Abstract

Fresh basidiomes of species belonging to the genera Aurantiporus, Ganoderma, Lentinus, and Panus species were collected from a cloud forest patch located in a natural protected area. Tissue portions of the fresh basidiomes were excised and grown in axenic culture with potato dextrose medium at 27 °C obtaining six strains. Additionally, a commercial strain of Pleurotus ostreatus was included for comparison with previous works. Mycelium films were obtained and morpho-anatomic characterized considering the main features. After that, the films were dried at room temperature and pressed at 7.5 g/cm2. SEM images were taken with a scanning electron microscope, and mechanical and thermo gravimetric analyses were carried out. The tensile modulus values obtained vary between 3.5 and 128.8 MPa and the tensile strength values between 0.27 and 1.5 MPa. The density was not uniform and is not related to the mechanical performance. The Maximum decomposition temperature of the mycelium films was reached at around 300 °C. The results showed significant differences in physic-mechanical behavior of mycelium films obtained with different fungal species, some of them with promissory characteristics for biotechnological applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Among the wide variety of biotechnological applications with fungi, the use of fungal mycelium for the manufacture of materials stands out. Hyphae, cylindrical fungal cells with a wall composed of polysaccharides like chitosan and other components [1] and a cytoskeleton composed of 60–70 different proteins [2], have shown promising characteristics for the development of sustainable materials with applications in various fields, from compostable packaging options [3] to thermal and acoustic insulation [4,5,6] or even textile alternatives [7]. Materials obtained from fungal mycelium have a very important characteristic, being completely and rapidly compostable, which suggests that products developed with mycelium could help to achieve the objectives of a more circular economy [8], and alleviate the damaging effect caused by synthetic materials on the environment and particularly in the ocean’s trophic chains [9,10,11].

Since the first academic works on this subject [12, 13], several types of fungal materials manufactured with various techniques have been developed and tested, using hyphae in the formulation as a binding agent. These types include mycelial biocomposites [6, 14, 15], sandwiches [16, 17], foams [18, 19], hybrids with synthetic resins or fibers [20,21,22], and films [23]. From these types, the mycelium films are the least studied, while mycelial biocomposites have been the most investigated, even already produced on a commercial scale (for example https://ecovativedesign.com/; https://mogu.bio/; https://www.mycoworks.com/). The foams were formulated recently [19, 24], however, some details of production and the fungal species involved, remain undocumented. Sandwiches and hybrids have also been formulated incorporating resins in different substrates, obtaining variable results [16, 17, 25], some with the disadvantage of including non-compostable materials in the composition of composites [20]. Haneef et al. [23] carried out a revision and characterization of these materials using strains of Ganoderma lucidum and Pleurotus ostreatus. Currently, a company (https://www.mycoworks.com/) manufactures leather substitutes and a textile developed with mycelium, with promising results for the replacement of petroleum-based plastics or other materials. However, there is no documentation of the methods and results of these commercial products.

In the different mycelial materials mentioned, the approach to the development of production techniques arose from the point of view of engineering and design, leaving aside the importance of the biological component present. In biocomposites, sandwiches and hybrids, the dry weight of the mycelium compared to the growth substrate is notably lower. However, it is evident that the inherent characteristics of the hyphae play an important role in the final mechanical performance of the products [26]. Furthermore, products such as foams and films, which are entirely composed of mycelium, are completely dependent on the morpho-anatomic characteristics of the hyphae to perform adequately.

Some factors that influence the final properties of mycelium materials are: species and fungal strains used, pressing conditions, substrate (in the case of biocomposites, hybrids and sandwiches), growth time and drying methods [27]. Among these variables, the selection of species used to develop fungal materials in almost all the previous studies has been made considering the popularity or the availability of strains of commercially known edible, or medicinal species of fungi, such as Trametes versicolor used by Elsacker et al. [6] or T. multicolor and P. ostreatus used by Appels et al. [28]. Although this method of selection seems arbitrary, some of the strains used have shown adequate performance [29]. However, the biodiversity of Agaricomycetes is calculated at around 20,000 species [30], with many fungal species existing in nature with interesting characteristics to generate mycelium materials not yet explored.

Mycelium films are the focus of this study, which have a variety of potential uses, and are practically unexplored. Considering the aforementioned fungal properties, in this work we characterized and performed physical–mechanical tests on mycelium films obtained from different strains of wild fungal species. To generate more resistant mycelium films compared to the previous studies, the species used were selected considering: being species not studied before and with hyphal systems that produce hard and resistant carpophores.

Materials and Methods

Study Site and Basidiomes Collection

Basidiomes were collected in the “Santuario del Bosque de Niebla” (SBN), a remnant of the mountain cloud forest, which is under the protection of the Instituto de Ecología A.C. It is a peri urban natural area in Xalapa, Veracruz, Mexico, located at 1360 m above sea level, characterized by hosting high biodiversity [31], and high relative humidity that allows a great biodiverse assembly of fungal species, some of these endemic and recently described [32,33,34,35,36,37].

An opportunistic method of recollection was developed [38], i.e., randomly walking the site in search of visible sporocarps, and considering fresh and in good conditions basidiomes, without insect or pest damage. Special attention was paid to fructifications with corky or leathery appearance, avoiding soft or weak structures. The fresh specimens were covered in foil and transported to the laboratory, where descriptive taxonomic characters were annotated. Fresh portions of the basidiomes were excised for axenic culture and molecular identification. After that, the specimens were dried in a hot air dryer at 60 °C for 72 h for their preservation. The edible species of P. ostreatus complex [39] have often been used in previous works [7, 14, 28], so a strain of P. ostreatus was isolated and included in this work to compare results and performance.

Axenic Culture and Mycelium Films Production

Tissue portions of the basidiomes were incubated in 90 mm Petri dishes, at 27 °C, filled with Potato Dextrose Agar medium (PDA) following the manufacturer's instructions (Bioxon). After isolation, the strains were stored on vials, covered with mineral oil for later use and kept at room temperature at 20–23 °C [40]. Once the mycelium growth of each species covered the entire surface of the Petri dish, three circular portions of 0.5 cm diameter of the mycelium were placed in Erlenmeyer flasks, containing 100 mL of sterilized potato-dextrose broth, prepared following the manufacturer's instructions (Sigma-Aldrich). The flasks were incubated at 25 °C in dark and agitated at 120 rpm for the first 72 h to promote faster colonization [41]. Then, they remained static at the same temperature and light conditions for 18 more days. Mycelium films of six different species were obtained (Table 1).

The mycelium films were extracted from the flasks after 21 days and the remains of the medium adhering to the films were removed. Circular films of between 5 and 9 cm diameter were obtained, then dried at room temperature for 8 h and pressed with an even weight at 7.5 g/cm2 for 72 h to avoid recurved margins or wrinkles.

Molecular Identification

DNA was extracted according to César et al. [36]. PCR was performed to amplify the nuc rDNA ITS (Internal Transcribed Spacer) using primers ITS1F, ITS5/ITS4 [42, 43]. The sequences were obtained using a Genetic Analyzer 3730XL sequencer (Applied Biosystems) and deposited at GenBank database [44]. Table 1 shows the access numbers. A similarity search analysis was performed with the BLAST program. Sequences with a similitude percentage of 99% or higher were considered conspecific. The names of species indicated in Table 1 correspond to the results with the highest percentage of identity, obtained from the similarity analysis above.

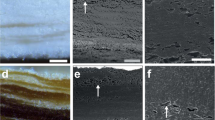

Morphological Analysis of Mycelial Films

The different types of hyphae were characterized and measured under an optical microscope (Nikon Eclipse E400), mounted in 3% potassium hydroxide (KOH), 1% Congo Red aqueous solution, and Melzer’s reagent. SEM images of mycelial films were taken from the top, bottom and the fracture site after mechanical testing (Fig. 1), under a scanning electron microscope (JEOL JSM.6360 LV) and after the samples were covered with gold using a sputter applicator for 60 s.

Density and Thickness Measurements

After drying, ten 1 cm2 replicates were cut and measured with a caliper from each film. Weights were determined with a digital scale. The thickness was measured with an optical microscope with a ruler (Nikon Eclipse E400), using a Plan ×4/0.10 objective, recording measurements in three linear sections of each film (10 measures per linear section).

Mechanical Tests

Fifteen specimens of the mycelium films of each species were obtained for the tensile strength test. The TAPPI T494 om-06 method [45] was used. The samples were conditioned 24 h before the test at 25 °C and 50% humidity. A universal testing machine (Shimadzu AGS-X Autograph) with a 100 N cell and a crosshead speed of 5 mm/min was used.

Thermo Gravimetric Analysis

Thermo gravimetric analysis was performed with a TGA-7 (Perkin Elmer, USA) using a nitrogen flow of 20 mL/min to maintain an inert atmosphere. Temperature increased from 50 to 700 °C with a rate of 10 °C/min.

Results and Discussion

Strains Obtained

One strain of each of the six fungal species selected was isolated (Table 1): Lentinus crinitus (CC16), Panus aff. conchatus (CC39), Ganoderma curtisii (CC52), P. ostreatus (CC90), Ganoderma mexicanum (CC228) and Aurantiporus sp. (CC243).

Characterization of Mycelium Films Before Pressing

Given the uniform growth conditions, the mycelium of the different isolates developed films of different thickness, the thinnest was Aurantiporus sp. with 0.33 mm, and the thickest was Panus aff. conchatus with 0.76 mm. There is no relationship between thickness and tensile strength as observed in Table 2. The density of the mycelium films ranged between 0.152 g/cm3 for Panus aff. conchatus, and 0.513 g/cm3 for Aurantiporus sp., which shows that density is also not related to the tensile strength of the samples.

Lentinus crinitus, CC16 [Fig. 1(1)]. Mycelium white and cottony at the beginning of the development, turning coriaceous and reddish-brown, with a radial development, with two different types of hyphae: thin (1–2 µm ⌀), with thick walls (< 0.3 µm), clamped, septate, bifurcate, not tortuous; second type, broad (2.5–4 µm ⌀), with thick walls (ca. 0.5 µm ⌀), diverticulate and tortuous. Chlamydospores absent.

Panus aff. conchatus, CC39 [Fig. 1(2)]. Mycelium white, cottony, with transparent exuded drops, with certain water repellency, forming concentric light brown custards, with two types of hyphae: broad (3.5–4.5 µm ⌀), with thin walls, straight and clamped; the second type thin (1–1.5 µm ⌀), with thick walls (ca. 0.2 µm), straight and more resistant to abrasion. Chlamydospores absent.

Ganoderma curtisii, CC52 [Fig. 1(3)]. Mycelium white, leathery at the beginning of the development turning yellow, with a remarkable resistance to puncture, with a somewhat radial pattern of development, with two types of hyphae: thin (1–1.5 µm ⌀), with thick walls (< 0.3 µm), not septate or clamped, curvy and abundant; the second type are broader (2–2.5 µm ⌀), with thick walls (< 0.5 µm), also without visible septa or clamp connections, hyphal pegs as terminal elements (16–21 × 13.5–16.5 µm). Chlamydospores absent.

Pleurotus ostreatus, CC90 [Fig. 1(4)]. Mycelium white and cottony, dense and irregular; hyphae without concentric or radial arrangement, 0.75–2.5 µm ⌀, clamped, septate, tortuous and some bifurcate and with slightly thicker wall. Chlamydospores absent.

Ganoderma mexicanum, CC228 [Fig. 1(5)]. Mycelium leathery, white, turning mustard yellow and light brown, with some hyphae in radial arrangement, two types of hyphae present: narrow (1–1.5 µm ⌀), with thick walls (< 0.2 µm), not tortuous and bifurcate, unclamped, not septate; the second type broad (3.5–4 µm ⌀), with thick walls (ca. 1 µm thick), tortuous, unclamped, not septate, with ellipsoid and thin-walled hyphal pegs as terminal elements (14.5–16 × 10.5–11.5 µm). Chlamydospores absent.

Aurantiporus sp. CC243 [Fig. 1(6)]. Mycelium white, translucent, velvety, soft irregular, with denser growth in some areas; hyphae (2.5–4 µm ⌀) with thin wall, tortuous, presenting occasional bulges, clamped and septate, with globose, thin-walled terminal elements (7.5–13.5 × 8–11.5 µm). Chlamydospores absent.

Mechanical Test

Figure 2 shows the stress–strain curves of the films and Table 2 the mechanical parameters. Regarding the tensile modulus, Panus aff. conchatus CC39 presented the lowest value, with 3.5 MPa, showing a weak entanglement between hyphae, in contrast to other species with higher results that reached up to 128.8 Mpa. Panus aff. conchatus also showed the lowest tensile strength of the samples with 0.27 Mpa. Meanwhile, G. mexicanum CC228 showed the highest value in tensile strength, with 1.5 Mpa. This last mechanical parameter presents a great dispersion due to the heterogeneous nature of the samples. The differences in mechanical properties are significant, demonstrating a wide variation in mechanical behavior between mycelium films obtained from the different species of fungi. In a previous work by Haneef et al. [23], the modulus values were registered between 4 and 28 MPa, being higher for P. ostreatus grown in cellulose. In the present work the modulus value shown by P. ostreatus was 44.4 MPa.

Of the strains studied here, CC228 and CC52, belonging to G. mexicanum and G. curtisii respectively, showed the best performance in the mechanical test. The CC16-Lentinus crinitus strain, even though it did not show the greatest resistance, is a species suitable for developing mycelium films, due to the aggressive and rapid growth of its mycelium. We consider that after monosporic mycelium intercrossing, it might be possible to enhance desirable traits. Our results indicate that the tensile strength achieved by G. curtisii could exceed the performance of other materials such as leather, and in this way, mycelium films could be a substitute for both disposable and long life products.

Termogravimetric Analysis (TGA)

Figure 3 shows the TGA and differential TGA (DTGA) curves of the mycelium films. It can be observed in Fig. 3a that the TGA curves present three zones of mass loss, due to thermal degradation of the components constituting the mycelium. The first zone shows a mass loss of around 9% at 100 °C, due to the evaporation of water absorbed by the mycelium. In the second zone, from 200 to 370 °C, the main degradation of the sample is observed with a mass loss of 55–70%. This zone is observed as a peak in the DTGA curves, where the maximum decomposition temperature (TDmax) is reached at 300 °C. Here, the thermal decomposition of the components of the mycelia, such as proteins, chitin and cellulose take place. At temperatures higher than 370 °C, a monotonic mass loss is observed, with a residual mass of 7–20%. At 700 °C the residual mass varies between 2 and 12%.

Conclusions

This is the first work to test mycelium films obtained directly from wild fungal species not used commercially to produce edible or medicinal carpophores. As has already been observed, the differences in the mechanical behavior of the mycelium films obtained from different species are important and are related to the morphology and structure of the mycelium.

The enormous biodiversity of fungal species, especially in tropical areas, presents interesting opportunities for applications in the development of mycelium materials and biocomposites. When developing mycelium materials to replace other non-compostable, an important characteristic of the chosen strain is the resistance it offers. To select the most suitable species for this purpose, among others, the distinctive taxonomic characteristics between the genera are important. In this context, the patterns of hyphal system [46] could serve as a starting point for selection, which considers the different morpho-anatomic types of hyphae present in the carpophores.

One of the groups of fungi in which the hyphal system has been recognized as taxonomically informative is that of the Polyporales. Hyphal systems consider characteristics of different hyphae present in carpophores. These characters are different from those present in the mycelial stage before the morphogenesis of the carpophores [47], so to choose suitable species to manufacture mycelial materials, such classification systems could not be very precise based only on wild carpophores. Except P. ostreatus, all the species evaluated here can be considered Polyporales, and show different behaviors in the mechanical test.

It is necessary that in the search for species of fungi suitable for the elaboration of mycelial materials, the specimens under study be accurately reported and identified at the species level. This would offer a clearer idea of the performance of specific taxa. To exemplify this, let´s consider the popular use of Ganoderma spp. strains, indiscriminately mentioned in previous research on mycelium materials under the name Ganoderma sp. or under the popular Chinese name “reishi”. The species complex under that name encompasses more than 13 different species [48, 49], with different morpho-anatomical characters and probably different physico-mechanical behaviors to form mycelium materials. In fact, two different closely related species of Ganoderma, tested in the present work, showed different behaviors. It is important also, to continue studying the chemical composition and antibacterial properties of the mycelium of different species to evaluate its usefulness in some medical applications.

With the exception of P. ostreatus, the fungi used in this work are Neotropical species that have never before been tested in their application for the manufacture of mycelium films. More research is needed on the performance of different groups of fungi, with the aim of developing sustainable materials to reduce pollution problems occasioned by non-compostable synthetic materials.

Data Availability

The sequences generated in this study are available in the NCBI GenBank (https://www.ncbi.nlm.nih.gov/genbank/) under the accession numbers explained in the text.

References

Gooday GW (1995) Cell walls. In: Gow N, Gadd GM (eds) The growing fungus. Chapman and Hall, London

Heath IB (1995) The cytoskeleton. In: Gow N, Gadd GM (eds) The growing fungus. Chapman and Hall, London

Holt GA, Mcintyre G, Flagg D, Bayer E, Wanjura JD, Pelletier MG (2012) Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: 1260352Evaluation study of select blends of cotton byproducts. J Biobased Mater Biol 6:431–439. https://doi.org/10.1166/jbmb.2012.1241

Pelletier MG, Holt GA, Wanjura JD, Bayer E, McIntyre G (2013) An evaluation study of mycelium based acoustic absorbers grown on agricultural by-product substrates. Ind Crops Prod 51:480–485. https://doi.org/10.1016/j.indcrop.2013.09.008

Xing Y, Brewer M, El-Gharabawy H, Griffith G, Jones P (2018) Growing and testing mycelium bricks as building insulation materials. IOP Conf Ser: Earth Environ Sci 121:022032. https://doi.org/10.1088/1755-1315/121/2/022032

Elsacker E, Vandelook S, Brancart J, Peeters E, De Laet L (2019) Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 14:e0213954. https://doi.org/10.1371/journal.pone.0213954

Silverman J, Cao H, Cobb K (2020) Development of mushroom mycelium composites for footwear products. Cloth Text Res J 38:119–133. https://doi.org/10.1177/0887302X19890006

Vink K (2020) Sustainable life cycle design aspects: how aware are material scientists? SN Appl Sci 2:1364. https://doi.org/10.1007/s42452-020-3151-z

Rochman C, Hoh E, Kurobe T, Teh S (2013) Ingested plastic transfers hazardous chemicals to fish and induces hepatic stress. Sci Rep 3:3263. https://doi.org/10.1038/srep03263

Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, Narayan R, Law KL (2015) Plastic waste inputs from land into the ocean. Science 347:768–771. https://doi.org/10.1126/science

Boucher J, Friot D (2017) Primary microplastics in the oceans: a global evaluation of sources. IUCN. https://doi.org/10.2305/iucn.ch.2017.01.en

Revin V, Kadimaliev DA, Shutova VV, Samuilov VD (2002) Modification of wood lignin by the fungus Panus tigrinus. Prikl Biokhim Mikrobiol 38:529–533. https://doi.org/10.1023/A:1019920502658

Kadimaliev D, Revin V, Shutova VV, Samuilov V (2004) Use of Panus tigrinus fungi for production of pressed materials from cotton plant waste. Prikl Biokhim Mikrobiol 40:57–61. https://doi.org/10.1023/B:ABIM.0000010351.03034.0a

López Nava JA, Méndez González J, Ruelas Chacón X, Nájera Luna JA (2015) Assessment of edible fungi and films bio-based material simulating expanded polystyrene. Mater Manuf Process 31:1085–1090. https://doi.org/10.1080/10426914.2015.1070420

Ziegler AR, Bajwa SG, Holt GA, McIntyre G, Bajwa DS (2016) Evaluation of physico-mechanical properties of mycelium reinforced green biocomposites made from cellulosic fibers. Appl Eng Agric 32:931–938. https://doi.org/10.13031/aea.32.11830

Jiang L, Walczyk D, McIntyre G, Bucinell R (2016) A new approach to manufacturing biocomposite sandwich structures: mycelium-based cores. In: Proceedings of the ASME 2016. International Manufacturing Science and Engineering Conference. Blacksburg, Virginia, June 27–July 1, 2016. https://doi.org/10.1115/msec2016-8864

Jiang L, Walczyk D, McIntyre G, Bucinell R, Tudryn G (2017) Manufacturing of biocomposite sandwich structures using mycelium-bound cores and preforms. J Manuf Process 28:50–59. https://doi.org/10.1016/j.jmapro.2017.04.029

Islam MR, Tudryn G, Bucinell R, Schadler L, Picu RC (2017) Morphology and mechanics of fungal mycelium. Sci Rep 7:13070. https://doi.org/10.1038/s41598-017-13295-2

Pelletier MG, Holt GA, Wanjura JD, Greetham L, McIntyre G, Bayer E, Kaplan-Bie J (2019) Acoustic evaluation of mycological biopolymer, an all-natural closed cell foam alternative. Ind Crops Prod 139:111533. https://doi.org/10.1016/j.indcrop.2019.111533

He J, Cheng CM, Su DG, Zhong MF (2014) Study on the mechanical properties of the latex-mycelium composite. Appl Mech Mater 507:415–420

Jones M, Bhat T, Kandare E, Thomas A, Joseph P, Dekiwadia C, Yuen R, John S, Ma J, Wang CH (2018) Thermal degradation and fire properties of fungal mycelium and mycelium—biomass composite materials. Sci Rep 8:17583. https://doi.org/10.1038/s41598-018-36032-9

Sun W, Tajvidi M, Hunt CG, McIntyre G, Gardner DJ (2019) Fully bio-based hybrid composites made of wood, fungal mycelium and cellulose nanofibrils. Sci Rep 9:3766. https://doi.org/10.1038/s41598-019-40442-8

Haneef M, Ceseracciu L, Canale C, Bayer IS, Heredia-Guerrero JA, Athanassiou A (2017) Advanced materials from fungal mycelium: fabrication and tuning of physical properties. Sci Rep 7:41292. https://doi.org/10.1038/srep41292

Bayer E, McIntyre G (2015) Substrate composition and method for growing mycological materials, United States Patent 0315687

Jiang L, Walczyk D, McIntyre G, Bucinell R, Li B (2019) Bioresin infused then cured mycelium-based sandwich-structure biocomposites: resin transfer molding (RTM) process, flexural properties, and simulation. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.09.2

Jones M, Huynh T, John S (2018) Inherent species characteristic influence and growth performance assessment for mycelium composite applications. Adv Mater Lett 9:71–80. https://doi.org/10.5185/amlett.2018.1977

Manan S, Ullah MW, Ul-Islam M, Atta OM, Yang G (2021) Synthesis and applications of fungal mycelium-based advanced functional materials. J Bioresour Bioprod 6:1–10. https://doi.org/10.1016/j.jobab.2021.01.001

Appels F, Camere S, Montalti M, Karana E, Jansen K, Dijksterhuis J, Krijgsheld P, Wösten H (2019) Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater Des 161:64–71. https://doi.org/10.1016/j.matdes.2018.11.027

Jones M, Mautner A, Luenco S, Bismarck A, John S (2020) Engineered mycelium composite construction materials from fungal biorefineries: a critical review. Mater Des 187:108397. https://doi.org/10.1016/j.matdes.2019.108397

Kirk P, Cannon P, Minter D, Stalpers J (2008) Ainsworth and bisbys dictionary of the fungi. CABI, Wallingford

Samain MS, Castillo-Campos G (2020) Biodiversidad del Santuario del Bosque de Niebla, Xalapa, Veracruz. Instituto de Ecología, A.C., Xalapa Mexico, pp. 321

Bandala VM, Montoya L, Horak E (2006) Crepidotus rubrovinosus sp. nov. and Crepidotus septicoides, found in the cloud forest of eastern Mexico, with notes on Crepidotus fusisporus var. longicystis. Mycologia 98:131–140. https://doi.org/10.1080/15572536.2006.11832719

Bandala VM, Montoya L, Mata M (2008) New species and records of Crepidotus from CostaRica and Mexico. Fungal Divers 32:9–29

Bandala VM, Ryoo R, Montoya L, Ka KH (2012) New species and new records of Crinipellis from tropical and subtropical forests of the east coast of Mexico. Mycologia 104:733–745. https://doi.org/10.3852/11-223

Bandala VM, Montoya L, Ramos A (2016) Two new Lactarius species in a subtropical cloud forest in eastern Mexico. Mycologia 108:967–980. https://doi.org/10.3852/15-310

César E, Bandala VM, Montoya L, Ramos A (2018) A new Gymnopus species with rhizomorphs and its record as nesting material by birds (Tyrannideae) in the subtropical cloud forest from eastern Mexico. MycoKeys 42:21–34. https://doi.org/10.3897/mycokeys.42.28894

César E, Montoya L, Bandala VM, Ramos A (2020) Three new marasmioid-gymnopoid rhizomorph-forming species from Mexican mountain cloud forest relicts. Mycol Prog 19:1017–1029. https://doi.org/10.1007/s11557-020-01608-1

Lodge JD, Ammirati JF, O’Dell TE, Mueller GM (2004) Collecting and describing macrofungi. In: Muller GM, Bills GF, Foster MS (eds) Biodiversity of fungi. Inventory and monitoring methods. Elsevier Academic Press, San Diego

Li J, Han L-H, Liu X-B, Zhao Z-W, Yang ZL (2020) The saprotrophic Pleurotus ostreatus species complex: late Eocene origin in East Asia, multiple dispersal, and complex speciation. IMA Fungus 11:10. https://doi.org/10.1186/s43008-020-00031-1

Smith D, Kolkowski J (1996) Fungi. In: Hunter JC, Belt A (eds) Maintaining cultures for biotechnology and industry. Academic Press, San Diego

Elisashvili V (2012) Submerged cultivation of medicinal mushrooms: bioprocesses and products (review). Int J Med Mushrooms 14:211–239. https://doi.org/10.1615/IntJMedMushr.v14.i3.10

White TJ, Bruns TD, Lee SB, Taylor JW (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In: Innis MA, Gelfand DH, Sninsky JJ, White TJ (eds) PCR protocols: a guide to methods and applications. Academic Press, San Diego. https://doi.org/10.1016/B978-0-12-372180-8.50042-1

Gardes M, Bruns D (1993) ITS primers with enhanced specificity for basidiomycetes application to the identification of mycorrhizae and rusts. Mol Ecol 2:113–118. https://doi.org/10.1111/j.1365-294X.1993.tb00005.x

Benson DA, Cavanaugh M, Clark K, Karsch-Mizrachi I, Lipman DJ, Ostell J, Sayers EW (2017) GenBank. Nucleic Acids Res 45:D37–D42. https://doi.org/10.1093/nar/gkw1070

TAPPI (2006) Test method T494 om-06. Tensile properties if paper and paper board (using constant rate of elongation apparatus).

Pegler DN (1996) Hyphal analysis of basidiomata. Mycol Res 100:129–142. https://doi.org/10.1016/S0953-7562(96)80111-0

Moore D (1998) Fungal morphogenesis. Cambridge University Press, Cambridge

Zhou L-W, Cao Y, Wu S-H, Vlasák J, Li D-W, Li M-J, Dai Y-C (2015) Global diversity of the Ganoderma lucidum complex (Ganodermataceae, Polyporales) inferred from morphology and multilocus phylogeny. Phytochemistry 114:7–15. https://doi.org/10.1016/j.phytochem.2014.09.023

Loyd AL, Barnes CW, Held BW, Schink MJ, Smith ME, Smith JA et al (2018) Elucidating “lucidum”: distinguishing the diverse laccate Ganoderma species of the United States. PLoS ONE 13:e0199738. https://doi.org/10.1371/journal.pone.0199738

Acknowledgements

This research was supported in part by CONACYT (FORDECYT-PRONACES/CF 263959). Assistance in the field and laboratory was provided by D. Ramos, and B. Perez assisted us with some molecular procedures, both at Instituto de Ecología, A.C.

Funding

This study was funded by CONACYT (FORDECYT-PRONACES/CF 263959).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by EC, GC-E and SD-A. Molecular data was obtained by AR. Review and editing were performed by LM and VB. The first draft of the manuscript was written by EC and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest concerning the research, authorship, and publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

César, E., Canche-Escamilla, G., Montoya, L. et al. Characterization and Physical Properties of Mycelium Films Obtained from Wild Fungi: Natural Materials for Potential Biotechnological Applications. J Polym Environ 29, 4098–4105 (2021). https://doi.org/10.1007/s10924-021-02178-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02178-3