Abstract

Green thermoplastic elastomer vulcanizates (GTPV) nanocomposites using poly (vinyl chloride) (PVC) and nitrile butadiene rubber (NBR) containing 5 wt% Cloisite 30B as an organoclay and various concentrations of rice straw natural fibers were made by melt mixing process and compression molding. The effect of used organoclay and various loadings of rice straw was monitored through using scanning electron microscopy (SEM), thermogravimetric analysis (TGA), tensile tests and rheological measurements. The morphological investigations revealed that the GTPV nanocomposites reinforced by rice straw natural fiber show a more rough fracture surfaces indicated the existence of some interactions between the natural fiber and polymer matrix. Thermal decomposition measurements revealed a higher thermal stability for GTPV nanocomposites containing higher rice straw natural fibers. The tensile test analysis suggested that there is an optimum value for the weight fraction of rice straw to enhance the Young’s modulus and tensile strength of the prepared GTPV nanocomposites up to 9 MPa and 35 MPa, respectively. The effect of rice straw loading on the Young’s modulus of the PVC/NBR/organoclay GTPV nanocomposites was predicted through using the parallel and series equations of modified Ji’s model. The results show that the theoretical model can precisely predict the variation of Young’s modulus with respect to the rice straw loading.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural fiber composites have recently gained many attentions due to their several benefits such as large quantity [10], recyclability [27], light weight [11], low cost [28] and energy saving [1] besides their acceptable specific mechanical properties compared to the traditional polymer composites containing artificial fibers i.e. glass [6] and carbon fibers [13].

Rice straw fiber with its lignocellulosic characteristics can be used as a reinforcing material in many polymers to form an eco-friendly composites with high mechanical properties which can be used in many fields such as construction [31] and automotive [14] industries due to their applied new and strong environmental policies. Grozdanov et al. [5] studied the possibility of the use of rice straw fiber into the maleated polypropylene through using the extrusion and compression molding processes. They found that the incorporation of 20 and 30% by weight rice straw into the polymer matrix leads to produce an eco-friendly composites with higher thermal stability and mechanical properties. Yao et al. [32] investigated the effect various rice straw types on the properties of high density polyethylene and reported that the higher concentrations of natural fibers leads to the increased mechanical properties and decreased tensile and impact strength. Qin et al. [26] presented the effect of surface modified rice straw fiber with butyl acrylate on the mechanical properties of the poly (lactic acid) (PLA) and reported the higher mechanical properties and thermal stability with higher rice straw fibers.

Nanocomposites have recently been the subject of many researchers due to their superior properties at very low concentrations especially in case of multiphase polymer systems such as thermoplastic elastomer vulcanizates (TPVs) ([15], [23, 24]). Huang et al. [7, 8] focused on the shape memory bio based TPVs and gained a designed TPVs with excellent multi-stimuli responsive shape memory behavior and significantly improved impact strength. Liu et al. [12] investigated the effect of silica on the toughness of PLA/natural rubber (NR) TPVs and found that the introduction of silica into the TPVs cause a rise in impact strength without a decrease in tensile strength. Chen et al. [3] studied the bio-based TPVs based on PLA/NR to achieve a ternary TPV with enhanced stiffness and toughness. Xu et al. [29, 30] developed the TPVs based on polypropylene (PP)/ethylene propylene diene monomer (EPDM) containing zinc oxide particles to make a shape memory materials with balanced stiffness and toughness.

Our previous studies have focused on the effect of various loadings of the organically modified nanoclays on the properties of TPVs based on the poly (vinyl chloride) (PVC) and nitrile butadiene rubber (NBR) [4]. The results show that the ultimate mechanical properties of prepared PVC/NBR/organoclay TPV nanocomposites could be enhanced depending on the organoclay loading and dispersion state. A detailed discussion was carried out about the optimization of mechanical properties with respect to the organoclay concentration and processing conditions.

Our findings suggested a detailed study about the effect of rice straw on the morphology and mechanical properties of the PVC/NBR/organoclay green thermoplastic elastomer vulcanizate (GTPV) nanocomposites could be attractive in view of research and industrial applications. The objective of this study was to investigate the effect of various rice straw fiber loading on the morphology, mechanical and thermal properties of PVC/NBR/organoclay GTPV nanocomposites prepared through using melt mixing process. A sufficient experimental investigations regarding the hybrid PVC/NBR/organoclay nanocomposites containing various rice straw loading was carried out and the trends was monitored to obtain the optimal nanocomposites with considerable mechanical properties. The stiffness analysis of prepared GTPV nanocomposites was investigated through using parallel and series modified Ji’s theoretical model. The theoretical Young’s modulus of various GTPV nanocomposites was compared with the experimental results and the ability of the modified Ji’s model to predict the effect of rice straw natural fiber on the mechanical properties of the nanocomposites was investigated.

Theoretical Background

The Ji’s theoretical model for prediction the Young’s modulus of nanocomposites was developed by Zare and Garmabi [33] for the nanocomposites containing two type of fillers. The Ji’s model [9] was modified on the basis of possible arrangements of two fillers with respect to the applied stress. The theoretical Ji’s model for parallel status of fillers was developed as the following equation [33]:

The subscripts 1 and 2 indicated the fillers 1 and 2 respectively. The parameters Em and Ef are the Young’s moduli of polymer matrix and fillers, respectively. The parameters α and β are functions of filler volume fraction (φf) and thickness of interphase region (ti) and the filler (tf). Furthermore, k defined as the ratio of the Young’s modulus of the interphase region between each filler with the polymer matrix (Ei) and Em, so k = Ei/Em.

The modified Ji’s model in series status of fillers could be represented as the following equation [33]:

The Young’s modulus of the GTPV nanocomposites can be predicted by combination of two above equations by considering the randomly oriented conditions for both organoclay and rice straw fillers [33]:

The terms α and β for each fillers could be calculated from the following equations:

where B is dependent on the characteristics of the interphase region and determined from a linear correlation on the basis of Pukanszky’s model [25]:

where σR is defined as the relative yield strength of the composite to the matrix.

Materials and Methods

Materials

Poly (vinyl chloride) (PVC), suspension grade, with K-value of 65 was purchased from Bandar-e-Emam Petrochemical Company (Iran). Nitrile butadiene rubber (KNB 35L) containing 34% of acrylonitrile with Mooney viscosity of 45 (ML (1 + 4), 100 °C), was supplied from Kumho Petrochemical Co. Ltd (Korea). Heat stabilizer, Mark 1900, for PVC processing was adopted from Galata chemicals company (USA) with specific gravity of 1.77 g/cm3. Cloisite 30B, a natural montmorillonite modified with a methyltallow- bis(2-hydroxyethyl) quaternary ammonium salt with cation exchange capacity of 95 mequiv./100 g clay was provided by Southern Clay, Inc. (USA). Rice straw fiber with density of 0.23 g/cm3 and 35.5% of hemicellulose, was obtained from the agricultural center of Sari, Iran. The vulcanization of TPV nanocomposites was carried out through using stearic acid (SA), zinc oxide (ZnO), sulfur (S), tetramethylthiuramdisulfide (TMTD), and mercaptobenzthiazyldisulfide (MBTS) were purchased from Bayer (M) Ltd, Germany.

Nanocomposite Preparation

The PVC/NBR/organoclay GTPV nanocomposites containing 5 wt% of Cloisite 30B and various loadings of rice straw according to Table 1, were prepared through melt mixing process in a laboratory size internal mixer (Brabender Plasti-Corder, W50, Germany) at 160 °C and 50 rpm for 6 min. The designed quantities of PVC, heat stabilizer and organoclay were introduced into the internal mixer to achieve a unique mixture based on the steady state of mixing torque. Then rice straw was added to the mixture after 30 s of mixing. The NBR was fed into the mixer 1 min after the stabilization mixing torque. The curative ingredients were added to the melting mixture 30 s after the steady state of mixing torque. The mixing process was continued to achieve a unique mixture. As the torque –time curve of mixing reaches a plateau, the compound was removed from the mixer and sheeted on a cold two-roll mill. The prepared samples were compression molded by hot press at 160 °C for 5 min to obtain suitable samples for tensile, morphological and rheological characterizations.

Characterization

The morphology and microscopic structure of prepared GTPV nanocomposites was investigated using a VegaII XMU scanning electron microscope (SEM). The suitable samples were prepared by cryogenic fracture surfaces of the samples in liquid nitrogen. The fracture surfaces were coated with gold in order to enhance the conductivity.

Tensile measurement of the TPV nanocomposites containing various rice straw were carried out at a cross head speed of 50 mm/min at room temperature using an Instron 6025 universal testing machine according to ASTM D638, type IV. The average of three measurements for each formulation was reported.

Thermogravimetric analysis (TGA) for the prepared GTPV nanocomposites was performed on a Netzsch TG 209 apparatus. Samples (ca. 5 mg) were placed in a corundum dish. Measurements were conducted in a nitrogen atmosphere in the temperature range 25–600 °C at a heating rate of 10 °C/min.

Rheological characteristics of GTPV nanocomposites were measured in oscillation mode by using a MCR300 strain controlled rheometer from Anton Paar. The experiments were carried out in parallel plate geometry with a diameter of 25 mm under a nitrogen atmosphere at 160 °C. A frequency sweep test was conducted on the samples from 0.5 rad/s to 200 rad/s.

Results and Discussion

Morphology Observation

The morphology of the used rice straw is depicted in Fig. 1. It is evident that the rice straw fibers have a wide distribution of the length from 3.5–8.5 μm and aspect ratio in the range of 2–11.

SEM photomicrographs of cryogenically fracture surfaces of various PVC/NBR GTPV nanocomposites containing 5 wt% organoclay and 40 wt% rice straw are compared in Figs. 2 and 3. It is evident that the TPV nanocomposites containing rice straw exhibited a more rough fracture surfaces which may be due to the some interactions between the rice straw and polymer matrix in presence of organoclay [16].

Thermal Stability

The effect of organoclay and various rice straw loadings on the thermal stability of PVC/NBR GTPV nanocomposites are monitored through using thermogravimetric analysis (TGA). As can be seen in Fig. 4, the introduction of organoclay into the polymer matrix cause a rise in the thermal stability due the physical structure of nanofiller and some interactions with the polymer matrix [18]. One can see that, the higher rice straw concentration leads to increase in thermal stability and higher thermal decomposition temperature. It is believed that the physical structure, especially the aspect ratio of rice straw can act as an obstacle for the volatile products resulted from the thermal decomposition of polymer [34]. Furthermore, the interactions between the rice straw and polymer matrix retarded the thermal decomposition process of the polymer. The results indicated that the rice straw natural fibers and organoclay can simultaneously increase the thermal stability with the higher residue content at the end of thermal decomposition process.

Mechanical Properties

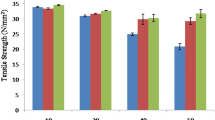

Figure 5 depicted the effect of organoclay and various rice straw loading on the mechanical properties of PVC/NBR GTPV nanocomposites. It is obvious that the introduction of Cloisite 30B into the TPV matrix leads to the increase of Young’s modulus due to the higher stiffness and physical structure of the nanoplatelets [19]. However, the interfacial interactions between the organoclay and polymer matrix is a key factor in determining the ultimate mechanical properties of the nanocomposites [17]. Figure 5a shows that the incorporation of rice straw into the GTPV nanocomposite can greatly affect the Young’s modulus. It is evident that the Young’s modulus of the PVC/NBR GTPVs in more pronounced dependent on the concentration of rice straw due to their micro structure [2]. However, the effect of rice straw loading decreased in 40 wt% of the natural fibers due to their inappropriate dispersion state at higher concentrations. Figure 5b depicted that the tensile strength of PVC/NBR GTPVs was improved with the incorporation of organoclay due to the some possible interactions between the nanoplatelets and polymer matrix [17]. Furthermore, the higher loading values of rice straw cause a rise in tensile strength of nanocomposites up to 30% compared to the neat PVC/NBR nanocomposites. It seems that the physical structure of rice straw and its concentration have a considerable effect onto the tensile strength. However, the results of tensile strength revealed that there is an optimum loading value of rice straw to increase the mechanical properties of the prepared nanocomposites. Figure 5c revealed that the introduction of both organoclay and rice straw leads to decrease in elongation at break due to the higher Young’s modulus of PVC/NBR GTPV nanocomposites.

The predictions of Young’s modulus for various PVC/NBR GTPVs containing various loading of rice straw natural fibers are investigated in Fig. 6. The results indicated that there is a good correlation between the experimental data and predicted values of Young’s modulus. However, there is some deviations from experimental values especially at higher concentrations of rice straw due to the effect of dispersion state of fibers and some complex interactions between the inclusions at the interphase regions which could not be significantly considered by the theoretical model [20].

Rheology Measurements

The effect of organoclay and rice straw introduction into the PVC/NBR GTPV nanocomposites was investigated through using rheology analysis in a various frequency sweep represented in Fig. 7. The results of storage modulus for PVC/NBR GTPVs and their corresponding GTPV nanocomposites show a higher values with the applied frequencies due to the inability of chain segments of polymer matrix to follow the applied strain [22]. It is evident from Fig. 7 that the incorporation of both Cloisite 30B and rice straw leads to an increase in storage modulus especially at low applied frequencies. However, there is a lower power-law dependency of storage modulus at terminal slope for GTPV nanocomposites. This may be due to the structure formation of organoclays resulted from their interactions with the polymer matrix and rice straw [21]. Figure 7 revealed a shear thinning behavior in the complex viscosity of PVC/NBR GTPV nanocomposites with respect to the applied frequencies. As can be observed, the organoclay and rice straw can enhance the shear thinning behavior in GTPV nanocomposites, especially at low frequencies. Furthermore, the introduction of nanoplatelets and rice straw leads to the earlier onset of shear thinning at lower applied frequencies.

Conclusions

The effect of organoclay nanoplatelets and various concentrations of natural rice straw with cylindrical structure on the microstructure, physical and mechanical properties of PVC/NBR GTPV nanocomposites prepared via a melt mixed process method was experimentally monitored. Morphological investigations revealed that the PVC/NBR GTPV nanocomposites containing both organoclay and rice straw exhibited a more rough fracture surfaces compared to the corresponding PVC/NBR TPVs. Thermogravimetric analysis show that the introduction of rice straw into the PVC/NBR/organoclay GTPV nanocomposites could enhance the thermal stability of the nanocomposites. Mechanical properties explorations show that the rice straw could significantly increases the Young’s modulus of the polymer matrix. However, there is an optimum concentration of rice straw in case of Young’s modulus. The results suggested a reduction of elongation at break with higher rice straw loading. Rheological experiments show the higher quantities in both complex viscosity and storage modulus for PVC/NBR TPV nanocomposites with the incorporation of rice straw. The results of detailed experimental investigations for PVC/NBR GTPV nanocomposites containing 5 wt% Cloisite 30B recommended a good balanced physical and mechanical properties by introduction of proper loadings of natural rice straw into the PVC/NBR GTPV nanocomposites.

References

Ahmad F, Choi HS, Park MK (2015) A review: natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol Mater Eng 300:10–24

Ashori A (2013) Effects of nanoparticles on the mechanical properties of rice straw/polypropylene composites. J Compos Mater 47:149–154

Chen Y, Wang W, Yuan D, Xu C, Cao L, Liang X (2018) Bio-Based PLA/NR-PMMA/NR ternary thermoplastic vulcanizates with balanced stiffness and toughness:“soft–hard” core–shell continuous rubber phase, in situ compatibilization, and properties. ACS Sustain Chem Eng 6:6488–6496

Esmizadeh E, Naderi G, Ghoreishy MHR, Bakhshandeh GR (2011) Optimal parameter design by Taguchi method for mechanical properties of NBR/PVC nanocomposites. Iran Polym J 20(7):587

Grozdanov A, Buzarovska A, Bogoeva-Gaceva G, Avella M, Errico ME, Gentille G (2006) Rice straw as an alternative reinforcement in polypropylene composites. Agron Sustain Dev 26(4):251–255

Holbery J, Houston D (2006) Natural-fiber-reinforced polymer composites in automotive applications. JOM 58:80–86

Huang J, Cao L, Yuan D, Chen Y (2018) Design of multi-stimuli-responsive shape memory biobased PLA/ENR/Fe3O4 TPVs with balanced stiffness-toughness based on selective distribution of Fe3O4. ACS Sustain Chem Eng 7:2304–2315

Huang J, Cao L, Yuan D, Chen Y (2018) Design of novel self-healing thermoplastic vulcanizates utilizing thermal/magnetic/light-triggered shape memory effects. ACS Appl Mater Interfaces 10:40996–41002

Ji B, Gao H (2004) Mechanical properties of nanostructure of biological materials. J Mech Phys Solids 52:1963–1990

Joshi SV, Drzal L, Mohanty A, Arora S (2004) Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos A 35:371–376

Ku H, Wang H, Pattarachaiyakoop N, Trada M (2011) A review on the tensile properties of natural fiber reinforced polymer composites. Compos B 42:856–873

Liu Y, Cao L, Yuan D, Chen Y (2018) Design of super-tough co-continuous PLA/NR/SiO2 TPVs with balanced stiffness-toughness based on reinforced rubber and interfacial compatibilization. Compos Sci Technol 165:231–239

Malkapuram R, Kumar V, Negi YS (2009) Recent development in natural fiber reinforced polypropylene composites. J Reinf Plast Compos 28:1169–1189

Mutlu I (2009) Investigation of tribological properties of brake pads by using rice straw and rice husk dust. J Appl Sci 9:377–381

Naderi G, Lafleur PG, Dubois C (2007) Microstructure-properties correlations in dynamically vulcanized nanocomposite thermoplastic elastomers based on PP/EPDM. Polym Eng Sci 47:207–217

Orts WJ, Shey J, Imam SH, Glenn GM, Guttman ME, Revol J-F (2005) Application of cellulose microfibrils in polymer nanocomposites. J Polym Environ 13:301–306

Paran S, Naderi G, Ghoreishy M (2016) Mechanical properties development of high-ACN nitrile-butadiene rubber/organoclay nanocomposites. Plast, Rubber Compos 45:389–397

Paran S, Naderi G, Ghoreishy M (2016) XNBR-grafted halloysite nanotube core-shell as a potential compatibilizer for immiscible polymer systems. Appl Surf Sci 382:63–72

Paran S, Naderi G, Ghoreishy M (2017) Microstructure and mechanical properties of thermoplastic elastomer nanocomposites based on PA6/NBR/HNT. Polym Compos 38:E451

Paran S, Naderi G, Ghoreishy M, Heydari A (2018) Enhancement of mechanical, thermal and morphological properties of compatibilized graphene reinforced dynamically vulcanized thermoplastic elastomer vulcanizates based on polyethylene and reclaimed rubber. Compos Sci Technol 161:57–65

Paran SMR, Abdorahimi M, Shekarabi A, Khonakdar HA, Jafari SH, Saeb MR (2018) Modeling and analysis of nonlinear elastoplastic behavior of compatibilized polyolefin/polyester/clay nanocomposites with emphasis on interfacial interaction exploration. Compos Sci Technol 154:92–103

Paran SMR, Naderi G, Babakhani A (2017) An experimental study of the effect of CNTs on the mechanical properties of CNTs/NR/EPDM nanocomposite. Polym Compos 39(11):4071–4079

Paran SMR, Vahabi H, Ducos F, Formela K, Zarrintaj P, Laachachi A, Lopez cuesta JM, Saeb MR (2018) Crystallization kinetics study of dynamically vulcanized PA6/NBR/HNTs nanocomposites by nonisothermal differential scanning calorimetry. J Appl Polym Sci 135(28):46488

Paran SR, Naderi G, Ghoreishy MR (2016) Effect of halloysite nanotube on microstructure, rheological and mechanical properties of dynamically vulcanized PA6/NBR thermoplastic vulcanizates. Soft Mater 14:127–139

Pukánszky B, Mudra I, Staniek P (1997) Relation of crystalline structure and mechanical properties of nucleated polypropylene. J Vinyl Addit Technol 3:53–57

Qin L, Qiu J, Liu M, Ding S, Shao L, Lü S, Zhang G, Zhao Y, Fu X (2011) Mechanical and thermal properties of poly (lactic acid) composites with rice straw fiber modified by poly (butyl acrylate). Chem Eng J 166:772–778

Saheb DN, Jog JP (1999) Natural fiber polymer composites: a review. Adv Polym Technol 18:351–363

Westman MP, Fifield LS, Simmons KL, Laddha S, Kafentzis TA (2010) Natural fiber composites: a review. Pacific Northwest National Laboratory (PNNL), Richland

Xu C, Wu W, Zheng Z, Wang Z, Nie J (2018) Design of shape-memory materials based on sea-island structured EPDM/PP TPVs via in situ compatibilization of methacrylic acid and excess zinc oxide nanoparticles. Compos Sci Technol 167:431–439

Xu C, Zheng Z, Wu W, Wang Z, Fu L (2019) Dynamically vulcanized PP/EPDM blends with balanced stiffness and toughness via in situ compatibilization of MAA and excess ZnO nanoparticles: preparation, structure and properties. Compos B 160:147–157

Yang H-S, Kim D-J, Kim H-J (2003) Rice straw–wood particle composite for sound absorbing wooden construction materials. Bioresour Technol 86:117–121

Yao F, Wu Q, Lei Y, Xu Y (2008) Rice straw fiber-reinforced high-density polyethylene composite: effect of fiber type and loading. Ind Crops Prod 28:63–72

Zare Y, Garmabi H (2015) A developed model to assume the interphase properties in a ternary polymer nanocomposite reinforced with two nanofillers. Compos B 75:29–35

Zhao Y, Qiu J, Feng H, Zhang M, Lei L, Wu X (2011) Improvement of tensile and thermal properties of poly (lactic acid) composites with admicellar-treated rice straw fiber. Chem Eng J 173:659–666

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Paran, S.M.R., Naderi, G., Shokoohi, S. et al. Mechanical and Thermal Properties of Green Thermoplastic Elastomer Vulcanizate Nanocomposites Based on Poly (vinyl chloride) and Nitrile Butadiene Rubber Containing Organoclay and Rice Straw Natural Fibers. J Polym Environ 27, 2017–2026 (2019). https://doi.org/10.1007/s10924-019-01491-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01491-2