Abstract

Biological hydrogel is important in drug delivery system and tissue engineering. In this paper, we prepared a series of biological hydrogels with N,O-carboxymethyl chitosan and oxidized pumpkin polysaccharide-II (oxidized PP-II). Morphological analyses indicated that the N,O-carboxymethyl chitosan/oxidized PP-II hydrogels (CPHs) had porous interior structures. The pore diameters ranged from several tens to several hundreds of micrometers. The storage modulus (G′) of the hydrogels ranged from 11 to 77 Pa, which indicated that the hydrogels had suitable mechanical strength. In vitro release test showed that the cumulative release of bovine serum albumin decreased from 95 to 60 % along with the proportion of oxidized PP-II to N,O-carboxymethyl chitosan from 1:1 to 1:3. After CPH-2 implanted in muscle tissues of mice for 15 days, fibroblast grew well in the CPH-2 pieces without inflammatory reaction. Therefore, the CPH-2 presented good histocompatibility with the muscle tissues of mice. Taken together, the N,O-carboxymethyl chitosan/oxidized PP-II hydrogels (CPHs) might have potential applications in the drug delivery system and tissue engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Hydrogels are macromolecular network materials, which has important medical applications. As we known, hydrogel is a polymer that can swell and be insoluble in water. Moreover, it has a three-dimensional structure. These properties make it widely used to control release of drugs, immobilization of enzyme, and control of protease activity, etc. [1]. Early developments in hydrogels focused mainly on synthetic materials such as poly(ethylene glycol)/poly(butylene glycol) block copolymers, poly (ethylene glycol)/poly (lactic acid) block copolymers, and copolymers of N-isopropylacrylamide, and so on. Although these materials are basically suitable for drug delivery, their applications are limited because they are non-biodegradable and some of them have slight toxicity [2]. In order to solve the drawbacks of the synthetic materials, many natural polymers are developed and investigated, such as hydroxyethylacryl chitosan/alginate hydrogel films, alginate/polyoxyethylene hydrogels, alginate/gelatin hydrogels, and hyaluronate/polygalacturonic acid hydrogels, and so on [1–3]. Hydrogels prepared from natural materials has not only above excellent properties, but also advantages of biodegradable and nontoxic, etc. [3–5]. In this study, hydrogels from natural materials were prepared and analyzed.

Chitosan (CS) is a kind of natural polysaccharide obtained from the deacetylation of chitin [6]. It was often used to make hydrogels for its biocompatibility, non-toxicity and biodegradability as well as the functions of antihypertension, antibacterial, and antineoplastic activity, and so on [7, 8]. Chitosan is not water-soluble. Acetic acid or other acids can facilitate dissolution of CS in water, which can generate cytotoxicity [9, 10]. Therefore, the water-solubility of CS was improved by covalent attachment of hydrophilic groups to the –NH3 and C6–OH [11–13].

Pumpkin polysaccharide-II (PP-II) can function, according to recent literature, as a hypoglycemic role, anti-infective, and anticoagulant, etc. Moreover, it has good biocompatibility and biodegradability [14]. PP-IIis comprised of d-glucose, d-mannose, d-xylose, l-arabinose, d-galactose and d-glucuronic acid [15].

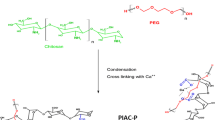

Up to now, it was not reported wether hydrogels can be made from chitosan and pumpkin polysaccharides, and further be used in drug delivery system and tissue engineering. In this study, PP-II was modified with NaIO4 to produce aldehyde groups serving as a macromolecular cross-linker to those polymers bearing free amino groups to form hydrogels [16]. Hereby, a novel hydrogel based on oxidized PP-II and N,O-carboxymethyl chitosan was prepared and analyzed.

2 Experimental

2.1 Materials

Chitosan [deacetylation degree (DD) of 95 %, Mw = ~210 KDa] was purchased from Qingdao Dive Light Biological Engineering CO. LTD (China). Pumpkin polysaccharide-II (PP-II, Mη = 3.6 × 104) was purchased from West Anrui Bo Biological Technology CO. LTD (China). Chloroacetic acid and sodium periodate (NaIO4) were purchased from Tianjin Evergreen Chemical Reagent Manufacturing CO. LTD (China). CBB (Coomassie brilliant blue) and BSA (bovine serum albumin) supplied by Biotopped (China). All other chemicals used in this paper were analytical grade, without further purification. Ultrapure water (Milli-Q Gradient A10 Water Purification System, Millipore Corporation, MA, US), it was used to prepare all solutions.

Male KM mices weighing 25–30 g were used to investigated the histocompatibility in vivo. All animals received humane care and surgical procedures according to the guidelines approved by the Institutional Animal Care and Use Committee (IACUC) of National Lanzhou University of Technology.

2.2 Synthesis and characterization of N,O-carboxymethyl chitosan and oxidized PP-II

N,O-carboxymethyl chitosan was prepared by electrophilic substitution reaction [17]. Specifically, chitosan (5 g) was added into 25 mL of NaOH (40 %, w/w) solution at −20 °C overnight. The chloroacetic acid (20 g) dissolved into 100 mL of isopropanol. Then chloroacetic acid solution was added into the frozen chitosan suspension drop-wise for 30 min. The mixture was stirred at 25 °C for 2 h, and then at 60 °C for additional 2 h. Finally, the resultant was filtered and washed three times with 95 % ethanol. After drying by oven at 40 °C, the final product of N,O-carboxymethyl chitosan was obtained and characterized by 1H NMR (Agilent NMR inova600) analysis. The substitution degree of chitosan was measured by potentiometric titration method [13].

Oxidized PP-II was prepared by methods as reported previously [18]. Specifically, a weight of PP-II was first added into an ethanol/water (1:1, v/v) solution (100 mL) with continuous stirring at 25 °C for 2 h. Then, a weight of NaIO4 (20, 40 and 60 % molar equivalent with PP-IImonomer) dissolved into 20 mL of distilled water was added to the PP-II solution for another 8 h at dark. Subsequently, an equimolar amount of diethylene glycol with NaIO4 was added into reaction system to quench the unreacted NaIO4. The resultant was filtered and the residue was dissolved into water, dialyzed 3 days in a dialyzer, then lyophilized to obtain the final product. The oxidized PP-II was characterized by 1H NMR (Agilent NMR inova600) analysis. PP-II with theoretical oxidization degrees of 20, 40 and 60 % were prepared and named as OPP-1, OPP-2, and OPP-3, respectively. OPP-1′, OPP-3′ was also prepare by a similar method, but the oxidation time is 6 and 10 h, respectively. To find out influence of dosage of NaIO4 and oxidization time on oxidization degree, the oxidization degree of OPP-1 to OPP-3′ were measured by a potentiometric titration method [19, 20].

2.3 Preparation and characterization of CPH

OPP-1′ was used to prepare the CPH for further analysis and characterization. A calculated weight of OPP-1′ and N,O-carboxymethyl chitosan were dissolved into 10 mL distilled water to form 5 and 14 % (w/w) solutions, respectively. Then, 4 mL of OPP-1′ and N,O-carboxymethyl chitosan solutions, regardless of the weight ratio (1:1; 1:2; 1:3, w/w) were mixed at room temperature with gentle stirring. Then mixed solutions were placed at 37 °C for 10 min to form the hydrogels (CPHs). The CPH was characterized by 1H NMR (Agilent NMR inova600) analysis. The obtained CPHs with weight ratios (1:1; 1:2; 1:3, w/w) were named CPH-1, CPH-2 and CPH-3, respectively [20].

2.4 Appearance morphologic characterization

The morphology of the hydrogels (CPH-1, CPH-2, and CPH-3) were studied with scanning electron microscopy (SEM; JSM-6010LV JEOL, Japan) at 20 kV. The lyophilized rupture pieces of the CPHs were sputtered with gold, and placed in a cabinet drier for 24 h before observation [20].

2.5 Swelling ratio of CPHs

The swelling ratio of CPHs (CPH-1, CPH-2, and CPH-3) were measured by gravimetrical method. Hydrogels (CPH-1, CPH-2 and CPH-3) dried to constant quality were placing in acidic aqueous solution (hydrochloric acid, pH 2), phosphate buffered saline (PBS, pH 7.4) and alkaline aqueous solution (sodium hydrate, pH 12) at 37 °C, respectively. Twenty-four hours later, samples were taken from the mediums and weighed after the surface water was removed with filter paper [20]. The swelling ratio of CPHs were calculated as follows:

M24 and M0 are the weights of the swollen wet hydrogels and initial dry hydrogels, respectively. Measurements were performed in triplicate.

2.6 In vitro degradation

The CPH samples (CPH-1, CPH-2 and CPH-3) were prepared in three 50 ml beaker. Then, 5 ml PBS (pH 7.4) solution were added into beaker, followed by incubated at 37 °C. Samples were removed from the PBS and they were weighed at pre-determined time-points (7, 14, 21, 28 days) [20]. The degree of in vitro degradation was expressed by the weight loss:

M0 is the original weight of the hydrogels before degradation and Mt is the weight of the hydrogels at pre-determined time-points. Measurements were performed in triplicate.

2.7 In vitro protein release

Bovine serum albumin (BSA) was selected as a model protein to evaluate the release of biomacromolecules from the CPHs. Briefly, 0.01 g of BSA was dissolved into N,O-carboxymethyl chitosan aqueous solution in a 15 mL centrifuge tube. Then various amounts of oxidized PP-II were added with vigorous stirring. The mixed solutions were placed at 37 °C for 10 min in order to form the BSA-loaded CPHs. After the hydrogels formed, 5 mL of PBS (pH 7.4) was added to the CPHs and the tubes were placed in a shaker (100 rpm/min) at 37 °C. At each time-point (12 h), the PBS medium was removed for BSA determination and the fresh PBS was supplemented [20]. Protein concentrations were measured according to the Coomassie Brilliant Blue assay [21]. Measurements were performed in triplicate.

2.8 Rheological analysis

Rheological measurement was performed using a RS6000 rheometer (TA Instruments, GER). Mixing N,O-carboxymethyl chitosan with oxidized PP-II solutions to formed CPH-1, CPH-2 and CPH-3, respectively. Then, 1 mL of the CPHs were immediately loaded onto a lower stationary thermostatted rheometer plate (35 mm diameter) and the upper plate was adjusted to the predefined gap size (1 mm gap) at 25 °C. Ten minutes later, the oscillation measurements were carried out in a controlled deformation mode at a constant frequency of 1 Hz with 5 Pa shear stress in 5 min [22].

2.9 Elemental analysis

The element distribution of the CPH was studied with scanning electron microscopy (SEM; JSM-6010LV JEOL, Japan) and X-ray spectrometer (Finder-1000, Institute of Scientific Instruments Factory, China) at 20 kV. The lyophilized rupture piece of the CPH-2 was sputtered with gold. Then, elemental analysis was carried out by X-ray spectrometer in scanning electron microscopy (SEM) [23].

2.10 Histocompatibility experiments

Male KM mice were fed according to reported previously [24]. The mice were anesthetized with 5 % chloral hydrate at a dose of 7 mL/kg. Ruptured pieces of the lyophilized CPH-2 were implanted into muscle tissues of mice. After 15 days, the implanted tissues were prepared for paraffin-cut sections and observed by microscope [25].

2.11 Statistical analysis

Statistical analyses were performed by t test. P value less than or equal to 0.05 means significant difference (Origin Pro 7.5). Values of results are shown as the mean and standard deviation.

3 Results and discussion

3.1 Characterization of N,O-carboxymethyl chitosan and oxidized PP-II

Chitosan is insoluble in neutral water, but dissolved in acetic acid solution. This property limits its scope of application [8]. In order to improve its water-solubility, chloroacetic acid was used to graft carboxymethyl groups onto the chitosan skeleton in an alkaline medium [17, 20]. The resultant N,O-carboxymethyl chitosan was characterized by 1H NMR. The 1H-NMR spectra of carboxymethyl chitosan showed the successful synthesis of N,O-carboxymethyl chitosan (Fig. 1a, b). The methylene protons of O- and N-substituted carboxymethyl chitosan were found at chemical shift 3.91 and 3.26 ppm, respectively. The methine proton at position-C2 of carboxymethyl chitosan was showed at chemical shift 2.61 ppm (Fig. 1b), which was accordance with previous study [26]. The substitution degree of carboxymethyl was measured by titration method, which was 32 % on N,O-carboxymethyl chitosan [13].

Based on the oxidation method, the PP-II was oxidized into their dialdehyde derivatives by NaIO4 [18]. Compared with the 1H NMR spectrum of PP-II, oxidized PP-II has a new peak of aldehyde proton at 5.4 ppm (Fig. 1c, d), which was accordance with previous study [20]. In addition, the actual oxidization degrees of PP-II were varied from 11.9 to 65.5 % at the different NaIO4 concentrations and the oxidization degree (34.6 %) of PP-II didn’t change at different oxidization times (Tables 1, 2). Thereby, the dosage of NaIO4 contributed more to degree of oxidation than oxidization time. However, pumpkin polysaccharide was becoming more disaggregately with the increase of the NaIO4 concentration, which influenced its inherent properties greatly, for example, reducing its water-solubility and viscosity [20]. Therefore, the amount of NaIO4 used for oxidization of PP-IIshould be strictly controlled. In addition, the appropriate amount of aldehyde groups on oxidized PP-II has yet to be investigated. In this study, OPP-1′ with aldehyde group concentration of 3.2 mmol/g was selected to prepare the following hydrogel.

3.2 Characterization of CPH formation

After the CPH was prepared, it was detected by 1H NMR. Theoretically, amino groups on N,O-carboxymethyl chitosan and aldehyde groups on oxidized PP-II could react into a Schiff base in hydrogel [3, 12]. In Fig. 1e, the disappeared peak at 5.4 ppm of the oxidized PP-IIindicates that a Schiff base reaction between oxidized PP-II and N,O-carboxymethyl chitosan did occur. Figure 2a, b showed the appearance of N,O-carboxymethyl chitosan/oxidized PP-II system before and after formation of hydrogel. As can be seen, mixture solution showed a flowing state before hydrogel formation, but the mixture turned into hydrogel by crosslinking soon.

3.3 Morphological analysis

Morphology of the hydrogels (CPH-1, CPH-2, and CPH-3) were observed with scanning electron microscope (SEM). As can be seen in Fig. 2, the CPHs had porous interior structures with interconnecting pores, pores diameter ranging from several tens to several hundreds of micrometers. Moreover, with the proportion of oxidized PP-IIto N,O-carboxymethyl chitosan from 1:1 to 1:3, the more crosslinking between amino group and aldehyde group, the dense of pores increased. That is to say, when there are sufficient number of aldehyde groups in oxidized PP-II, with the amount of N,O-carboxymethyl chitosan increasing, the amount of amino group is increasing accordingly. Therefore, intramolecular and intermolecular crosslinking of N,O-carboxymethyl chitosan will be more, and the compactness of pores will increase [3, 10–12]. This porous interior structures showed that the CPH can be used in drug delivery and cell culture system.

3.4 Swelling behavior analysis

As we can see from Fig. 3, with the proportion of oxidized PP-II to N,O-carboxymethyl chitosan from 1:1 to 1:3, the swelling ratio of the CPHs decreased. This might be due to higher crosslinking degree and smaller pore diameter created by crosslinking between amino group and aldehyde group [27]. The swelling ratio of CPHs is relatively low at pH 2. This might be attributed to the protonation of –COO− to –COOH in acid environment lead to the formation of hydrogen bonds between N,O-carboxymethyl chitosan and oxidized PP-II, which prevent the entry of water molecules. Furthermore, the protonation of –NH2 − to –NH3 + and unprotonation of –COO− result in net charge reducing to zero, which lead to free ion concentration closed to zero, and outside osmotic pressure make the hydrogel dehydrate and shrank [27, 28]. Finally, these two reasons induce the swelling ratio of CPHs significantly to decrease at pH 2.0. The swelling ratio is relatively high at pH 12. This was caused by a large swelling force created by the electrostatic repulsion of the ionized carboxylic acidic groups (–COO−). Because carboxymethylation of chitosan was only 32 %, the electrostatic repulsion slightly lower between pH 7.4 and pH 12, which also lead to the swelling ratio close to each other [25, 28]. This might have potential applications in pH sensitive drug delivery system.

3.5 In vitro release behavior

We measured the release behavior of BSA over 204 h from CPHs at 37 °C in PBS (pH 7.4), the total amount of BSA is 0.01 g in each sample. From the Fig. 4, the results showed that the BSA released from CPH-1 reach 95 % in 180 h, while 72 and 64 % from CPH-2 and CPH-3, respectively, and the cumulative release of BSA were approximately 97, 79 and 71 % in 204 h. This is probably a result of the larger pore sizes in CPH-1 that we observed by SEM. However, CPH-2 and CPH -3, with a greater degree of crosslinking and more compact microstructure, would decrease the diffusion of BSA. This result is similar to cumulative BSA release of 80 % from N,O-carboxymethyl chitosan/oxidized alginate hydrogel reported previously [20].

3.6 In vitro degradation

We performed in vitro degradation behavior of the hydrogels (CPH-1, CPH-2, and CPH-3) at pH 7.4 in PBS. As shown in Fig. 5, CPH-1 exhibits a relatively rapid degradation rate, which is approximately 40 % in 7 days, faster than 33 % of CPH-2 and 26 % of CPH-3. Samples lost 84, 72 and 65 % of their weight at 28 days, respectively [29, 30]. This could attributed to increased stability from CPH-1 to CPH-3 for more crosslinking between N,O-carboxymethyl chitosan and oxidized PP-II. Hence, we can control the rate of degradation by adjusting compositions of the CPHs.

3.7 Rheological analysis

In rheology analysis, storage modulus (G′) also called elasticity modulus, which reflects the stiffness of material [31]. As shown in Fig. 6, storage modulus (G′) of CPH-1, CPH-2 and CPH-3 increased in turn. There might be due to CPHs became more and more compact structure from CPH-1 to CPH-3. Storage modulus (G′) of CPH-1 was stable at about 11 Pa, which indicated that CPH-1 has been fully formed in 10 min. However, storage modulus (G′) of CPH-2 and CPH-3 increased gradually. This could attributed to the crosslinking and gel formation process still continues after 10 min. From Fig. 6, the results showed that the hydrogels has suitable stiffness (11–77 Pa). Moreover, there is an increasing trend in the CPH-2 and CPH-3 [22, 32]. Therefore, the CPH has suitable mechanical strength for application in the drug delivery system and tissue engineering.

3.8 Elemental analysis

As shown in Fig. 7, the CPH-2 contained elemental carbon, oxygen, nitrogen and sodium, and the more bright spots indicated that the more amount of certain element [33]. The CPH-2 is made from N,O-carboxymethyl chitosan and oxidized PP-II. Therefore, the percentage composition of carbon and oxygen elements are relatively high, which are 66.3 and 30.2 %, respectively. The element of nitrogen came from N,O-carboxymethyl chitosan, percentage composition of which was about 0.9 %. The elemental sodium should came from sodium hydroxide, and its content was about 2.6 %. We did not found element of iodine in CPH, which indicated that sodium periodate is fully cleared away by dialysis in 3 days. Therefore, we don’t have to consider toxicity of residual iodine.

3.9 Histocompatibility analysis

As we all known, chitosan belongs to ationic polysaccharides, which was dyed red by H–E staining [34]. As shown in Fig. 8a, large numbers of fibroblasts grew well and spread throughout the hydrogel. In addition, we did not find obvious fibrous encapsulation and macrophage between muscle tissue and the hydrogel (Fig. 8b, c), which indicated that they were integrated together completely without inflammation. From Fig. 8c, we could see most of the hydrogel have been degraded in 15 days. These results suggest that the CPH is biodegradable and biocompatible.

4 Conclusions

A series of N,O-carboxymethyl chitosan/oxidized pumpkin polysaccharide hydrogels (CPHs) were prepared. With amounts of N,O-carboxymethyl chitosan increasing, crosslinking degree of the CPHs was increased. Meanwhile, the swelling ratio, degradation rate and the cumulative release of BSA were reduced. The CPHs exhibits porous three-dimensional structure, which is very important in the drug delivery and cell culture. The CPHs showed suitable stiffness and can withstand several tens to several hundreds pressure. Importantly, the CPH is histocompatible, degradable and non-cytotoxic. All of these showed that the CPHs can be used in tissue engineering and biomedical application.

References

N.A. Peppas, Annu. Rev. Biomed. Eng. 02, 9–29 (2000)

J.A. Rowley, G. Madlambayan, D.J. Mooney, Biomaterials 20, 45–53 (1999)

M.S. Shoichet, Macromolecules 43, 581–589 (2010)

M. Rinaudo, Polym. Int. 57, 397–430 (2008)

L.C. Alvarez, F.B. Blanco, A.M. Puga, A. Concheiro, Adv Drug Deliv. Rev. 65, 1148–1171 (2013)

L. Chen, C. Tang, N. Ning, C. Wang, Q. Zhang, J. Polym. Sci. 27, 739–746 (2009)

H. Honarkar, M. Barikani, Monatshefte Fur Chemie. 140, 1403–1420 (2009)

C.M. Yeng, H. Salmah, S.T. Sam, Polym. Plast. Eng. Technol. 52, 1496–1502 (2013)

W. Li, Biomaterials 29, 05–13 (2008)

T. Athanasiadis, W.D. Smith, Laryngoscope 118, 88–94 (2008)

S.H. Lim, S.M. Hudson, Carbohydr. Res. 339, 313–319 (2004)

G. Ma, D. Yang, Y. Zhou, M. Xiao, J.F. Kennedy, J. Nie, Carbohydr. Polym. 74, 121–126 (2008)

J.S. Fu, Q.R. Sun, Pet. Chem. Ind. Prog. 12, 56–58 (2010)

Y. Liu, H. Jin, Z.Q. Xu, Chin. J. Appl. Physiol. 22, 358–361 (2006)

Y.J. Zhang, H.Y. Yao, Chin. J. Grain Oil 04, 59–62 (2002)

D. Jaydee, E. Cabral, R. Marina, S. Zheng, L.Q. Liu, J. Mater. Sci. Mater. Med. 25, 2743–2756 (2014)

Y.W. Lin, C. Xu, C.H. Liu, Ion Exch. Adsorpt. 16, 54–59 (2000)

C.Y. Lin, H.H. Peng, J.S. Sun, T.Y. Liu, J. Mater. Sci. Mater. Med. 168, 04–12 (2015)

Q.M. Wang, Y.M. Liao, W. Chen, Chin. J. Anal. Lab. 04, 12–15 (2008)

X.Y. Li, Y.H. Weng, X.Y. Kong, J. Mater. Sci. Mater. Med. 23, 2857–2865 (2012)

P. Lu, T.Q. Yu, S.Y. Wang, J.L. Wang, L. Yang, J. Beijing Agric. Coll. 02, 18–25 (2006)

S. Tamburic, D.Q.M. Craig, Pharm. Sci. 01, 107–109 (1995)

Q.J. Lin, Fujian Anal. Test. 22, 49–54 (2013)

W.X. Guo, Y. Shu, X.P. Yang, Plant Foods Hum. Nutr. 71, 145–150 (2016)

W.J. Zhang, Z. Chen, J.Z. Ma, Int. J. Polym. Mater. Polym. Biomater. 65, 38–46 (2016)

A. Jaidee, P. Rachtanapun, S. Luangkamin, Adv. Mater. Res. 506, 158–161 (2012)

R. Jayakumar, Prog. Mater. Sci. 55, 675–709 (2010)

R. Muzzarelli, P. Jari, M. Petrarulo, Int. J. Biol. Macromol. 16, 177–180 (1994)

C.J. Ostrowska, D.M. Gierszewska, Carbohydr. Polym. 77, 590–598 (2009)

L. Fan, Y. Du, B. Zhang, J. Yang, J. Zhou, J.F. Kennedy, Carbohydr. Polym. 65, 447–452 (2006)

H.H. Winter, F. Chambon, J. Rheol. 30, 367–382 (1986)

M. Kreilgaaed, Adv. Drug Deliv. Rev. 54, 77–98 (2002)

J.Y. Lee, Y.S. Lee, Knee Surg. Sports Traumatol. Arthrosc. 19, 867–872 (2011)

M. Aziz, J. Biomed. Mater. Res. B Appl. Biomater. 12, 21–34 (2014)

Acknowledgments

We thank for this work was supported by Doctor Fund of Lanzhou University of Technology under Grant (NO: 0908ZXC128), Gansu Provincial Natural Science Fund under Grant (NO: 145RJZA123). Foundation of Gansu province Educational Committee under Grant (1208ZTC029). National Natural Science Foundation of China under Grant (NO: 81560737). National Natural Science Foundation of China under Grant (NO: 51463012). National Natural Science Foundation of China under Grant (NO: 81260070). Fund of Lanzhou Administration of Science and Technology under Grant (NO: 2012-2-68). Also, acknowledges the fellowship received from the Department of Pharmacy in College of Life Science and Engineering, The Key Lab of screening, Evaluation and Advanced Processing of TCM and Tibetan Medicine Gansu Educational Department.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, W., Wang, X., Ma, J. et al. Preparation of chitosan/pumpkin polysaccharide hydrogel for potential application in drug delivery and tissue engineering. J Porous Mater 24, 497–506 (2017). https://doi.org/10.1007/s10934-016-0285-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-016-0285-x