Abstract

Porous Ni/Co-organic framework with honeycomb-like structure was directly grown on the carbon cloth (Ni/Co-MOF@CC) through a hydrothermal process. The Ni/Co-MOF@CC displayed a high specific surface area with an average pore size of 3.05 nm and excellent conductivity. The electrochemical performances of the porous Ni/Co-MOF@CC as the electrode of supercapacitors were evaluated using cyclic voltammetry, galvanostatic charge/discharge, and electrochemical impedance spectroscopy measurements in 2 M KOH electrolyte. The Ni/Co-MOF@CC electrode exhibited a maximal specific capacity of 1180.5 mC cm−2 at 3 mA cm−2, good high-rate discharge ability (624.1 mC cm−2 at 60 mA cm−2), and long-term cycling life (97.6% capacity retention after 5000 cycles). Our experiments demonstrated the practical application of mixed-MOFs as supercapacitors for next-generation energy storage devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In this energy-dependent world, electrochemical devices for energy storage play a vital role in overcoming fossil fuel exhaustion [1]. Among various electrochemical energy storage devices, supercapacitors have attracted significant interest in both academia and industry during the past several decades owing to their superior power density, fast charge/discharge rate and long cycle life [2,3,4]. In order to obtain the high-performance supercapacitors including electric double-layer capacitors and faradaic capacitors, high surface area and good pore-size distribution are critical factors [5, 6].

Metal–organic frameworks (MOFs) are relatively newer kind of porous materials with preternatural porosities, and they have been widely used in many fields such as gas separation and storage, catalysis, sensing and drug delivery [7,8,9,10]. Very recently, investigations on the direct use of MOFs as supercapacitor electrode materials have expanded. For instance, Yaghi et al. synthesized a series of MOF compounds for supercapacitors with multiple organic ligands and central metal ions, which revealed singularly high areal specific capacity [11]. Zeng et al. developed the Co3O4/Ni-based MOFs on carbon cloth, which exhibited a specific capacity of up to 209 mAh g−1 at 1 A g−1 [12]. Besides, Naderi et al. controlled the hydrothermal conditions to grow bimetallic Ni/Co-MOF particles, which exhibited a high specific capacity of 1049 F g−1 at discharge current density of 1A g−1 in 3 M KOH solution [13]. The newly developed mixed-metal method for MOFs allows for the incorporation of two different central metal ions into the same framework to form mixed-metal organic frameworks (M-MOFs), which offers MOFs with an additional degree of structural stability and could endow them with some new performances [14]. Hence, Chen et al. found that the M-MOFs exhibited an excellent energy density (49.5 Wh kg−1) and power density (1450 W kg−1) [15]. However, studies into the direct use of MOFs as electrode materials are still a tough challenge due to their poor intrinsic conductivity and low capacity of most MOFs during the electrochemical charge–discharge process.

Previous works have studied many transition metal organic frameworks, such as Ni-MOF [16], Co-MOF [9], Ni/Co-MOF [13], and ZIF-8 [17]. These studies confirmed that Ni/Co-MOF is one of the most promising candidates for its good electrical conductivity and electrochemical activity. Although some progress has been made in the study of the Ni/Co-MOF, there is still scope for improving its capacity properties. Besides, conductive substrates play a key role as a conductive skeleton and current collector in supercapacitors. Carbon cloth is a common conductive substrate and possesses a number of attractive properties, such as good electrical conductivity, flexibility and large specific surface area [18]. It displays adequate electrochemical properties, making them suitable for electrodeposition of Ni/Co nanostructures. However, the traditional electrode manufacturing process still employs the slurry-painting technology, which limits the contact between the active material and electrolyte, resulting in a lower density of the Faraday reaction point. Moreover, the addition of any binder further hinders the transfer of ions and decreases the electron storage capacity leading to inconsistent cycle life-time in conventional Ni/Co-MOF powder-based supercapactiors [19]. Therefore, in order to obtain a significantly better supercapacitor behavior, it is necessary to directly disperse the mesoporous Ni/Co-MOF on the conductive substrate.

Herein, we designed a novel type of porous honeycomb-like Ni/Co-MOF@CC via a simple hydrothermal method. The Ni/Co-MOF@CC electrode exhibited a maximal specific capacity of 1180.5 mC cm−2 at 3 mA cm−2, good high-rate discharge ability (624.1 mC cm−2 at 60 mA cm−2), and long-term cycling life (97.6% capacity retention after 5000 cycles). In the energy storage field, specific capacitance does not represent the capacity of the material clearly when the delivered charge has a nonlinear dependency on the potential, so we used specific capacity instead of capacitance [20]. In contrast, the Ni-MOF@Carbon cloth (Ni-MOF@CC) and Co-MOF@Carbon cloth (Co-MOF@CC) exhibited specific capacities of 811.8 and 927.1 mC cm−2, respectively. The electrochemical performance of Ni/Co-MOF@CC is better than either Ni-MOF@CC or Co-MOF@CC, which can be attributed to a mixed central metal ion synergistic effect that can efficiently improve the conductivity of MOFs@CC and enhance the specific surface area. Therefore, Ni/Co-MOF@CC electrode provides a great potential for the application of the MOF family in the electrochemical energy storage field.

2 Experimental

2.1 Synthesis of hierarchical Ni-MOF@CC, Co-MOF@CC and Ni/Co-MOF@CC nanosheet-assembled honeycomb-like structures

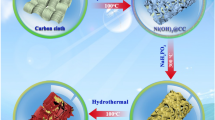

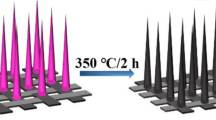

According to the schematic illustration (Fig. 1a) of the synthesis of Ni/Co-MOF on a carbon cloth, Co(NO3)2·6H2O (2.1 g), Ni(NO3)2·6H2O (1.9 g), were heated at 120 °C for 1 h to remove the crystal water in the raw materials. After cooling to room temperature, the above raw materials, H32Mo7N6O28 (catalyst, 0.2 g) and p-phthalic acid (0.336 g) were dissolved in DMF (51.2 mL) under magnetic stirring for 30 min at room temperature. After that, the mixture was transferred into a 100 mL Teflon-lined stainless-steel autoclave with a loading volume of 80% and one piece of washed carbon cloth (1 × 2 cm2) was included in the Teflon vessel. The autoclave was heated to 120 °C for 16 h, and then cooled to room temperature. The products were thoroughly washed several times with DMF and alcohol to washout extra organic materials. The samples were fully activated by removing the solvent under vacuum at 60 °C over 12 h and annealed at 325 °C for 2 h with a heating rate of 5 °C min−1 under the nitrogen atmosphere. After cooling to room temperature, Ni/Co-MOF@CC was finally obtained. The loading mass of Ni/Co-MOF on the surface of carbon cloth was estimated to be 1.5 mg cm−2.

A similar procedure was employed to prepare Co-MOF@CC and Ni-MOF@CC separately for comparison.

2.2 Materials characterization

A field emission scanning electron microscope (FESEM) (Inspect F, FEI Co., U.S.) and a high-resolution transmission electron microscope (HRTEM) (Libra 200FE, Germany) were used to observe micromorphologies of the samples. X-ray diffraction (XRD) was used to determine the crystalline phases and their crystallinity using a rotating target X-ray diffractometer (Philips Xpert X-ray diffractometer) with Ni-Filtered Cu Kα radiation. Fourier transform infrared (FTIR) spectroscopy analysis of the samples was carried out on an FTIR spectrometer (Shi-madzu) in the range of 400–4000 cm−1 using KBr pellets of samples. Using a JW-BK112 Surface Characterization Analyzer (Beijing JWGB Sci & Tech Co. China), N2 adsorption and desorption isotherms were determined. The specific area, pore volume and pore size distributions of the as-synthesized materials were measured by the Brunauer–Emmett–Teller (BET) methods. The samples were evacuated at 100 °C for 3 h to remove moisture from the pores and then placed in an automatic surface area analyzer to measure adsorption/desorption of nitrogen at 77 K.

2.3 Electrochemical measurements

In order to study the electrochemical performance of the as-prepared products, a standard three electrode system was used at room temperature on a CHI660D electrochemical working station (CH Instrument) and a CT2001A rapid sampling battery testing system (LAND, China). The geometric area of the as-prepared product was about 1 cm2. The as-prepared product, platinum foil and a saturated calomel electrode were used as the working, counter and reference electrodes, respectively. The electrolyte was 2 M KOH solution. Cyclic voltammetry (CV) was performed using the above system at the scan rates of 1–10 mV s−1 within the potential window ranging from 0 to 0.55 V versus Hg/HgO. Galvanostatic charge–discharge (GCD) measurements were performed at different current densities ranging from 0 to 0.5 V. Long-term cycling test was performed at room temperature by using the CT2001A rapid sampling battery testing system. The electrochemical impedance spectroscopy (EIS) data was collected with an AC voltage of 5 mV amplitude in the frequency range from 0.01 to 100 kHz.

The specific capacity of the electrode can be calculated from the discharge curves according to the following equation:

where C is the specific capacity (mC cm−2), Q is the quantity of charge, A (cm2) is the area of the active materials, I is the constant discharge current (mA) and Δt is the discharge time (s).

The energy efficiency of the electrode can be calculated from the energy density according to the following equation:

3 Results and discussion

3.1 Materials characterization

Representative FESEM images of the as-prepared Ni/Co-MOF@CC electrode are shown in Fig. 1. As can be seen from Fig. 1a, nanosheet-assembled honeycomb-like Ni/Co-MOF with an average size of ~ 500 nm is grown on CC. High magnification image revealed that all the nanosheets are aggregated and crossed each other, forming a large number of outwardly opening holes giving the appearance of a honeycomb, as shown in Fig. 1b. Besides, the nanaosheets are uniform in thickness of about 10 nm. The special honeycomb-like structure is attributed to the self-assembly through Gibbs free energy on the surface of the nanosheets during hydrothermal co-precipitation [21]. The honeycomb-like porous architecture facilitates interaction between the active substance and the electrolyte, shortening the path of electron transport and increasing the activity point of the electrochemical reaction [22]. Moreover, the porous honeycomb-like Ni/Co-MOF@CC also ensures excellent conductivity of the electrode because the nanosheets are directly deposited on the skeleton of the carbon cloth without any binder. Figure 1c reveals that the lattice fringe is ca. 0.93 nm, matching well with the d-spacing of the (100) plane of Ni-MOF. For the analyses of Ni/Co-MOF@CC, the position of the selected portion is moved toward the edge of the plane in the selected area electron diffraction (SAED) mode so that honeycomb-like nanosheet would be exposed to the beam. The SAED pattern of Ni/Co-MOF@CC (the inset figure of Fig. 1d) also indicates the polycrystalline nature of the material.

Figure 2a shows XRD patterns of both the Ni-MOF and Ni/Co-MOF, which were deposited on the surface of the carbon cloth electrode along with carbon cloth and a simulated pattern from the single-crystal data of [Ni3(OH)2(C8H4O4)(H2O)4]·2H2O (CCDC No. 638866). All of the patterns are similar, indicating that all of the MOFs probably have the same layered topology and crystal structure which is built by connected central metal ions with BDC ligands to form a 2D layered structure [23]. The lattice parameters of a, b, and c are 10.2077, 8.0135, and 6.3337 Å, respectively. Meanwhile, these layers were connected by hydrogen bonds to ensure the stability of the MOFs. Accordingly, it might indicate that Co2+ partly substituted for Ni2+ in the MOFs could retain the Ni-MOF crystal structure [24]. The EDX spectra of Ni/Co-MOF@CC (Fig. 2b) suggest that the ratio of Ni/Co is about 1.5. This agrees well with the FTIR result shown in Fig. 2c, where all of the FTIR peaks of all the samples are almost the same, which further confirmed that these frameworks are isostructural and have the same layered topology. In the FTIR spectrum, the bands at ~ 3500 and 1383 cm−1 were attributed to the stretching vibrations of OH− and para-aromatic CH groups, respectively. The stretching vibrations of water molecules at around 3500 cm−1 indicate that coordinated H2O molecules are present within the Ni-based material. The peaks at 1583 and 1680 cm−1 correspond to the asymmetric stretching and the band at 1383 cm−1 is related to the symmetric stretching vibrations of carboxylate groups. Moreover, the bands near 683 cm−1 can be assigned to Ni–O and Ni–N. These results are all in good agreement with the XRD results and further confirmed that the synthesized Ni-based MOF was a kind of nickel hydroxyl-terephthalate-based compound.

Using the BET method to calculate the pore size and specific surface areas of the Ni-MOF, Co-MOF and Ni/Co-MOF. The pore size and specific surface areas are exhibited in Table 1 and Fig. 2d. The specific surface areas of the different metal based isostructural MOFs follow the order of Ni/Co-MOF (691 m2 g−1) > Co-MOF (372 m2 g−1) > Ni-MOF (344 m2 g−1). It is well-known that large surface area and high porosity are always related to high electrochemical performance [25]. Moreover, the presence of crystalline water in the M-MOFs is advantageous for their performance when used in supercapacitors [26]. Therefore, Ni/Co-MOFs are theoretically expected to exhibit excellent electrochemical performance as battery-type electrode materials for supercapacitor.

The wireframe views of Ni-MOF (Fig. 3a, b) exhibit that this material has a layered structure, and each layer is built up from one-dimensional chains of octahedron nickel outspread parallel to the c-axis and connected by a bridging terephthalic acid ligand [27]. Hydrogen bonds between the Ni ions and water molecules connect the adjacent layers, which ensure the cohesion of the structure and contribute to the stability of the MOF [28]. The largest exposed facet of (100) exhibited a perfect structure for the transport of electrons and diffusion of electrolyte solution [29]. Moreover, the interlayer space between each layer (about 0.95 nm) is larger than the ionic radius of OH− (0.137 nm) so that Ni-MOFs can provide enough space for electrolyte diffusion and storage, fast ion intercalation and deintercalation. Therefore, such a layered material might exhibit excellent electrochemical performance as an electrode in a supercapacitor.

Three-electrode CV curves of Ni-MOF@CC, Co-MOF@CC and Ni/Co-MOF@CC at the same scan rate of 10 mV s−1 are shown in Fig. 4a. The capacities are correlated to the average areas of the CV curves which follow the order of Ni/Co-MOF@CC > Co-MOF@CC > Ni-MOF@CC, indicating that more reactions occur in the M-MOF electrodes. The incorporation of cobalt influences both the ionic and electronic conductivity of the active materials, which results in better electrode utilization and the improvement of reaction kinetics. Figure 4b shows the CV response of Ni/Co-MOF@CC at different scan rates ranging from 1 to 10 mV s−1. A reversible redox process is notably observed. With the increase of scanning rate, the current response is also gradually increased, exhibiting good capacitive behavior and charge storage characteristics. The internal resistance of the Ni/Co-MOF@CC electrode with increasing scan rate led to an increased peak separation between the anodic and cathodic peaks [15]. The GCD curves of the Ni-MOF@CC,Co-MOF@CC and Ni/Co-MOF@CC are shown in Fig. 4c. For all samples, the potential time response is nonlinear, originating from faradaic behavior. This process might be represented by the following equations:

a CV curves of the pristine Ni-MOF@CC, Co-MOF@CC and Ni/Co-MOF@CC at a scan rate of 10 mV s−1; b CV curves of Ni/Co-MOF@CC at the scan rate between 1 and 10 mV s−1; c Charge and discharge curves of Ni-MOF, Co-MOF and Ni/Co-MOF@CC at a current density of 3 mA cm−2; d Charge and discharge curves of Ni/Co-MOF@CC at different current densities; e Capacity of Ni-MOF@CC, Co-MOF@CC and Ni/Co-MOF@CC at various current densities; f Cycling performance of Ni/Co-MOF@CC at a discharge current density of 20 mA cm−2

From Fig. 4c, the capacities of Ni-MOF@CC, Co-MOF@CC and Ni/Co-MOF@CC are calculated to be 811.8, 927.1 and 1180.5 mC cm−2, respectively based on the discharging curves at a current density of 3 mA cm−2. Therefore, the mixed-metal organic frameworks (M-MOFs@CC) show a longer duration of time for charging-discharging than the Ni-MOF@CC or the Co-MOF@CC. Figure 4e shows the capacities of Ni-MOF@CC, Co-MOF@CC and Ni/Co-MOF@CC at various current densities. It is exciting to find that the porous honeycomb-like Ni/Co-MOF@carbon cloth electrode exhibits excellent high-rate performance with specific capacities of 1180.5, 1180, 1026, 976, 921, 624.1 mC cm−2 at current densities of 3, 5, 12, 20, 30, 60 mA cm−2, respectively. When the current density is 20 times that of the initial current density, it could retain 52.1% of its capacity (Fig. 4e). With the same time, the energy efficiencies of the Ni/Co-MOF@CC are 72.32%, 70.27%, 67.41%, 62.12%, 58.08%, 54.98% at current densities of 3, 5, 12, 20, 30, 60 mA cm−2, indicating the Ni/Co-MOF@CC, with a high energy efficiency, is of practical interest [30]. For supercapacitor, the cyclic stability is also an important criterion to measure performance. A long time repeated charge–discharge test was carried out at a constant current density of 20 mA cm−2. The test results are shown in Fig. 4f. The specific capacity of the electrode gradually decreased to 1168.3 mC cm−2 after 5000 cycle test, resulting in only 2.4% capacity loss.

The obtained maximum specific capacity (787.01 C g−1 at 2 A g−1) and long cycle stability (97.6% retention after 5000 cycles) for the synthesized Ni/Co-MOF@CC is higher than those of most MOFs and metal oxides derived from MOFs such as Co3O4/Ni-based MOFs (752.41 C g−1 at 1 A g−1 and 90% retention after 3000 cycles) [12], Ni–Tp/PANI (516.36 C g−1 at 1.818 A g−1 and 85.4% retention after 3000 cycles) [16], Ni/Co-MOF/rGO (516 C g−1 at 1 A g−1 and 91.6% retention after 6000 cycles) [31] and NiCo-MOFs (833 C g−1 at 0.5 A g−1 and 95.6% retention after 5000 cycles) [32] that have been reported in the literature as presented in Fig. 5. The high capacity and long cyclic stability of Ni/Co-MOF@CC can be ascribed to the participation of both ions in redox reactions and unique honeycomb-like porous structure. The honeycomb-like porous structure possessing high specific surface area, offers abundant active sites for electrochemical reactions, as well as appropriate channels for diffusion and adsorption of electrolytes. High surface area is the intrinsic demand for supercapacitor electrodes, which has been confirmed by many reports such as colloidal supercapacitor electrodes [33]. Importantly, electrolyte solution involved in honeycomb-like porous structure is beneficial in decreasing the diffusion distance of ions and retaining a relatively stable concentration of electrolyte in the interface between active material and solution.

As an important parameter to evaluate the electrochemical performance of electrodes, EIS measurement was used to investigate the charge-transfer resistance (Rct). Figure 6 shows the EIS results of Ni-MOF@CC, Co-MOF@CC and Ni/Co-MOF@CC. The semicircles for the Ni/Co-MOF@CC and Co-MOF@CC in the high-frequency ranges are smaller than that of the Ni-MOF. A smaller semicircle indicates a smaller Rct [34], whereas the calculated Rct for the Ni-MOF, Co-MOF and Ni/Co-MOF are 6.85, 1.07 and 0.24 Ω, respectively. The intercept of the real axis in the high frequency range of the Nyquist plots indicates the equivalent series resistance (ESR), which is the combined series resistance of the electrolyte, electrode, electrolyte and electrode contact resistance. The ESR values of the Ni-MOF, Co-MOF and Ni/Co-MOF are 1.49, 1.47 and 1.14 Ω, respectively. The above low ESR values resulted from the excellent electrical properties of our samples. In the low-frequency region (Fig. 6), the slope of the straight line is related to the mass transfer of the electrolyte. The angles of straight lines were clearly greater than 45°, suggesting lower diffusion resistances of the electrolyte in our sample because of the currently designed honeycomb-like porous structure with a relatively high specific surface area [34]. These results evidently indicate that the porous honeycomb-like Ni/Co-MOF@CC electrode is promising for high-performance energy storage devices on account of their long cycle life and excellent conductivity.

4 Conclusion

In summary, porous honeycomb-like Ni/Co-MOF@carbon cloth electrodes were properly grown on Carbon cloth by a simple hydrothermal method followed by a post heat treatment. The 2D M-MOFs@Carbon cloth materials were first used as battery-type electrodes, which showed superior electrochemical performance compared to that of the Ni-MOF or Co-MOF. The enhanced performance can be attributed to the synergetic effect contributed from the improved electronic conductivity, higher specific surface area, and porosity increase, which enlarged the electrode and electrolyte contact area and shortened the path length for ion transport. Owing to the special porous honeycomb-like nanosheets and excellent conductivity, the electrode exhibited a high specific capacity of 1180.5 mC cm−2 at the current density of 3 mA cm−2. Moreover, the electrode possessed good cyclic performance, which showed a capacity retention of 97.6% after 5000 cycles. Therefore, M-MOF@CC-based electrode could provide a great potential for the application of the MOF family in the electrochemical energy storage field.

References

C. Zhong, Y. Deng, W. Hu, J. Qiao, L. Zhang, J. Zhang, A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 44, 7484–7539 (2015)

X. Wang, Y. Yang, Y. Zhang, Q. Li, M. Gong, R. Zhang, S. Xiong, Facile synthesis and capacitance properties of N-doped porous carbon/iron oxide composites through the single-step pyrolysis of coal-based polyaniline. J. Porous Mater. 25, 845–853 (2018)

N. Wang, H. Song, H. Ren, J. Chen, M. Yao, W. Huang, W. Hu, S. Komarneni, Partly nitrogenized nickel oxide hollow spheres with multiple compositions for remarkable electrochemical performance. Chem. Eng. J. 358, 531–539 (2019)

K. Chen, D. Xue, Colloidal supercapattery: redox ions in electrode and electrolyte. Chem. Rec. 18, 282–292 (2018)

Q. Zhang, K. Zhou, J. Lei, W. Hu, Nitrogen dual-doped porous carbon fiber: a binder-free and high-performance flexible anode for lithium ion batteries. Appl. Surf. Sci. 467, 992–999 (2019)

C. Ma, R. Wang, Z. Xie, H. Zhang, Z. Li, J. Shi, Preparation and molten salt-assisted KOH activation of porous carbon nanofibers for use as supercapacitor electrodes. J. Porous Mater. 24, 1437–1445 (2017)

S. Chen, S. Xiao, J. Liu, Z. Li, Synthesis and hydrogen storage properties of zirconium metal-organic frameworks UIO-66(H2ADC) with 9,10-anthracenedicarboxylic acid as ligand. J. Porous Mat. 25, 1783–1788 (2018)

Y. An, Y. Liu, P. An, J. Dong, B. Xu, Y. Dai, X. Qin, X. Zhang, M.-H. Whangbo, B. Huang, NiII coordination to an Al-based metal-organic framework made from 2-aminoterephthalate for photocatalytic overall water splitting. Angew. Chem. Int. Ed. 56, 3036–3040 (2017)

S. Zheng, X. Li, B. Yan, Q. Hu, Y. Xu, X. Xiao, H. Xue, H. Pang, Transition-metal (Fe, Co, Ni) based metal-organic frameworks for electrochemical energy storage. Adv. Energy Mater. 7, 1602733 (2017)

T.Q.N. Tran, G. Das, H.H. Yoon, Nickel-metal organic framework/MWCNT composite electrode for non-enzymatic urea detection. Sens. Actuators B 243, 78–83 (2017)

K.M. Choi, H.M. Jeong, J.H. Park, Y.-B. Zhang, J.K. Kang, O.M. Yaghi, Supercapacitors of nanocrystalline metal-organic frameworks. ACS Nano 8, 7451–7457 (2014)

L. Zhang, Y. Zhang, S. Huang, Y. Yuan, H. Li, Z. Jin, J. Wu, Q. Liao, L. Hu, J. Lu, S. Ruan, Y.-J. Zeng, Co3O4/Ni-based MOFs on carbon cloth for flexible alkaline battery-supercapacitor hybrid devices and near-infrared photocatalytic hydrogen evolution. Electrochim. Acta 281, 189–197 (2018)

H. Gholipour-Ranjbar, M. Soleimani, H.R. Naderi, Application of Ni/Co-based metal-organic frameworks (MOFs) as an advanced electrode material for supercapacitors. New J. Chem. 40, 9187–9193 (2016)

Y. Jia, G. Chen, D. Chen, J. Pei, Y. Hu, Bimetal-organic framework assisted polymerization of pyrrole involving air oxidant to prepare composite electrodes for portable energy storage. J. Mater. Chem. A 5, 23744–23752 (2017)

Y. Jiao, J. Pei, D. Chen, C. Yan, Y. Hu, Q. Zhang, G. Chen, Mixed-metallic MOF based electrode materials for high performance hybrid supercapacitors. J. Mater. Chem. A 5, 1094–1102 (2017)

Q. Chen, S. Lei, P. Deng, X. Ou, L. Chen, W. Wang, Y. Xiao, B. Cheng, Direct growth of nickel terephthalate on Ni foam with large mass-loading for high-performance supercapacitors. J. Mater. Chem. A 5, 19323–19332 (2017)

Z. Jia, G. Wu, D. Wu, Z. Tong, W.S.W. Ho, Preparation of ultra-stable ZIF-8 dispersions in water and ethanol. J. Porous Mater. 24, 1655–1660 (2017)

X. Liang, K. Chen, D. Xue, A flexible and ultrahigh energy density capacitor via enhancing surface/interface of carbon cloth supported colloids. Adv. Energy Mater. 8, 26 (2018)

P. Zhao, N. Wang, W. Hu, S. Komarneni, Anode electrodeposition of 3D mesoporous Fe2O3 nanosheets on carbon fabric for flexible solid-state asymmetric supercapacitor. Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.02.101

A. Eftekhari, Metrics for fast supercapacitors as energy storage devices. ACS Sustain. Chem. Eng. 7, 3688–3691 (2019)

C. Qu, Y. Jiao, B. Zhao, D. Chen, R. Zou, K.S. Walton, M. Liu, Nickel-based pillared MOFs for high-performance supercapacitors: design, synthesis and stability study. Nano Energy 26, 66–73 (2016)

K. Chen, D. Xue, High energy density hybrid supercapacitor: in-situ functionalization of vanadium-based colloidal cathode. ACS Appl. Mater. Inter. 8, 29522–29528 (2016)

C. Liu, C. Zhang, H. Song, C. Zhang, Y. Liu, X. Nan, G. Cao, Mesocrystal MnO cubes as anode for Li-ion capacitors. Nano Energy 22, 290–300 (2016)

P.-Y. Tang, L.-J. Han, A. Genç, Y.-M. He, X. Zhang, L. Zhang, J.R. Galán-Mascarós, J.R. Moranteb, J. Arbiol, Synergistic effects in 3D honeycomb-like hematite nanoflakes/branched polypyrrole nanoleaves heterostructures as high-performance negative electrodes for asymmetric supercapacitors. Nano Energy 22, 189–201 (2016)

M. Yao, N. Wang, W. Hu, S. Komarneni, Novel hydrothermal electrodeposition to fabricate mesoporous film of Ni0.8Fe0.2 nanosheets for high performance oxygen evolution reaction. Appl. Catal. B 233, 226–233 (2018)

G. Zhu, C. Xi, M. Shen, C. Bao, J. Zhu, Nanosheet-based hierarchical Ni2(CO3)(OH)2 microspheres with weak crystallinity for high-performance supercapacitor. ACS Appl. Mater. Inter. 6, 17208–17214 (2014)

P. Wen, P. Gong, J. Sun, J. Wang, S. Yang, Design and synthesis of Ni-MOF/CNT composites and rGO/carbon nitride composites for an asymmetric supercapacitor with high energy and power density. J. Mater. Chem. A 3, 13874–13883 (2015)

A. Policicchio, R. Filosa, S. Abate, G. Desiderio, E. Colavita, Activated carbon and metal organic framework as adsorbent for low-pressure methane storage applications: an overview. J. Porous Mater. 24, 905–922 (2017)

J. Yang, C. Zheng, P. Xiong, Y. Lia, M. Wei, Zn-doped Ni-MOF material with a high supercapacitive performance. J. Mater. Chem. A 2, 19005–19010 (2014)

A. Eftekhari, Energy efficiency: a critically important but neglected factor in battery research. Sustain. Energy Fuel 1, 2053–2060 (2017)

M.S. Rahmanifara, H. Hesarib, A. Noorib, M.Y. Masoomib, A. Morsalib, M.F. Mousavi, A dual Ni/Co-MOF-reduced graphene oxide nanocomposite as a high performance supercapacitor electrode material. Electrochim. Acta 275, 76–86 (2018)

C. Ye, Q. Qin, J. Liu, W. Mao, J. Yan, Y. Wang, J. Cui, Q. Zhang, L. Yang, Y. Wu, Coordination derived stable Ni-Co MOF for foldable all-solid-state supercapacitor with high specific energy. J. Mater. Chem. A (2019). https://doi.org/10.1039/c8ta11948a

K. Chen, D. Xue, Colloidal paradigm in supercapattery electrode systems. Nanotechnology 29, 024003 (2018)

N. Wang, C. Wang, L. He, Y. Wang, W. Hu, S. Komarneni, Incomplete phase separation strategy to synthesize P/N co-doped porous carbon with interconnected structure for asymmetric supercapacitors with ultra-high power density. Electrochim. Acta 298, 717–725 (2019)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Wang, N., Hu, W. et al. In situ construction of porous Ni/Co-MOF@Carbon cloth electrode with honeycomb-like structure for high-performance energy storage. J Porous Mater 26, 921–929 (2019). https://doi.org/10.1007/s10934-019-00735-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-019-00735-9