Abstract

A polycrown loaded silica composite material named Polycrown/SiO2-P was firstly prepared by impregnating and immobilizing polycrown into porous silica and was characterized by scanning electron microscope (SEM), and Fourier transformed infrared (FT-IR) spectroscopy, nitrogen adsorption and desorption isotherms. Polycrown/SiO2-P was tested with regard to adsorption performance. Interestingly, Polycrown/SiO2-P preferred Pd(II) than alkali metals, alkaline-earth metals and actinides. Pd(II) adsorption with Polycrown/SiO2-P as functions of HNO3 concentration, contact time, initial Pd(II) concentration, temperature were thus investigated. The results showed the optimal adsorption acidity was determined as 5.0 M nitric acid, proving good acidity-resistant. Pseudo-second-order kinetics model fitted adsorption well indicating chemical adsorption. The isotherm adsorption equilibrium was well described by Langmuir isotherm model with maximum adsorption capacity of 14.30 mg/g. Pd(II) adsorption increased with temperature increased. The positive ΔH° and ΔS°, and the negative ΔG° indicated the adsorption was endothermic, entropy increase and spontaneous in nature. Pd(II) loaded Polycrown/SiO2-P was characterized by XPS. Further, the adsorption efficiency of recovered Polycrown/SiO2-P retained up ~93.7% after five ad-desorption cycles. Polycrown/SiO2-P was promising to separate Pd(II) from highly acid medium.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Palladium, one of platinum group, is a precious metal. Because of specific ductibility, malleability, and inertness, palladium is widely used in fields of industries such as: jewelry and ornament [1], electronics [2], telephone circuits [3], heat and corrosion resistance apparatus [4], catalysts [5, 6], and dental alloys [7]. The increasing demand stimulates recovery of palladium from the second resources as the low palladium concentration in terrestrial crust [8]. A commercial light water reactor at a burn-up of 33 GWd/t produces the burnt spent nuclear fuel with ca. 1 kg palladium. By 2030 spent nuclear fuel could supply up to 1000 t palladium worldwide. Fission palladium is comprised of isotopes 104 (17 wt%), 105 (29 wt%), 106 (21 wt%), 107 (17 wt%), 108 (12 wt%), and 110 (4 wt%). Among them, Pd-107 is the only radioactive isotope with a half-life of 6.5 × 106 years [9]. In addition, palladium separation is helpful to the final follow-up treatment for the spent nuclear fuel of high radioactivity risk. Therefore palladium deserves recovery from the spent nuclear fuel. Notably, palladium made in this way is finally concentrated in high level radioactive liquid waste of 3.0–6.0 M nitric acid, leading a big challenge for separation.

First generation supramolecular crown has unique affinity toward metal ions. 15-Crown-5 commonly complexes sodium cation while complexes other metal ions once modification. N-phenylaza-15-crown-5 recognizes Fe having potential as a selective electrode [10]. Monoaza-15-crown-5 containing an optically active aminobenzoxazinone moiety responds to Mg, Ca, Ba, Sr, Cd and particularly responds to Hg and Pb [11]. Benzo-15-crown-5 is capable to detect uranyl [12] and naphthaleneacetamide modifying benzo-15-crown-5 can become Mg-responsive fluorescent chemosensor [13]. Thus 15-crown-5 via proper modification has reason to complex Pd. Moreover, polymers including polymeric crowns have special characters such as high resistance to chemicals, to temperature, and to radiolysis [14]. It has been utilized for selective separating lead [15], neodymium [16], uranium [15], barium [17], etc.

Authors have devoted to metals separation from high level radioactive liquid waste by preparing various silica-based materials [18–20], most of which possessed outstanding acid resistance. The made (Calix[4]+MODB)/SiO2-P has cesium distribution coefficient of over 10 even nitric acid concentration beyond 6.0 M [21]. (DtBuCH18C6+TBP)/SiO2-P can selectively adsorb strontium from La(III), Y(III), Na(I), K(I), Cs(I), Ru(III), Mo(VI) and Pd(II) under 2.0 M HNO3 [22]. Base on above materials, authors developed an advanced partitioning technology SPEC (stronium/cesium partitioning from high level radioactive liquid waste by extraction chromatography) process. Cs(I) and Sr(II) can be successfully separated from high HNO3 concentration medium [23].

In the present work, polycrown (poly 4-[3-(3-benzo-15-crown-5)methyl-4-hydroxy-phenyl]methylethyl-phenol) loaded silica composite material (Polycrown/SiO2-P for short) was prepared. Recognition ability and high acidity resistance endowed Polycrown/SiO2-P suitable in palladium separation from highly acid medium. Effects of experimental parameters such as nitric acid concentration, contact time, initial palladium concentration, temperature and coexistence metal on adsorption were studied. The isotherms and kinetics models were used to fit and describe adsorption. The adsorption mechanism was researched in microscopic level by XPS.

2 Materials and methods

2.1 Materials

The polycrown synthesized using formic acid, bisphenol A, benzo-15-crown-5, and concentrated sulfuric acid [24] was provided by Prof. Tatsuya Suzuki, Tokyo Institute of Technology, Japan. The analytical grade chemicals of MINO3 (MI=Na(I), K(I), Rb(I) and Cs(I)), MII(NO3)2 (MII=Sr(II) and Ba(II)), hydrochloric acid and 30% hydrogen peroxide were purchased from Sinopharm Chemical Reagent Co.,Ltd. 68% HNO3 was purchased from Zhongxing Chemical Limited Company, Hangzhou, China. Palladium nitrate solution with 4.5 wt% Pd(II) was from Tanaka Noble Metal Co. Inc., Japan. Deionized water with purity of conductivity <0.5 μs/cm was used throughout. U(VI) stock solution was prepared as following. To 7.0167 g U3O8 in a 100 mL beaker 10 mL hydrochloric acid (ρ = 1.18 g⋅mL− 1) and 2 mL 30% hydrogen peroxide were added. After heated to near dry, the solution was added with 10 mL hydrochloric acid (ρ = 1.18 g⋅mL− 1) and then diluted to 1,000 mL with distilled water to make U(VI) concentration of 5.0 × 10− 2 M [25].

Polycrown/SiO2-P was prepared according to an available method in lab in Fig. 1 [26–28]. The preparation method for Polycrown/SiO2-P in detail is as following. The silica particles were put into a evacuated glass flask, and into the flask the following was sucked such as a mixture of monomers composed of 85 wt% of m/p-formyl-styrene, 15 wt% m/p-dinvinylbenzene, dioctyl phthatate and methylbenzoate, initiators made of α,α-azobisiso-butyronitrile (AIBN) and 1,1′-az-obiscyclohexane-1-carbonitrile, and diluents consisted of 1,2,3-trichloropropane and m-xylene. The flask was rotated continuously for complete soaking silica particles and then filled with N2 gas. The flask was then heated at 363 K for 20 h with a silicone oil bath. The grafted material (SiO2-P) was obtained after wash with acetone and water and then dry overnight at 323 K.

To increase affinity of the styrene–divinylbenzene copolymer contained in SiO2-P for polycrown molecule, SiO2-P particles were washed in advance with methanol for three times prior to synthesizing Polycrown/SiO2-P. 1.0 g polycrown dissolved with about 150 mL dichloromethane and 9.0 g of above prepared SiO2-P particles were mixed into a 500 mL flask and mechanically stirred for nearly 90 min at room temperature. Later, the mixture was transferred into a silicon-oil bath and kept at ca. 45 °C for about 180 min under stirring. After drying in vacuum at 50 °C for 24 h, the polymeric adsorption material Polycrown/SiO2-P was obtained. Physical and chemical parameters of Polycrown/SiO2-P were shown in Table 1.

2.2 Instruments and spectroscopic measurements

An EYELA SB-2000 rotary evaporator was used to prepare Polycrown/SiO2-P. A TAITEC MM-10 Model auto-thermostated water bath shaker was applied in adsorption experiment. A Varian AA 240 FS Model atomic adsorption spectroscopy with RSD less than 0.5% was used to analyze metal ion concentration. Morphology of Polycrown/SiO2-P was observed by a scanning electron microscope (SEM) (HITACHI S-4800). Secondary electron resolutions of SEM are 1.4 nm (1 kV, deceleration mode) and 1 nm (15 kV). FT-IR spectrum was measured on a BRUKER Vector 22 FT-IR spectrometer and the background spectrum was measured on pure KBr. The resolution ratio and wavenumber accuracy of FT-IR are 1 and 0.01 cm− 1, respectively. Nitrogen adsorption and desorption isotherms were measured at 77 K using an ASAP 2020 M analyzer. The measurement accuracy of BET surface analyzer is 1%. Surface area was calculated by Brunauer–Emmett–Teller (BET) method, and pore volume and pore size distribution were calculated using Barret–Joyner–Halenda (BJH) model. The XPS photoelectron spectra was recorded using an ADES 400 angle-resolved photoelectron spectrometer (VG Scientific, UK) equipped with a rotatable hemispherical electron energy analyser with a Mg Kα X-ray source (1253.6 eV, Specs). The XPS wide spectra was recorded with a pass energy of 100 eV, step − 1 eV and dwell time 0.1 s. The high-resolution spectra with 20 eV, step 0.1 eV and dwell time 0.1 s.

2.3 Adsorption studies

The adsorption of metal ions of the desired concentration and HNO3 concentration on 0.25 g Polycrown/SiO2-P was investigated batch wise in 10 mL polyethylene centrifuge tubes. After shaken at 120 rpm for the adsorption equilibrium, solid and liquid phases were separated by filtration. The metal ion concentration was determined using the Varian AA 240 FS Model atomic adsorption spectroscopy except U which was analyzed using the arsenazo III method with a 721 type spectrophotometer at 650 nm. Distribution coefficient (K d) and the adsorption amount (q e) were calculated by the following equations:

where C 0 (mg/L) is the initial concentration, C e (mg/L) denotes the equilibrium concentration, V (L) is solution volume and W (g) is Polycrown/SiO2-P weight. All of the experimental data were averages of duplicate detections after deducting the tiny adsorption values of SiO2-P, i.e. blank experiments.

2.4 Desorption studies

After each adsorption study, the solution was filtered to recover the spent Polycrown/SiO2-P, which was then washed with acidic solution (0.01 M HNO3) to remove the adsorbed Pd(II). The recovered Polycrown/SiO2-P was thoroughly washed with water and ethanol, dried in a vacuum, and used for further adsorption studies. During the repeated adsorption studies, Pd(II) adsorption amount (q e) was determined. The adsorption and desorption processes were repeated up to 5 times, to further ascertain the recyclability of Polycrown/SiO2-P.

3 Results and discussion

3.1 Characterization of Polycrown/SiO2-P

SEM micrograph of Polycrown/SiO2-P is shown in Fig. 2a. It could be seen that Polycrown/SiO2-P was a sphere structure with a diameter of 50 μm.

The FT-IR spectra of Polycrown/SiO2-P (Fig. 2b) exhibited several characteristic bands at 3453, 2925, 1627, 1511, 1462, 1074, 794 cm− 1, respectively assignable to hydroxyl [29], methylene band [30], polymer, phenolic hydroxyl [31], C-H methyl and methylene deformation [32], Si-O-Si bending [33], Si-O stretching [34].

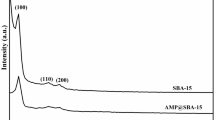

Low-temperature nitrogen adsorption–desorption isotherms spectra was obtained as Fig. 2c. The isotherms were of type III as defined by IUPAC, which indicated the weak interaction between Polycrown/SiO2-P and nitrogen molecules. The BET surface area was 3.118 m2⋅g− 1 and the pore volume was 0.008 mL⋅g− 1. Pore size distribution presented as Barret-Joyner-Halenda (BJH) plot showed the average pore diameter was ca. 4.0 nm.

3.2 Effect of HNO3 concentration on adsorption

Nitric acid is almost sole medium employed in reprocessing process of nuclear spent fuel, which is dissolved by hot and concentrated nitric acid. After recovery uranium and plutonium by the famous PUREX process, palladium exists in the raffinate, the aqueous phase treated by 30% tributyl phosphate/kerosene. By protonation with the oxygen atom in Polycrown/SiO2-P, nitric acid is considered to probably influence the complexation of Pd(II) [35, 36]. The effect of HNO3 concentration on distribution coefficient of Pd(II) are presented in Fig. 3.

It can be seen from Fig. 3 that K d(Pd) slightly changed as HNO3 concentration increased from 0.4 to 2.0 M, later drastically increased to 5.0 M, then decreased significantly to 6.0 M. Main reactions of complexation and protonation were shown in Fig. 3 [25]. The optimal nitric acid concentration was determined as 5.0 M, proving good acid-resistance and making possibility for using Polycrown/SiO2-P to separate Pd(II) from highly acid raffinate. The investigated Na(I), K(I), Rb(I), Cs(I), Sr(II), Ba(II) and U(VI) showed low K d indicating those metal ions hardly interrupted Pd(II) adsorption. It is thus predicts that alkali, alkaline earth, and actinide metal ions would not be adsorbed. Such selectivity is interesting as the crown ether compounds normally selectively bind alkali or alkaline-ether metal ions and especially 15-crown-5 with cavity diameter of 0.170–0.220 nm is commonly known to fit well with potassium in monovalence with effective ionic radii of 0.138 nm [37]. Thus the selectivity of crown compounds with metal ions can’t be simplified with the size match. In fact when one ion can fit within the cavity, the crown ether-metal ion coordination reacts in 1:1 ratio; and if the ion size is too different with the cavity, the crown ether has a tendency to “sandwich” or “coil” the metal ion [38]. The effective ionic radii of the divalent palladium is 0.100 nm, more coincident than K(I) and other metals. Thus palladium ion probably exclusively forms 1:1 type complex with Polycrown/SiO2-P.

3.3 Adsorption kinetics

The effect of contact time on Pd(II) adsorption on Polycrown/SiO2-P is shown in Fig. 4. As could be seen, K d(Pd) rapidly increased in the first 90 min, then slowly increased from 90 to 950 min. The decreasing concentration gradient attributes to the decrease in adsorption rate. In order to interpret the kinetic in detail, pseudo-first-order and pseudo-second-order were used to fit the experimental data [39]. The resultant fitness represents the corresponding mechanism [40]. The pseudo-first-order and pseudo-second-order models can be described using Eq. 2 and Eq. 3 [41].

where k 1 (min− 1) and k 2 (g/(mg⋅min)) represent adsorption rate constants of pseudo-first-order, pseudo-second-order models, respectively; q t (mg/g) is the adsorption amount at time t (min) and q e (mg/g) is the amount at equilibrium. Kinetic parameters of two kinetic models are listed in Table 2.

Validity of each model could be checked by fittness of the straight lines (R 2 values). As shown, the good fitness (R 2 = 0.991) with pseudo-second-order model and the close experimental (7.155 mg⋅g− 1) and theoretical q e (7.401 mg⋅g− 1) jointly confirmed validity of pseudo-second-order model, which suggested that chemical adsorption was the ruling way. Pd(II) and Polycrown/SiO2-P shared electrons when adsorption happened. The initial adsorption rates (h) was calculated as 0.215 mg⋅g− 1⋅min− 1 using h = k 2 q e 2.

3.4 Adsorption isotherm

To understand adsorption better, Pd(II) uptakes at different initial concentrations were investigated and the result was shown in Fig. 5. It was found that Pd(II) uptake firstly increased with increasing equilibrium concentration, and kept at constant beyond the equilibrium concentration of ca. 500 mg/L. Langmuir and Freundlich [42], were utilized to simulate adsorption data. Langmuir model (shown in Eq. 4) presupposes homogeneous and equal energy sites on adsorbent, which present an ideal adsorption behavior. Freundlich model (shown in Eq. 5) is an empirical equation with the assumption of hetergeneous surfaces on adsorbent.

where C e is the aquatic concentration (mg⋅L− 1) of Pd(II) at equilibrium; q e is the equilibrium uptake (mg⋅g− 1); q m is the maximum adsorption capacity (mg⋅g− 1); a is the Langmuir constant related to the affinity between adsorbate and adsorbent (L⋅mg− 1), and K is Freundlich isotherm constant (mg⋅g− 1), n is adsorption intensity. The parameters calculated from the plots of C e/q e vs. C e and lnq e vs. lnC e are listed in Table 3.

The Freundlich plots had a lower regression coefficient suggesting a restriction on the use of Freundlich isotherm. The Langmuir model with R 2 of 0.983 showed a better fittness and Q m given by the Langmuir model was 14.30 mg⋅g− 1, consistent with the experimental value of 13.79 mg⋅g− 1 at 5.0 M HNO3. The Langmuir model was thus determined to describe the Pd(II) adsorption process as a monolayer adsorption. We would like comparing the maximum adsorption capacity of 14.30 mg⋅g− 1 at 5.0 M HNO3 with other adsorbents, but as far as we known, data about the adsorbent performance at acidity greater than 1.0 M is rare.

The separation factor (R L, R L=1/(1 + aC 0)), a dimensionless constant, can be used to explain the essential characteristics of a Langmuir isotherm. R L values can be related to the equilibrium isotherm as follows: unfavorable, R L >1; linear, R L = 1; favorable 0 < R L<1; and irreversible, R L=0 [43, 44]. According to studied concentrations, all calculated R L values (0.018–0.882) were found to lie in between 0 and 1, proving a favorable adsorption process.

3.5 Thermodynamics

Effect of the temperature on Pd(II) adsorption is shown in Fig. 6. As could be seen, increasing the adsorption temperature from 298 to 328 K resulted in a significant increasement in K d from 17.24 to 20.84, denoting an endothermic nature. A linear plot of lnK d vs. 1/T was constructed. Thermodynamic parameters including the change in enthalpy (ΔH°), free energy (ΔG°) and entropy (ΔS°) were calculated using the Arrhenius law dlnK d/dT = ΔH o/RT 2 and Gibbs free energy ΔG° = ΔH° − TΔS° and were shown in Table 4. The positive value (5.032 kJ⋅mol− 1) of ΔH o means an endothermic process. One possible explanation for the endothermic process was that the solvated Pd(II) needed energy to strip the hydration shell before adsorption. The positive value (27.270 J⋅mol− 1⋅K− 1) of ΔS° represented that Polycrown/SiO2-P had affinity toward Pd(II). The negative values of ΔG° (−3.068 kJ⋅mol− 1 at 298 K, −3.406 kJ⋅mol− 1 at 308 K, −3.642 kJ⋅mol− 1 at 318 K, and − 3.895 kJ⋅mol− 1 at 328 K) confirmed the adsorption was spontaneous.

3.6 Reusability

As shown in Fig. 7, K d(Pd) slightly decreased from 7.15 mg⋅g− 1 to 6.05 mg⋅g− 1 during cycles from 1 to 5 in sequence. For another, the adsorption capability remained at considerable ~93.7% for the 5th cycle. This indicated that the chemisorption activity of Polycrown/SiO2-P was still high even after 5 regenerations. The adsorption/desorption cycle data also indicate that the effective composition in Polycrown/SiO2-P are regenerated without losing adsorption activity (recycling), and further proved the ability for reuse. As an adsorbent, Polycrown/SiO2-P was very expensive compared with the low-cost activated carbon [45]. But the novel properties of Polycrown/SiO2-P such as high acidity resistance, mechanical strength, high adsorption efficiency, easy desorption and repeated usability provide a reason to be a novel adsorbent in Pd(II) recovery from acid solution.

3.7 XPS analyses

The action between Pd(II) and Polycrown/SiO2-P in electron was analyzed by XPS and the result was shown in Fig. 8. In wide spectra before and after adsorption, 106 eV and 156.6 eV were denoted as Si 2p and Si 1 s peaks. 286.5 eV was assigned as C 1 s peak. O 1 s peaks were observed around 535 eV. The embedded Fig. 8(1) showed magnified spectra in the range from 335 to 350 eV. The spectra after adsorption showed two obvious peaks at 340 and 345.6 eV with the difference of 5.6 eV. Two peaks were defined as Pd 3d5/2 and Pd 3d3/2. The embedded Fig. 8(2) offered O 1 s spectra in which O 1 s before adsorption was at 535 eV and O 1 s after adsorption was at 535.2 eV [46]. These little difference of 0.2 eV was because the binding energy change for one palladium atom was averaged by five oxygen atoms.

4 Conclusion

For effective separation of Pd(II) from highly acid medium, the inorganic–organic composite silica-based material Polycrown/SiO2-P was successfully prepared. The adsorption results indicated that Polycrown/SiO2-P had ability to separate Pd(II) from the aqueous solution containing Na(I), K(I), Rb(I), Cs(I), Sr(I), Ba(II) and U(VI). The adsorption process depended on contact time, HNO3 concentration and slightly on temperature. The optimal acidity of HNO3 concentration was determined as 5.0 M. The pseudo-second-order kinetics fitted the adsorption well, suggesting that chemical adsorption was the rate-limiting step. Positive ΔH° and ΔS°, and negative ΔG o demonstrated an adsorption of endothermic, freedom increase, and spontaneous nature. XPS proved the effective adsorption of Polycrown/SiO2-P toward Pd(II). The experimental results demonstrate Polycrown/SiO2-P is promising in partitioning of Pd(II) from acid medium of 5.0 M HNO3.

References

M. Seltzer, R. Michel, Preparation of electrodeless discharge lamps for atomic fluorescence spectrometry. Anal. Chem. 55, 1817–1819 (1983)

H. Tan, I. Houpis, R. Liu, Y. Wang, Z. Chen, M.J. Fleming, Palladium-catalyzed coupling of sulfonylhydrazones with heteroaromatic 2-amino-halides (barluenga reaction): exploring the electronics of the sulfonylhydrazone. Org. Process. Res. Dev. 19, 1044–1048 (2015)

E. Yavuz, Ş. Tokalıoğlu, H. Şahan, Ş. Patat, Nano sponge Mn2O3 as a new adsorbent for the preconcentration of Pd(II) andRh(III) ions in sea water, wastewater, rock, street sediment and catalytic converter samples prior to FAAS determinations. Talanta 128, 31–37 (2014)

S. Barson, P. Skeldon, G. Thompson, A. Kolitsch, E. Richter, X. Wieser, J. Piekoszewski, A. Chmielewski, Z. Werner, Investigation of ion assisted palladium treatments for improved corrosion resistance of titanium foil in the electron beam dry scrubber process. Surf. Coat. Technol. 127, 179–192 (2000)

J. Tsuji, Palladium reagents and catalysts: new perspectives for the 21st century, Wiley (2004)

B. Lim, M. Jiang, J. Tao, P. Camargo, Y. Zhu, Y. Xia, Shape-controlled synthesis of Pd nanocrystals in aqueous solutions. Adv. Funct. Mater. 19, 189–200 (2009)

A. Milheiro, J. Muris, C.J. Kleverlaan, A.J. Feilzer, Influence of shape and finishing on the corrosion of palladium-based dental alloys. J. Adv. Prosthodont 7, 56–61 (2015)

M. Ruiz, A.M. Sastre, E. Guibal, Palladium sorption on glutaraldehyde-cross-linked chitosan. React. Funct. Polym. 45, 155–173 (2000)

Z. Kolarik, E.V. Renard, Potential applications of fission platinoids in industry. Platin. Met. Rev. 49, 79–90 (2005)

M. Aghaie, M. Giahi, H. Aghaie, M. Arvand, M. Pournaghdy, F. Yavari, New Fe(II) ion-selective electrode based on N-phenylaza-15-crown-5 as neutral carrier in PVC matrix. Desalination 247, 346–354 (2009)

R. Addleman, J. Bennett, S. Tweedy, S. Elshani, C. Wai, Response of a benzoxainone derivative linked to monoaza-15-crown-5 with divalent heavy metals. Talanta 46, 573–581 (1998)

G. Rounaghi, Selective uranyl cation detection by polymeric ion selective electrode based on benzo-15-crown-5. Mater. Sci. Eng. C 31, 1637–1642 (2011)

H. Hama, T. Morozumi, H. Nakamura, Novel Mg2+-responsive fluorescent chemosensor based on benzo-15-crown-5 possessing 1-naphthaleneacetamide moiety. Tetrahedron Lett. 48, 1859–1861 (2007)

A.E. Osmanlioqlu, Removal of radioactive contaminants by polymeric microspheres. Environ. Technol. 37, 2830–2834 (2016)

B.S. Mohite, A.S. Jadhav, Column chromatographic separation of uranium(VI) and other elements using poly(dibenzo-18-crown-6) and ascorbic acid medium. J. Chromatogr. A 983, 277–281 (2003)

S.N. Lad, B.S. Mohite, Analytical application of poly[dibenzo-18-crown-6] for column chromatographic separation of Nd(III) from Ce(III), U(VI) and other elements. J. Radioanal. Nucl. Ch. 302, 1481–1487 (2014)

B.S. Mohite, D.N. Zambare, B.E. Mahadik, Separation of barium from associated elements using poly(dibenzo-18-crown-6) and column chromatography. Analyst 119, 2033–2036 (1994)

W. Zhang, A. Zhang, L. Xu, Z. Chai, Extraction of cesium and some typical metals with a supramolecular recognition agent 1,3-di(1-nonyloxy) -2,4-crown-6- calix [4] arene. J. Chem. Eng. Data 58, 167–175 (2013)

A. Zhang, J. Jiang, Z. Chai, Preparation of a macroporous silica - based multidentate soft-ligand material and its application in the adsorption of palladium and the others. Sep. Sci. Technol. 48, 1500–1509 (2013)

A. Zhang, Y. Zhu, Z. Chai, New insight into the partitioning of minor actinides i: extraction of palladium and some typical metals with a multidentate soft-ligand 2,6- bis(5,6- dinonyl- 1,2,4- triazine- 3- yl)pyridine. J. Chem. Eng. Data 57, 1267–1273 (2012)

A. Zhang, Q. Hu, Adsorption of cesium and some typical coexistent elements onto a modified macroporous silica-based supramolecular recognition material. Chem. Eng. J. 159, 58–66 (2010)

A. Zhang, W. Wang, Z. Chai, M. Kumagai, Separation of strontium ions from a simulated highly active liquid waste using a composite of silica-crown ether in a polymer. J. Sep. Sci. 31, 3148–3155 (2008)

C. Xiao, A. Zhang, Z. Chai, Synthesis and characterization of novel macroporous silica-polymer-calixcrown hybrid supramolecular recognition materials for effective separation of cesium. J. Hazard. Mater 267, 109–118 (2014)

K. Otake, T. Suzuki, H. Kim, M. Nomura, Y. Fujii, Novel syntheses method of phenol type benzo-15-crown-5 ether resin and its application for lithium isotope separation. J. Nucl. Sci. Technol. 4, 419–422(2006)

Z. Zhang, J. Liu, X. Cao, X. Luo, R. Hua, Y. Liu, X. Yu, L. He, Y. Liu, Comparison of U(VI) adsorption onto nanoscale zero-valent iron and red soil in the presence of U(VI)-CO3/Ca-U(VI)-CO3 complexes. J. Hazard. Mater 300, 633–642 (2015)

A. Zhang, Y. Wei, M. Kumagai, Synthesis of a novel macroporous silica-based polymeric material containing 4, 4′,(5′)-di(tert-butylcyclohexano)-18-crown-6 functional group and its adsorption mechanism for strontium. React. Funct. Polym 61, 191–202 (2004)

Y. Wei, M. Kumagai, Y. Takashima, R. Odoj, Studies on the separation of minor actinide from high-level wastes by extraction hromatography using novel silica-based extraction resins. Nucl. Technol. 132, 413–423 (2000)

A. Zhang, Z. Chai, Adsorption property of cesium onto modified macroporous silica-calix [4] arene-crown based supramolecular recognition materials. Ind. Eng. Chem. Res 51, 6196–6204 (2012)

M.G. Sujana, S. Anand, Iron and aluminium based mixed hydroxides: a novel sorbent for fluoride removal from aqueous solutions. Appl. Surf. Sci 256, 6956–6962 (2010)

K. Hong, S. Sun, W. Tian, G.Q. Chen, W. Huang, A rapid method for detecting bacterial polyhydroxyalkanoates in intact cells by Fourier transform infrared spectroscopy. Appl. Microbiol. Biot 51, 523–526 (1999)

J.R. Dai, Y.F. Hallock, J.H. Cardellina, M.R. Boyd, Hiv-inhibitory and cytotoxic oligostilbenes from the leaves of hopea malibato. J. Nat. Prod 61, 351–353 (1998)

V. Ermini, E. Finocchio, S. Sechi, G. Busca, S. Rossini, An FT-IR and flow reactor study of the conversion of propane on γ-Al2O3 in oxygen-containing atmosphere. Appl. Catal. A Gen. 190, 157–167 (2000)

N. Rouhi, B. Esfandyarpour, S. Mohajerzadeh, P. Hashemi, M.D. Robertson, K. Raffel, Low temperature growth of silicon dioxide using hydrogenation assisted nano-crystallization and plasma enhanced oxidation. J. Non-Cryst. Solids 356, 1027–1031 (2010)

R.K. Nariyal, P. Kothari, B. Bisht, FTIR measurements of SiO2 glass prepared by sol–gel technique. Chem. Sci. Trans. 3, 1064–1066 (2014)

A. Zhang, C. Xiao, E. Kuraoka, M. Kumagai, Molecular modification of a novel macroporous silica-based impregnated polymeric composite by tri-n-butyl phosphate and its application in the adsorption for some metals contained in a typical simulated HLLW. J. Hazard. Mater 147, 601–609 (2007)

C. Xiao, A. Zhang, Z. Chai, Synthesis and characterization of novel macroporous silica- polymer-calixcrown hybrid supramolecular recognition materials for effective separation of cesium. J. Hazard. Mater 267, 109–118 (2014)

J. Han, N. Song, X. Tian, Synthesis and structure analysis of sandwich complexes of potassium and cesium with benzo-15-crown-5 derivatives. J. Incl. Phenom. Macr. 77, 301–308 (2013)

S. Alexandratos, C. Stine, Synthesis of ion-selective polymer supported crown ethers: a review. React. Funct. Polym 60, 3–16 (2004)

M. Yurdakoç, Y. Seki, S. Karahan, K. Yurdakoç, Kinetic and thermodynamic studies of boron removal by Siral 5, Siral 40, and Siral 80. J. Colloid. Interf. Sci 286, 440–446 (2005)

L. Zhou, J. Liu, Z. Liu, Adsorption of platinum(IV) and palladium(II) from aqueous solution by thiourea-modified chitosan microspheres. J. Hazard. Mater 172, 439–446 (2009)

J. Simonin, On the comparison of pseudo-first order and pseudo-second order rate laws in the modeling of adsorption kinetics. Chem. Eng. J 300, 254–263 (2016)

R. Hu, X. Wang, S. Dai, D. Shao, T. Hayat, A. Alsaedi, Application of graphitic carbon nitride for the removal of Pb(II) and aniline from aqueous solutions. Chem. Eng. J 260, 469–477 (2015)

V. Gallardo, R. Navarro, I. Saucedo, M. Avila, E. Guibal, Zinc(II) extraction from hydrochloric acid solutions using Amberlite XAD-7 impregnated with Chyphos IL101 tetradecyl (trihexyl) phosphonium chloride). Sep. Sci. Technol. 43, 2434–2459 (2008)

A. Nilchi, R. Saberi, M. Moradi, H. Azizpour, R. Zarghami, Adsorption of caesium on copper hexacyanoferrate-PAN composite ion exchanger from aqueous solution. Chem. Eng. J 172, 572–580 (2001)

J. Moon, C. Jung, B. Lee, C. Shin, Adsorptive separation of palladium from a simulated nuclear waste solution with activated carbon fibers. Sep. Sci. Technol. 43, 567–581 (2008)

C. Wanger, W. Riggs, L. Davis, J. Moulder, G. Muilenberg, Handbook of X-ray photoelectron spectroscopy, Published by Perkin-Elmer Corp., USA, (1979)

Acknowledgments

The present work was financially supported by National Natural Science Foundation of China (No. 11605027, No. U1407115 and No. 91126021), the Project of the Jiangxi Provincial Department of Education (Grant No. GJJ150560), the Doctoral Research Fund of East China University of Technology (Grant No.DHBK2015301), the Natural Science Foundation of Jiangxi Province (No.20151BDH80073), the Research Foundation of Education Bureau of Jiangxi Province (No. GJJ150566) and the Zhejiang Provincial Natural Science Foundation of China (No.LY17B060004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, Y., Liu, Y. & Zhang, A. Preparation and characterization of a mesoporous polycrown impregnated silica and its adsorption for palladium from highly acid medium. J Porous Mater 24, 1037–1045 (2017). https://doi.org/10.1007/s10934-016-0343-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-016-0343-4