Abstract

In the present study, the edible and biodegradable Zein microfiber is prepared using the glacial acetic acid solvent and electrospinning approach. It is possible to produce uniform nanofibers without bead by changing several parameters such as the concentrations of Zein and drug, gap between the needle tip and collector, electrospinning voltage and solution’s flow rate. Here, the solution of Zein and black seed (Nigella sativa) oil has been produced and electrospun at three different oil concentrations of 5, 10 and 15% w/v. The electrospinning voltage, gap between the needle tip and collector and flow rate were kept fixed for these three concentration levels as 20 kV, 15 cm and 4 mL/h, respectively. According to the obtained results, the concentration variation of the black seed oil has a significant effect (P ≤ 0.05) on the fiber diameter in such a way that fiber diameter increases with an increment in the oil concentration. Further aim of the present study is to prepare as well as evaluate the membrane properties of Zein nanofibers containing black seed oil using the electrospinning method for modern drug delivery uses.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today, the creation of new and effective drug delivery methods is considered as one of the most popular and commonly used researches in the medical field. One of the effective drug delivery techniques is the drug loading in nanofibers. The polymeric nanofibers are composed of very fine polymeric fibers having a diameter ranging from a few micrometers to a few nanometers. Such a very small diameter leads to a relatively high surface to volume ratio. Such an increment in the surface, significantly affects the physicochemical and morphological properties of the nanofibers, creation of very fine pores, wound healing acceleration, water vapor and gas permeability and bacterial invasion preventing. Various techniques are available for creating the nanofibers from which electrospinning is the most commonly used one. Compared to the other spinning techniques, electrospinning is a simple and cost effective method for producing nanofibers with diameter within the range of nanometer. The electrospinning process includes a high voltage power supply, a pump for adjusting the injection rate of the polymer solution, a syringe attached to an injection needle through which the polymer passes and a collector (drum). The needle tip is attached to one electrode of the power supply while the collector is linked to the other electrode. The basic principle in the electrospinning technique is the process of providing high voltages for the polymeric droplets formed at the needle tip. The polymeric molecules in the droplet formed by the same voltage, are electrically charged. Therefore, the electrospinning repulsion occurs which leads to the Taylor cone formation in the polymeric droplet. Eventually, polymer moves from the needle tip towards the loaded collector on the opposite side during which the solvent is evaporated and very thin polymeric fibers are deposited on the collector surface [1, 2].

From the most important properties of the electrospinning process, one can point out to the possibility of using a wide variety of polymers. Nowadays, biodegradable polymers are extensively used in the human body as drug carriers [3, 4]. Very low complications for the human body, non-toxicity and being economical are considered as the benefits of these polymers [3, 5, 6]. The two main categories of polymers used for the medical applications are the natural and synthetic biocompatible polymers. Zein is a type of prolamin or the main stored protein in the corn, which accounts for about 45 to 50% of the corn protein content and was first introduced in 1897 due to its solubility properties in aqueous alcoholic solutions.

The existence of non-polar amino acids like leucine, proline and alanine has led to the hydrophobicity property of Zein. Zein has been also used in the drug industry for covering capsules, creating protection, controlled releasing and hiding flavors and odors [7]. Furthermore, Zein can be easily converted into various forms and structures such as films, microspheres, nanoparticle, micelle, gel and fiber. Some of the Zein’s properties, such as the mechanical strength of films composed of it, can be modified by using other natural polymers without damaging the integrity of this tool during the production process. Zein has been used in the form of micro and nanoparticles to control the release of essences, colors, antimicrobials, anticancer drugs, targeting macrophages, oral drug delivery with protection against gastrointestinal conditions and gene transfer [8, 9]. Thus, a Zein coating can be used as an effective insulation against oxygen, lipid and moisture [9]. The electrospinning method is an approach being used for treating several diseases such as wounds healing and cancers, loading some natural and synthetic drugs in a variety of polymers and fiber creating. One of the most commonly used natural drugs used in this method is the use of herbal extracts. Black seed, is a one-year-old plant from Ranonculaceae family, native to the Mediterranean areas with height of 20–30 cm and white, yellow, pink, light blue or red flowers. This plant has been used in the traditional medicine of the Middle East, North Africa, Far East and Asia for 2000 years in the treatment of various diseases. Due to the high antioxidant content, considerable attention is being paid to the black seed in the traditional medicine, medical profession and food industry [10, 11]. Till now, many properties have been reported for black seed such as anti-inflammatory, anti-oxidant, anti-tumor, anti-diabetic, antimicrobial, antifungal and so on [11,12,13]. The seeds of this plant contain non-volatile oil, essence oil, alkaloids and saponin. Further to these, its seeds contain nutrient contents including proteins, mineral elements, vitamins and carbohydrates [10]. The extract of black seed has been widely used in various investigations due to having effective ingredients such as thymoquinone, thymol and carvacrol [10, 14,15,16,17,18,19].

The present research aims to produce the protein Zein microfiber and black seed oil from the acetic acid solution. Further goals of this study is the preparation and evaluation of the properties of Zein nanofiber membrane containing black seed oil via the electrospinning method for utilization in the modern drug delivery, etc.

Ingredients

Corn Zein

The corn Zein (grade Z3625) (Fig. 1) was purchased from Sigma-Aldrich company (Madrid, Spain) and used without further purification upon the delivery. Also, black seed oil was purchased from Barij Essence company and glacial acetic acid prepared from molecula company (UK) with a purity of 99.7%.

Preparation of the Electrospinning Solution

The electrospinning solution was prepared by adding black seed oil with three different concentrations of 5, 10 and 15% w/v to the Zein solution (24.5% w/v). To prepare the Zein solution, the required amount of Zein powder was weighed, dissolved in glacial acetic acid and prepared using a vortex machine (manufactured by Bocco, Germany) in order to completely resolve the protein and oil. The resulting solution was kept at room temperature for 24 h in order to remove the air bubbles, form intermolecular bonds in Zein and obtain a uniform solution.

Viscosity Measurement

To measure the viscosity of the polymeric solutions, the rotational viscometer of Brookfield RV DVIII UItra model (manufactured by Brookfield, USA) was implemented. The measurements were accomplished at room temperature (25 °C) using a SC4-31 spindle within the cutting speed range 1–80 S−1.

The Electrospinning Process

In order to create the Zein fibers containing black seed oil, a unidirectional electrospinning setup was utilized which has been equipped with a high voltage power supply within the range of 0–35 kV of ES1000 model fabricated by Fanavaran Nano-Meghyas (Tehran, Iran). The stainless steel needle tip with a diameter of 0.9 mm (18 G) was used for the nanofiber creation. The polymeric solutions were inserted into 10 mm syringes and moved to the needle tip through a narrow tube. The syringe was placed in a horizontal position on a digitally controlled pump. The needle was placed vertically in front of the collector drum. The needle tip was connected to the positive charge electrode and high voltage power supply. After the nanofiber creation, a jet of polymeric solution with positive charge was formed and electrospun on a collector covered by aluminum foil at room temperature for 210 min.

Preparation of the Microfiber Layer

The solution used for electrospinning was obtained from dissolving Zein powder and black seed oil in glacial acetic acid solution. The prepared solutions for the electrospinning were adjusted at various values of the flow rate, electrospinning voltage and distances between the needle tip and collector. These solutions were prepared and electrospun for three different concentrations of black seed oil as 5, 10 and 15% w/v. For all three concentrations, the electrospinning voltage, gap between the needle tip and collector and flow rate were kept fixed as 20 kV, 15 cm and 4 mm/h, respectively. The electrospun microfibers were dried for one night at 38 °C in order to be observed with a scanning electron microscope (SEM) for further investigation.

SEM

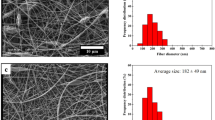

The electrospun fibers morphology was investigated using a Hitachi S-4100 SEM after the gold atomic bombardment in vacuum. All SEM examinations were performed at a voltage of 0.8 kV. The electrospun fibers’ diameter was determined using Image J software on SEM micrographs in their actual magnification by measuring 50 sections of each image.

Elasticity and Tensile Strength Tests

Fibers with dimension of 1 × 4 cm and specified thickness were placed between the two clips of Hounsfield H50SK device using a cardboard mold and tensile test was performed at a specific speed. After recording the corresponding chart, Young’s modulus and yield point were investigated as well. This test was carried out for four samples of Zein, Zein/black seed oil of 5, 10 and 15%.

Water Absorption Investigation

In order to determine the water absorption amount by the membrane, the samples which had been dried until reaching the constant weight were placed inside the phosphate buffer environment with pH of 7.4 at 37 °C for 24 h. The weight of the specimens was measured at different time intervals up to 24 h.

FTIR Analysis

In order to identify the functional groups and also determine the type of reaction and established bonds between Zein and available thymoquinone in the black seed oil of the electrospun fibers, the FTIR analysis was carried out. All experiments were carried out using the Thermo Nicolet spectrometer of AVATAR 370 FTIR model within the length range of 400–4000 cm−1 and resolution of 4 cm−1. The test was accomplished for five samples including the black seed oil, membrane of the loaded nanofiber with essence (5, 10 and 15%) and Zein’s membrane.

Drug Releasing Investigation

The released thymoquinone from the nanofiber membrane was measured at wavelength of 257 nm using the UV spectrophotometer device. A certain amount (with the dimension of 4 × 4 cm and specified weight) was placed in 5 ml of buffer phosphate and tween 80 solution inside the test tube with pH of 7.4 at 37 °C in the shaking incubator with 80 rpm velocity. At the intervals of one minute, then an hour and a few hours and finally intervals of one day, the releasing environment was evacuated and the new one added to the test tube. Then, the prepared specimens by the UV spectrophotometer were measured. The amount of released drug was calculated using the area under the curve and the chart via the standard drug solutions.

Results and Discussion

Fibers Morphology: The Effect of Solution Concentration

The viscosity values of the three solutions were measured: Zein and Zein/black seed oil mixtures of 5, 10 and 15%. As would be observed from Fig. 2, the viscosity of the sample containing black seed oil of 5% meets the maximum value while that of Zein mixture only has the minimum one. Given that the fibers obtained via the electrospinning of all four solutions (Zein only and Zein/black seed oil mixtures of 5, 10 and 15%) are uniform with no bead, it can be concluded that the viscosity of all four samples is within the appropriate range for the production of bead lacking fibers. According to Figs. 3, 4, 5, 6, it can be achieved that for all four above mentioned solutions, the polymeric solution’s viscosity decreases with an increment in the shear stress. This behavior shows the pseudo-plastic property of the solutions. By adding the black seed oil to the Zein solution, its rheological behavior changes from Newtonian to pseudo-plastic. The pseudo-plastic behavior (degree of pseudo-plasticity) increases as the oil concentration increases in the Zein solution. The statistical studies indicate that the viscosity has significant changes at different concentrations (P < 0.05). The average viscosity for the oil concentration of 5% is more than that associated with other concentrations to the amount of 0.77 ± 0.04.

The statistical studies indicated in Table 1, illustrate that the viscosity decreases as the concentration of black seed oil increases.

Electrical Conductivity

The electrical conductivity of the Zein 24.5% solutions and those containing black seed oil 5, 10 and 15%, were measured using a conductometer device. According to the results illustrated by Fig. 7, the maximum electrical conductivity is dedicated to the solution containing black seed oil 5% and the minimum electrical conductivity is dedicated to the solution containing black seed oil 15%. As indicated by Table 2, the electrical conductivity of the Zein/black seed oil 5% mixture is higher than solutions with other oil concentrations. According to the results with increasing of black seed oil extract, the electrical conductivity is reduced. Increasing the electrical conductivity of the solution will increase the charge of the polymer fount, its tension and expansion. The solution tension during the fibers formation leads to a decrease in the fibers diameter and this fact is in agreement with the present achievements.

The Electrospun Fibers Morphology: The Influence of Process Parameters

Among the black seed oil loaded fibers, those loaded with the oil concentration of 15% meet the highest diameter. The loaded fibers diameter was compared using the Tukey test and the results indicated significant differences between the fibers loaded with black seed oil 5 and 15% and also 10 and 15% (P < 0.05). Performing the Kolmogorov–Smirnov statistical test, it was found that the distribution of fiber diameters for all three types of fiber loaded with different concentrations of black seed is normal (Fig. 8).

The effect of the process parameters such as black seed oil concentration on the fibers diameter, is depicted in Figs. 9, 10, 11. Figure 12 depicts the similar plot for Zein with no black seed oil. As would be observed, the fibers diameter increases with an increment in the black seed oil concentration. In a similar research conducted by Torres-Giner et al., it was concluded that the process parameters have no significant effect of the Zein fibers morphology [20]. However, the diameter increases with an increment in the voltage and solution flow rate and it decreases as the gap between the needle tip and collector increases. In this study, by fixing the process parameters and changing the black seed oil concentration, it was observed that increasing the drug amount increases the fibers diameter. But according to the observed differences between the fibers loaded with black seed oil 5 and 15% the fiber loaded with black seed oil 10% fiber diameters it must between the fibers loaded with black seed oil 5 and 15% (more than 5% and less than 15%) but it seems due to power fluctuations and device error increasing trend between the fiber loaded with black seed oil 5 and 15% it not seen.

Tensile Test

According to the results illustrated in Fig. 13, from the strength evaluation of the Zein nanofibers without drug and after loading with drug, it is observed that the highest tensile strength is dedicated to the membrane of the black seed oil 5%. Besides, the tensile strength decreases with the increasing black seed oil concentration.

Water Absorption Test

As illustrated by Fig. 14, the fibers of Zein and Zein/black seed oil 5, 10 and 15%, lose weight over time after an increase. It can be concluded that this is not related to the dissolution and removal of the effective substance from the membrane, but it is likely due to the high contact area of Zein with the buffer medium which causes some of it to be dissolved in water and yields weight loss during the experiment. Also, the size of the fiber membrane decreases at the end of the experiment.

Fourier-Transform Infrared Spectroscopy (FTIR)

The FTIR spectroscopy was carried out in order to identify the functional groups and determine the type of reaction and bonds established between Zein and black seed oil in the electrospun nanofibers. According to Figs. 15, 16, 17, 18, 19 and comparing the FTIR spectrums corresponding to the different concentrations of black seed oil on the Zein’s polymeric bed, it can be concluded that the peak intensity and width in the absorption region of ʋ = 2500–3500 cm−1 related to the tensile vibrations of the acid hydroxyl groups of black seed oil and amine of the Zein’s polymeric bed increases with an increment in the black seed oil concentration of the compound. In addition, this absorption band shifts from ʋ = 3283 cm−1 to ʋ = 3278 cm−1 as concentration changes from 5 to 15%, respectively and this shift towards lower wave number can be the result of the hydrogen bonding formation between the black seed oil structures and Zein’s polymeric bed in the mixture. Furthermore, as can be seen, the absorption band intensity in the region of ʋ = 1742 cm−1 associated with the tensile vibrations of acid carbonyl groups in the black seed oil structure increases with an increment in the oil concentration which further verifies the concentration increase and presence of black seed oil in the mixture.

Drug Release

Based on the obtained results, the release of Zein/black seed oil 15% fiber is higher than the others and can be observed for fibers with three different concentrations of the black seed oil (Fig. 20).

References

Abrigo M, Kingshott SL (2014) Electrospun nanofibers as dressings for chronic wound care: advances, challenges, and future prospects. Macromol Biosci 14(6):772–792

Bhardwaj N, Kundu SC (2010) Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv 28(3):325–347

Karp JM, Langer R (2007) Development and therapeutic applications of advanced biomaterials. Curr Opin Biotechnol 18(5):454–459

Ranganath SH, Wang CH (2008) Biodegradable microfiber implants delivering paclitaxel for post-surgical chemotherapy against malignant glioma. Biomaterials 29(20):2996–3003

Gunasekaran S, Ko S, Xiao L (2007) Use of whey proteins for encapsulation and controlled delivery applications. J Food Eng 83(1):31–40

Uchegbu FI, Schätzlein GA (2006) Polymer in drug delivery. CRC Press, Taylor & Francis Group, Boca Raton

Shukla R, Cheryan M (2001) Zein: the industrial protein from corn. Ind Crops Prod 13:171–192

Paliwal R, Palakurthi S (2014) Zein in controlled drug delivery and tissue engineering. J Contr Release 189:108–122

Singh N, Singh S, Kaur A, Bakshi MS (2012) Zein: structure, production, film properties and applications. Nat Polym 1:118–204

Ali BH, Blunden G (2003) Pharmacological and toxicological properties of Nigella sativa. Phytother Res 17(4):305–299

Al-Johar DNA (2005) Effect of Nigella sativa and its antioxidant constituents on colon cancer in rats. King Saud University, Riyadh

Salem ML (2005) Immunomodulatory and therapeutic properties of the Nigella sativa L. seed. Int Immunopharmacol 5(13):1770–1749

Salomi NJ, Nair SC, Jayawardhanan KK, Varghese CD, Panikkar KR (1992) Antitumour principles from Nigella sativa seeds. Cancer Lett 63(1):46–41

Amooaghaie R, Saeri MR, Azizi M (2015) Synthesis, characterization and biocompatibility of silver nanoparticles synthesized from Nigella sativa leaf extract in comparison with chemical silver nanoparticles. Ecotoxicol Environ Saf 408–400:120

Fragoon A, Li J, Zhu J, Zhao J (2012) Biosynthesis of controllable size and shape gold nanoparticles by black seed (Nigella sativa) extract. J Nanosci Nanotechnol 12(3):2345–2337

Katti K, Chanda N, Shukla R, Zambre A, Suibramanian T, Kulkarni RR et al (2009) Green nanotechnology from cumin phytochemicals: generation of biocompatible gold nanoparticles. Int J Green Nanotechnol 1(1):39–52

Kumar PM, Vinmathi V, Gautam P, Wilson AH, Jacob SJP (2015) Green synthesis of silver nanorods using aqueous seed extract of Nigella sativa and study of its antidiabetic activity. Aust J Basic Appl Sci 9(10):295–298

Manju S, Malaikozhundan B, Chen J-C, Vaseeharan B (2014) Essential oil of Nigella sativa based synthesis of silver nanoparticles and its effect on pathogenic vibrio harveyi and vibrio parahaemolyticus isolated from aquatic environments. J Fish Soc Taiwan 41(2):134–123

Ranjan P, Das MerinaPaul, Kumar MS, Anbarasi P, Sindhu S, Sagadevan E, Arumugam P (2013) Green synthesis and characterization of silver nanoparticles from Nigella sativa and its application against UTI causing bacteria. J Acad Ind Res (JAIR) 2(1):45

Torres-Giner S, Gimenez E, Lagaron JM (2008) Characterization of the morphology and thermal properties of ZeinProlamine nanostructures obtained by electrospinning. Food Hydrocoll 22:601–614

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Teilaghi, S., Movaffagh, J. & Bayat, Z. Preparation as Well as Evaluation of the Nanofiber Membrane Loaded with Nigella sativa Extract Using the Electrospinning Method. J Polym Environ 28, 1614–1625 (2020). https://doi.org/10.1007/s10924-020-01700-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01700-3