Abstract

In this study, we have developed a simple technique to prepare cationic chitosan hydrogel with interconnected porous structure using freeze–thaw process and the obtained hydrogel was named FCS hydrogel. Scanning electron microscopy (SEM) imaging discovered that the synthesized hydrogel demonstrated interconnected porous structure in the scope of 5–20 μm. We also showed that the FCS hydrogel exhibits pH responsiveness behavior, and demonstrated reversible swelling and de-swelling behaviors maintaining their mechanical stability. We demonstrate that the FCS hydrogel swelling capacity decreased at alkaline pH and rose with a decline in pH value. Besides, the FCS hydrogel presented specific surface area of 78.25 ± 8.75 m2 g−1, due to the cryogenic treatment of glutaraldehyde cross-linked chitosan hydrogel could increase the surface area and permeability of composite hydrogel and then strongly increasing the adsorption capacity. Subsequently, the FCS monolithic hydrogel tested dyes removal, which provides a high removal efficiency towards anionic dyes including congo red (CR) and sodium fluorescein (SFL) dyes. Significantly, we show that the FCS hydrogel could be regenerated and reused as an adsorbent for wastewater treatment without significant loss of pollutants removal efficiency over a number of adsorption and washing cycles. This study offers a promising environmental friendly and sustainable interconnected porous hydrogel for anionic dye removal from wastewater.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

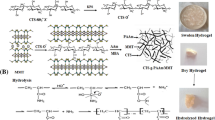

Nowadays, water contamination produced by hazardous organic compounds is becoming a significant and serious danger to the ecosystem [1, 2]. Dyes are the main source of wastewater toxicity in different industrial activities such as paper, textile, plastics, food and pharmaceutical industries [3]. Dye wastewater have harmful effect to the human and animal health and all the natural ecosystems due to these materials contain many aromatic compounds, which are chemically stable and highly toxic [4, 5]. Therefore, developing new strategies and materials for eliminating these contaminants from wastewater has attracted important attention. Various techniques like solid-phase extraction, chemical precipitation, separation, ion exchange, biological treatment, and adsorption have been used for wastewater treatment [6,7,8]. Adsorption is thought to be the most efficient of these methods, versatile and promising method for dyes removal owing to the flexible operation, convenient processing, cost-effective, and high removal efficiency [9]. Activated carbon has been a common adsorbent material, being used for removing many types of dyes [10,11,12,13,14]. However, sometimes the preparation of activated carbon is comparatively expensive and the separation and regeneration from treated water is complicated, which limited its application for water purification and thus increases requirements for substitutes adsorbent materials being economical and sustainable [15]. Hydrogels are considered novel materials used as adsorbents with rapid removing of dyes owing to their unique 3-dimensional porous network structure, which can absorb big amounts of water with lack of solubility in water because of the physical or chemical crosslinking between the chains of polymeric [16, 17]. Furthermore, hydrogel materials contain hydrophilic function groups that can operate as an active site for the elimination of organic contaminants [18]. In addition, the hydrogel simply separates from treated solution and have the ability to recover and reuse a number of times, which meets the demand for sustainability and eco-friendly development [19]. Some types of hydrogels are named smart materials, which often respond to the stimulus of the surrounding environment, for example, temperature, light, pH, magnetic and electric field owing to their functional groups presented along the polymer chains [20]. For instance, the swelling and deswelling behavior of these materials may be sensitive to variations in pH, solution temperature, or even to the presence of the light [21]. Polysaccharides are desired candidates for preparing hydrogels as adsorbent materials for the treatment of wastewater because they are non-toxic, biodegradable, and available in nature [22]. In particular, chitosan is a widely used biopolymer for preparing hydrogel for pollution remediation owing to its the second most abundant biopolymer in nature after cellulose and have high adsorption capacity due to containing a big number of function groups like amine and hydroxyl groups, that make them efficient adsorbent for different organic pollutants removal [23, 24]. Chitosan considerable to be an excellent example of a pH-responsive natural polymer [25]. Moreover, because chitosan could be dissolved in acid media, chitosan hydrogel has a higher adsorption capacity than chitosan polymer with non-crosslinking [26]. Chitosan hydrogels designed via either chemical or physical cross-linking using different crosslinker agents like formaldehyde, glyoxal, glutaraldehyde, ethylene glycol diglycidyl ether, epichlorohydrin and oxalic acid were reported [27,28,29,30]. The mechanical properties and the chemical stability of chitosan are improved after cross-linking process [31]. However, unmodified chitosan hydrogel has a lake of porosity and a small surface area, which causes low adsorption capacities [30]. To overcome these restrictions, there are different chemical and physical techniques have been used for modifying chitosan hydrogel in order to increase the surface area and to create desirable porous structure and improve the mechanical properties, which are very important in our application [32, 33]. Chitosan has been chemically modified by grafting with nanoparticles or crosslinking with other polymers. Ehsan and co-workers have grafted chitosan with polyacrylamide matrix and TiO2NPs were dispersed in the network structure (TiO2-PAM-CS) utilizing in situ method. This composite material was applied for the adsorption of dye (Sirius yellow K-CF) from the solution and it was displayed high removal efficiency of this anionic dye [3]. Hu Tu et al. enhanced the chitosan hydrogel by constructing chitosan with different ratios of cellulose by using the environmentally friendly method and materials. The prepared hydrogels were not only low cost, but also possessed high mechanical properties. Besides, the hydrogels had outstanding high adsorption ability towards anionic dyes in aqueous solution and preformed a surface area 33.9 m2 g−1 when the ratio between chitosan: cellulose was 9:1 [34]. Mahmoodi et al. have studied the use of GO for modifation of chitosan hydrogel (GO–CTS) and amine graphene oxide–chitosan (AGO–CTS) hydrogel which boosting the adsorption capacity. The removal of diclofenac GO–CTS hydrogel was investigated and it was exhibited high adsorption efficiency with a superior adsorption capacity of about 132.11 mg g−1 [35]. Alves D.C.S. et al. loaded carbon nanotubes on chitosan hydrogel (HyCNT) and tested its adsorption efficiency towards phenol. They showed that HyCNT have a large surface area, that is interesting property for adsorption application [36]. However, these chemical modifications for chitosan hydrogel suffer from a number of disadvantages including synthesis these materials can be costly and time consuming [37]. In addition, the regeneration of these modified materials for adsorption application were very complicated [38]. Besides, added another polymer with different function groups led to a lack the selectivity in the adsorption process. Furthermore, concerns have been raised about the effect on the environment of CNT and GO, that if seeped from chitosan composites, can insert the aquatic environment and harm the watery ecosystem [39]. Moreover, GO and CNT particles may be blocking the pores of chitosan hydrogel, which is impact on the diffusion of the pollutants through the porous structure and led to decrease the adsorption capacity [40]. Therefore, various researches have been used physical modifications of hydrogels to control the porosity to form superporous structure with high swelling properties such as gas blowing or freeze drying techniques, which can increase its adsorption capacity [41,42,43]. The freeze–drying technique has its own disadvantage as well such as high energy required, time consuming and may led to shrinkage the network structure because the interfacial tension resulted by solvent evaporation thus limiting their usage [44, 45]. This work provides new ideas for physical modification of chitosan hydrogel was used. Freezing and thawing method have been carried out on glutaraldehyde cross-linked chitosan hydrogel in order to produce porous chitosan hydrogel to increase the diffusion properties. It is worth noting that freeze–thaw process is preferred because it provides opens the pores in the structure of the CS matrix therefore, solute interactions allow breakthroughs from the sorbent’s outer surface to the intraparticle pores, as well as adsorption on both the inner and outer obtainable surfaces. Therefore, an increase in the specific surface area because of the amplification of the chitosan network structure by changing the pores from close or blind pores to interconnected pores, which are desirable in wastewater treatment field. This is shown schematically in Fig. 1A, B. To the best of our knowledge, there have been no studies about using this type of modification for chitosan hydrogel by freezing–thawing treatment and used for adsorption of anionic dyes.

Schematic illustration of A the synthesis of cationic chitosan with interconnected hydrogel using glutaraldehyde as a crosslinking agent and treated by freezing and thawing method B its application for removal of anionic dye by adsorption (Congo Red dye as typical model for anionic dyes) (Color figure online)

Materials and Methods

Materials

Chitosan (CS) was gotten from across organics with a medium molecular weight (Mwt 100,000–300,000). Glutaraldehyde (50%), congo red, fluorescein dye (acid yellow 73) and methylene blue dye were bought from Sigma-Aldrich. Rhodamine (6G) was obtained from Chem. Supply. Acetic acid was bought from macron fine chemicals. All other chemicals in this research were used directly without extra purification. Distilled water was used to prepare all of the solutions in this study.

Preparation of CS Hydrogel

The chemically cross-linked CS hydrogel was created based on a modified version of the method described by Xinhong Chang et.al. using glutaraldihyde as cross linker agent [27]. At room temperature, 1.0 g of CS was dissolved in 50.0 mL of 1.0 vol % acetic acid solution with magnetic stirring (solution 1), then 1.0 mL of glutaraldehyde (50 wt %) was dissolved at room temperature in 20.0 mL distilled water (solution 2). The two solutions were mixed at room temperature under vigorous stirring for 2 min. After that, the samples were immediately put into plastic syringes with an internal diameter of 1 cm, where they slowly converted into wet gels within 10 min and were aged for 1 day. The obtained CS hydrogels were frozen in a freezer at – 20 °C for 2 days and then melted at room temperature to create a porous CS hydrogel for wastewater treatment. After cooling, the frozen CS hydrogel was washed with a 0.01 M hydrochloric solution followed by distilled water to eliminate any unreacted material. Finally, the obtained porous monolithic chitosan hydrogel was named FCS and it was kept in distilled water at room temperature pending use.

Characterization

SEM (JEOL JSM-6480 LV SEM instrument) was used to examine the structural morphology of the fabricated CS hydrogel. The sample was fractured to create a fresh surface, then adhered onto an SEM stub. The sample was then sputter coated with gold via sputter coater and then transferred into the SEM chamber. The functional groups of CS powder and the synthesised chemical cross-linked CS were studied by Thermo Scientific Nicolet 380 FT-IR, provided with (ATR). The total pore volume, pore size distribution and specific surface area for the freeze dried CS hydrogel material was measured by using a BET-N2 surface area analyser with N2 gas adsorption analysis and stabilising at – 196 ºC. CS hydrogel was freeze-dried using (VirTis SP SCIENTIFIC) to produce a monolithic CS aerogel sample, which was then degassed for 12 h before measurement of surface area. The BJH (Barett-Joyner-Halenda) model was used to calculate the pore size distributions. The zeta potential of FD-chitosan hydrogel surface was measured using a Malvern Instruments Zetasizer Nano instrument. Chitosan hydrogel porosity percent (P%) were calculated from the density of wet FCS hydrogel (ρ FCS wet) and the density of dry FCS hydrogel (ρFCS dry) using the following equation:

The swelling degree (SD) of FCS hydrogel was measured by using gravimetric analysis from pH 2–10. Before measurement, the hydrogels were left in DW for 1 day. Then, the sample was immersed in water with the required pH for 1 day. The extra water on the sample’s surface was gently removed with filter paper. The hydrogel weight at pH 2 (Ws) and the dehydrated hydrogel weight at pH 10 (Wd) were measured and then applied to calculate SD using the following equation:

Gravimetric analysis was also used to determine the swelling kinetics and water uptake ratio (WU) of FCS hydrogel. Briefly, the hydrogel was initially plunged into a pH 2 solution that had been reaching equilibrium. Then, the hydrogel was immersed in pH 10 solution for 24 h till equilibrium was obtained in the dehydrated condition and weighed (Wg). The sample was then immersed again in pH 2 and then the weight of the hydrogels was recorded (Wt) at different times for one hour. As previously stated, the extra water on the hydrogels' surfaces was absorbed with filter paper prior to weighing. The water uptake ratio WU is calculated using the following equation:

The deswelling kinetics and the water retention ratio (WR) of the FCS hydrogel were also studied by gravimetry analysis. The FCS hydrogels, firstly kept in distilled water at pH 2 for 1 day then the weight of the hydrogels was recorded (Wg), were then transferred in pH 10 solution. Then, the weight of the hydrogels was recorded (Wt) at the same time for the swelling study. As mentioned above, before measuring the weight the extra water on the hydrogels' surfaces was absorbed carefully with filter paper. The water retention ratio WR was calculated using the following equation:

The zeta potential of FCS hydrogel was evaluated by DLS. FCS hydrogel was crashed into small parts and then dispersed in deionized water. The measurement was carried out in triplicate at room temperature.

Adsorption Studies

CR, MB, R6G, and FL were applied to examine the adsorption and removal activity of the chemically cross-linked CS hydrogel. The study results were measured via a UV–Vis spectrophotometer at 498 nm, 664 nm, 525 nm, and 490 nm for CR, MB, R6G and FL respectively. The prepared FCS hydrogels were put into 100 mg/L dye solutions. Then, the solutions were shaken in the dark condition regularly for 3 h using a platform shaker (Gemmy orbit shaker model: VRN-480). The absorbance at the maximum absorption wavelength was recorded before and after adsorption. The batch adsorption tests were conducted to evaluate the percentage of dye removal (R%) and the adsorption uptake quantity (Qe) of CR or SFL on FCS hydrogel whereby the monolithic hydrogel (~ 0.05 g of FCS, 3 mL volume) were plunged into isolated conical flasks with 100 mL serial solutions of CR or SFL dyes (10–60 mg L−1). The samples were gently shaken in the dark condition at room temperature (25 ± 2 °C) in the dark condition with a shaker speed of 100 rpm until reached the equilibrium. All measurements were done in triplicate and the anionic dyes concentration was calculated at the maximum absorbance of CR dye (498 nm) and FL dye (490 nm). The R% and the adsorption quantity of the dye adsorbed per unit mass of adsorbent at equilibrium Qe (mg g−1) and at particular time Qt were determined using the equations:

where C0 and Ct represent the initial dye concentration (mg L−1) prior to adsorption and the dye concentration after adsorption at time t. at equilibrium, the concentration is Ce (mg L−1), The dose of FCS hydrogel and the dye solution volume is represented by m (g) and V (L), respectively.

Adsorption Isotherm

The adsorption isotherms were examined via Freundlich and Langmuir isotherms for the adsorption of CR and FL dyes on the FCS hydrogel. The Freundlich model is an empirical model and more applicable at low adsorbate concentrations. In the theoretical Freundlich model, it is assumed that adsorption of dye takes place on the adsorbent's heterogeneous surface, it suggests multilayer adsorption and there is an interaction among the adsorbate and adsorbent molecules depend on the electrostatic attraction among negative and positive charges. The following equation was used to calculate the Freundlich isotherm parameters:

where, Qe (mg/g) is amounts of dyes adsorbed at equilibrium. KF and (1/n) are Freundlich isotherm constants. The Langmuir model assumes that the dye adsorbs in a monolayer around the homogeneous surface of the adsorbent with no attraction among the dye molecules and the adsorbent. The Langmuir isotherm parameters were calculated using the equation:

where Ce (mg L−1) represents the equilibrium concentration of the FL and CR dyes in solution, the equilibrium adsorption capacity of FL and CR dyes on the FCS hydrogel is expressed as Qe (mg g−1), the maximum amount of dyes on the FCS hydrogel that can form a monolayer on the surface is defined as Qmax (mg g−1), the Langmuir constant KL (L mg−1) describes the affinity of adsorption active sites.

Results and Discussion

Characterization of FCS Hydrogel

The surface characteristics of the FCS hydrogel of the fracture surface were examined by SEM, and the data were presented in Fig. 2. In the cross-sectional images of the FD-CS hydrogel, there are a highly porous matrix with interconnected pores extending from the core to the surface of the monolithic hydrogel, indicating the successful crosslinking of chitosan polymer chains to form chitosan composite hydrogels. Furthermore, the prepared chitosan hydrogel with freeze-thawing treatment exhibited open pores with high interconnectivity structure. In contrast with SEM images of CS hydrogel without freeze and thawing treatment, which presented a rough surface but with no pores were observed on the surface as shown in Fig.S1, which is consistent with other studies [25]. This is due to the freeze–thawing method has been used to create porous chitosan hydrogel with interconnected pores [42]. During cooling the prepared chitosan hydrogel, the nucleation and the ice crystals was grown and moves into non-nucleated solution leading to change the morphology and form interconnected pores [46]. At a temperature below the freezing temperature (room temperature), these ice crystals melt and gives rise to interconnected macroporous networks [47, 48]. This network structure can improve the specific surface area and then increase the adsorption capacity of the dye molecules from aqueous media due to promoted diffusion of the dyes molecules within the hydrogel structure and makes contact between the functional groups of the chitosan hydrogel with dye molecules more efficient [49]. The specific surface area and pore size distributions of FDCS hydrogel was determined by employing the nitrogen sorption technique. The N2 adsorption–desorption isotherms of FDCS are represented in Fig. 3A.

The N2 adsorption–desorption isotherm for FCS belongs to type H3 hysteresis loop according to IUPAC classification, which proves interconnected pore structure with a parallel plate shape [50]. The synthesized FCS in this work displayed a specific surface area of 78.25 ± 8.75 m2 g−1. The BET of the synthesized FCS chitosan compared with previous studies in the literature and it was found that the surface area for the FCS hydrogel was larger value [50,51,52].

These results strongly support the fact that the surface area and porosity of FCS were increased after freezing the CS hydrogel. Obviously, cryogenic treatment for the synthetic glutaraldehyde cross-linked chitosan hydrogel played an impressive role in the increasing of the surface area of this hydrogel. As expected, after freezing the CS hydrogel convert the porous structure from close pores to interconnected pores, which can allow more active sites in the hydrogel to interact with dye molecules and led to improve adsorption efficiency [53, 54]. Therefore, FCS hydrogel with larger specific surface area and more active groups are a promising adsorbent materials due to these properties are especially significant for adsorption applications for wastewater treatment [55]. The BET results well proved the SEM images as the pores development can be seen obviously in the surface morphology of FCS hydrogel. For a better evaluation of the impact of the initial CS concentrations on the porosity % of FCS hydrogel, four different CS concentrations were used by fixing the crosslinking agent concentration constant. Increasing the CS concentration decreased the porosity of final FCS hydrogel as shown in Fig. 3B. The average porosity of FCS composite hydrogels decreases from 93.49 to 80.05% when the initial concentration of CS increases from 0.5 to 2.5% w/v. This is because raising the polymer concentration increases the cross-link densities of the network structure of the prepared hydrogel, which is lead to decrease the porosity [56].

To more validate the successful crosslinking and the structural changes of composite hydrogel after crosslinking, the infrared spectra were investigated for powder chitosan and cross-linked chitosan hydrogel as displayed in Fig. 3C. Comparison of the FTIR data shows that the FCS cross-linked chitosan hydrogel shows spectra that are different from those of non-cross-linked chitosan. Non-cross-linked chitosan demonstrate peaks at 949 and 1104 cm−1 are attributed to C–O–C bridge of chitosan unit. The absorption bands at 2911 and 2873 cm−1 can be corresponds to C–H symmetric and asymmetric stretching. A broad band in the area of 3240- 3400 cm−1 attributed to the associated of the vibrations of –NH2 and -OH groups. Band at about 1564 cm−1 are attributed to the bending of the primary amine’s N–H bond [57]. After chemical crosslinking of chitosan using glutaraldehyde, these band present a change in it is intensity and width, this is occurring because of the bond generated by overlapped the N–H, O–H, and C-O bonds of CS with the GA during the crosslinking reaction. This proves that some of the H2 bonds in the CS structure are broken and new H2 bonds among GA and CS polymer chains are created as NH2 and OH functional groups engaged in H2 bonds [58]. A new peak was discovered at approximately 1646 cm−1, which is most probably attributed to the imine bond (C = N). This bond produces and observed in the spectrum of FCS hydrogel due the chemical crosslinking reaction between GA and CS amino groups [26]. The FTIR results indicate that GA cross-linking occurs via the reaction of aldehyde groups of glutaraldehyde with amine groups of CS. Fig. S2 shows alteration of the CS hydrogel color from transparent light yellow to orange this also validates the creation of cross-links among CS polymer chains by GA. This is most likely due to the formation of a chromophore as stable crosslinking products, which is not present in the starting precursors [59]. The Z-potential of FCS hydrogel in deionized water was measured by the DLS of suspensions that were prepared by dispersing 0.05 g of the vacuum dried FCS hydrogel in 50 mL of deionized water by a digital sonicator. The zeta potential of FCS hydrogel was found to be + 26.5 ± 5 mV as shown in Fig. 3D. At this point, the positive surface charge of FCS hydrogel contributed to increase the adsorption capacity towards the anionic contaminated and this result agrees with previous studies [60,61,62].

It is significant to mention that the positive value of ZP for FCS hydrogel indicating that the high protonation of the NH2 groups, which are did not take part in the crosslinking reaction and suggests that the interactions between the FCS hydrogel and anionic dyes molecules may occur by H2 bonding and/or electrostatic connections [63].

The gravimetric method was used to examine the swelling properties of both FCS and CS hydrogel. In detail, a tiny piece of vacuum dried hydrogel (~ 0.05 g) was immersed in deionized water at room temperature for 1 day (25 ± 3 °C) at pH 7. The FCS hydrogel shows remarkable and quick volume change due to capillary forces allowing water to pass thru the hydrogel. This was owing to the interconnected porous structure and the abundance of hydrophilic functional groups on the backbone [64].

Swelling behavior of FCS and CS hydrogels as a function of pH was evaluated (Fig. 4). As illustrated in Fig. 4A both hydrogels demonstrated a pH responsive swelling behavior as the swelling degree of the hydrogels increased with decreasing the pH value from 12 to 3. However, the FCS hydrogel sample exhibited pronounced increases in the swelling degree with decreasing the pH value, while the CS hydrogel sample showed not so significant increase in the swelling degree as the pH values decreased. This might be due to CS hydrogel having a close porous which prevents diffusing water molecules. Besides, the swelling degree of FCS hydrogels in pH 3 was 26.3, which doubled compared to the same sample in pH 12 (11.7). It is worth noting that, FCS hydrogel in acidic environment showed higher swelling ratio than the same sample in basic and neutral environment. In order to explain this phenomenon, it was due to in acidic media ionized the –NH2 groups in the FCS hydrogel to ammonium ion (NH3+) and these cationic charges made repulsive forces between polymer chains [65]. Figure 4B shows the swelling deswelling reversibility for ten cycles of FCS and CS hydrogel between pH 3 and pH 10. The results demonstrated that the reversibility of CS hydrogel toward the pH changes was negligible. Whereas, the FCS hydrogel exhibited the ability of rapid absorb and release the swelling medium upon changing the pH values. Figure 4C demonstrates the swelling of CS and FCS hydrogels in acidic media as a function of time. Figure 4D shows deswelling kinetics of the CS and FCS hydrogels at pH 10. FCS hydrogel demonstrated remarkable water uptake, while CS hydrogel exhibits slightly water uptake with decrease the pH values. FCS hydrogels exhibited quicker loss most of water after change the pH value from 3 to 10 in comparison with water uptake of the same FCS sample. This results are reasonable since both swelling and deswelling processes start from the surface of the hydrogels to inside the hydrogel through its porous structure. During swelling, water will take longer time to penetrate inside the sample, while it will take a shorter time for the transportation from the hydrogel during deswelling. These results indicated that the freezing and thawing treatment of chitosan hydrogel significantly affected the swelling properties. Figure 4E demonstrated schematic represented the swelling and deswelling properties of FCS hydrogel in acidic and alkaline conditions respectively.

A Swelling degree (SD) as a function of pH of CS and FCS hydrogel at room temperature, B Reversibility cycle of swelling–deswelling of CS and FCS hydrogel as a function of time by varying the pH from 3 to 10, C Water uptake ratio (WU) for CS and FCS hydrogel as a function of time, when plunged in a pH 3 after initial equilibration at pH 10. D Water retention ratio (WR) of CS and FCS hydrogel as a function of time, when plunged in a pH 10 after initial equilibration at pH 3. E Diagram drawing of swelling and deswelling behavior of the FCS hydrogel in wet conditions at 25 °C and at different pH. Consistent visual image of the swollen and shrunk situations of FCS hydrogel in basic and acidic media

Adsorption Study

The synthesized three-dimensional FCS hydrogel with unique pore structure were evaluated for the elimination of some organic dyes. In the current work, Congo Red and Sodium Fluorescent dyes as an anionic dye model and Methylene Blue and Rodamine 6G as cationic dye model to test the ability of FCS hydrogel to remove organic dyes. It is also important to note that the preparation process of our FCS hydrogel requires only mixing of chitosan and the chemical cross linker in acidic media and then freeze–thaw treatment to generate the pores, with no further drying step required to form the hydrogel absorbent. This low energy fabrication method, together with the use of the green solvent, water, renders our approach relatively environmentally friendly. Further, we described the dye adsorption process utilizes monolithic hydrogel, with no required for the additional steps of centrifugation or adsorbent separation, unlike methods that utilized particulate-based absorbents. Fig. S3 show a photograph of the adsorption process of CR and SFL by FCS monolithic hydrogels. After immersing the FCS monolithic hydrogel by 24 h into CR and SFL dyes solutions separately, the red and yellow solutions containing CR and SFL dyes become very light and almost transparent and clear, while the hydrogels converted red and dark yellow due to the adsorption of CR and SFL dyes respectively. The images show that the composite FCS pores hydrogels have highly efficient of anionic dyes adsorption. In contrast, FCS hydrogel demonstrates very low removal towards MB and R6G as shown in Fig. S4. However, the monolithic FCS hydrogel turned to blue and dark orange after immersing these hydrogels into MB and R6G solutions by 24 h. The reason for this is due to the interconnected porous structure of FCS hydrogel make easily filled by these dyes solutions without being adsorbed [66]. The adsorption capacities of the FCS hydrogel toward CR and SFL dyes were evaluated by using the UV − Vis spectra to measure the concentrations of the dye solution before and after adsorption as shown in Fig. 5A, B. Removal and adsorption of CR and SFL dyes onto the FCS monolithic hydrogels from the aqueous solution was observed. UV–Vis spectroscopy shows low absorption bands for these two dyes in the solution after adsorption. This phenomenon may be explained by electrostatic attraction between NH3+ group protonated in the acid medium of FCS hydrogel and anionic dye molecules formation (Dye-NH3+), which is cause the captured of this type of dyes on FCS hydrogel [3]. We discovered that the H2 bonding and electrostatic attractions played an important role in the adsorption of the anionic dyes [67]. Similarly, FCS hydrogel adsorption capacity were tested towards MB and R6G dyes aqueous solutions as cationic dyes. In contrast to CR and SFL dyes, no significant adsorption was observed toward MB and R6G (less than 10%), with little change in the UV–Vis spectrum of the dyes solutions after adsorption as shown in Fig. 5C, D.

This confirmed that FCS monolithic hydrogel has no obvious adsorption of cationic dyes on its surface due to the electrostatic repulsion among the dyes and the cationic FCS hydrogel [67]. However, it should be noted that the poor removal efficiency of cationic dye due to the hydroxyl groups in the FCS may also participate to chelation with cationic dyes [68]. CS hydrogel without freeze–thaw treatment was also investigated for removal of CR dye from its aqueous solution as shown in Fig. S5. The removal efficiency of CR dye on CS hydrogel was found 30.91%, which is much smaller than that of removal efficiency of CR dye on FCS hydrogel (96.73%). Figure 6A and B show photographs of CR dye adsorption on FCS and CS hydrogels over 24 h, respectively. The cylindrical FCS hydrogel displayed a homogenous red color after CR dye adsorption, and the dye diffused uniformly into the FCS hydrogel surface and core. Whereas the cross-section of CS hydrogel showed no dye adsorption on the internal surface of the cylindrical CS hydrogel. Figure 6C and D shows photographic images of trackers test of the permeability of CS and FCS hydrogels columns. MB dye was used to MB dye shows very low adsorption on the chitosan hydrogel. Evaluate the permeability of CS and FCS hydrogels column due to this dye exhibited very low adsorption capacity on chitosan hydrogel. The column with freezing and thawing treatment exhibited high permeability with rapid diffusion of the MB dye within the hydrogel column. Whereas, the CS hydrogel column without freezing and thawing treatment show that there is no diffusion of the MB dye from the hydrogel column. To explain this phenomena, freeze and thaw treatment method was employed to develop a chitosan hydrogel with interconnected pores structure. The ice crystals nucleated and grown during freezing stage to help open the pores in the hydrogel and then thawing at temperature above the freezing temperature to form interconnected porous structure. Thus, this method improved the surface area of chitosan hydrogel by allowing more active sites in the hydrogel to interact with dye molecules. This results indicates that freeze and thaw treatment enhanced the porous structure of the prepared hydrogel and improve the removal efficiency to a great extent.

Photograph images show (A) and (B), FCS and CS monolithic hydrogels after used for adsorption of CR dye respectively, which is show the internal surface of the hydrogels after dye adsorption process, C and D FCS and CS hydrogels columns after used for filtration of MB dye respectively to test the permeability of the hydrogel before and after freeze and thaw treatment

A batch adsorption method was also used to investigate the adsorption behavior of the FCS porous monolithic hydrogel towards CR and SFL dyes. The batch adsorption of these two anionic dyes was investigated at various concentrations with constant weight of FCS hydrogel (0.05 g) for different adsorption times intervals at pH 6. Figure 7A demonstrates the adsorption process of both CR and SFL dyes (the concentrations were 60 mg L–1) onto the FCS monolithic hydrogel were progressed rapidly in the initial stage and the rate of adsorption steadily declined as it approached equilibrium after 12 h. The best possible explanation for this phenomenon is that at the beginning of the reaction, the higher available active site with the higher driving force on the FCS hydrogels surfaces provides better opportunity of collision between anionic dyes molecules and the adsorbent [69]. As the adsorption reaction reached equilibrium the adsorption capacity was remained constant, which is may be attributed to saturated the available adsorption sites of the FCS hydrogel by dyes molecules [70]. The adsorption capacity at equilibrium of CR and SFL dyes were calculated and it were found 104.9–99.6 mg g−1 respectively. The removal percentage of CR and SFL dyes were up to 96.73–95% at equilibrium as shown in Fig. 7B. This small difference in the removal efficiency of these dyes was owing to their different affinities for adsorption. The slightly higher removal of CR dye by FCS when compared to SFL dye is might be attributed to the higher charge density of dye molecules. A CR dye molecule has two sulphonate groups that could electrostatically interact with the amine groups on the FCS surface via electrostatic attraction, whereas SFL dye molecule only contains one carboxyl group. As a result, CR dye molecules are more likely to interact strongly to the FCS hydrogel, resulting in a higher removal efficiency than SFL dye [71]. Besides, the electrostatic interaction between CR dye and FCS hydrogel more stable compared with SFL dye due to CR dye has higher molecular weight and contains more aromatic groups, which is increase the adsorption stability and led to increase the adsorption capacity and removal percentage [72]. The study of the adsorption isotherm play a significant role to describe how adsorbates molecules interact with adsorbents surface [73]. In the present work, to investigate the equilibrium condition of anionic dyes (CR and SFL) onto FCS hydrogel, two types of isotherms including Langmuir and Freundlich isotherm models were evaluated. The Langmuir model represents a single layer adsorption system on a homogeneous surface, while the Freundlich model are considered as a heterogeneous multi layers adsorption system [74]. As we can see in Fig. 7C, D the plots of Langmuir and Freundlich isotherm for CR and SFL dyes. The fitted parameters and data are shown in Table S1. The results indicate that the Freundlich adsorption isotherm showed a better value of correlation coefficient (R2). Therefore, the adsorption of both CR and SFL dyes onto FCS hydrogel obeyed the Freundlich model and is primarily multilayer adsorption. In the fitting of the Langmuir model, the maximum adsorption capacity qm values for CR and SFL dyes onto FCS hydrogel were obtained and it were found 136.69 and 142.857 mg g−1 respectively.

A The influence of adsorption time on adsorption capacity of CR and SFL by FCS hydrogels (the initial dye concentration: 60 mg/L, adsorbent dosage: 0.05 g in 100 mL of dye solutions, pH of 6, t = 25 °C, shaking rate is constant at 100 rpm). B The effect of contact time on the removal percentage of CR and SFL dyes of dye (C) and D Freundlich and Langmuir adsorption isotherms respectively

As a results, the high adsorption capacity of FCS hydrogel due to the adsorption mechanism is affected by the interconnected porous structure of the hydrogel, which is allow better access of dye molecules through the internal structure of the hydrogel and increase the available active adsorption sites [75].

Additionally, the strong electrostatic force between the positively charged amine groups (–NH3+) in the hydrogel FCS interact with the negatively charged groups on anionic dyes and the like hydrogen bonds interaction encourage anionic dyes adsorption on hydrogels resulting high adsorption capacity [16, 76]. To perform the adsorption characteristics of the FCS hydrogel, kinetic models containing pseudo-first-order (PFO) and pseudo-second-order (PSO) models were used, as shown in Tables S2 and S3 for the CR and SFL dyes, respectively. Figure 8 depicts the fitting plots for the adsorption kinetic model. The correlation coefficient (R2) for the PFO model was found to be lower than that for the PSO model. Furthermore, the outcomes displayed that the simulation adsorption capacity from the plot of the PSO model was observed to be well fit with the results obtained than that calculated from PFO. Therefore, PSO model better describe the adsorption mechanism for both CR and SFL dyes on FCS hydrogel. It is worth to note that the adsorption reaction of CR and SFL dyes on to FCS hydrogel is more tending towards physical adsorption. Basically, the adsorption mechanism of dye molecules on a porous hydrogel adsorbent material cannot be described by only the PFO and PSO models due to the adsorption on these materials may include a multi-stage process [77]. As a result, a model of intraparticle diffusion was used for further interpretation to show the dye molecules mobility from the solution into the interconnected pores of the FCS hydrogel. Figure 8E and F show that the linear plot doesn’t really transfer thru the origin for both CR and SFL dyes, indicating that the intraparticle diffusion models is based on the migration of the adsorbates into the hydrogel pores and controlling the rate adsorption process and the results of adsorbent parameters for intraparticle diffusion model were listed Table S2 and S3 for CR and SFL dyes respectively. This model represents two stages, the first stage where there is a rapid adsorption of dye molecules on the outside surface of the hydrogel and the next step where the intraparticle diffusion is the rate-limiting step [78]. Therefore, in addition to PSO, the intraparticle diffusion model is important for understanding the adsorption technique.

Reusability and Desorption Studies

To assess the reusability and regeneration of FCS monolithic hydrogel as adsorbents in order to determine whether they are a cost-effective material, desorption experiments were carried out using FCS hydrogel as adsorbent and CR and SFL dyes as adsorbates. So the desorption of adsorbed CR and SFL dyes from FCS monolithic hydrogel was investigated in a batch desorption system. Because the FCS is a monolithic hydrogel, the collection of the adsorbent was fast and easy. The FCS hydrogel was recovered by immersing it in a 0.01 M NaOH solution for 6 h to desorb the CR and SFL dyes that had become adsorbate on the hydrogel. Then the hydrogel was protonated in excess 0.01 M HCl for 1 h to regenerate cationic active sites to use in the next adsorption cycle. The regenerated FCS was further washed by deionization water to reach neutrality. The reusability of FCS hydrogel was evaluated over five cycles of adsorption/desorption utilizing a solution of NaOH as the desorption factor with FCS monolithic hydrogel (0.05 g) in 100 mL dye solution (10 ppm) at 25 °C for 24 h (each cycle) as displayed in Fig. 8. Even after five cycles of reusability, no significant losses in dye adsorption performance were observed (Fig. 9). It was observed that about 9% and 3% reduction in removal efficiency of FCS hydrogel for CR and SFL dyes respectively.

Thus, the results depict that the electrostatic attraction is dominating driving power in the adsorption process in this study. It is important to highlight that the positively charged amino group in FCS hydrogel was deprotonated in alkaline conditions, which is affecting the electrostatic interactions between FCS hydrogel and anionic dye and then desorbed the loaded dye from adsorption active site [79]. Therefore, it can be concluded that FCS monolithic hydrogel promising ecofriendly adsorbent material due to can be regenerated easily and used repeatedly as an active adsorbent for water treatment.

Conclusion

In the present study, macroporous FCS hydrogel was successfully prepared using a new and simple freeze–thaw strategy as physical modification of glutaraldehyde cross-linked chitosan hydrogel with the aim of fabrication interconnected porous hydrogel. This porous structure in the hydrogel materials improves the accessibility of adsorbates in the hydrogel active sites and increases the dye adsorption ability of the FCS hydrogel. To the best of our knowledge, no studies have been conducted on the use of the freeze–thaw method for the fabrication of macroporous chitosan hydrogel with interconnected pores. The FCS hydrogel was characterized and the results demonstrated that FCS hydrogel had a highly porous matrix with interconnected pores widening from the core to the monolithic hydrogel surface as revealed by SEM. The swelling-deswelling behavior of FCS hydrogel was examined and the outcomes showed that the FCS hydrogel exhibited good swelling properties in acidic media than the same sample in basic media. The reason behind that the amine groups (–NH2) of chitosan in acidic medium protonation to ammonium ion (NH3+) due to the presence of hydrogen ions and these cationic charges made repulsive forces between polymer chains and increase the capillary force. The swelling deswelling reversibility results of FCS hydrogel showed a significant pH dependent, which demonstrated that the reversibility toward the pH changes was retained even after more than ten cycles. The detailed evaluation of adsorption behavior of different organic dyes by FCS hydrogel revealed that this hydrogel possesses the unique adsorption toward anionic dyes with a large adsorption capacity, but very low adsorption capacity toward cationic dyes. The electrostatic interactions dominated the interaction between the FCS hydrogel and the dye molecules regardless to their charge states. The adsorption isotherms data of CR and SFL onto FCS displayed a well fit with the Ferunditich model. The adsorption kinetics analysis revealed that the pseudo-second-order model adequately described the adsorption method. The obtained FCS provided not only selective absorption towards anionic dyes with a high removal efficiency but also exhibited excellent adsorption efficiency with no significant loss even after five cycles of reusability. From the obtained results, the synthesized FCS hydrogel by the freeze–thaw method is considered to be a promising candidate for the elimination of anionic dyes from a solution due to its excellent adsorption ability and cost-effective properties.

References

Zhao J, Yin J, Zhong J et al (2019) Facile preparation of a self-assembled artemia cyst shell–TiO2–MoS2 porous composite structure with highly efficient catalytic reduction of nitro compounds for wastewater treatment. Nanotechnology 31:85603

Wang C, Yin J, Han S et al (2019) Preparation of palladium nanoparticles decorated polyethyleneimine/polycaprolactone composite fibers constructed by electrospinning with highly efficient and recyclable catalytic performances. Catalysts 9:559

Binaeian E, Zadvarzi SB, Yuan D (2020) Anionic dye uptake via composite using chitosan-polyacrylamide hydrogel as matrix containing TiO2 nanoparticles; comprehensive adsorption studies. Int J Biol Macromol 162:150–162

Islam MA (2020) Synthesis of manganite (γ− MnOOH) for the adsorptive degradation of methylene blue (MB) and orange green (OG) from aqueous solution. Cell 1818:482533

Kapoor RT, Danish M, Singh RS et al (2021) Exploiting microbial biomass in treating azo dyes contaminated wastewater: mechanism of degradation and factors affecting microbial efficiency. J Water Process Eng 43:102255

Demirbas A (2009) Agricultural based activated carbons for the removal of dyes from aqueous solutions: a review. J Hazard Mater 167:1–9. https://doi.org/10.1016/j.jhazmat.2008.12.114

Gupta VK, Suhas (2009) Application of low-cost adsorbents for dye removal a review. J Environ Manage 90:2313–2342. https://doi.org/10.1016/j.jenvman.2008.11.017

Vashi H, Iorhemen OT, Tay JH (2017) Aerobic granulation: a recent development on the biological treatment of pulp and paper wastewater. Environ Technol Innov 9:265–274

An B, Choi J (2019) An experimental application of four types of chitosan bead for removal of cationic and anionic pollutants. Water Air Soil Pollut. https://doi.org/10.1007/s11270-019-4365-9

Mezohegyi G, van der Zee FP, Font J et al (2012) Towards advanced aqueous dye removal processes: a short review on the versatile role of activated carbon. J Environ Manage 102:148–164. https://doi.org/10.1016/j.jenvman.2012.02.021

Halbus AF, Athab ZH, Hussein FH (2021) Review on preparation and characterization of activated carbon from low cost waste materials. Egypt J Chem 64:7255–7268

Hussein FH, Halbus AF, Lafta AJ, Athab ZH (2015) Preparation and characterization of activated carbon from iraqi khestawy date palm. J Chem. https://doi.org/10.1155/2015/295748

Zahraa HA (2015) Production and characterization of activated carbon from iraqi palm fiber. Asian J Chem 27:3658–3662

Halbus AF, Athab ZH, Hussein FH (2013) Adsorption of disperse blue dye on Iraqi date palm seeds activated carbon. Int J Chem Sci 11:1219–1233

Ren J, Wang X, Zhao L et al (2021) Effective removal of dyes from aqueous solutions by a gelatin hydrogel. J Polym Environ 29:3497–3508

Sinha V, Chakma S (2019) Advances in the preparation of hydrogel for wastewater treatment: a concise review. J Environ Chem Eng 7:103295

Hou N, Wang R, Geng R et al (2019) Facile preparation of self-assembled hydrogels constructed from poly-cyclodextrin and poly-adamantane as highly selective adsorbents for wastewater treatment. Soft Matter 15:6097–6106

Loo S-L, Vásquez L, Athanassiou A, Fragouli D (2021) Polymeric hydrogels—a promising platform in enhancing water security for a sustainable future. Adv Mater Inter 8:2100580. https://doi.org/10.1002/admi.202100580

Weerasundara L, Gabriele B, Figoli A et al (2020) Hydrogels: novel materials for contaminant removal in water—a review. Crit Rev Environ Sci Technol 51:1–45. https://doi.org/10.1080/10643389.2020.1776055

Kaith BS, Singh A, Sharma AK, Sud D (2021) Hydrogels: synthesis, classification, properties and potential applications—a brief review. J Polym Environ 29:3827–3841

Yu Y, Cheng Y, Tong J et al (2021) Recent advances in thermo-sensitive hydrogels for drug delivery. J Mater Chem B 9:2979–2992

Qi X, Tong X, Pan W et al (2021) Recent advances in polysaccharide-based adsorbents for wastewater treatment. J Clean Prod 315:128221. https://doi.org/10.1016/j.jclepro.2021.128221

Hassanzadeh P, Gharbani P, Derakhshanfard F, Maher BM (2021) Preparation and characterization of PVDF/gC 3 N 4/chitosan polymeric membrane for the removal of direct blue 14 dye. J Polym Environ. https://doi.org/10.21203/rs.3.rs-218812/v1

Younes I, Rinaudo M (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar Drugs 13:1133–1174

Ostrowska-Czubenko J, Gierszewska M, Pieróg M (2015) pH-responsive hydrogel membranes based on modified chitosan: water transport and kinetics of swelling. J Polym Res 22:1–12

Galan J, Trilleras J, Zapata PA et al (2021) Optimization of chitosan glutaraldehyde-crosslinked beads for reactive blue 4 anionic dye removal using a Surface response methodology. Life 11:85

Chang X, Chen D, Jiao X (2008) Chitosan-based aerogels with high adsorption performance. J Phys Chem B 112:7721–7725

Bratskaya S, Privar Y, Nesterov D et al (2019) Chitosan gels and cryogels cross-linked with diglycidyl ethers of ethylene glycol and polyethylene glycol in acidic media. Biomacromol 20:1635–1643. https://doi.org/10.1021/acs.biomac.8b01817

Yang C, Shi X, Qi L et al (2021) Electrical writing induced covalent cross-linking on hydrogel for multidimensional structural information storage. ACS Appl Mater Interfaces 13:36538–36547. https://doi.org/10.1021/acsami.1c09548

Pérez-Calderón J, Santos MV, Zaritzky N (2020) Synthesis, characterization and application of cross-linked chitosan/oxalic acid hydrogels to improve azo dye (Reactive Red 195) adsorption. React Funct Polym 155:104699

Mathew AP, Laborie M-PG, Oksman K (2009) Cross-linked chitosan/chitin crystal nanocomposites with improved permeation selectivity and pH stability. Biomacromol 10:1627–1632. https://doi.org/10.1021/bm9002199

Kayan GÖ, Kayan A (2021) Composite of natural polymers and their adsorbent properties on the dyes and heavy metal ions. J Polym Environ. https://doi.org/10.1007/s10924-021-02154-x

Reghioua A, Barkat D, Jawad AH et al (2021) Magnetic chitosan-glutaraldehyde/zinc oxide/Fe 3 O 4 nanocomposite: optimization and adsorptive mechanism of remazol brilliant blue r dye removal. J Polym Environ. https://doi.org/10.1007/s11356-022-20673-5

Tu H, Yu Y, Chen J et al (2017) Highly cost-effective and high-strength hydrogels as dye adsorbents from natural polymers: chitosan and cellulose. Polym Chem 8:2913–2921

Mahmoodi H, Fattahi M, Motevassel M (2021) Graphene oxide–chitosan hydrogel for adsorptive removal of diclofenac from aqueous solution: preparation, characterization, kinetic and thermodynamic modelling. RSC Adv 11:36289–36304

Alves DCS, Goncalves JO, Coseglio BB et al (2019) Adsorption of phenol onto chitosan hydrogel scaffold modified with carbon nanotubes. J Environ Chem Eng 7:103460

Alves DC, Healy B, Yu T, Breslin CB (2021) Graphene-based materials immobilized within chitosan: applications as adsorbents for the removal of aquatic pollutants. Materials (Basel) 14:3655

Niu Z, Liu L, Zhang L, Chen X (2014) Porous graphene materials for water remediation. Small 10:3434–3441

da Silva Alves DC, Healy B, Pinto LA et al (2021) Recent developments in chitosan-based adsorbents for the removal of pollutants from aqueous environments. Molecules 26:594

Chatterjee S, Chatterjee T, Lim S-R, Woo SH (2011) Effect of the addition mode of carbon nanotubes for the production of chitosan hydrogel core–shell beads on adsorption of Congo red from aqueous solution. Bioresour Technol 102:4402–4409

Annabi N, Nichol JW, Zhong X et al (2010) Controlling the porosity and microarchitecture of hydrogels for tissue engineering. Tissue Eng Part B Rev 16:371–383. https://doi.org/10.1089/ten.TEB.2009.0639

Xue C, Wilson LD (2021) An overview of the design of chitosan-based fiber composite materials. J Compos Sci 5:160

Sun S, Tang Y, Fu Q et al (2012) Preparation of agarose/chitosan composite supermacroporous monolithic cryogels for affinity purification of glycoproteins. J Sep Sci 35:893–900

Ho M-H, Kuo P-Y, Hsieh H-J et al (2004) Preparation of porous scaffolds by using freeze-extraction and freeze-gelation methods. Biomaterials 25:129–138

Quirk RA, France RM, Shakesheff KM, Howdle SM (2004) Supercritical fluid technologies and tissue engineering scaffolds. Curr Opin Solid State Mater Sci 8:313–321

Deville S, Saiz E, Nalla RK, Tomsia AP (2006) Freezing as a path to build complex composites. Science 311:515–518

Sornkamnerd S, Okajima MK, Kaneko T (2017) Tough and porous hydrogels prepared by simple lyophilization of LC gels. ACS Omega 2:5304–5314

Hwang Y, Sangaj N, Varghese S (2010) Interconnected macroporous poly (ethylene glycol) cryogels as a cell scaffold for cartilage tissue engineering. Tissue Eng Part A 16:3033–3041

Ding Y, Song C, Gong W et al (2021) Robust, sustainable, hierarchical multi-porous cellulose beads via pre-crosslinking strategy for efficient dye adsorption. Cellulose 28:7227–7241

Luo W, Bai Z, Zhu Y (2018) Fast removal of Co (ii) from aqueous solution using porous carboxymethyl chitosan beads and its adsorption mechanism. RSC Adv 8:13370–13387

Azlan K, Saime WNW, Liew LAI (2009) Chitosan and chemically modified chitosan beads for acid dyes sorption. J Environ Sci 21:296–302

Pivarčiová L, Rosskopfová O, Galamboš M et al (2016) Sorption of pertechnetate anions on chitosan. J Radioanal Nucl Chem 308:93–98

Dui J, Zhu G, Zhou S (2013) Facile and economical synthesis of large hollow ferrites and their applications in adsorption for As (V) and Cr (VI). ACS Appl Mater Interfaces 5:10081–10089

Zhang Y, Yan W, Sun Z et al (2015) Fabrication of porous zeolite/chitosan monoliths and their applications for drug release and metal ions adsorption. Carbohydr Polym 117:657–665

Song W, Xu J, Gao L et al (2021) Preparation of freeze-dried porous chitosan microspheres for the removal of hexavalent chromium. Appl Sci 11:4217

Kizilay MY, Okay O (2003) Effect of initial monomer concentration on spatial inhomogeneity in poly (acrylamide) gels. Macromolecules 36:6856–6862

Nematidil N, Sadeghi M, Nezami S, Sadeghi H (2019) Synthesis and characterization of schiff-base based chitosan-g-glutaraldehyde/NaMMTNPs-APTES for removal Pb2+ and Hg2+ ions. Carbohydr Polym 222:114971

Ostrowska-Czubenko J, Gierszewska-Drużyńska M (2009) Effect of ionic crosslinking on the water state in hydrogel chitosan membranes. Carbohydr Polym 77:590–598

Roberts GAF, Taylor KE (1989) Chitosan gels, 3. The formation of gels by reaction of chitosan with glutaraldehyde. Die Makromol Chemie Macromol Chem Phys 190:951–960

Raju L, SCL AR, Prakash NKU, Rajkumar E (2021) Chitosan-terephthaldehyde hydrogels effect of concentration of cross-linker on structural, swelling, thermal and antimicrobial properties. Materialia 16:101082

Leduc J-F, Leduc R, Cabana H (2014) Phosphate adsorption onto chitosan-based hydrogel microspheres. Adsorpt Sci Technol 32:557–569

Saïed N, Aïder M (2014) Zeta potential and turbidimetry analyzes for the evaluation of chitosan/phytic acid complex formation. J food Res 3:71

Boardman SJ, Lad R, Green DC, Thornton PD (2017) Chitosan hydrogels for targeted dye and protein adsorption. J Appl Polym Sci. https://doi.org/10.1002/app.44846

Lone S, Yoon DH, Lee H, Cheong IW (2019) Gelatin–chitosan hydrogel particles for efficient removal of Hg (II) from wastewater. Environ Sci Water Res Technol 5:83–90

Park H, Park K, Kim D (2006) Preparation and swelling behavior of chitosan-based superporous hydrogels for gastric retention application. J Biomed Mater Res Part A 76:144–150

Ullah F, Othman MBH, Javed F et al (2015) Classification, processing and application of hydrogels: a review. Mater Sci Eng C 57:414–433. https://doi.org/10.1016/j.msec.2015.07.053

Wu M, Chen W, Mao Q et al (2019) Facile synthesis of chitosan/gelatin filled with graphene bead adsorbent for orange II removal. Chem Eng Res Des 144:35–46

Domard A (1987) Determination of N-acetyl content in chitosan samples by cd measurements. Int J Biol Macromol 9:333–336

Hameed BH, El-Khaiary MI (2008) Malachite green adsorption by rattan sawdust: isotherm, kinetic and mechanism modeling. J Hazard Mater 159:574–579

Zhao R, Zheng H, Zhong Z et al (2021) Efficient removal of diclofenac from surface water by the functionalized multilayer magnetic adsorbent: kinetics and mechanism. Sci Total Environ 760:144307. https://doi.org/10.1016/j.scitotenv.2020.144307

Wong S, Ghafar NA, Ngadi N et al (2020) Effective removal of anionic textile dyes using adsorbent synthesized from coffee waste. Sci Rep 10:1–13

Khraisheh MAM, Al-Ghouti MA, Allen SJ, Ahmad MNM (2004) The effect of pH, temperature, and molecular size on the removal of dyes from textile effluent using manganese oxides-modified diatomite. Water Environ Res 76:2655–2663

Hosseinzadeh H, Ramin S (2018) Effective removal of copper from aqueous solutions by modified magnetic chitosan/graphene oxide nanocomposites. Int J Biol Macromol 113:859–868

Yang S, Zhao F, Sang Q et al (2021) Investigation of 3-aminopropyltriethoxysilane modifying attapulgite for congo red removal: mechanisms and site energy distribution. Powder Technol 383:74–83. https://doi.org/10.1016/j.powtec.2021.01.046

Kıvanç MR, Ozay O, Ozay H (2020) Ilgin P (2020) Removal of anionic dyes from aqueous media by using a novel high positively charged hydrogel with high capacity. J Dispers Sci Technol. https://doi.org/10.1080/01932691.2020.1847658

Puchana-Rosero MJ, Adebayo MA, Lima EC et al (2016) Microwave-assisted activated carbon obtained from the sludge of tannery-treatment effluent plant for removal of leather dyes. Coll Surf A Physicochem Eng Asp 504:105–115

Pan M, Lin X, Xie J, Huang X (2017) Kinetic, equilibrium and thermodynamic studies for phosphate adsorption on aluminum hydroxide modified palygorskite nano-composites. RSC Adv 7:4492–4500

Zhou C, Wu Q, Lei T, Negulescu II (2014) Adsorption kinetic and equilibrium studies for methylene blue dye by partially hydrolyzed polyacrylamide/cellulose nanocrystal nanocomposite hydrogels. Chem Eng J 251:17–24

Chiou MS, Li HY (2003) Adsorption behavior of reactive dye in aqueous solution on chemical cross-linked chitosan beads. Chemosphere 50:1095–1105

Acknowledgements

The authors express their gratitude to the College of Science, University of Babylon in Iraq for supporting this research. Z.H.A. and A.F.H. would like to express their acknowledgment to the University of Hull.

Funding

This study was supported by the University of Babylon, Environmental Research and Studies Center and College of Science, Iraq.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Athab, Z.H., Halbus, A.F., Abbas, A.S. et al. Enhanced Macroporous Cationic Chitosan Hydrogel by Freezing and Thawing Method with Superadsorption Capacity for Anionic Dyes. J Polym Environ 30, 3815–3831 (2022). https://doi.org/10.1007/s10924-022-02462-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02462-w