Abstract

Insect repellent fabrics are now of interest to secure human beings from the harmful effects of insects, but control the release of insect repellent from such fabrics is much important. The present study showed a good strategy to release effectively of N,N-diethyl-3-methylbenzamide (DEET) as insect repellent, from natural fabrics. Copper-benzene-1,3,5-tricarboxylic acid (Cu-BTC) as metal organic framework (MOF) material was in-situ incorporated into the matrix of natural fabrics including Cotton, Linen and Silk. DEET was then loaded onto the modified fabrics and the release of DEET from fabrics was studied. The successfulness of Cu-BTC incorporation was confirmed by scanning electron microscope, energy dispersive X-ray, X-ray diffraction and attenuated total reflectance—fourier transform infrared spectroscopy. The measured contents of Cu and Cu-BTC in fabrics were ranged in 35.9–38.9 and 115.4–130.3 mg/g fabrics, respectively. After loading the DEET into fabrics, the measured content of DEET was followed the order of Silk < Linen < Cotton and the modified fabrics exhibited much higher DEET by percent of 65–110%. Due to MOF modification, the released amount of DEET from fabrics was considerably increased by value of 205–220 mg/g and the release time became as long as 24–36 h. The release rate was fitted well to zero order model as the rate is independent of the reactant concentration. The so-obtained product can be applicable as disposable insect repellent materials for controllable and effective release of DEET for such a long residence time exceeded 9 days.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Studying the manufacturing of protective fabrics is one of the most growing researches’ interests to modify the textile field by providing the required characteristics for protection of human working in hazardous environments [1–12]. These materials included many types of functional fabrics such like UV protection [1, 2, 4, 6], biologically active [2–9] and insect repellent [10–12]. Insects are the real problem faced by people through their everyday lives. As, filariasis, malaria, nile fever, dengue hemorrhagic fever (DHF) and chicken gunia are serious diseases caused by insects [13–15]. For instance, mosquitoes are responsible for disease transmission for >700 million people annually and caused death of 1 from each 17 human. According to the World Health Organization (WHO) reported in 2015, 214 million person suffered globally from malaria, and nearly among whom 438 thousand ones were annually death [16].

Due to no real vaccines are available in market for controlling the diseases caused by insects, prevention of exposure to insects such as ticks, mosquitoes, chiggers and mites, is the main strategy to diminish incidence of such diseases [17]. Initially people can avoid insects and their harmful effects by applying insect repellents on their skin directly as cream or lotion. It is sufficient for just few hours and most of them can be toxic for human beings or harmful for human skin and causing irritation. Owing to these disadvantages, using of insect repellent fabrics is the most perfect solution to protect human beings from these serious diseases, especially in the equatorial regions. The protective fabrics against insects can be used in several forms including tents, curtains, bed-sheets, nets and garments. Therefore, several works have been recently published focused on preparation of insect repellent textiles based on different materials [10–12, 15]. Nowadays, several insect repellents are available in market. Pyrethroids are a family of synthetic insect repellents including; cypermethrin, permethrin and permethrin. Comparing to the others, permethrin is the broad spectrum insect repellent owing to its odorless, non-stainable or non-destructive effects on cloths [8]. As an example from insect repellent, limonene is extracted from natural products [11]. Both of natural and synthetic products have been applied for designing insect repellent fabrics [10–12, 15].

Metal organic frameworks (MOFs) are a new hybrid porous materials with 1D, 2D or 3D structures [18]. They have three main advantages represented in porous structure, high surface area and chemical stability, leaded to its utilizing in several applications including gas and vapors adsorption [19, 20], chemicals separation [21, 22], biomedicine and drug carrier [22], catalysis [23, 24] and luminescence [25], depending on the central metal ion used. Due to its largely sorption capacity, MOFs were newly used to remove hazardous organic materials from water such as dyes’ aromatic molecules and insecticides [26–29]. Also MOFs were been used as matrix for encapsulation of essential oils as insect repellents for water treatment in swimming pools [30]. Recently, textiles were modified with micro-porous materials like zeolite and MOFs for protection, therapy and degradation of chemical-warfare agents [31–33].

N,N-diethyl-3-methylbenzamide (DEET) is one of the most widely insect repellent substrate used in the United States, and the amount consumed reached to ∼1800 tons by 110 million people annually [34]. Moreover, DEET used more often than any other mosquito repellent, with over 200 million users worldwide [35] and its mode of action on insects depends on inhibition of cholinesterase [36]. DEET is discovered in 1946 and is synthesized by converting 3-methylbenzoic acid to m-toluoyl chloride and then reacted with diethylamine [37, 38]. It is firstly used by the US military as protector against mosquitoes, ticks, fleas, chiggers, leeches and many biting insects. According to US environmental protection agency (USEPA), DEET is applied on human skin as lotion and its effectiveness remain up to maximum 10 h [39]. Additionally, DEET is practically difficult to apply on fabrics, owing to its quite low durability even at mild laundering. Hence, finding the way to apply DEET onto textile materials with reasonable durability and withstanding for longer duration is much promising way to permit DEET application in insect repellent fabrics.

In the current research, we offered a good strategy to control the release of DEET as insect repellent with sufficient amount, from natural fabrics represented in cotton, linen and silk. The designed fabrics are planned to be widely applicable as insect repellent materials used for manufacturing protective tents, curtains, bed-sheets, coatings…etc, especially in endemic areas. Fabrics were firstly modified by direct incorporation of metal organic framework (MOF) based on Copper- benzene-1,3,5-tricarboxylic acid (Cu-BTC). DEET was then loaded onto the so-obtained Cu-BTC@fabrics and its release profile was studied. The formation of Cu-BTC inside fabric matrix was studied by scanning electron microscope (SEM), energy dispersive X-ray (EDX), X-ray diffraction (XRD) and attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR). Presence of DEET on Cu-BTC@fabrics was confirmed by (ATR-FTIR) and the net content was detected. Release of DEET from modified and unmodified fabrics was studied as function of time.

2 Experimental section

2.1 Chemicals and materials

Copper(II) nitrate trihydrate (>99%) and N,N-dimethylformamide (DMF, 99.9%) from Aldrich, USA, benzene-1,3,5-tricarboxylic acid from Merck, Darmstadt—Germany, sodium carbonate (99%) from Egyptian company for chemicals and pharmaceuticals, tenth of Ramadan-Egypt, and commercial Cu-BTC MOF (Basolite C 300, HKUST-1) from Aldrich-USA, were all used as received without any purification.

Scoured and bleached 100% Linen fabrics (212 g/m2) were supplied from SDL Textile innovator—USA. Desized, scoured and bleached plain-woven 100% Cotton fabrics (160 gm/m2), scoured and bleached 100% Silk fabrics (65 g/m2) were all kindly supplied from El-Mahalla Company for Spinning and Weaving, El-Mahalla El-Kubra—Egypt. To remove the impurities, fabrics were washed using 2 g/L nonionic detergent (Hospatal CV—Clariant) with 1/50 material to liquor ratio at 50 °C for 30 min. Washing process was performed at 50 °C for all fabrics except linen at 90 °C. Fabrics were rinsed thoroughly with tap water at RT and then air dried at RT.

2.2 Synthesis of Cu-BTC@fabric

Direct incorporation of Cu-BTC into fabrics was carried out according to our modified method as follows: a 2.077 g of Copper(II) nitrate trihydrate and 1.0 g of benzene-1,3,5-tricarboxylic acid were both dissolved in 50 mL of DMF and then fabric specimens with dimension of 8 × 8 cm2 was added to solution and stirred for 30 min. Afterwards, the solution mixture was heated at 160 °C on open air until complete evaporation of DMF. The reaction vessel was cooled down to room temperature and the produced fabrics were rinsed by tap water five times to remove the excess and un-reacted materials. The product was then dried on oven at 75 °C over night prior to analyses and characterizations.

2.3 Loading of insect repellent onto Cu-BTC@fabric

In the current study, one of the most familiar insect repellent was used namely; N,N- diethyl-3-methylbenzamide (DEET). Loading of insect repellent into fabrics was carried out as follows: specimen of the Cu-BTC@fabric with dimension of 2 × 2 cm2 was placed in a 8 mL vial and 2 mL of pure insect repellent was added. The contents of the vial were stand at room temperature for 1 h and then fabric was removed from solution and transferred to petri dish.

2.4 Characterization of materials

The morphologies of the modified Cu-BTC@fabrics were characterized using a scanning electron microscope (SEM, Hitachi SU-70) operating at an accelerating voltage of 25 kV at the required magnification at room temperature. The same microscope equipped with an energy dispersive X-ray spectrometer (EDX) using a field emission gun to measure the elemental analysis.

Fabric, Cu-BTC and the modified Cu-BTC@fabric samples were subjected to powder X-ray diffraction, XRD, Philips X’Pert MPD diffractometer (Cu Kα X-radiation at 40 kV, 50 mA and λ = 1.5406 Å) at room temperature. Data were collected in the two theta ranging from 3.5 to 50° with a step size of 0.03° and scanning rate of 1 s.

Fabric and Cu-BTC@fabric samples were characterized by attenuated total reflection Fourier transform infrared spectroscopy (ATR-FTIR). Fabric samples were subjected to ATR-FTIR spectroscopy (Mattson 5000 FTIR spectrometer) in the wave number range of 4000–350 cm−1 using absorption mode. FTIR was equipped with a deuterated triglycine sulfate detector and accessory attenuated total reflectance (ATR unit with Golden Gate diamond crystal).

The color coordinates of CIE lab (L, a*, b*) for both of pristine and modified fabrics were recorded with a spectrophotometer with pulsed xenon lamps as light source (UltraScan Pro, Hunter Lab, USA). The equipment was adjusted as follows: CIE LAB color space, 10° observer with D65 illuminant, viewing geometry of d/2 and 2 mm measurement area. Color coordinates parameters are lightness (L*) from black to white (0–100), a* is a red/green ratio (+/-) and b* is yellow/blue ratio (+/-) [40]. The corresponding absorbance spectrum was measured at λmax of 700 nm. All samples were measured at three independent areas, considering with both sides of fabrics and the mean values were recorded.

Optical spectra of the samples represented in color strength (K/S) as Kubelka–Munk function, were determined on a JASCO UV 3100 spectrometer, in the range of 250–700 nm, with 0.2 nm in step-size, and using BaSO4 as reference.

Copper contents onto Cu-BTC@fabrics were performed for the extracted solution using inductively coupled plasma atomic emission spectrometry (ICP-AES—Agilent 725) from HORIBA Jobin Yvon Activa. For measurements, Argon was used as carrier gas and to create the plasma. Fabric sample was dissolved for 1 h in solution mixture containing 5 mL nitric acid, 3 mL hydrochloric acid and 0.5 mL hydrogen peroxide using a 600 W microwave oven from Anton Parr (max. 240 °C and 60 bars).

The estimated amount of MOF was calculated based on the measured Cu content. While the actual contents of MOF onto fabrics were measured via isolation of MOF by ammonia using the method reported in literature [41]. Known weigh of fabric was stirred in 23 M of ammonia solution (28 wt%, 30 mL) for 15 min resulting in complete dissolution of MOF. Fabric was isolated and washed with water several times and then dried in vacuum. The weight of fabrics before and after dissolution process was recorded and the differences between two weights were referred to the content of Cu-BTC.

2.5 Release of insect repellent

To evaluate how is the material controlling in level of release behavior, the release of DEET insect repellent entrapped in Cu-BTC@fabrics to air was tested. Certain weight of samples was kept in oven at 35 °C and the samples were then reweighed at time intervals. Then, the cumulative release percentage of insect repellent was calculated according to Eq. 1. The untreated fabrics were examined as a control for release of insect repellent. All experiments were performed in triplicate and the average value was considered.

where R% is a cumulative release percentage of DEET, W0 and Wt are the masses of the Cu-BTC@fabric at the beginning and after exposure to the imitated environment for a definite time, respectively.

2.6 Kinetic of release

The data obtained from DEET release study were fitted into kinetic mathematical model (zero-order model). Zero-order equation was presented in Eq. 1.

where Q is the cumulative amount of DEET released at residence timet and t1/2 is half of residence timet.

3 Results and discussion

The present work focused on two novel approaches; (1) in-situ synthesis of Cu-BTC into different natural fabrics matrixes via quite simple, one-pot and costless technique. (2) Application of the so-prepared Cu-BTC@fabrics in controlling the release of insect repellent with sufficient amount. The significance of this work represented in using of natural fabrics as template during the formation of Cu-BTC to increase the content of fixed Cu-BTC onto the fabrics and consequently raise the material effectiveness in applications. Additionally, in application side, controlling the release of insect repellent with appropriate amount from fabrics increases the durability and effectiveness of insect repellent as function of residence time and therefore further benefits will be achieved through retaining the effective materials for longer residence time with controllable liberation.

3.1 In-situ modification of fabrics by Cu-BTC

Primarily, Cu-BTC was directly synthesized into fabrics and hence the Cu and Cu-BTC content into modified fabrics was measured. Data in Table 1 shows that, Cu and Cu-BTC contents in fabrics were both insignificantly changed by fabric types. Contents of copper were ranged in 35.9 ± 1.1–38.9 ± 1.8 mg/g fabrics. Taking in mind that 1 mol of MOF containing 190 g Cu depending on the calculation of molecular formula of MOF (C18H6Cu3O12), the estimated MOF content was in the range of 114.9 ± 6.0–123.9 ± 9.5 mg/g. The actual content of MOF calculated from the difference in wt of fabrics after MOF dissolution, was nearly similar (115.4 ± 10.7–130.3 ± 3.2 mg/g) to the estimated one. Similarity in MOF content between the estimated and actual values reflects the efficiency of the presented technique for in-situ incorporation of Cu-BTC into fabrics. The modified fabrics were further characterized using SEM, EDX, XRD and ATR-FTIR to confirm the presence of Cu-BTC and the data was presented in the next section.

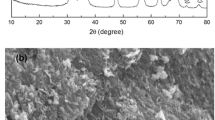

3.2 SEM analysis

The topographical features of the different natural fabrics were investigated by examination of fabrics’ surface using electron microscope and EDX analysis. Electron micrographs and EDX data presented in Fig. 1, confirmed the in-situ synthesis of Cu-BTC into fabrics. Cu-BTC crystals were clearly observed on the clear coarse surface of all treated fabrics. EDX analysis assured the presence of Cu-BTC on fabrics by recording signal of Cu. Fibrils of fabrics were seen densely covered with MOF materials, the shape and the visual amount of the formed Cu-BTC was obviously depended on fabric types (inset figure). Crystalline structure of MOF with enlarged size was detected in case of Cotton/Linen while particles like in shape were seen on the surface of Silk. It may reflect the role of fabric structure in MOF preparation, which represented in contribution through different function groups including OH for Cotton/Linen and NH- for Silk. For Cu-BTC@Cotton, morphology of Cu-BTC was similar to that shown in literature for Cu-BTC after loading onto Cotton [29].

3.3 X-ray diffraction patterns

For further confirmation, XRD analyses were applied for pristine fabrics and Cu-BTC@fabrics samples as shown in Fig. 2. XRD analysis for commercial Cu-BTC was measured for comparison with Cu-BTC@fabrics. Compared to the original fabrics, Cu-BTC@fabrics samples exhibited new diffraction peaks confirming the presence of Cu-BTC. In case of Linen and Cotton, new similar diffraction peaks at 2θ = 6.8°, 9.6°, 11.8°, 13.6° and 19.1° were measured. Main diffraction peak of silk was disappeared and a lot of new intensive diffraction peaks at 2θ = 6.7°, 9.4°, 11.6°, 13.4°, 17.4°, 19.1°, 20.1°, 25.9°, 29.4°, 35.3° and 39.2° were appeared. All of these diffraction peaks detected are in match with commercial Cu-BTC and previous PXRD data for pure Cu-BTC [42]. XRD patterns for Cu-BTC@Cotton through in-situ preparation were similar to that for Cu-BTC@Cotton prepared by Cotton coated Cu-BTC [29]. Difference in intensity and number of diffraction peaks as function of fabrics type, reflects the role of fabrics structure in formation of Cu-BTC and consequently bonded together through chemical interactions. Micrographs confirmed this hypothesis via observing different shapes of Cu-BTC onto fabrics.

3.4 ATR-FTIR spectra analysis

ATR-FTIR spectra of fabrics and Cu-BTC@fabrics were shown in Fig. 3. For Cotton, a broad absorption band at 3400–3300 cm−1 and band at 2890 cm−1 were observed corresponding to stretching of OH group and asymmetric C–H stretching vibration, respectively [1, 4, 29]. Absorption bands at 1640 and 1440 cm−1 are attributed to C=O group and H–C–H scissoring, respectively [1, 4, 29]. Due to the same composition of fabrics as cellulose, similar absorption spectra were detected for Linen. In case of Silk, absorption bands of N–H stretching and deformation appeared respectively at 3250 and 1450 cm−1. Asymmetric stretching of C-H recorded at 2950–3100 cm−1, while symmetric bending and stretching of C–C observed respectively at 1150 and 950 cm−1. Absorption bands of amide I, amide II and amide III were recorded at 1670, 1530 and 1260 cm−1, respectively [43, 44].

Regarding to Cu-BTC@fabrics, absorption bands as same as pristine fabrics were recorded. Additionally, ATR-FTIR spectra of all Cu-BTC@fabrics showed two new bands at 730 and 770 cm−1. This bands are related to copper substitution on carboxylate groups of benzene-1,3,5-tricarboxylic acid, which can be considered as the characteristic bands of Cu-BTC [45].

3.5 Colorimetric data

Table 2 and Fig. 4 represented the change in colorimetric data of fabrics by MOF modification. From Table 2, lightness (L*) was diminished from 89.22–91.35 to 78.77–51.21 by modification, reflecting the change in fabrics color to dark color, which was attributed to the presence of Cu-BTC MOF, and additionally Silk fabrics were more darkened. Values of a* were changed from 0.38 to −25.84 and −0.35 to −21.17 for Cotton and Linen fabrics, respectively. While, b* values were varied from −0.28 to −7.39 and from 8.95 to 4.31 for Linen fabrics. In case of Silk fabrics, MOF modification resulted in data changing from 0.80 to −4.77 and from 8.05 to 16.69 for a* and b* values, respectively. From Fig. 4, color strength (K/S) for Cu-BTC showed a peak of 650–750 nm, indicating the bluish color of MOF. Similar peaks were recorded for all modified fabrics which confirmed the presence of Cu-BTC onto fabrics. From these data it can be summarized that, (1) color of Cotton was changed from originally white to blue after Cu-BTC modification. (2) Color of linen and silk were turned from yellow and creamy white, respectively to greenish due to modification and small peak appeared at 390–450 nm. The defects at MOF surface, is accompanied by presence of Cu2+ ions which could be easily reduced by action of hemicellulose in linen and amide group of silk, resulted in greenish color. (3) K/S and absorbance at λmax (Table 2) confirmed that the color of fabrics became darker by MOF modification, however, Silk exhibited the maximum darkness. (4) The change in color data of fabrics confirmed the presence of Cu-BTC onto fabrics and reflected the interaction between fabrics’ macromolecules and Cu-BTC molecules as different color produced for different fabrics.

3.6 Application of Cu-BTC@fabrics in insecticide control releasing

DEET as familiar insect repellent remains on the human skin for only 10 h when it used as lotion. This section is interested in impregnation of DEET into fabrics to raise the durability of DEET from 10 h to several days and for easy handling to be widely applicable. In addition to, prevention or inhibition of direct attaching of insect repellent with human skin to avoid further problems of skin. DEET was loaded onto the modified fabrics and the release behavior was tested.

Figure 3 shows ATR-FTIR spectrum of DEET, DEET@fabrics and DEET@Cu-BTC@fabrics. Pure DEET exhibited three different peaks at 2950, 1630 and 1150 cm−1 are assigned to asymmetric aliphatic C–H, C=O of amide and C–C stretching, respectively [46]. Regardless to fabric types and modification, these three significant peaks were all recorded in case of DEET@fabrics and DEET@Cu-BTC@fabrics, confirming DEET loading onto unmodified and modified fabrics. For cellulosic fabrics (Linen and Cotton), intensity of absorption band of carbonyl at 1640 cm−1 was extensively increased after DEET loading due to interpenetration of carbonyl group for DEET.

The contents of DEET into fabrics were measured and data presented in Table 3. Regardless to modification of fabrics, amount of DEET entrapped within fabrics was observed to be varied according to fabric types and follow the order of Silk < Linen < Cotton. DEET amount on fabrics were 180 ± 15, 250 ± 17 and 310 ± 18 mg/g with the same order. Owing to porosity structure of Cu-BTC, the modified fabrics showed much higher DEET content by an estimated amount of ≈200 ± 8.7 mg/g whatever fabrics type. However, the increment percentage in DEET amount due to modification of fabrics by Cu-BTC was ranged from 65 to 110%, the amount of increment in DEET by modification was mainly the same (195–210 mg/g).

3.7 Release of DEET from fabrics

The release study of DEET from unmodified and modified fabrics up to ten consecutive days (240 h) at 35 °C was represented in Fig. 5. From these results, it can be found that (1) the release profile of DEET from fabrics was similar for all three fabrics with nearly identical release rate and the release percentage was varied depending on fabric type and Cu-BTC modification. The DEET released from fabrics was 175–280 mg/g for unmodified fabrics and 380–500 mg/g for modified ones and follow the order of Silk < Linen < Cotton. (2) The release rate was so rapid in the first hour achieving a percentage ranged in 11.1–19.6 and 13.5–22% for modified and unmodified fabrics, respectively. While the amount of DEET released from fabrics in first hour was 40–50 and 60–80 mg/g which increased to 50–70 and 95–115 mg/g after 12 h for unmodified and modified fabrics, respectively. (3) Compared to cellulosic fabrics (Cotton and Linen), Silk showed faster release as almost all DEET (99% = 175 mg/g) was liberated after 144 h. Meanwhile, the same percent of 99% from DEET was released from Linen (240 mg/g) and Cotton (280 mg/g) fabrics after longer residence time of 180 and 192 h, respectively. (4) Modified fabrics with Cu-BTC displayed slower release and exhibited longer residence time compared to unmodified one and followed as the same order as unmodified fabrics. After Cu-BTC modification, the release of DEET from fabrics was enhanced. The release time was increased by value of 24–36 h and the release amount was frequently enlarged by 205–220 mg/g. However, release percentage was not significantly improved by Cu-BTC modification; the amount of DEET released from fabrics was considerably increased. This is a result of Cu-BTC presence, which helps in adsorption of much higher DEET and controls its release with highly sufficiently amount. (5) The high amount of DEET onto Cotton reflects the high amount of DEET released. However, the slower release was recorded for cotton as 85 ± 2 and 75 ± 3% were released after 6 days from Cotton and Cu-BTC@Cotton fabrics, respectively. This could be explained by the efficiency of cellulose macromolecules to control the release of DEET and the release profile of Linen supported this hypothesis as its slower than Silk. These release data confirmed that the in-situ modification of fabrics by Cu-BTC improved both of release rate and residence time of DEET. Compared to unmodified fabrics, DEET was remained on modified fabrics for longer residence time and liberated with quite high amount which is much sufficient to repel insects.

3.8 Kinetics and mechanism of DEET release

By studying the kinetics of DEET release, it was found that release of DEET from fabrics fitted well to kinetic mathematical model of zero-order model achieving correlation coefficients (R2) > 0.95. Release constant (k0) and the half of release residence time(t1/2) for DEET from fabrics (Table 4) were followed the order of Cotton > Linen > Silk and the fabrics after MOF modification showed much higher k0 values. This data could be explained by the release profile of DEET from fabric discussed formerly which is following the same order. Due to the modification, the half of release time was grown from 104.81 to 109.81 h and from 86.54 to 97.65 h for Cotton and Silk, respectively. Moreover, release constant was enlarged from 1.04 to 1.48 mg/h for unmodified fabrics to 1.92–2.17 mg/h for modified fabrics, achieving increment in DEET release by percentage of 32–46% due to MOF incorporation. In zero order model, the rate of reaction is obviously independent on the reactant concentration. This explained that the rates of DEET release do not vary with increasing nor decreasing DEET contents on fabrics.

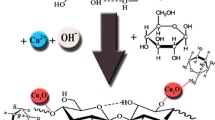

The kinetic of DEET release provides more information for the function of Cu-BTC@fabrics, this information’s leads to polishing the detailed mechanism and the structure–function relationship. In general, the main release mechanisms from polymeric matrices are solute diffusion, polymeric matrix swelling and material degradation [47]. In present study, DEET loading was occurred through physical deposition in pores of Cu-BTC. Hence, the suggested mechanisms of DEET release from fabrics may be physical pathway. DEET was diffused from the pores of Cu-BTC during thermal heating at 35 °C (Fig. 6c).

3.9 Tentative mechanism

Directly preparation of Cu-BTC into fabrics was confirmed via SEM micrographs, XRD patterns and FTIR spectra. Based on these data, the in-situ synthesis of Cu-BTC was depended on fabric types and hence the interaction with fabrics was varied according to type of fabrics. Figure 6 shows the proposed mechanism between fabrics and Cu-BTC. In case of Cotton and Linen as cellulosic materials (Fig. 6a), have high active sites represented in hydroxyl groups which offered a good way to interact with Cu of Cu-BTC by complexation [1, 2, 48]. Hence Cotton and Linen may interact with Cu-BTC through coordination bonding between Cu and their OH groups [29]. Silk as proteinic fabrics, have a several amide groups with basic character which highly reactive and hence easily bind with Cu via coordination linkage forming complex (Fig. 6b). Besides amide, there is a primary alcohol group which can share in the Cu complexation.

The interaction between DEET and Cu-BTC@fabrics can be suggested as shown in Fig. 6c. Porous structure of Cu-BTC act as trapping sites for physical deposition/adsorption of DEET molecules onto Cu-BTC@fabrics [29]. In case of unmodified fabrics, DEET molecules may be deposited in the fabrics’ pores and interspaces between fibrils.

4 Conclusion

The current research offered a quite easy and good strategy to release of DEET insect repellent with sufficient amount from natural fabrics namely; Cotton, Linen and Silk. The work was designed as follows; firstly, Cu-BTC as MOF material was directly incorporated into the matrix of fabrics. Secondly, DEET was uploaded onto the fabrics and then the release of DEET was studied at 35 °C up to 144 h. In-situ incorporation of Cu-BTC was affected by fabrics’ structure represented in its active sites. While loading and release of DEET was influenced by fabrics’ macromolecules and MOF contents and the later affected by binding sites of fabrics.

Cu-BTC formation inside fabrics was studied and confirmed by SEM, EDX, XRD and FTIR. The morphology and the amount of the formed Cu-BTC were noted to be dependent on type of fabrics. The contents of Cu and Cu-BTC in fabrics were measured and were 35.9–38.9 mg Cu/g fabric and 115.4–130.3 mg Cu-BTC/g fabric. Color of fabrics was changed to bluish/greenish by Cu-BTC modification. DEET loaded on fabrics was measured and Cotton showed highest amount followed by Linen and lastly Silk. Thus, the highest amount of DEET released was realized by Cotton. Owing to presence of Cu-BTC, the modified fabrics exhibited higher DEET content by value of 65–110%. By studying the release profile, it was found that the amount of DEET released from fabrics was significantly raised from 175 to 280 to 380–520 mg/g due to modification. Presence of MOF into fabrics was accompanied by slower release, achieving 24–36 h longer time. The rate of DEET release was fitted well to zero order model in which the rate is apparently independent of the DEET content on fabrics. DEET release mechanism was suggested to be physical pathway through diffuse from Cu-BTC pores.

These results revealed that, the in-situ formation of Cu-BTC into natural fabrics offered good control in the release of insect repellent with high amount. The designed fabrics are planned to be used as disposable insect repellent products in the form of protective tents, curtains, bed-sheets, coatings…etc, especially in endemic areas, with noticeable release for longer time surpassed 9 days. The composite materials based on fabrics can be reused several times by applying and release the DEET. As an extension of the current study, the application potential of DEET@CuBTC@fabrics in insect repellent field is under investigation in outstanding work.

References

H.E. Emam, T. Bechtold, Appl. Surf. Sci. 357, 1878 (2015)

H.E. Emam, A.P. Manian, B. Široká, H. Duelli, P. Merschak, B. Redl, T. Bechtold, Surf. Coating. Technol. 254, 344 (2014)

H.E. Emam, A.P. Manian, B. Široká, H. Duelli, B. Redl, A. Pipal, T. Bechtold, J. Clean. Prod. 39, 17 (2013)

H.B. Ahmed, H.E. Emam, Fiber. Polym. 17, 418 (2016)

H.E. Emam, M. El-Rafie, H.B. Ahmed, M. Zahran, Fiber. Polym. 16, 1676 (2015)

H.E. Emam, N. Saleh, K.S. Nagy, M. Zahran, Int. J. Biol. Macromol. 84, 308 (2016)

H.E. Emam, N. Saleh, K.S. Nagy, M. Zahran, Int. J. Biol. Macromol. 78, 249 (2015)

H.E. Emam, M.K. Zahran, Int. J. Biol. Macromol. 75, 106 (2015)

M. El-Rafie, H.B. Ahmed, M. Zahran, Carbohydr. Polym. 107, 174 (2014)

F. Abdel-Mohdy, M.M. Fouda, M. Rehan, A. Aly, Carbohydr. Polym. 73, 92 (2008)

A. Hebeish, M.M. Fouda, I. Hamdy, S. El-Sawy, F. Abdel-Mohdy, Carbohydr. Polym. 74, 268 (2008)

K. Ramya, V. Maheshwari, Int. J. Pharm. Pharm. Sci. 6, 115 (2014)

S. Palanisami, E. Natarajan, R. Rajamma, J. Innov. Biol. 1, 132 (2014)

R. Maheswaran, S. Sathis, S. Ignacimuthu, Int. J. Integr. Biol. 2, 214 (2008)

D. Vijayalakshmi, C. Vigneswaran, Melliand China 12, 014 (2010)

W. H. O. (WHO), “World Malaria Report”, WHO, (NLM classification: WC 765) (2015)

S.A. Farag, H. Osama, R. Mohamed, H. Mohamed, Mater. Sci. Appl. 2, 200 (2011)

J.-C. Tan, B. Civalleri, CrystEngComm 17, 197 (2015)

K. Sumida, D.L. Rogow, J.A. Mason, T.M. McDonald, E.D. Bloch, Z.R. Herm, T.-H. Bae, J.R. Long, Chem. Rev. 112, 724 (2011)

S. Bourrelly, B. Moulin, A. Rivera, G. Maurin, S. Devautour-Vinot, C. Serre, T. Devic, P. Horcajada, A. Vimont, G. Clet, J. Am. Chem. Soc. 132, 9488 (2010)

J.-R. Li, J. Sculley, H.-C. Zhou, Chem. Rev. 112, 869 (2011)

P. Horcajada, T. Chalati, C. Serre, B. Gillet, C. Sebrie, T. Baati, J.F. Eubank, D. Heurtaux, P. Clayette, C. Kreuz, Nat. Mater. 9, 172 (2010)

J. Liu, L. Chen, H. Cui, J. Zhang, L. Zhang, C.-Y. Su, Chem. Soc. Rev. 43, 6011 (2014)

R.M. Abdelhameed, M.M. Simões, A. Silva, J. Rocha, Chem. A Eur. J. 21, 11072 (2015)

Z. Hu, B.J. Deibert, J. Li, Chem. Soc. Rev. 43, 5815 (2014)

R.M. Abdelhameed, L.D. Carlos, A.M. Silva, J. Rocha, Chem. Commun. 49, 5019 (2013)

A.J. Howarth, Y. Liu, J.T. Hupp, O.K. Farha, CrystEngComm 17, 7245 (2015)

Z. Hasan, S.H. Jhung, J. Hazard. Mater. 283, 329 (2015)

R.M. Abdelhameed, H. Abdel-Gawad, M. Elshahat, H.E. Emam, RSC Adv. 6, 42324 (2016)

L. Paseta, E. Simón-Gaudó, F. Gracia-Gorría, J. Coronas, Chem. Eng. J. 292, 28 (2016)

A.M. Grancarić, A. Tarbuk, I. Kovaček, Chem. Ind. Chem. Eng. Q. 15, 203 (2009)

E. Pérez, L. Martín, C. Rubio, J.S. Urieta, E. Piera, M.A.n. Caballero, C. Téllez, J.n. Coronas, Ind. Eng. Chem. Res. 49, 8495 (2010)

E. López-Maya, C. Montoro, L.M. Rodríguez-Albelo, S.D. Aznar Cervantes, A.A. Lozano-Pérez, J.L. Cenís, E. Barea, J.A. Navarro, Angew. Chemie Int. Ed. 54, 6790 (2015)

G. Rivera-Cancel, D. Bocioaga, A.G. Hay, Appl. Environ. Microbiol. 73, 3105 (2007)

S. J. Moore, M. Debboun, M. Debboun, S. Frances, D. Strickman, Insect repellents: principles, methods, and uses, vol. 3 (CRC press, Boca Raton, 2007)

D.R. Swale, B. Sun, F. Tong, J.R. Bloomquist, PloS ONE 9, e103713 (2014)

S.I. Gertler, “Nu, nu-diethylbenzamide as an insect repellent”, Google Patents, (1946)

B.J. Want, J. Chem. Educ. 51, 631 (1974)

United States Environmental Protection Agency (USEPA), “Reregistration Eligibility Decision (RED) DEET, " WASHINGTON USEPA,, D.C, 20460, (1998)

A. T. M., “AATCC Evaluation Procedure 6-2003”,(2008)

T. Uemura, Y. Kadowaki, N. Yanai, S. Kitagawa. Chem. Mater. 21, 4096 (2009)

K.-J. Kim, Y.J. Li, P.B. Kreider, C.-H. Chang, N. Wannenmacher, P.K. Thallapally, H.-G. Ahn, Chem. Commun. 49, 11518 (2013)

X. Zhang, P. Wyeth, Sci. China Chem. 53, 626 (2010)

E. Steven, W.R. Saleh, V. Lebedev, S.F. Acquah, V. Laukhin, R.G. Alamo, J.S. Brooks, Nat. Commun. 4 (2013)

N. Sani, W.J. Lau, A. Ismail, RSC Adv. 5, 13000 (2015)

T. İnceboz, G. Erkan, G.C. Türkoğlu, A.M. Sarıışık, S. Bakırcı, S. Üner, A. Üner, Text. Res. J. 85, 2071 (2015)

P.T. Wong, S.K. Choi, Chem. Rev. 115, 3388 (2015)

H.E. Emam, A.P. Manian, B. Široká, T. Bechtold, Carbohydr. Polym. 90, 1345 (2012)

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Emam, H.E., Abdelhameed, R.M. In-situ modification of natural fabrics by Cu-BTC MOF for effective release of insect repellent (N,N-diethyl-3-methylbenzamide). J Porous Mater 24, 1175–1185 (2017). https://doi.org/10.1007/s10934-016-0357-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-016-0357-y