Abstract

The influence of addition of lead borate Pb(BO2)2 and boron oxide B2O3 on the phase evolution and superconducting properties of (Bi, Pb)-2223 HTSs synthesized by the solid-state reaction method in alumina crucibles has been studied. X-ray diffraction, resistivity, critical current density, and AC susceptibility measurements were performed on the prepared compounds. Obtained results have shown that boron-containing dopants lead to the drastic enhancement of the (Bi, Pb)-2223 phase formation. Boron-doped samples reveal a significant increase in both the zero resistivity temperature and transport critical current density compared to the undoped specimen. On the other hand, a high content of boron-containing dopants causes the appearance of a very low-T c 2201 phase and leads to a deterioration of coupling between superconducting grain boundaries. Obtained results could enable us to develop a cheap and energy efficient fabrication technology for nearly single (Bi, Pb)-2223 phase superconducting materials via heat treatment of boron-incorporated precursors in an alumina crucibles.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Material processing still remains the key factor in realizing the application potential of high-temperature superconductors. The synthesis of a nearly pure single-phase Bi-2223 HTS (T c≈110 K) is a time consuming and complicated process due to its slow formation kinetics and extremely narrow stability range, which results in the formation of intergrowth of the multiple phases coexisting with the 2223 phase [1–3]. Partial substitution of Bi by Pb is the most widely used method to enhance the formation of the Bi-2223 phase [4]. It was also found that the high-T c 2223 phase formation is very sensitive to the partial pressure of oxygen [5]. Thus, many factors, including the starting nominal compositions, preparation conditions, element of dopants, and their concentration, significantly influence the final physical properties of the samples.

According to our preliminary results, B2O3-added precursors drastically promote the formation of the (Bi, Pb)-2223 phase when heat treated in alumina crucibles [6]. No measurements of critical current densities (J cs) were performed in [6]. On the other hand, no studies on the effect of lead borate Pb(BO2)2 incorporation on the phase formation and critical current density in the (Bi, Pb)-2223 HTSs have been reported yet. On the basis of the above background, the purpose of the present paper is to investigate the impact of boron-containing dopants, Pb(BO2)2 and B2O3, on the formation, critical temperature, and transport critical current density of (Bi, Pb)-2223 HTSs prepared via heat treatment of the precursors in alumina crucibles.

2 Experimental

Two series of the Pb(BO2)2-doped and B2O3-doped (Bi, Pb)-2223 HTSs with the nominal compositions Bi1.7Pb0.3−x Ca2Sr2Cu3O y [Pb(BO2)2] x , x=0.05, 0.15, 0.3 (0.1, 0.3, 0.6 wt% of boron, respectively) and Bi1.7Pb0.3Ca2Sr2Cu3 B x O y , x=0.05, 0.1, 0,3, 0.5 (0.05, 0.1, 0.3, 0.5 wt% of boron, respectively) were prepared by the solid state reaction method. The appropriate mixtures of Bi2O3, PbO, SrCO3, CaCO3, CuO, Pb(BO2)2, and B2O3 were thoroughly ground and sintered at 850 °C for 45 h with intermediate grindings. The resulting materials were pressed into pellets under hydrostatic pressure at 29 MPa and annealed at 850 °C for 10 h in air, then cooled to room temperature in the furnace. All the heat treatment procedures were performed in alumina crucibles. For comparison, an undoped (reference) sample was also prepared under the same conditions. The synthesized compounds were characterized by powder X-ray diffraction (XRD) analysis using the Dron-3M diffractometer (Cu K α radiation). The resistivity as a function of temperature, ρ(t), and transport critical current were measured by a standard four-probe method for bar-shaped specimens (∼10×0.5×0.5 mm3) cut from the sintered pellets. The transport critical current densities were evaluated at the liquid nitrogen temperature in the self-field, with a criterion of 1 μV/cm. Temperature dependences of the real part of AC susceptibility χ′(T) were measured using the so-called phase method, i.e., by determining the phase shift between the voltage and current [7].

3 Results and Discussion

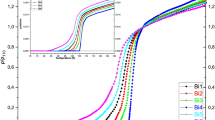

XRD patterns of the undoped and boron-doped specimens are shown in Fig. 1. The dominance of the low-T c 2212 phase over the high-T c 2223 phase was observed in the undoped sample. It can be seen from Fig. 1, that with the increasing of boron-doping level, the 2223 phase is markedly enhanced in both series and its increase is associated with the decrease of the 2212 phase; although the weak peaks of the very low-T c 2201 phase appear at doping level of 0.3 wt% B and are intensified with increasing a boron content. In addition, no peaks related to boron-containing dopants are observed. The volume fraction (H) of the 2223 phase relative to the 2212 phase could be estimated from the XRD data using the relation: H=I(0010)/I(0010)+I(008), where I(0010) is the intensity of the (0010) diffraction peak for the 2223 phase and I(008) is the intensity of the (008) peak for the 2212 phase [2]. It is observed that introduction of boron-containing dopants leads to marked increase of the volume fraction of the 2223 phase in a short total sintering time of 55 h from ∼15 % for the undoped sample up to ∼75 % and ∼50 % at 0.1 wt% boron doping for Pb(BO2)2 and B2O3-doped samples, respectively. Figure 2 represents the temperature dependence of resistivity for the undoped and boron-doped (Bi, Pb)-2223 samples. Onset temperature of superconducting transition is near 110 K for the undoped sample and remains almost unchanged with increasing the boron content. For the undoped specimen, zero resistivity is reached at T c=73 K. It is seen that T c increases drastically with the introduction of boron-containing compounds, passes through a maximum at 0.10 wt% B doping, and then decreases gradually with increasing doping level. Low level doping with Pb(BO2)2 and B2O3 (0.10 wt% B) enhances the critical temperature by about 30 K up to 102.5 K and 101 K, respectively, compared to an undoped specimen. Gradual decrease of T c may be related to the appearance and increase of the secondary 2201 phase upon increasing the boron concentration. Figure 3 illustrates the temperature dependence of the AC susceptibility (χ′) for reference and boron doped samples. It could be seen that the χ′(T) curves show a two-step behavior. Superconducting grains first shield the applied magnetic field, whereas the transition at relatively lower temperature is originated by the weak coupling between the grains. The undoped sample exhibits a weak diamagnetic signal due to the presence of the small amount of the 2223 phase. Figure 4 reveals the relationship between the transport J c values (77 K, zero field) and the boron content. For both series, after passing the maximum value at 0.10 wt% B (215 A/cm2 and 190 A/cm2 for Pb(BO2)2 and B2O3-doped samples, respectively), J c turns to decrease with the increasing dopant content. This increase in J c seems to result from the increase of the volume-fraction of the 2223 phase. In agreement with the resistivity data shown in Fig. 2, lower J c values for a level of 0.3 wt% doping imply the deterioration of coupling at grain boundaries due to appearance of minor amounts of 2201 phase in the 0.3 wt% B-doped samples. It is generally believed that in case of the melt assisted solid state reaction, elements required to form the 2223 phase can rapidly diffuse through the melt and enhance the formation of the 2223 phase [8, 9]. We can conclude that due to very low melting point of Pb(BO2)2 and B2O3, T m=500 °C and 450 °C, respectively, boron-containing dopants act as a flux during the sintering process, and thereby promote extra liquid formation and accelerating the (Bi, Pb)-2223 phase growth. It is also possible that the boron-doping process allows an uptake of the optimal oxygen content into matrix, which is beneficial to the (Bi, Pb)-2223 phase formation and transport properties.

4 Conclusion

Two series of (Bi, Pb)-2223 HTSs doped with lead borate Pb(BO2)2 and boron oxide B2O3 were prepared by the heat treatment of Bi1.7Pb0.3−x Ca2Sr2Cu3O y [Pb(BO2)2] x (x=0–0.3) and Bi1.7Pb0.3Ca2Sr2Cu3B x O y (x=0–0.5) precursors in an alumina crucibles. Boron-containing dopants promote the formation of (Bi, Pb)-2223 phase and lead to the drastic increase in both the critical temperature and the intergranular critical current density compared to the undoped sample. We could conclude that by choosing the optimum content of boron-containing dopants, it could be possible to prepare a significant amount of nearly single (Bi, Pb)-2223 phase materials in alumina crucibles after a relatively short solid-state reaction time.

References

Eltsev, Y., Lee, S., Nakao, K., Tajima, S.: The electrical transport properties of high quality Bi-2223 crystal. Supercond. Sci. Technol. 23, 055007 (2010). doi:10.1088/0953-2048/23/5/055007

Liang, B., Bernhard, C., Wolf, Th., Lin, C.T.: Phase evolution, structural and superconducting properties of Pb-free Bi2Sr2Ca2Cu2O10+δ single crystals. Supercond. Sci. Technol. 17, 731–738 (2004)

Garnier, V., Monot-Laffez, I., Desgardin, G.: Kinetics study of the Bi-2223 grain growth thickness. Physica C 349, 103–112 (2000)

Takano, M., Takada, J., Oda, K., Kitaguchi, H., Miura, Y., Ikeda, Y., Tomii, Y., Mazaki, H.: High-T c phase promoted and stabilized in the Bi, Pb–Sr–Ca–Cu–O system. Jpn. J. Appl. Phys. 27, L1041–L1043 (1988)

Watanabe, K., Kojima, M.: The effect of V2O5 additive on the high-T c (2223) phase of Bi–Pb–Sr–Ca–Cu–O system superconductor. Supercond. Sci. Technol. 11, 392–398 (1998)

Margiani, N.G., Medoidze, T.D., Metskhvarishvili, I.R., Papunashvili, N.A., Zhghamadze, V.V., Dzanashvili, D.I., Aliyev, V.A.: Enhancement of (Bi, Pb)-2223 HTS formation by boron-doping. J. Supercond. Nov. Magn. 23, 1241–1243 (2010)

Khavronin, V.P., Luzianin, I.D., Ginzburg, S.L.: Dynamical magnetic susceptibility in Y–Ba–Cu–O near T c. Phys. Lett. A 129, 399–403 (1988)

Ghattas, A., Annabi, M., Zouaoui, M., Ben Azzouz, F., Ben Salem, M.: Flux pinning by Al-based nano particles embedded in polycrystalline (Bi, Pb)-2223 superconductors. Physica C 468, 31–38 (2008)

Guilmeau, E., Andrzejewski, B., Noudem, J.G.: The effect of MgO addition on the formation and superconducting properties of the Bi2223 phase. Physica C 387, 382–390 (2003)

Acknowledgements

This work has been fulfilled by financial support of the Shota Rustaveli National Science Foundation (Grant No. GNSF/ST09_844_7-121). One of the authors (N.G. Margiani) acknowledges Shota Rustaveli National Science Foundation (Travel Grant No. 2012-tr-226) financial support for participation in the 3rd International Conference on Superconductivity and Magnetism (ICSM2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Margiani, N.G., Metskhvarishvili, I.R., Adamia, Z.A. et al. Influence of Boron-Containing Dopants on Superconducting Properties of (Bi, Pb)-2223 HTS. J Supercond Nov Magn 26, 965–968 (2013). https://doi.org/10.1007/s10948-012-1886-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-012-1886-5