Abstract

Sm123 and Sm211 were prepared by melt-powder-melt-growth and solid-state-reaction techniques, respectively, to have the nominal composition of (Sm123)0.75(Sm211)0.25. After the preparation of this composition, the Fe-B magnetic powder (MP) was added to the composition for 0.000, 0.010, 0.015, 0.025, 0.050 wt.% to investigate the effect of MP addition on the levitation force density (LFD). Additionally, different permanent magnets (PM) were used as magnetic-field source to investigate the effect of magnetic-field gradient on the LFD of MP added superconductors. Our findings indicate that the MP addition acts as a flux pinning centre in the sample and enhances the LFD up to 0.025 wt.% adding amount, and the optimum flux gradient which produces a screening current in the sample occurs when the B/d (magnetic-field intensity/ diameter of PM) ratio is equal to 0.060. These results imply that the experimental data can be useful for fabricating process of superconducting samples with larger MLF values, and designing of superconducting magnets, flywheel energy storage and maglev systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The high-T c superconductors (HTSs) which have large attractive or repulsive magnetic levitation force (MLF) above or below a permanent magnet (PM) have significant potential for various engineering applications such as contactless magnetic bearings [1–3], flywheel energy storage [4, 5], superconductor motor/generators [6] and magnetic levitation transportation systems [7]. Since the discovery of the HTSs, most of the studies were focused on enhancing the MLF. The magnitude of the levitation forces that one can obtain depends upon the size and shapes of the interacting magnets and superconductor samples and their relative positions and orientations, as well as the intrinsic properties of the magnetic materials and superconductors, such as the magnetization of the magnets and the critical current densities of the superconductors. Additionally, MLF depends on some parameters such as the geometry of the HTS [8], number, configuration and geometry of the PM [9], intensity of applied magnetic field [10, 11], angle between the HTS and PM [12], MLF measurement temperature of the HTS [13], cooling process [14], etc. It is well known that the adding of secondary phase particles into superconductors can enhance the flux pinning performance of melt-processed bulk samples. The nonsuperconducting and interface of 211–123 phases [15], dislocations [16], twins and stacking faults [17] have been proved to be flux pinning centers in HTS. It was also observed that the RE2BaCuO5 (RE211) secondary phase addition used popularly in the past years and enhanced the superconducting properties of the samples [18]. Inserting of chemical dopants such as Li or Zn into CuO2 planes increases critical current densities, thus magnetic trapped fields become higher than twice compared with the values of the undoped material at 77 K [19, 20]. It was observed that magnetic powder addition such as Fe-B and Fe2O3 improved the flux pinning and critical current density of Gd123 and (Bi1.6Pb0.4)Sr2Ca2Cu3O10 HTSs [21, 22]. The RE1+x Ba2−x Cu3O6+δ (RE: Nd, Sm, Gd, Yb) superconductors have higher J c, T c and irreversible field values, compared with YBCO. It was observed that Sm123 superconductors have higher trapped magnetic-field value than YBCO (trapped fields for Sm123 and Y123 are 1.3 T and 1 T, respectively) [23, 24].

The goal of this study is to improve the structural properties and magnetic levitation force of (Sm123)0.75(Sm211)0.25 bulk samples by adding different amounts of Fe-B magnetic powder and using different diameter of PM. Therefore, we focused on improving levitation force density by means of the increasing of pinning centers in the sample with adding of MP and changing of the magnetic-field gradient of the PM. We fabricated the samples by using MPMG (melt-powder-melt-growth) method and measured levitation force density (LFD: force per volume of HTS) as a function of adding ratio of magnetic powder (MP) under both the field cooling (FC) and zero field cooling (ZFC) regimes. Although few studies have been carried out on the study of MP addition into the HTS to increase the magnetic and pinning properties, no studies have been reported on the effect of MP to enhance the value of MLF. In this study it was observed that the value of the LFD first increased up to a saturation value and after that decreased with further amount of Fe-B addition. The effect of the magnet size and magnetic-field intensity on the LFD was also investigated.

2 Experimental Procedure

The polycrystalline Sm123 samples were prepared by the MPMG [25] method. Commercially available high purity Sm2O3, BaCO3 and CuO powders were weighed to have a nominal composition of SmBa2Cu3O7−x (Sm123) and Sm2BaCuO5 (Sm211). The Sm211 was prepared by the solid-state-reaction technique. The mixtures of Sm2O3, BaCO3 and CuO powders were thoroughly grounded for an hour, calcined at 910 °C and then sintered at 920 °C for 12 h in air to have the Sm211 nominal composition. The mixtures of Sm2O3, BaCO3 and CuO powders were thoroughly grounded for an hour, calcined two times at 900 °C for 12 h, and then melted for 5 min. in a platinum crucible at 1460 °C. After melting, the melted materials were quenched to room temperature. The quenched samples were grinded and mixed well. At this stage, powder of Sm211 and MP of Fe-B were added to the Sm123 to have a nominal composition of (Sm123)0.75(Sm211)0.25+x wt.% MP, x=0.000, 0.010, 0.015, 0.025, 0.050 structure. Following this procedure, the powders were mixed and then pressed into a pellet form with a diameter of 13 mm under 360 MPa pressure. The samples were heated to 1000 °C at the rate of 10 °C/min, and then heated to 1175 °C at the rate of 5 °C/min. After waiting for 10 minutes, samples were cooled down to 1000 °C at the rate of 1.7 °C/min. This was followed by slow cooling down to 880 °C at the rate of 0.04 °C/min and finally cooled to room temperature at the rate of 3 °C/min. At the final stage of the cooling, the samples were subjected to oxygenation process at 550 °C for 150 minutes, then cooled down to 300 °C at the rate of 2 °C/min under oxygen flow. Finally, the samples were cooled down to room temperature at the rate of 5 °C/min. All of the values of temperatures for the thermal processes were obtained from differential thermal analysis (DTA) measurements.

The morphology of the samples was observed by means of scanning electron microscope (SEM, Zeiss Evo LS10) and polarized optical microscope. The resistance measurements in Quantum Design PPMS system after ZFC regime were carried out under a constant magnetic field, from 50 to 100 K by the step of 0.25 K while the heating rate of 3 K/min. The samples that are used for the electrical resistance measurement have rectangular shape and the typical dimensions of the samples are 2.6×3.2×5.8 mm3. The critical transient temperature was determined between 90 and 92 K. In the resistance measurement it was also seen that the critical transient temperature value decrease when the magnetic powder ratio increase.

The levitation force measurements of the samples were determined by using a self-made device [26]. The vertical forces between the bulk HTSs and NdFeB PM were measured for both FC and ZFC conditions at liquid nitrogen temperature. The measurements were performed by first placing the bulk samples at the same cooling height and approximately over the centre of the PM. The samples were fixed at liquid nitrogen temperature and PM was moved toward or away from the HTS by using a servo motor. The vertical distances were measured by using a displacement sensor and the vertical force is measured by load cells. All of the measurements were controlled by PC.

The X-ray diffraction patterns of the samples were obtained by using a Rikagu D/Max-IIIC diffractometer with Cu K α X-radiation. The X-ray diffraction patterns showed that all of the samples have orthorhombic structure as consistent with superconducting phase.

3 Results and Discussion

Figure 1 shows the scanning electron microscopy image of magnetic powder which was added into the samples. We tried to employ the magnetic powder as the secondary phase to enhance the pinning force. It can be seen from the image that the MP have a granular structure and the average size of the particles is about 5–10 μm.

Figure 2 displays the SEM image of (Sm123)0.75(Sm211)0.25 sample for x=0.025 taken from 100 μm depth of upper surface. The average grain size of the sample is estimated to be 40–50 μm. The pure sample (not shown in here) exhibits non-uniform structure and it has both a relatively large size of pores and non-uniform grain size distribution which varies from 10 to 40 μm. As shown in Fig. 2, the MP added sample for x=0.025 has more uniform grain size distribution and a dense structure than pure sample. The edges of grains in added sample are more round than pure sample. These results indicate that structural properties of the (Sm123)0.75(Sm211)0.25 sample improve with adding of the magnetic impurity.

It is known that the levitation force between a superconductor and a PM is produced by the mutual interaction between the induced shielding current in the superconductor sample and the magnetic field produced by the PM. The levitation force is then proportional with the magnetic moment of the superconductor and magnetic-field gradient of the magnet as F=m(dH/dz), where m is the magnetic moment of a superconductor which is proportional to the shielding current in superconductor and dH/dz is the field gradient produced by the PM. The magnetic moment of the superconductor is m=AJ c rV, where A is a constant depending on the sample geometry, J c is the critical current density of the superconductor, and r is the radius of a shielding current loop [18, 25]. This formulation indicates that it is necessary to have r, J c (which increase with increasing the number of pinning centers in the superconductor), and dH/dz as large as possible to acquire a high levitation force. For this reason, this study focused on improving levitation force density by means of the increasing of pinning centers in the sample with adding of MP and changing of the magnetic-field gradient of the PM.

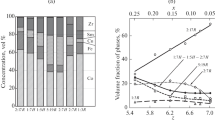

The levitation force densities of the samples were measured for FC and ZFC regimes as shown in Figs. 3 and 4, respectively. One can see from the figures that the LFD of the samples enhanced with adding suitable amount of MP. It is seen in figures that the MP added sample for x=0.025 has maximum LFD values. One can conclude that increasing of the LFD with magnetic impurity up to x=0.025 imply that the nonsuperconducting region density which acts as flux pinning centre in the sample increase [18]. Figures 3 and 4 display that the attractive force in FC regime is stronger than in ZFC regime while the repulsive force in ZFC regime is stronger than in FC regime consistent with the literature. The effect of magnet geometry on the LFD was also investigated in this study. The magnets which used as the magnetic-field source have diameters of 8 mm, 9 mm and 10 mm. The PMs have magnetic-field intensities on centre of the top surface as 0.48 T, 0.59 T and 0.55 T, respectively. Because of the magnetic-field profile of the magnets depends on its shape, we used cylindrical PMs to keep the homogeneous variation of the magnetic-field in the direction perpendicular to the movement. Figure 5 displays the magnetic levitation force density of pure Sm123 samples measured by using magnets in different diameters. The LFD increases with increasing of the magnet diameter as shown in this figure. It is seen from the figure that the LFD reaches its maximum value when diameter of the sample close to diameter of the PM. When the PMs which have diameter of 9 mm and 10 mm are compared each other, it is seen that although the magnetic-field intensity on the surface of PM with d=10 mm lower than d=9 mm, the LFD is higher for PM with d=10 mm is higher than that of d=9 mm. This implies that the diameter of PM is effective on the magnetic flux density as well as the magnetic-field intensity.

Comparing of Figs. 5 and 6 it is concluded that when the magnetic impurity is added to sample, the maximum value of LFD depends on the magnetic-field intensity of the PM much more than the diameter of the PM, because the flux pinning centers are increased by adding of the magnetic powder.

The maximum attractive and repulsive force densities of the samples are plotted in Fig. 7 as a function of MP content. One can see from this figure that both the repulsive and attractive forces enhance with increasing of the MP adding up to x=0.025 and decrease for excess amount of MP. This increase is attributed to the increasing of nonsuperconducting region density which acts as flux pinning centre in the sample. The decreasing of LFD with excess amount of MP is attributed to the excessive increasing of nonsuperconducting region density and so suppressing of superconductivity.

Figures 8 and 9 display the LFDs of MP added samples for x=0.000 and x=0.025 versus B/d (magnetic-field intensity/diameter of PM) ratio under FC and ZFC regimes, respectively. As observed in Fig. 8, the increasing of B/d ratio increases the maximum attractive force density of MP added sample for x=0.025. The maximum attractive force density of the sample for x=0.000 increased up to a maximum value and then saturated by increasing of the B/d ratio. This means that the magnetic flux density which trapped in the sample for x=0.000 is less than MP added sample for x=0.025. This is because the number of pinning centre of the MP added sample is more than the pure sample and the MP addition acts as pinning centre in the sample. In addition, it is shown in Fig. 9 that increasing of the B/d ratio increases the maximum repulsive force density for x=0.025. This means that the screening current and bulk properties of superconductor sample improved by adding of MP. The repulsive force density of pure sample initially increased to a maximum value and then decreased. This state represents that the optimum flux gradient, which induces a screening current in the sample, is possible when the B/d ratio is equal to 0.060. It is considered that the additional increasing of B/d ratio decrease the flux gradient in the sample, thus the critical current density and the repulsive force density decrease.

4 Conclusion

In this study, we prepared the MP added (Sm123)0.75(Sm211)0.25 samples for 0.000, 0.010, 0.015, 0.025 and 0.050 wt.% by using MPMG method. As different from the literature, it is the first time that the effect of MP addition on the magnetic levitation force of superconductor investigated. It is seen that the LFD of the (Sm123)0.75(Sm211)0.25 superconductor increases with addition of the MP up to x=0.025 MP content and decreases for excess amounts of MP. This increase is attributed to the increasing of nonsuperconducting region density which acts as flux pinning centre in the sample. In this study the effect of magnet size on the LFD was also investigated. The experimental results showed that the optimum flux gradient which produces screening current in the sample is possible when the B/d ratio is equal to 0.060. As a result, it is thought that the results which are obtained in this study can be useful for the fabricating process of superconducting samples with larger MLF values, and designing of superconducting magnets, flywheel energy storage and maglev systems.

Abbreviations

- HTS:

-

High T c superconductor

- MLF:

-

magnetic levitation force

- PM:

-

Permanent magnet

- MPMG:

-

melt-powder-melt-growth

- LFD:

-

levitation force density

- MP:

-

magnetic powder

- ZFC:

-

zero field cooling

- FC:

-

field cooling

References

Hull, J.R., Hilton, E.F., Mulcahy, T.M., Yang, Z.J., Lockwood, A., Strasik, M.: J. Appl. Phys. 78, 6833 (1995)

Moon, F.C.: Superconducting Levitation. Wiley-VCH, Weinheim (2004)

Fukuyama, H., Endo, S., Takizawa, T., Sakaguchi, K.: Adv. Supercond. 6, 1341 (1993)

Hull, J.R.: Supercond. Sci. Technol. 13, R1 (2000)

Borneman, H.J., Tonoli, A., Ritter, T., Urban, C., Zaitsev, O., Weber, K., Reischel, H.: IEEE Trans. Appl. Supercond. 5, 618 (1995)

Gawalek, W., Habisreuthe, T., Strasser, T., Wu, M., Litzkendorf, D., Fischer, K., Gornert, P., Gladum, A., Stoye, P., Verges, P., Ilushin, K.V., Kovalev, L.K.: Appl. Supercond. 2, 465 (1994)

Wen, Z., Liu, Y., Yang, W., Qiu, M.: J. Phys. D, Appl. Phys. 40, 7281 (2007)

Chan, W.C., Wang, C.Y., Lee, J.J.: Physica C 282–287, 1455 (1997)

Yang, W.M., Chao, X.X., Bian, X.B., Liu, P., Feng, Y., Zhang, P.X., Zhou, L.: Supercond. Sci. Technol. 16, 789 (2003)

Ito, E., Suzuki, T., Sakai, T., Koga, S., Murakami, M., Nagashima, K., Sakai, N., Hirabayashi, I., Sawa, K.: Physica C 445–448, 412 (2006)

Liu, W., Wang, S.Y., Jing, H., Zheng, J., Jiang, M., Wang, J.S.: Physica C 468, 974 (2008)

Yang, W.M., Feng, Y., Zhou, L., Zhang, P.X., Wu, M.Z., Shaokai, C., Wu, X.Z., Gawalek, W.: Physica C 319, 164 (1999)

Jiang, H., Wang, J., Wang, S., Ren, Z., Zhu, M., Wang, X., Shen, X.: Physica C 378–381, 869 (2002)

Zhou, Y.H., Zhang, X.Y., Zhou, J.: J. Appl. Phys. 103, 123901 (2008)

Lee, D.F., Selvamanickam, V., Salama, K.: Physica C 202, 83 (1992)

Pi, U.H., Khim, Z.G., Kim, D.H.: Phys. Rev. B 69, 094518 (2004)

Ramesh, R., Jin, S., Nakahara, S., Tiefel, T.H.: Appl. Phys. Lett. 57, 1458 (1990)

Ozturk, K., Celik, S., Cansiz, A.: Phys. Status Solidi A 206(4), 2569 (2009)

Krabbes, G., Fuchs, G., Schätzle, P., Gruß, S., Park, J.W., Hardinghaus, F., Stöver, G., Hayn, R., Drechsler, S.-L., Fahr, T.: Physica C 330, 181 (2000)

Shlyk, L., Krabbes, G., Fuchs, G., Stöver, G., Nenkov, K.: Physica C 377, 437 (2002)

Xu, Y., Izumi, M., Zhang, Y.F., Kimura, Y.: Physica C 469, 1215 (2009)

Lau, K.T., Yahya, S.Y., Abd-Shukor, R.: J. Appl. Phys. 99, 123904 (2006)

Sawamura, M., Morita, M.: Physica C 357–360, 892 (2001)

Sawamura, M., Morita, M.: Supercond. Sci. Technol. 15, 774 (2002)

Murakami, M., Oyama, T., Fujimoto, H., Gotoh, S., Yamaguchi, K., Shiohara, Y., Koshizuoka, N., Tanaka, S.: IEEE Trans. Magn. 27, 1479 (1991)

Celik, S., Ozturk, K.: Phys. Status Solidi A 206(4), 724 (2009)

Acknowledgements

This study was supported by the Research Fund of Karadeniz Technical University with project No.2008.111.01.10 and partly the Scientific and Technological Research Council of Turkey (TUBITAK), with project No. 108T659.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdioglu, M., Ozturk, K., Kutuk, S. et al. Effect of Magnetic Flux Distribution and Magnetic Powder Addition on the Magnetic Levitation Force of Sm123 Superconductors. J Supercond Nov Magn 25, 923–929 (2012). https://doi.org/10.1007/s10948-011-1391-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-011-1391-2