (Re = La, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu, from the largest to the smallest radius). Re elements substitute for both Y and Ba sites in Y123 compounds. In the case of trivalent Re ions substitution for Y 3+ and Ba 2+, there is a strong correlation between the solution energies and the size of dopant, the solution energy increases with increasing ionic radius. The Re ions towards the Lu end of the lanthanide series are comparable in size to Y 3+, and a degree of mixing among the yttrium and barium sites might be expected to occur [17]. Moreover, Lu cannot wholly substitute for Y [2, 3], probably its small radius, but it can be incorporated along with co-substitution of a small amount of Sr for Ba [18]. Raychaudhuri et al. [4] reported that partial Lu-substituted YBCO (Y 0.75Lu 0.25Ba 2Cu 3 O 7) sample shows much more Meissner effect than pure YBCO measured by DC magnetic susceptibility data at 20 K. It was also reported that after the further annealing treatment, the sample doped with 0.5 wt.% Lu oxide, prepared by top-seeding melt texture growth process, exhibits better critical current density than the undoped Y123 sample [16]. Ozturk et al. [19] reported the effect of Lu doping on the superconducting parameters such as lattice constants, transition temperature, and critical current density in Y 1−xLu xBa 2Cu 3 O y superconductors prepared by the conventional solid-state reaction method. In their work, the highest critical current density measured at 20 K was observed in the sample where x = 0.5 among the other dopant amount. Although cationic substitutions have been studied quite a lot lately, Lu is not the most usual dopant, and it is of interest to investigate further the effect of Lu in YBCO ceramic superconductors on various physical parameters.In this work, we investigated the effect of Lu doping (x = 0.5) in Y 1−xLu xBa 2Cu 3 O y ceramic superconductors prepared by modified melt powder melt growth (MPMG) method on the transition temperature and critical current density. In our exploration, we have selected three different sintering temperatures in the heat treatment while keeping Lu amount fixed as x = 0.5 in Y 1−xLu xBa 2Ca 3 O 7−δ since it was the best dopant amount in our previous work [19].

2 Experimental Procedure

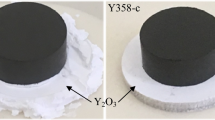

The superconducting samples studied in this paper were prepared by the MPMG method described in ref. [20] changing the final temperature in the quenching process from room temperature to liquid N 2 temperature (77 K); hence, we call it modified MPMG method. Powders of Y 2 O 3, BaCO 3, CuO, and Lu 2 O 3 in the stoichiometric ratios of 1:2:3 compositions were thoroughly mixed in the appropriate amounts to prepare precursor YBCO bulk materials. After the mixed powders had been well-reground using a planar ball mill machine model of Retsch PM100, they were put into alumina crucible and calcined at 900 ∘ C for 24 h in air in an 818 Eurotherm Controller/Programmer Muffle furnace. After regrinding the powders, the calcination procedure was repeated at 910 ∘ C for 12 h. Then, the material in platinum crucible was dwelled at 1,460 ∘ C for 5 min and then it was rapidly put into a liquid nitrogen Dewar (− 196 ∘ C) [21–22]. We note that temperature change in the quenching process is increased by 200 K compared with the same quantity in ref [20]. The molten material was reground well and then it was compressed into pellet form using a pressure of 300 MPa on a 13-mm diameter. This material was sintered in a tube furnace in air at temperatures of 920, 930, and 940 ∘ C. We have investigated the effects of the sintering temperature and Lu doping on the magnetic behavior of MPMG Y 1−xLu xBa 2Ca 3 O 7−δ samples. Labeling of the samples is listed in Table 1.

Magnetization measurements were done using VSM option of a Quantum Design Physical Property Measurement System (PPMS) by the sweep rate of 50 Oe/s, upon zero-field cooling (ZFC) process. The magnetic relaxation rate was obtained by measuring the time decay of the magnetic moment for about 180 s as described by van Dalen et al. [23]. The first data point was taken after 33 s to avoid deviation from a pure logarithmic decay. Superconducting transition temperatures were obtained by means of the AC Measurement System (ACMS) option of the Quantum Design PPMS. The signals due to the in-phase and out-of-phase magnetization were taken simultaneously. The transition temperatures and the dimensions of the samples are listed in Table 1.

3 Results and Discussions

In Fig. 1, we display the isothermal magnetization curves at 20 K (a) for sample A1 and sample A2, (b) for sample B1 and sample B2, and (c) for sample C1 and sample C2, with the applied field H a, increasing from zero to a maximum value of 30 kOe, then decreasing to zero, reversing in sign to a maximum negative value of 30 kOe, and finally increasing again to 30 kOe. Each curve is called the envelope of the major hysteresis loop. It is well-established that the width and behavior of this hysteresis loop is the manifestation of the bulk critical current density in type II superconductors and its dependence on the magnetic flux density. The wider the hysteresis loop, the higher the bulk critical current density will be. Hence, it can readily be seen from Fig. 1 that Lu doping increased the bulk critical current density at 20 K for three different sintering temperatures. We note that the first penetration field H ∗ is defined as the field at which the virgin curve merges the major hysteresis envelope. H ∗ is proportional to the critical current density and the dimension of the sample perpendicular to the applied field. The penetration field for Lu-doped YBCO samples (A2, B2, and C2) is larger than for the corresponding undoped YBCO samples (A1, B1, and C1). Therefore, we can extract the same conclusion that Lu doping in YBCO increased the bulk critical current density at 20 K for three different sintering temperatures.

Figure 2 shows the isothermal magnetization curves at 77 K, (a) for sample A1 and sample A2, (b) for sample B1 and sample B2, and (c) for sample C1 and sample C2, with the applied field H a, increasing from zero to a maximum value of 20 kOe, then decreasing to zero, reversing in sign to a maximum negative value of 20 kOe, and finally increasing again to 20 kOe. It is also well-known that in some type II superconductors there exists Meissner current circulating along the periphery of the sample, which shifts the hysteresis loop to diamagnetic quadrant [24]. In our samples studied, we have seen this effect indicating that there exists Meissner current in addition to bulk critical current. To explore the effect of Lu doping in YBCO on the Meissner flux expulsion, we have measured field-cooled magnetization M FC as a function of temperature (Figs. 3, 4 and 5).

We note that M–H loop is shifted to the diamagnetic quadrant which manifests the existence of Meissner surface current in the samples. The existence of the Meissner current can also be confirmed from the data of field-cooled (FC) magnetization M FC (see Figs. 3–5). In the field-cooled magnetization process, as T descends below T c, the expulsion of flux lines, arising from their mutual repulsion, will be opposed by pinning forces in the body of the specimen. Hence, the magnitude of the diamagnetic signal depends on the temperature-dependent critical current density as well as the equilibrium Meissner surface current. As the temperature decreases, some of the flux lines will be expelled from the sample. The larger the pinning strength hence the critical current density J c is, the smaller the flux expulsion will be, i.e., the more magnetic flux will be trapped in FC process. This can be readily seen by the inspection of flux density profile shown schematically in Fig. 6. For the high J c sample (see Fig. 6b), the flux density gradient will be steeper than that for the low J c sample (see Fig. 6a). Therefore, a small diamagnetic signal in the field-cooled magnetization measurement is an indication of high J c of the samples. In the light of this discussion and from the inspection of Figs. 3–5, it can be concluded that Lu doping in YBCO increased the critical current density J c and sample C2 has the highest J c among the others.

The configurations of the magnetic flux density, which are encountered as the temperature is decreased (T1 >T2 >T3) during the field-cooling process at a selected magnetic field, where the horizontal axis represents the distance from the center to the surface of the cylinder. As the temperature decreases, flux shielding Meissner current and flux holding bulk current increases, resulting in diamagnetic signal or negative magnetization. The dashed area represents the flux expelled during the decrease of temperature from T c to T 1

Regarding to transition temperature, it can readily be seen that Lu doping in YBCO decreased the transition temperatures consistent with the data obtained from AC susceptibility (see Fig. 9) listed in Table 1. Note that the measurements in Figs. 3b–5b are done at the field of H a = 500 Oe. Therefore, the transition temperatures measured by field-cooling process are T c (at 500 Oe) for each sample, which are less than those measured by AC susceptibility at 1 Oe.

We estimated the critical current density J c from magnetization curves using the following equation derived by Chen and Goldfarb [25] using Bean’s model for orthorhombic samples:

where a and b are half width of the infinite orthorhombic specimen (a ≤ b) and ΔM = (M ↑−M ↓) is the width of the major hysteresis loop. Figures 7 and 8 display the magnetic field dependence of the critical current density of Y 1−xLu xBa 2Ca 3 O 7−δ samples at 20 and 77 K, respectively. The values of the critical current density J c for Lu-doped YBCO samples (A2, B2, and C2) are higher than those for undoped YBCO samples (A1, B1, and C1, respectively) both for 20 and 77 K. For example, J c for C2 at 20 K and zero field is about six times larger than that for C1 (see Table 1). The field dependence of the critical current density for each sample at 77 K is larger than that at 20 K.

Figure 9 displays the AC susceptibility as a function of temperature at the field amplitude of 80 A/m and frequency of 1 kHz. The labeling of the samples is given in the legend. The onset of the superconducting transition has been used to determine T c listed in Table 1. The diamagnetic transition temperatures are decreased by Lu doping as reported in [19], where the samples were prepared by conventional solid-state reaction method. We note that the measurement of the remanent magnetization as a function temperature, upon FC process, yields the values of T c 2 or 3 K larger than those determined from AC susceptibility for each sample. For example, T c is 92.5 for sample C1, while T c is 91.5 K for sample C2. Raychaudhuri et al. [4] reported the transition temperature of the Y 0.75Lu 0.25Ba 2Cu 3 O 7 system was 89 K measured by four-probe method. Tarascon et al. [3] reported the transition temperature of the LuBa 2Cu 3 O 7−x system was 88.2 K by using resistive method. Our results are consistent with above-mentioned references in terms of decrease in T c by Lu doping in YBCO. We normalized experimental AC susceptibility data (both imaginary part χ′(T) and real part \(\chi \prime \)(T)) to the |\(\chi \prime \)|at the lowest temperature for each sample since the demagnetizing correction would cause \(\chi \prime \quad = \quad -\)1 for low enough temperature at low field amplitude. The granularity of the superconducting samples is manifested by two-step structure in the real part of the AC susceptibility. The sharpest transition is observed in sample C2, which is another evidence that sample C2 has the highest critical current density. We also note that for a given AC field amplitude, the peak temperature of the imaginary part gives consistent information for the comparison of the critical current density of the samples.

Magnetic relaxation or flux creep measurements are commonly used to study flux dynamics and estimate the pinning energy of superconductors. All the samples studied have shown magnetic relaxation. The typical time dependence of the magnetic relaxation is displayed in Fig. 10 in the remanent magnetization regime upon excursion of 30 kOe for samples C1 and C2, at 20 K. We note that a linear dependence of the magnetic decay on the logarithmic time scale was found [26–27]. We deduced the normalized relaxation rate S hence the activation energy from the curve of the M rem vs lnt. Thus, the effective pinning energy \(U_{0}^{\ast } \)defined by \(U_{0}^{\ast } =-\text {kT}/S.\;\mathrm {U}_{0}^{\ast } \) has been determined as 85.6 meV for sample C1 and 81.3 meV for sample C2 in the absence of magnetic field, where k is the Boltzman constant. Here, S is defined as

where M i is the initial magnetization; see ref. [28] for detailed discussion.

4 Conclusions

We have measured isothermal magnetization curves, field-cooled magnetization, and AC susceptibility of Y 1−xLu xBa 2Ca 3 O 7−δ (x = 0, 0.5) samples synthesized by a modified melt powder melt growth (MPMG) method at three different sintering temperatures (920,930,940 ∘ C). The critical current densities as a function of magnetic field have been estimated from M–H hysteresis loop. Partial Lu substitution for Y in YBCO superconductors improved the bulk critical current density obtained M–H hysteresis curves. This conclusion is drawn from (i) the width of the hysteresis loop, (ii) the comparison of the penetration fields, (iii) the comparison of field-cooled magnetization data, and (iv) AC susceptibility measurements. However, transition temperatures are slightly decreased by Lu doping in YBCO system as reported by some researchers [3–4, 19].

References

Hosoya S., Shamoto S., Onada M., Sato, M.: Jpn. J. Appl. Phys. 26, L325–L326 (1987)

Hor, P.H., Meng, R.L., Wang, Y.Q., Gao, L., Huang, Z.J., Bechtold, J., Forster, K., Chu, C.W.: Phys. Rev. Lett. 58, 1891–1894 (1987)

Tarascon, J.M., McKinnon, W.R., Greene, L.H., Hull, G.W., Vogel, E.M.: Phys. Rev. B36, 226–234 (1987)

Raychaudhuri, A.K., Sreedhar, K., Rajeev, K.P., Mohan Ram, R.A., Ganguly, P., Rao, C.N.R.: Philos. Mag. Lett. 56, 29–34 (1987)

Nakao, K., Tatsuhara, K., Miura, N., Uchida, S., Takagi, H., Wada, T., Tanaka, S.: J. Phys. Soc. Japan 57, 2476–2481 (1988)

Yong, F., Lian, Z., Pingxiang, Z., Keguang, W., Ping, J., Xiaozu, W., Changxun, L., Mianrong, X.: Supercond. Sci. Technol. 5, 431–434 (1992)

Yong, F., Lian, Z.: Phys. C 202, 298–302 (1992)

Yoo S.I., Sakai N., Takaichi H., Higuchi T, Murakami, M.: Appl. Phys. Lett. 65, 633–635 (1994)

Balkin D.K., McGinn, P.J.: Supercond. Sci. Technol. 7, 72–79 (1994)

Wei, C.D., Liu, Z.X., Gan, Z.Z.Phys. C 222, 267–270 (1994)

Murakami, M., Sakai, N., Higuchi, T., Yoo, S.I.: Supercond. Sci. Technol. 9, 1015–1032 (1996)

Murakami, M., Sakai, N., Higuchi, T., Chikumoto, N., Yoo, S.I.: J. Low Temp. Phys. 105, 1751–1760 (1996)

Higuchi, T., Yoo, S.I.: Phys. Rev. B 59, 1514–1527 (1999)

Carrillo, A.E., Rodriguez, Jr., Puig, P., Palau, T. , Obradors, A., Zheng, X., Welp, U., Chen, L., Veal, B.W., Claus, H., Crabtree, G.W.: Phys. C 372–376, 1119–1122 (2002)

Koutzarova, T., Nedkov, I., Ausloos, M., Cloots, R., Midlarz, T., Nogues, M.: Phys. Stat. Sol. (a) 191, 235–242 (2002)

Delorme, F., Harnois, C., Monot-laffez, I.: Phys. C 399, 129–137 (2003)

Islam M.S., Baetzold, R.C.: Phys. Rev. B 40, 10926–10935 (1989)

Badri, V., Varadaraju, U.V.: Mater. Res. Bull. 27, 591–602 (1992)

Ozturk, A., Duzgun, I., Celebi, S.: J. Alloy. Comp. 495, 104–107 (2010)

Murakami, M., Oyama, T., Fujimoto, H., Gotoh, S., Yamaguchi, K., Shiohara, Y., Koshizuaka, N., Tanaka, S.: IEEE Trans. Magn. 27(2), 1479 (1991)

Kütük, S., Bolat, S., Basoglu, M., Öztürk, K.: J. Alloy. Comp. 488, 425–429 (2009)

Çelebi, S., Kütük, S., Bolat, S., Öztürk, A.: Magnetization anisotropy in YBCO superconductors prepared MPMG method. J. Supercond. Novel Magn. 25, 267–271 (2012)

van Dalen, A.J.J., Koblischka, M.R., Kojo, H., Sawada, K., Higuchi, T., Murakami, M.: Superconduct. Sci. Technol. 9, 659 (1996)

Celebi S., Ozturk A., Cevik, U.: J. Alloy Comp. 288, 249–254 (1999)

Chen, D.-X., Goldfarb, R.B.: J. Appl. Phys. 66, 2489 (1989)

Anderson, P.W.: Phys. Rev. Lett. 9, 309 (1962)

Anderson, P.W., Kim, Y.B.: Rev. Mod. Phys. 36, 39 (1964)

Beasley, M.R., Labusch, R., Webb, W.W.: Phys. Rev. 181, 682 (1969)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uysal, E., Ozturk, A., Kutuk, S. et al. Effects of Lu Doping on the Magnetic Behavior of YBCO Superconductors Prepared by MPMG Method. J Supercond Nov Magn 27, 1997–2003 (2014). https://doi.org/10.1007/s10948-014-2560-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-014-2560-x