Abstract

The indiscriminate disposal and the accumulation of non-biodegradable packaging have been causing serious environmental problems. One of the alternatives is the use of biodegradable films. Proteins are among the natural biopolymers most used to produce biofilms. This study aimed to produce and characterize biofilms obtained from hybrid sorubim (Pseudoplatystoma reticulatum × Pseudoplatystoma corruscans) protein isolate (HSPI) incorporated with glycerol (G) and clove essential oil (CEO). The HSPI was obtained by the pH shift method, using as raw material the mechanically separated meat of hybrid sorubim. The films presented different properties depending on the concentrations of the studied variables. In general, the film with the best characteristics was the treatment 6 (25% G, 2.5 g HSPI and 0.5 g CEO). Due to the low concentration of CEO used, the films were not able to efficiently inhibit microbial activity.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodegradable plastic films are obtained from biological materials that can make significant contributions to material recovery, reduction of landfill and utilization of renewable resources, replacing conventional polyethylene mulching films [1]. Among the natural biopolymers most used in film making are polysaccharides and proteins, which have some advantages because they are prevenient from renewable sources and capable of forming a continuous and cohesive matrix [2].

Fish proteins, including myofibrillar and sarcoplasmic proteins, have been used as film-forming material [3,4,5,6]. The properties of the film matrix depend on the material type, as well as the composition and processing methods and conditions, proteins have been widely explored for the elaboration of antimicrobial films [6]. Films based on fish proteins form networks, presenting good mechanical properties, such as plasticity and elasticity, and good oxygen barrier, but they absorb a lot of water due to the hygroscopicity of the amino acids of the protein molecules. This characteristic can be modified by the addition of plasticizers and/or additives [4, 7].

The increase in the number of foodborne diseases from pathogenic microorganisms led to the intensification of research related to the development of antimicrobial activity packaging. Antimicrobial films are a form of active packaging that can increase product shelf life and provide consumer safety. This type of packaging is intended to reduce, inhibit or delay the multiplication of pathogenic and deteriorating microorganisms in foods [8].

Thus, the aim of this study was to produce films from hybrid sorubim (Pseudoplatystoma reticulatum × Pseudoplatystoma corruscans) proteins incorporated with glycerol and clove essential oil for packaging applications.

Material and Methods

Obtaining Raw Materials

Hybrid sorubim (Pseudoplatystoma reticulatum × Pseudoplatystoma corruscans) byproducts from a fish processing plant in the region of Grande Dourados, MS, Brazil were put into a cooling box and taken to the laboratory. The mechanically separated meat (MSM) was obtained by using a mechanical meat bone-separator (HT 250, High Tech, Brazil), operating at inlet 6 °C and outlet 10 °C [9].

The hybrid sorubim protein isolate was obtained through a pH shift process. The obtained MSM of hybrid sorubim was homogenized with distilled water in a ratio of 1:9 (w/v) at 5 °C for 5 min., using a propeller stirrer (Fisatom 713D, São Paulo, Brazil). After homogenization, the protein was subjected to alkaline solubilization in an ultra-thermostatic water bath (QUIMIS model 214 D2, São Paulo, Brazil) for 20 min., under constant stirring with a propeller stirrer (Fisatom 713D, São Paulo, Brazil), using sodium hydroxide (NaOH 1N) as the alkalizing agent, at a solubilization pH of 11, and constant controlled temperature of 5 °C. After this step, the material was centrifuged at 9000×g for 20 min. (Nova Técnica, model MA 1815 centrifuge) to separate the solubilized product into three phases: lipids, soluble proteins and insoluble proteins, thus facilitating the removal of the supernatant. The intermediate phase resulting from centrifugation, corresponding to the soluble proteins, was separated and subjected to isoelectric precipitation, using hydrochloric acid (HCl 1N). The pH was adjusted to 5.8 at 5 °C under constant stirring (Fisatom 713D stirrer) for 20 min. Another centrifugation was carried out at 9000×g for 20 min. to separate the precipitated fraction, thus facilitating the collection of the precipitate and obtaining the protein isolate. The fish protein isolate was dried in an air circulating oven (MA model 035) at 45 °C for 16 h and then crushed in a double-bladed grinder and then stored in a sealed glass container at room temperature [10].

The glycerol (p.a.) was purchased from Merck KGaA (Darmstadt, Germany) and the clove (Eugenia caryophyllata) essential oil was purchased from Piping Rock (Ronkonkoma, NY, USA).

Obtaining Films

The films were produced by the casting technique, which consists in the scattering of the film-forming solution in a mould, according to the method proposed elsewhere [11] with adaptations [12].

Hybrid sorubim protein isolate was dispersed in distilled water and then heated at 70 °C under constant stirring (350 rpm) for 15 min. Then the plasticiser was added under stirring. After 5 min., the clove essential oil was added maintaining the stirring constant for further 15 min. Three levels (− 1, 0, + 1) of concentrations were evaluated for hybrid sorubim protein isolate (HSPI), glycerol plasticizer (G) and clove essential oil (CEO) (Table 1). For the formation of the film, 45 g of the film-forming solution was poured in the Petri dishes and subjected to drying in a forced-air circulation oven for 24 h. The films utilized for the characterization had their thickness standardized to 0.180 mm ± 0.001 mm.

Characterization of the Films

Opacity

The opacity was determined using a CR-400 colourimeter (Konica Minolta, Chroma Meter, Japan). The measurements were made in triplicate after calibration of the colourimeter with a white and a black background. The values for opacity were calculated according to the Eq. 1 [13]:

where: Y = opacity of the film (%); Yp = opacity of the film against a black background; Yb = opacity of the film against a white background.

Solubility in Water

The solubility of the films in water was determined according to the method proposed elsewhere [14]. Triplicate samples were prepared with 2 cm diameter circles extracted from the films. The initial dry matter of the samples was obtained by drying them in a forced-air circulation and renovation oven for 24 h at 105 °C. After the first weighing, the samples were immersed in a recipient containing 50 mL distilled water and maintained under constant slow agitation at 150 rpm in an orbital shaker at 25 °C for 24 h. The swollen samples were then removed and dried in a forced-air circulation and renovation oven at 105 °C for an additional 24 h before determining the final dry matter. The solubility of the film was represented by the total soluble material dissolved in water, calculated according to Eq. 2.

where: Sw = solubility in water (%); mi = initial dry mass of the sample (g); mf = final dry mass of the sample (g).

Water Vapor Permeability (WVP)

The water vapor permeability (WVP) was determined according to the modified standard method E-96 [15] for samples in triplicate. The films were fixed in permeation aluminum cells containing calcium chloride and sealed with paraffin to ensure migration of moisture only through the exposed area of the film. The permeation cells were placed in desiccators kept at 25 °C and 75% relative humidity. The amount of water vapor migrating through the film was determined from the gain in mass of the calcium chloride, measured every 24 h for 7 days [16]. The effect of the air space between the region below the film and the surface of the calcium chloride of the test cells was not considered in the calculation [17]. The WVP was calculated according to Eq. 3.

where: WVP = water vapor permeability (g mm) (m2 d kPa)−1; ΔW = mass gain (g); L = initial film thickness (mm); t = storage time (days); A = exposed film area (m2); ΔP = partial pressure difference (kPa).

Tensile Strength and Elongation

The tensile strength and elongation at break were determined in triplicate using a TA-XT2 Texture Analyzer (SMS, Surrey, UK), operated according to the standard method ASTM D 882-83 [18], as modified elsewhere [19]. The films were cut into rectangles of 80 cm long and 2.5 cm wide and fixed to claws with initial distance to the separation of 6 cm. The velocity of the tests was fixed as 1 mm/s. Tensile strength was calculated dividing the maximum force for film rupture by the cross-sectional area of the film (Eq. 4). Elongation in the rupture was determined dividing the difference of the final distance coursed up to the rupture and initial distance of separation by the initial distance of separation multiplied by 100 (Eq. 5).

where: RT = tensile strength (MPa); Fm = maximum force at the moment of rupture (N); A = cross-sectional area of the film (m2).

where: E = elongation (%); do = initial distance of separation between claws (cm); dr = distance to rupture (separation between the claws at the moment of rupture) (cm).

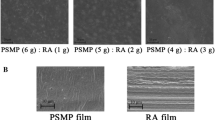

Scanning Electron Microscopy (SEM)

The surface morphology of the films was observed using a Scanning Electron Microscope (JEOL, JSM-6060, Japan), brand operated at 20 kV and 50 mA. Before testing the samples were placed on an aluminium support and covered with a thin gold layer (Sputter Coater, SCDO50) to improve the thermal conduction. Photographs were taken with × 100 magnification [12].

Differential Scanning Calorimetry (DSC)

Glass transition temperatures and the melting enthalpy variations of films were determined by using differential scanning calorimeter (Shimadzu, model DCS 60, Osaka, Japan) with the cooling module by liquid nitrogen. Samples with about 6–10 mg were hermetically sealed in aluminium capsules and preconditioned at 25 °C and 50% relative humidity. The measurements were performed in an inert atmosphere of ultra-dry nitrogen gas chromatographic grade, to the same feed flow rate and the drag of 50 mL/min. The tests were started at 40 °C, and then samples were heated at a rate of 10 °C/min up to attaining 200 °C. The material reference for this analysis was the atmospheric air [12].

X-ray Diffraction (DRX)

X-ray diffraction analyzes were performed using a D8 Advance Bruker diffractometer with Cu radiation. The analysis conditions were: (i) Voltage and current: 40 kV and 40 mA, respectively; (ii) scanning range: 2θ from 5° to 30°; (iii) Step: 0.1° and (iv) Speed 1°/min, provided with secondary beam monochromator graphite. The variation of the sizes of the crystals was determined using the PC-APD software Diffraction. The samples were stored at 25 °C room temperature and 50% RH, and analyzed in triplicate [12].

Antimicrobial Activity of the Films

The films that presented the best results according to the response surface were evaluated in triplicate for the antimicrobial activity. A film without essential oil was utilized as a negative control. The utilized Gram (−) bacteria were Escherichia coli ATCC 25,922, Pseudomonas aeruginosa ATCC 27,853 and Salmonella typhimurium ATCC 14,028, and the Gram (+) were Staphylococcus epidermidis ATCC 12,228 and Staphylococcus aureus ATCC 25,923.

An inoculum of each microorganism was prepared by the direct suspension in a sterile saline solution of a loopful of colonies isolated from a nonselective PCA medium Petry dish with the corresponding bacteria previously incubated at 35 °C for 24 h. The optical density of the suspensions was adjusted using a spectrophotometer. The absorbance of the McFarland solution at 0.5 was evaluated from 0.08 to 0.10 at 625 nm. Mueller Hinton agar plates were inoculated with the microorganisms by rubbing a swab of sterile cotton moistened with the inoculum solution. On the surface of the inoculated agar were placed discs (2.0 cm diameter) of the films, previously sterilized in a chamber with UV light for 3 min. Plates were incubated at 35 °C, and after 24 h the inhibition halos were measured, including the disc diameter [20].

Statistical Analysis

The Statistica® 5.5 (Stasoft, USA) program was used to calculate the analysis of variance (ANOVA). The Tukey test was used to determine the differences between the film’s properties in the range of 95% confidence using the Assistat software. The evaluations were performed from data obtained in triplicates, and the results were presented by the mean ± standard deviation.

Results and Discussion

Opacity, Solubility in Water, Water Vapor Permeability, Tensile Strength and Elongation

Table 2 presents the characterization of the hybrid sorubim films in terms of opacity, solubility in water, water vapor permeability, tensile strength, elongation.

A higher opacity was observed in experiments 6 (23.93%) and 8 (20.70%), which present higher values of HSPI and CEO in their composition. Experiment 3 presented the film with the lowest opacity value, resulting from the lowest protein and oil content. These results show that both the concentration of HSPI and CEO influence the colouration, probably due to the characteristic pigmentation of these elements. The opacity of the film is a consequence of the crystallinity and morphology of the material [21]. Opacity values ranging from 14.99 to 23.33% were found elsewhere for films obtained with oregano and clove oils [22], which are similar to those obtained here.

The water solubility of the films varied from 22.05% (experiment 6) to 44.90% (experiment 3) (Table 2). These obtained films were less soluble than that made with anchoita protein added of different antimicrobial agents, with solubilities ranging from 27.7 to 65.3% [5, 6], and that produced with corvina protein isolate added of palm oil, with solubilities varying from 28.3 to 47.2% [23]. However, films obtained with fish protein and clays incorporated with essential oils presented close solubility values, in the range of 22.32 to 33.54% [22].

The permeability to water vapor increased from 30.41 to 79.96; 125.80 to 234.67 and 89.52 for 225.45 g mm kPa−1 day−1 m−2 with the concentration of sorbitol, glycerol and polyethylene glycol increasing from 25 to 75%, respectively. It was reported that soluble fish surimi protein films had the water vapor permeability increased with the increase in the amount of plasticizer in the films [24].

The tensile strength varied from 0.55 MPa in experiment 3 (35% glycerol, 1.5 g HSPI and 0.1 g CEO) to 6.70 MPa at experiment 6 (25% glycerol, 2.5 g of HSPI and 0.5 g of CEO) (Table 2). The higher the protein concentration in the films, the greater the number of sulfuric groups, promoting a greater number of covalent S–S bonds in the filmogenic matrix, and consequently forming more resistant films [25]. The presence of plasticizers decreases the density of protein–protein interactions, increasing the mobility of the polypeptide chains and making the films less resistant and more deformable [24, 26]. The tensile strength of soy protein films produced with different concentrations of glycerol was reduced from 112.4 to 12.4 MPa when the amount of glycerol per 100 g of protein was increased from 30 to 50%, as reported elsewhere [27]. Similarly, in films made with wheat protein plasticized with different concentrations of glycerol, it was observed that the lower the glycerol concentration, the higher the tensile strength [28, 29].

The elongation varied from 10.40 to 44.39%, indicating an interaction between plasticizer, protein and CEO on the flexibility of the films, since that with the increase of glycerol concentration and reduction of the content of the other variables, the elasticity increased (Table 2). The increase in the elongation as a consequence of the increased concentration of the plasticizer is a classic behaviour observed in films [30, 31].

Analyses of the Effects and the Statistic Models

The effects of the concentrations of hybrid sorubim protein isolate (HSPI), glycerol (G), and clove essential oil (CEO) obtained for each variable were obtained from the factorial design analyses (Table 3). Solubility in water was the only response where the three linear factors (HSPI, X1) (G, X2) (CEO, X3) were statistically significant at 95% of confidence. HSPI was statistically significant (P < 0.05) for opacity and elongation and G for water vapor permeability and elongation. None of the factors was statistically significant (P < 0.05) for tensile strength. None of the responses presented second order effects statistically significant (P < 0.05).

The analysis of variance (ANOVA) was performed to test the suitability of the models for experimental responses (Table 4). The model was statistically significant (P < 0.05) when the F calculated is superior to the F tabulated, and predictive when the F calculated was 3–5 times superior to the F tabulated [32]. For all responses, except tensile strength, the F calculated was superior to the F tabulated. In these cases, models were statistically significant at 95% reliability.

The results which were considered statistically significant (Table 3) and predictive (Table 4) were submitted to the response surface methodology analysis, to evaluate the simultaneous effects of the variables hybrid sorubim protein isolate, glycerol and clove essential oil. However, only the WVP fulfilled these criteria. In this sense, response surfaces were obtained only for this response (Fig. 1).

Contour diagrams for the evaluation of hybrid sorubim protein films in terms of the significant variables at confidence interval of 95%: a water vapor permeability (WVP) in function of glycerol content (g 100 mL−1) and protein content (g 100 mL−1), and b WVP in function of CEO content (g 100 mL−1) and glycerol content (g 100 mL−1). Third variable fixed in the level 0

Two of the variables were considered (x- and y-axes) while a third variable was established as a fixed parameter for each response curve plot generated by the linear model. Glycerol presented statistical significance (P < 0.05) in WVP, while HSPI and CEO didn’t (P > 0.05) (Table 3). As this response presented a model statistically predictive (Table 4), it may be concluded that maintaining CEO at the central level (0) and increasing glycerol (Fig. 1a) or maintaining protein at the central level (0) and increasing glycerol (Fig. 1b) it obtains the higher values of WVP. So, the WVP is higher at high concentrations of plasticizer independently of the protein and CEO contents (Fig. 1a, b). The WVP increases from 6 to 8 g mm (m2 day kPa)−1 as the concentration of glycerol increases from 0.37 to 0.87 g 100 g−1.

Literature reports that the increase of clove essential oil causes an increase in the permeability of the film in collagen-based films [33]. As the structure of the protein chain is different and other compounds are present in the film, to form the filmogenic matrix, it seems that this parameter is quite dependent of the nature and concentration of the combined compounds that form the structure of the film.

Regarding the other significative responses, the solubility was influenced by the three variables, indicating that the hydrophilic characteristics of the plasticizer contributed to an increase in the solubility of the films with higher concentrations of glycerol. The CEO concentration was also an interfering factor in the solubility of the films. In the lower CEO concentration, one obtains the higher protein solubility, i.e., the lower the amount of oil, the greater the solubilization of the polymer matrix. This characteristic is probably related to the hydrophobic nature of clove essential oil. Oliveira et al. [34] also found greater solubility in films with lower oil content in its composition (17.01% in films with 1% oil and 14% with 1.5% oil), suggesting that incorporation of a hydrophobic compound into the protein film formulation reduces the ability of the film-forming matrix to bind with water molecules. Concerning elasticity, it observes that the films showed higher elongation when elaborated with a high concentration of glycerol and low concentration of HSPI. It also observes that there was a reduction in the elongation of the films with the increase in the amount of CEO. Probably the incorporation of CEO in the film-forming solution caused a destabilization of the matrix generating films with less elasticity.

Scanning Electron Microscopy

Scanning electron microscopy was obtained for hybrid sorubim protein isolate films without and with the incorporation of clove essential oil, respectively (Fig. 2). The control treatment did not have CEO, presenting many surface irregularities (depressions and small holes), beyond a notorious microbial development, that besides deteriorating the film, interfered in the visualization of the surface microstructure (Fig. 2a). In the treatment with CEO, it observed many structural discontinuities. However it is not possible to verify microorganisms in the structure (Fig. 2b).

Wang et al. [35] produced films of gelatin and corn oil and, likewise, found more regular surfaces in the films incorporated with essential oil. Although treatment 6 had micro-holes, possibly caused by the rapid evaporation of CEO during the drying process, these were not sufficient to facilitate the diffusion of the water vapor in the films, since this treatment was one of the less permeable to water vapor, when compared to the others (Table 1).

Differential Scanning Calorimetry (DSC)

Regarding the differential scanning calorimetry (DSC), the control treatment (a) (2.5 g of HSPI and 0.37 g of G) presented the following characteristics: starting reaction temperature, corresponding to the glass transition temperature (Tg), around 28.00 °C. From a certain temperature, the molecules were organized in the form of crystals, corresponding to the crystallization temperature (Tc), which was 109.79 °C. Heating above the Tc makes crystals to disorganize and melt due to the increase in temperature, forming an endothermic peak in the heat flow curve, which corresponds to the melting temperature (Tm). This peak occurred at 146.35 °C. The latent heat of melting (ΔH) represents the energy required to raise the state of molecular agitation which takes the compound from the solid state to the liquid state. ΔH was − 72.93 J g−1 (Fig. 3a).

For treatment (b), Tg was around 27.71 °C. Due to the more stable arrangement, it was not possible to identify Tc on the graph. The Tm was around 146.39 °C and the ΔH of the film was − 86.92 J g−1 (Fig. 3b). For treatment (c), the Tg was 28.15 °C, the Tc was 146.60 °C, the Tm was 154.44 °C, and the ΔH of -139.30° C g−1 (Fig. 3c).

The obtained data indicate that the treatments containing CEO had values of Tm and of ΔH greater than in the control film. This was possibly due to higher thermal stability of the filmogenic matrix of the CEO treatments since it was perceptible that with the addition of the essential oil the heat flux curves presented fewer variations. According to Hoque et al. [3], high Tm and ΔH can be explained by a higher interaction in the polymer network, affecting the thermal stability of the film by the presence of intermolecular interactions in the protein, e.g. hydrogen bonds, ionic interactions and hydrophobic interactions, which stabilize the polymer matrix.

X-ray Diffraction (XRD)

The X-ray diffraction (XRD) analysis shows that the film without CEO had a single reflection peak 2θ = 19.2812°, while the film with CEO presented reflection peaks at 19.7828° and 33.8802° (Fig. 4). These peaks indicate low crystallinity in the films, since XRD arises from the interaction of electromagnetic radiation with atoms of the crystalline lattice of a solid, once that the wavelength of the X-rays is of the same order than the separation of atoms in a crystal.

Another possible reason for the amorphization of films is that proteins are capable of forming amorphous three-dimensional structures, stabilized mainly by non-covalent interactions and plasticizers, by reducing the interactions between molecules and increasing the mobility of the polymer chains, decreasing the crystallinity of the polymers [26, 36]. The small peaks obtained near 20° are characteristic of the crystalline phase of polymers in biodegradable films [37].

Microbiological Analysis of IPP Films Incorporated with Clove Essential Oil

The results of the microbiological evaluation of the films performed by the disc diffusion method are presented in Fig. 5. The control treatment did not contain CEO in its formulation and, as expected, there was no microbiological inhibition for any of the bacteria tested (Fig. 5a, d and g). The films with CEO at concentrations of 0.1 and 0.5 g were not able to form inhibitory halo for any of the microorganisms tested, possibly due to the combination of the low CEO content and their high volatilization (Fig. 5b, c, e, f, h and i).

Antimicrobial activity of films prepared with 2.5 g of hybrid sorubim protein isolate (HSPI) and 0.37 g of glycerol (a, d, and g); 2.5 g of HSPI, 0.37 g of glycerol and 0.1 g of clove essential oil (CEO) (b, e, and h); 2.5 g of HSPI, 0.37 g of glycerol and 0.5 g of CEO (c, f, and i). Analyses for Staphylococcus aureus (a, b, and c), Escherichia coli (d, e, and f); and Salmonella enteritidis (g, h, and i)

According to De Lima et al. [38], clove essential oil when used as an antimicrobial agent in polyvinyl chloride films showed an inhibitory effect at a concentration of 1.5%. Based on that, it was figured to evaluate the use of clove essential oil in lower concentrations, in order to verify if it had the same or similar antimicrobial effect.

Ferreira [22], in his analysis on the microbiological evaluation of fish films, obtained results similar to the present work, where the treatments formulated with 1.0% of CEO were not able to form inhibition halo for the bacteria Staphylococcus aureus, Escherichia coli and Salmonella enteritidis. Menezes et al. [39] also did not identify the inhibitory halo formation in chicken protein films incorporated with 0.8 and 1.2% oregano essential oil for none of the microorganisms evaluated.

Conclusion

Hybrid sorubim protein isolate (HSPI) obtained from mechanically separated meat of hybrid sorubim showed itself a viable and low-cost alternative for the development of films. The obtained films presented different properties depending on the concentration of the variables protein, glycerol and clove essential oil (CEO). In general, the film with the best characteristics in relation to the performed analyzes was the treatment 6 (25% glycerol, 2.5 g of HSPI and 0.5 g of CEO). These characteristics make it suitable for packaging applications. However, more studies are needed to improve its mechanical and barrier properties, as well as to test its antimicrobial activity at higher concentrations of CEO.

References

Mostafa NA, Farag AA, Abo-dief Hala M, Tayeb AM (2018) Production of biodegradable plastic from agricultural wastes. Arab J Chem 11:546–553

Rhim JW, Ng PKW (2007) Natural biopolymer-based nanocomposite films for packaging applications. Crit Rev Food Sci Nutr 47:411–433

Hoque S, Benjakul S, Prodpran T (2010) Effect of heat treatment of film-forming solution on the properties of film from cuttlefish (Sepia pharaonis) skin gelatin. J Food Eng 96:66–73

Zavareze ER, El Halal SLM, Telles AC, Prentice C (2012) Biodegradable films based on myofibrillar proteins of fish. Braz J Food Technol IV SSA:53–57

Rocha M, Loiko MR, Tondo EC, Prentice C (2014) Physical, mechanical and antimicrobial properties of Argentine anchovy (Engraulis anchoita) protein films incorporated with organic acids. Food Hydrocoll 37:213–220

Rocha M, Prietto L, Souza MM, Furlong EB, Prentice C (2018) Effect of organic acids on physical-mechanical and antifungicidal properties of anchovy protein films. J Aquat Food Prod Technol 27:316–326

Paiva LB, Morales AR, Guimarães TR (2006) Mechanical properties of polypropylene and organophilic montmorillonite nanocomposites. Polím – Ciênc Tecnol 16:136–140.

Ojagh SM, Rezaei M, Razavi SH, Hosseini SMH (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122:161–166

Cavenaghi-Altemio AD, Hashinokuti AA, Albuquerque DM, Fonseca GG (2018) Transglutaminase addition increases quality and acceptation of sausages obtained from mechanically separated meat of hybrid sorubins. Emir J Food Agric 30:952–958

Silva RS, Santos BMM, Pizato S, Fonseca GG, Cortez-Vega WR (2018) Evaluation of protein isolate obtained from byproducts of hybrid sorubim (Pseudoplatystoma reticulatum x Pseudoplatystoma corruscans). J. Bioener Food Sci 5:1–11

Ardakani KM, Navarchian AH, Sadegui F (2010) Optimization of mechanical propertiens of thermoplastic starch/clay nanocomposites. Carbohydr Polym 79:547–554

Andrade CS, Fonseca GG, Innocentini-Mei LH, Fakhouri FM (2017) Development and characterization of multilayer films based on polyhydroxyalkanoates and hydrocolloids. J Appl Polym Sci 134:44458

Romani VP, Olsen B, Collares MP, Oliveira JRM, Prentice-Hernández C, Martins VG (2019) Improvement of fish protein films properties for food packaging through glow discharge plasma application. Food Hydrocoll 87:970–976

Gontard N, Duchez C, Cuq J, Guilbert S (1994) Edible composite films of wheat gluten and lipids. Water vapor permeability and other physical properties. Int J Food Sci Technol 29:39–50

ASTM (2000) American Society for Testing and Material, ASTM E96–00: Standard test method for water vapor transmission of materials. ASTM, Philadelphia

Pimentel T, Pizzuti L, Fakhouri FM, Innocentini-Mei LH, Fonseca GG (2018) Development of multilayer films obtained from epoxidized methyl esters, polyhydroxyalkanoates and their combinations. J Polym Environ 26:1661–1672

Gennadios A, McHugh TH, Weller CL, Krochta JM (1994) Edible coatings and films for processed foods. In: Krochta JM, Baldwin EA, Nisperos-Carriedo M (eds) Edible coatings and films to improve food quality. Technomic Publishing Co Inc, Lancaster

ASTM (1980) American Society for Testing and Material, ASTM D 882–83: Standard test methods for tensile properties of thin plastic sheeting. ASTM, Conshohocken

Tanada-Palmu PS, Hélen H, Hyvönen L (2000) Preparation, properties and applications of wheat gluten edible films. J Agric Food Sci 9:23–35

NCCLS (2003) Performance standards for antimicrobial disk susceptibility tests Approved standard, 8th ed NCCLS document M2-A8. NCCLS, Wayne

De Santis F, Pantani R (2013) Optical properties of polypropylene upon recycling. Sci World J. https://doi.org/10.1155/2013/354093

Ferreira FA (2014) Antimicrobial nanocomposites films obtained from fish proteins and nanoclay incorporated with essential oils. Dissertation. Federal University of Rio Grande: Rio Grande, Brazil, p 105

El Halal SLM, Zavareze ER, Rocha M, Pinto VZ, Nunes MR, Luvielmo MM, Prentice C (2016) Films based on protein isolated from croaker (Micropogonias furnieri) and palm oil. J Sci Food Agric 96:2478–2485

Bourtoom T, Chinnan MS, Jantawat P, Sanguandeekul R (2006) Effect of plasticizer type and concentration on the properties of edible film from water-soluble fish proteins in surimi wash-water. Food Sci Technol Int 12:119–126

Perez-Gago MB, Krochta JM (2001) Denaturation time and temperature effects on solubility, tensile properties, and oxygen permeability of whey protein edible films. J Food Sci 66:705–710

Cuq B, Gontard N, Guilbert S (1998) Proteins as agricultural polymers for packaging production. Cereal Chem 75:1–9

Guerrero P, Stefani PM, Ruseckaite RA, de la Caba K (2011) Functional properties of films based on soy protein isolate and gelatin processes by compression molding. J Food Eng 105:65–72

Tanada-Palmu PS, Grosso CRF (2002) Edible wheat gluten films: development, mechanical and barrier properties and application to strawberries (Fragaria ananassa). Bol Cent Pesq Process Alim 20:291–308

Adamu AD, Jikan SS, Talip BHA, Badarulzaman NA, Yahaya S (2017) Effect of glycerol on the properties of tapioca starch film. Mat Sci Forum 888:239–243

Paschoalick TM, Garcia FT, Sobral PJA, Habitante AMQB (2003) Characterization of some functional properties of edible films based on muscle proteins of Nile tilapia. Food Hydrocoll 17:419–427

Chirita M (2008) Mechanical properties of collagen biomimetic films formed in the presence of calcium, silica and chitosan. J Bionic Eng 5:149–158

Gacula MC, Singh J (1984) Statistical methods in food and consumer research. Academic Press Inc, London

Nakashima AY, Chevalier RC, Cortez-Vega WR (2016) Development and characterization of collagen films with added essential oil of clove India. J Bioener Food Sci 3:50–57

Oliveira SPLF, Bertan LC, De Rensis CMVB, Bilck AP, Vianna PCB (2017) Whey protein-based films incorporated with oregano essential oil. Polím—Ciênc Tecnol 27:158–164.

Wang L, Auty MAE, Rau A, Kerry JF, Kerry JP (2009) Effect of pH and addition of corn oil on the properties of gelatin- based biopolymer films. J Food Eng 90:11–19

Mali S, Grossmann MVE, Garcia MA, Martino MN, Zaritzky NE (2006) Effects of controlled storage on thermal, mechanical and barrier properties of plasticized films from different starch sources. J Food Eng 75:453–460

Pattabi M, Amma BS, Manzoor K (2007) Photoluminescence study of PVP capped CdS nanoparticles embedded in PVA matrix. Mat Res Bull 42:28–35

De Lima MSD, Carvalho DS, Malta SHS, Vinhas CVF, GM. (2007) Evaluation of the antimicrobial effect of clove essential oil on polyvinyl chloride films. Rev Bras Agrotecnol 7:294–298

Menezes BS, Cortez-Vega WR, Prentice C (2017) Nanocomposites films obtained from protein isolates of mechanically deboned chicken meat added with montmorillonite. Polím—Ciênc Tecnol 27:75–82.

Acknowledgements

The authors gratefully acknowledge the Brazilian research funding agencies CNPq, CAPES and FUNDECT for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Souza Silva, R., Santos, B.M.M., Fonseca, G.G. et al. Analysis of Hybrid Sorubim Protein Films Incorporated with Glycerol and Clove Essential Oil for Packaging Applications. J Polym Environ 28, 421–432 (2020). https://doi.org/10.1007/s10924-019-01608-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01608-7