Abstract

We fabricated a three-dimensional nanostructured macroporous bacterial cellulose scaffold (3D BC scaffold) and a three-dimensional nanostructured macroporous bacterial cellulose/agarose scaffold (3D BC/A). Results of scanning electron microscopy (SEM) and mercury intrusion porosimeter showed that both the 3D BC and the 3D BC/A have interconnected macropores characterized by nanofibrous pore walls (The diameter of the dominant pores was about 100 μm and ranges from <1 μm to >1,000 μm). 3D BC/A also has high surface area (80 ± 5 m2/g) and sufficient porosity (88.5 ± 0.4%) compare with 3D BC (surface area: 92.81 ± 2.02 m2/g; porosity 90.42 ± 0.24%). 3D BC/A do support C5.18 cell and hBMSC attachment, proliferation evaluated with SEM, confocal microscopy and cell proliferation assay. Furthermore, 3D/ABC has enhanced mechanical property (ultimate compressive strength: 26.26 ± 4.6 kPa, Young’s modulus: 39.26 ± 5.72 kPa)) than that 3D/BC has (ultimate compressive strength: 7.04 ± 2.34 kPa, Young’s modulus: 10.76 ± 3.52 kPa). Overall, the 3D BC/A scaffold had more potential than 3D BC scaffold for using as a scaffold for tissue engineering and tissue repair applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bacterial cellulose (BC), also named microbial cellulose, is a nano-composite scaffold composed of nano-cellulose fibres that has shown excellent biocompatibility [1–5]. BC has been studied as a potential scaffold for tissue engineering of cartilage, as a scaffold for bone tissue engineering and as a natural resource for healing wounds [3–5]. However, natural bacterial cellulose does not possess the macropores needed for cells to live in [2, 4–6], and we therefore call this a two-dimensional bacterial cellulose (2D BC). We had processed 2D BC samples into a three-dimensional nanostructured macroporous bacterial cellulose (3D BC) scaffold in a biomimetic way [7]. In contrast to BC, the 3D BC scaffold has the interconnected macropores characterized by nanofibrous pore walls. And the 3D BC scaffold exhibited large surface area and high porosities. A large surface area and high porosity in scaffolds have been proven to be an important characteristic of 3D scaffolds used in tissue engineering, due to its important advantage for the cell attachment and rapid nutrient diffusion required for cell survival and growth. As agarose can promote chondrocyte survival and phenotype maintenance [8, 9] and it can be used to reinforce scaffold for cartilage tissue engineering [9], we therefore hypothesized to use agarose to enhance the strength of the 3D BC scaffold. Furthermore, BC nanofibres will become BC/agarose nanofibers. It may be more in favor of cells interacting with nanofibres in the pore walls and it will be promote chondrogenic differentiation of the stem cells and chondrocytes phenotype maintenance.

In the present study, we have enhanced 3D BC mechanical properties with agarose and fabricate a three-dimensional nanostructured macroporous bacterial cellulose/agarose scaffold (3D BC/A). furthermore we seeded adult human bone marrow derived stromal cells (hBMSCs) and C5.18 cells in the scaffolds to evaluate the potential of the 3D BC and 3D BC/A respectively as biomimetic scaffolds for tissue engineering in vitro. hBMSCs are a kind of adult stem cells that exhibit an attractive ability to differentiate into various types of cells used in tissue engineering and tissue repair applications, including chondrocytes used to regenerate cartilage tissue [10], and C5.18, which is a novel clonal chondrogenic rat cell line [11]. hBMSCs and C5.18 cells have been widely applied as valid cell models for evaluating biomaterials for tissue engineering in vitro [5, 12].

2 Experimental procedure

2.1 Production of BC and preparation of the 3D BC scaffold

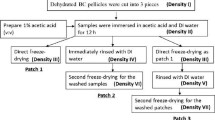

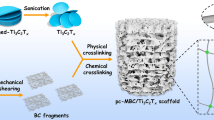

BC membranes were prepared and purified according to a previously described method [13]. The 3D BC scaffold was prepared via emulsion freeze-drying technique, which was considered as a valid method for preparing three-dimensional scaffolds for tissue engineering [7, 14]. Original BC gels were cultured in our lab and then freeze-dried for characterization. BC gels was crushed and mixed with distilled water to prepare a 0.25 wt% BC emulsion. The BC emulsion was poured into a 24-well tissue culture plate as a mold and frozen at −30 °C for 1 day, then freeze-dried at −50 °C for 1 day. The samples were then immersed in PEG400 (Tianjin Tianda Tianlong Sci. & Tech. Co., Ltd., Tianjin, China) for 1 day and then soaked in deionized water for exchanging the excess PEG400. Water was changed several times in the following 2 days and samples were then freeze-dried at −50 °C for another 2 days, as previous report [7].

2.2 Fabrication of the 3D BC/A scaffold

BC gel (50 g) were crushed and mixed with a 1% (w/v) or 2% (w/v) agarose (Solarbio, Spain) solution (50 mL), respectively. The solution was frozen at −30 °C for 1 day in a 24-well tissue culture plastic plate used as a mold. The resulting 3D BC/A scaffolds were obtained after freeze-drying at −50 °C for 2 days. The ratios of BC gels to agarose were listed in Table 1.

2.3 Surface property characterization

The surface structures of the 3D BC, 3D BC/A scaffolds were observed using scanning electron microscopy (JSM-6700F, Japan). The pore size distribution, porosity and surface area of the 3D BC and 3D BC/A scaffolds were determined by a mercury intrusion porosimeter (PoreMaster 60 GT, Quantachrome Instruments) that measured pore sizes ranging from 3.6 nm to 950 μm.

2.4 Mechanical testing

The mechanical properties of the 3D BC and 3D BC/A scaffolds in the dried state were determined using an Instron Testing Machine 8874 with a 250-N load cell. Samples with a diameter of 13 mm and a thickness of 7 mm were compressed at a speed of 2 mm/min, and the compressive modulus was determined from the linear region of the compressive phase. The Young’s modulus and ultimate compressive strength were determined for seven samples.

2.5 hBMSC isolation, culturing and characterization

All experimental protocols involving bone marrow collection were approved by the Ethics Committee of Shanghai Jiao Tong University School of Medicine. The bone marrow aspirates were obtained from femurs of three female donors without bone metabolic disease, with an age range of 22–45 years, during intramedullary fixation to treat femur fractures. The hBMSCs were isolated and expanded using the methods reported by Pittenger and Fang [5, 10]. hBMSCs prior to passage five were used in the following experiments. A growth medium was prepared using Dulbecco’s modified Eagle’s medium (DMEM, Sigma) supplemented with 10% fetal bovine serum (FBS, Hyclone), 100 U/mL penicillin and 100 mg/L streptomycin (Hyclone). To analyze cell surface expression, flow cytometry was performed using previously reported methods [5].

2.6 3D culture

hBMSCs and C5.18 cells (generously provided by Dr. Di Chen, University of Rochester, USA) were collected and resuspended in DMEM with 10% FBS at 2 × 106 cells/mL and 1 × 107 cells/mL, respectively. Samples with a diameter of 13 mm and a thickness of 7 mm were split into two half cylinders, and a half cylinder was treated as one sample. Then, cell suspensions were added dropwise to the samples at 500 μL/sample (3D BC, 3D BC/A). To distribute the cells uniformly over the entire scaffold, 3D samples were compressed repeatedly with tip while the cell suspension was added dropwise onto the 3D samples. The cell suspension was adsorbed onto the walls of pores of scaffolds uniformly. The scaffolds were then incubated in a 6-well plate at 37 °C in a 5% CO2 atmosphere for 4 h to allow the cells to attach to the scaffold. Additionally, 50 μL/sample of culture medium was added to every scaffold at an interval of 1 h to prevent the scaffolds from drying. After 4 h, the complete culture medium was added to the wells at 6 mL/well.

2.7 Confocal microscopy

After the cells had been cultured in the scaffolds for 4 weeks, viability was assessed using the vital dyes calcein acetoxymethyl (calcein-AM, Sigma) and ethidium homodimer-1 (EthD-1, Sigma). 3D BC scaffolds and 3D BC/A scaffolds with cells were rinsed with 1 × PBS two times and then incubated with calcein-AM at a final concentration of 1 μg/mL and EthD-1 at a final concentration of 4 μg/mL for 20 min [15]. The samples were then rinsed with 1 × PBS and examined under an epifluorescence confocal microscope (Leica TCS SP5, Germany) within 1 h. The viable and dead cells in the 3D scaffolds were observed and recorded.

2.8 SEM analysis of scaffolds with cells

After 4 weeks of culture, the cell-seeded 3D BC/A scaffolds were rinsed in 1 × PBS two times, fixed overnight in 2.5% glutaraldehyde buffer (pH 7.4), post-fixed in 1% osmium tetroxide in 0.1 M cacodylate buffer and then dehydrated by increasing the concentration of alcohol (50, 70, 80, 90, 95, 99, 100%). Drying of the specimens required liquid CO2; the specimens were then cut into two parts along the median line, sputter-coated with gold and examined using SEM (JSM-6700F, Japan).

2.9 Cell proliferation assay

For cell proliferation assays, cells were seeded in the 3D BC and the 3D BC/A scaffolds. The alamarBlue Cell Viability Reagent (Invitrogen) was used according to the manufacturer’s instructions. The cell-seeded scaffolds were transferred to a new 24-well plate and incubated in 2 mL of culture medium with 10% alamarBlue reagent for 4 h at 37 °C, 5% CO2. Aliquots (200 μL) of the culture medium were transferred to 96-well plates, and the fluorescence of the alamarBlue was read using a Cytofluor Micro-Plate reader (BIO-TEK Instruments, Inc, Vermont, USA) with excitation at 530 nm and emission at 590 nm. Non-cell-seeded scaffolds were analyzed similarly to blank controls. After the culture medium with alamarBlue had been prepared for testing, the scaffolds were transferred into a new 6-well plate, and culture medium was added at 6 mL/well as before.

2.10 Statistical analysis

Means and standard deviations (SD) were calculated and presented as mean values ±SD (mechanical test, N = 7; cell proliferation assay, N = 6). A t-test, followed by an independent-sample test was used (SPSS 16.0 software). Statistical significance was established at the p < 0.05 level.

3 Results and discussion

3.1 Potential of bacterial cellulose as a scaffold for tissue engineering

BC is a nanofibrous biomaterial that is synthesized extracellularly by the bacterium Acetobacter xylinum [16]. Nanofibrous BC is easier to obtain than other artificial nanofibrous biomaterials, since it does not require complex technology, such as electrospinning, self-assembly, phase separation, etc. BC has other properties desirable for biomaterials, such as good biocompatibility, a high surface area and a high porosity [5, 16, 17]. However, as a scaffold for tissue engineering, macropores (sufficiently large pores) are required to allow for cell incorporation, migration, proliferation and tissue growth into the scaffold [14]. Unmodified BC does not exhibit large pores; cells only live on the surface of the BC film [4–6]. Thus, BC must be further processed into a macroporous material. Backdahl et al. [2] conducted a helpful experiment, in which he developed a method for producing microporosity in BC samples by placing paraffin wax and starch particles of various sizes in a growing culture of Acetobacter xylinum. Recently, we developed a novel method for fabricating a macroporous bacterial cellulose scaffold (3D BC) and an agarose-enhanced macroporous bacterial cellulose scaffold (3D BC/A), the properties of two kind of 3D scaffolds were described as follow.

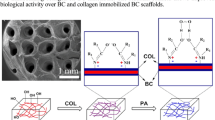

3.2 Nanofibers and macropores properties of scaffolds

Macroporous 3D BC scaffolds and 3D BC/A scaffolds were fabricated in various shapes, such as a cylinder (Fig. 1), consistent with the different molds used. Figure 1 shows both the 3D BC scaffold (Fig. 1a, d) and the 3D BC/A1 scaffold (Fig. 1b, e) display an irregular open pore geometry and an interconnected pore morphology characterized by nanofibers and macropores with diameters greater than 100 μm throughout the scaffold. By examining the walls of the pores, we find nanofibres (<100 nm in diameter) and distinct nano-fibrous ravines (<100 nm in width) on the walls in the 3D BC scaffold and the 3D BC/A1 scaffold (Fig. 1g, h). However, 3D BC/A2 does not display the open pore geometry and most of pores were closed due to high ratio agarose added in fabrication procedure (Fig. 1c, f).

3D BC (a) and 3D BC/A (b and c) scaffolds were in cylinder shape and scanning electron microscopy views of 3D BC (d and g), 3D BC/A1 (e and h) and 3D BC/A2 (f and i). Abundant macropores in 3D BC and 3D BC/A scaffolds with diameters greater than 100 μm were interconnected by macropores with diameters of more than 100 μm. Pore walls constructed by BC nanofibers with diameters <100 nm or characterized by nano-ravines <100 nm in width. However, 3D BC/A2 display a closed pore geometry (c, f and i)

3.3 Mechanical properties

The ultimate compressive strength and Young’s modulus (mean ± SD, N = 7) are plotted in Fig. 2. The 3D BC/A2 scaffold has the highest ultimate compressive strength (43 ± 2.4 kPa) and Young’s modulus (55.03 ± 3.22 kPa). And the 3D BC/A1 scaffold has higher ultimate compressive strength (26.26 ± 4.6 kPa) and Young’s modulus (39.26 ± 5.72 kPa) than 3D BC scaffolds (ultimate compressive strength: 7.04 ± 2.34 kPa, Young’s modulus: 10.76 ± 3.52 kPa).

Mechanical testing 3D BC The 3D BC/A scaffolds had a higher ultimate compressive strength (3D BC/A2: 43 ± 2.4 kPa, 3D BC/A1: 26.26 ± 4.6 kPa) and Young’s modulus (3D BC/A2: 55.03 ± 3.22 kPa, 3D BC/A1: 39.26 ± 5.72 kPa) than the 3D BC scaffolds (ultimate compressive strength: 7.04 ± 2.34 kPa, Young’s modulus: 10.76 ± 3.52 kPa). (N = 7, p < 0.01)

3.4 Surface area and porosity analysis

As 3D BC/A2 did not display the open pore geometry, the surface area and porosity of 3D BC/A2 were not analyzed. The diameter of the dominant pores in the 3D BC scaffold was about 100 μm, and the maximum diameter was about 1000 μm (Fig. 3a). In addition, the dominant pores in the 3D BC/A1 scaffold also exhibited a diameter of about 100 μm (Fig. 3b). The 3D BC/A1 scaffold also exhibited a high surface area (80.5 ± 5 m2/g) and porosity (88.5 ± 0.4%) in comparing to the 3D BC scaffold (surface area: 92.8 ± 2 m2/g, porosity: 90.4 ± 0.2%) (Table 2).

3.5 Long-term cell viability and morphology in 3D scaffolds

Both hBMSCs and C5.18 cells kept viable after they were cultured in the 3D BC scaffold and the 3D BC/A (3D BC/A1) scaffold for 4 weeks (Fig. 4). They proliferated and spread along the pore walls of the scaffolds. The hBMSCs exhibited long spindle shapes while the C5.18 cells stayed round. The hBMSCs and C5.18 cells aggregated inside the pores of the 3D BC/A (3D BC/A1) scaffold, respectively, and attached to the wall of the pores.

Live/dead staining and scanning electron microscopy (SEM) views hBMSCs and C5.18 cells cultured in scaffolds for 4 weeks. Live/dead staining images were recorded from a scaffold depth >100 μm by epifluorescence confocal microscopy. Live cells were stained green by calcein-AM and appeared to have adhered and attained a normal morphology. The hBMSCs and C5.18 cells aggregated inside the pores of the 3D BC/A scaffold, respectively, and attached to the wall of the pores. The C5.18 cells in the scaffolds are round while the hBMSCs are spindle-shaped. Dead cells were stained red by EthD-1, and very few were observed in either scaffold

3.6 Cell attachment and morphology in 3D scaffolds

Figure 5 shows that the C5.18 cells in the scaffolds are round while the hBMSCs are spindle-shaped. The hBMSCs and C5.18 cells aggregated inside the pores of the 3D A/BC scaffold respectively, and attached to the wall of the pores. High-magnification images show that the C5.18 cells (Fig. 5e) and hBMSCs (Fig. 5f) attached to the wall of the pores by their pseudopodium anchoring into walls of BC nanofibres. The SEM analysis of 3D BC with cells was not performed because 3D BC scaffolds seeded with cells are too fragile to endure treating process for SEM analysis after they were immersed in culture medium for more than 4 weeks.

Scanning electron microscopy views of C5.18 cells (a, c and e) and hBMSCs (b, d and f) cultured on 3D BC/A scaffolds for 4 weeks. C5.18 cells in the scaffold are round and the hBMSCs are spindle-shaped. C5.18 cells (e) and hBMSCs (f) attached to the wall of the pores by their pseudopodium anchoring into walls and holding BC nanofibres in 3D BC/A highlighted by rectangles

3.7 hBMSC and C5.18 cell proliferation in the 3D A/BC scaffold

Figure 6 shows the proliferation of hBMSCs (a) and C5.18 cells (b) cultured in the 3D BC and 3 D BC/A (3D BC/A1) scaffolds for 0, 1, 2, 3 and 4 weeks. The number of cells increased with culture time. There are more hBMSCs in 3D BC/A scaffolds after 4 weeks culture as compared with 3D BC, at which point the 3D BC scaffolds had been partly disintegrated and some cells fell off due to 3D BC scaffold’s weakly mechanical property. The results show the same on the two types of scaffold seeded with C5.18 cells.

3.8 Potential of 3D BC and 3D BC/A as scaffolds for cartilage tissue engineering

In contrast to BC, the 3D BC and 3D BC/A scaffolds have macropores that are interconnected by macropores, characterized by nanofibrous pore walls (Fig. 1). The diameter of the dominant pores in the 3D BC and 3D BC/A scaffolds was about 100 μm, as shown in Figs. 1 and 3, which is beneficial for cell migration and tissue growth. And the 3D BC and 3D BC/A scaffolds exhibited a large surface area, respectively. A large surface area in scaffolds has been proven to be advantageous for the cell attachment and rapid nutrient diffusion required for cell survival and growth. High porosity is another important characteristic of 3D scaffolds used in tissue engineering, due to its important effects on cell growth. The 3D BC and 3D BC/A scaffolds exhibited high porosities of 90.4 ± 0.2% and 88.5 ± 0.4%, respectively. In Figs. 4 and 5, viable cells are shown in the 3D BC and 3D BC/A scaffolds, and C5.18 cells in scaffolds are round, that maintained the rounded morphology important in promoting a chondrocytic phenotype [9]. Thus, we believe that the 3D BC and 3D BC/A scaffolds are more suitable for tissue engineering than BC. However, the 3D BC scaffold loses strength and become very fragility as seeded cells are exposed to 4 weeks culture, and cells number decreased after 4 weeks culture. So we used agarose to enhance the strength and biocompatibility of the 3D BC scaffold. As a result of this enhancement, the ultimate compressive strength and Young’s modulus of the 3D BC/A scaffold are significantly greater than those of the 3D BC scaffold. In addition, agarose promotes chondrocyte survival and phenotype maintenance [8, 18]. And the results show high ratio agarose may induced the closed pore geometry BC scaffold, the BC gel mixed with 1% (w/v) agarose solution (3D BC/A1) in fabrication procedure is the suitable ratio. Furthermore, nanofibres will become more obvious as agarose gradually degrades during long-term culture, and it maybe in favor of cells interact with nanofibres in the pore walls (Fig. 5). Both C5.18 cells and hBMSCs were shown to survive after being cultured in the 3D BC/A scaffold for 4 weeks (Fig. 4). Therefore, our results suggest that the 3D BC/A is more suitable than 3D BC as a scaffold for tissue engineering and tissue repair.

4 Conclusion

Both 3D BC and 3D BC/A scaffolds have distinguished nano properties and can surport hBMSCs and chondroblasts (C5.18 cell) to attachment and proliferation inside scaffolds. As 3D BC/A has enhanced mechanical property than 3D BC, the 3D BC/A scaffold has more potential than 3D BC scaffold for using as a scaffold for tissue engineering and tissue repair applications.

References

J. Wippermann, D. Schumann, D. Klemm, H. Kosmehl, S. Salehi-Gelani, T. Wahlers, Eur. J. Vasc. Endovasc. Surg. 37, 592 (2009)

H. Backdahl, M. Esguerra, D. Delbro, B. Risberg, P. Gatenholm, J. Tissue Eng. Regen. Med. 2, 320 (2008)

W. Czaja, A. Krystynowicz, S. Bielecki, R.M. Brown Jr., Biomaterials 27, 145 (2006)

A. Svensson, E. Nicklasson, T. Harrah, B. Panilaitis, D.L. Kaplan, M. Brittberg, P. Gatenholm, Biomaterials 26, 419 (2005)

B. Fang, Y.Z. Wan, T.T. Tang, C. Gao, K.R. Dai, Tissue Eng. Part A 15, 1091 (2009)

S.A. Hutchens, R.S. Benson, B.R. Evans, H.M. O’Neill, C.J. Rawn, Biomaterials 27, 4661 (2006)

Y.W. Chuan Gao, Chunxi Yang, Kerong Dai, Tingting Tang, Honglin Luo, Jiehua Wang, J. Porous. Mater. (2010)

P.D. Benya, J.D. Shaffer, Cell 30, 215 (1982)

F.T. Moutos, L.E. Freed, F. Guilak, Nat. Mater. 6, 162 (2007)

M.F. Pittenger, A.M. Mackay, S.C. Beck, R.K. Jaiswal, R. Douglas, J.D. Mosca, M.A. Moorman, D.W. Simonetti, S. Craig, D.R. Marshak, Science 284, 143 (1999)

A.E. Grigoriadis, J.N. Heersche, J.E. Aubin, Differentiation 60, 299 (1996)

E.V. Dare, S.G. Vascotto, D. Carlsson, M.T. Hincke, M. Griffith, Int. J. Artif. Organs 30, 619 (2007)

L. Hong, Y.L. Wang, S.R. Jia, Y. Huang, C. Gao, Y.Z. Wan, Mater. Lett. 60, 1710 (2006)

T.U.T.T. Guoping Chen, Macromol. Biosci. 2, 67 (2002)

C. Yang, G. Yuan, J. Zhang, Z. Tang, X. Zhang, K. Dai, Biomed. Mater. 5, 045005 (2010)

R. Kaushal, T.K. Walker, D.G. Drummond, Biochem. J. 50, 128 (1951)

G. Helenius, H. Backdahl, A. Bodin, U. Nannmark, P. Gatenholm, B. Risberg, J. Biomed. Mater. Res. A 76, 431 (2006)

T.A. Kelly, K.W. Ng, G.A. Ateshian, C.T. Hung, Osteoarthr. Cartil. 17, 73 (2009)

Acknowledgments

This work was supported by the National Basic Research Program (973 Program) (Grant No. 2007CB936101), the Fund for Key Disciplines of Shanghai Municipal Education Commission (J50206), Shanghai Rising-Star Program (Grant No. 08QA14045), and the National Natural Science Foundation of China (Grant No. 30600628). We would also like to thank Dr. Wendong Xue for mechanical testing, and Pro. Guangdong Zhou for providing editorial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, C., Gao, C., Wan, Y. et al. Preparation and characterization of three-dimensional nanostructured macroporous bacterial cellulose/agarose scaffold for tissue engineering. J Porous Mater 18, 545–552 (2011). https://doi.org/10.1007/s10934-010-9407-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-010-9407-z