Abstract

Removal of toxic pollutants from water and wastewater is becoming an important process with the increase of industrial activities. The present study focused on assessing the suitability and efficiency of water bamboo leaves (WBL) for the removal of cationic dye from aqueous solutions. The effect of different variables in the batch method including solution pH (2–12), initial dye concentration (50–250 mg L−1), adsorbent dose (0.05–0.30 g), contact time (5–180 min) and temperature (283–333 K) on the dye removal was investigated. The adsorption kinetics was discussed in view of four kinetics models. The results showed that the pseudo-second-order kinetics model described dye adsorption on WBL very well. The experimental equilibrium data were also tested by four isotherm models. It was found that adsorption of dye on WBL fitted well with the Langmuir isotherm model, implying the binding energy on the whole surface of the adsorbent was uniform and the dye molecules onto the surface of the adsorbent were monolayer coverage. Calculation of various thermodynamic parameters of the adsorption process indicated feasibility and exothermic nature of dye adsorption.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many manufacturing industries such as paper, plastics, cosmetics, textile and food utilize dyes for colouring their products. The discharge of effluents from these industries contains large amount of dyes, not only damages the aesthetic nature of receiving water bodies, but also may be toxic to aquatic life [1, 2]. Throughout world, 280,000 tons of textile dyes are discharged with industrial effluents every year [3]. To protect humans and the receiving ecosystem from contamination, the dyes must be eliminated from the dye containing wastewaters before being released into the environment. Various physicochemical and biological techniques have been employed to remove dyes from waste water, such as membrane separation process, coagulation/flocculation, adsorption, ion-exchange, chemical oxidation, electrochemical and biological treatment including bacterial and fungal biosorption, biodegradation in aerobic or anaerobic conditions. The technical and economical feasibility of each technique is determined by several factors such as dye type, waste water composition, operation costs and generated water products. All of these methods have their own advantages and disadvantages [4, 5].

Adsorption is the method for separation of mixtures on a laboratory and industrial scale where it is a surface phenomenon that can be defined as the increase in concentration of a particular component at the interface between two phases. Adsorption has been found to be superior to other techniques in terms of flexibility and simplicity of design, initial cost, insensitivity to toxic pollutants and ease of operation. Adsorption also does not produce harmful substances [6]. However, low-cost adsorbents with high adsorption capacities are still under development to reduce the adsorbent dosage and minimize disposal problems. Much attention has recently been focused on various low cost, easy obtainable and biodegradable adsorbent materials such as bones and shells wastes that can be obtained in large quantities and that are harmless to nature [7].

Agricultural wastes are lignocellulosic materials that consist of three main structural components which are cellulose, hemicelluloses and lignin. These components contribute mass and have high molecular weights. Lignocellulosic materials also contain extractive structural components which have a smaller molecular size [8]. Agricultural wastes are renewable, available in large amounts and less expensive as compared to other materials used as adsorbents. In addition, agricultural wastes are usually used without or with a minimum of processing (washing, drying, grinding) and thus reduce production costs by using a cheap raw material and eliminating energy costs associated with thermal treatment [9]. So a number of inexpensive and abundant agro-waste materials such as garlic peel [10], wheat shell [11], cereal chaff [12], hazelnut shell [13], pomelo peel [14], broad bean peel [15], coffee husk [16], peanut hull [17], Luffa cylindrical fibers [18], and orange peel [19] have been used to remove dyes from waste water in recent years.

Water bamboo (Zizania latifolia) belongs to perennial herbaceous water plant. As a special crop in Jiangnan area of China, water bamboo contributes to a variety of delicious food for our table. However, water bamboo leaves (WBL) become agricultural waste material, which have no economic value and create potential environmental problems. Although direct open burning in fields is a common option for disposal, but this alternative causes serious air pollution. As part of endeavor to develop the natural fuel resources, the increase in lignocellulosic wastes has led to the interest in converting these wastes into useful energetic products [20, 21]. Because WBL is insoluble in water, has chemical stability and high mechanical strength. It also contains abundant floristic fiber, and some functional groups such as carboxyl, hydroxyl and amidogen, etc., representing a favorable characteristic of WBL to be a potential adsorbent material. Such use of water bamboo wastes is undoubtedly beneficial, providing a natural adsorbent and decreasing the amount of agricultural wastes. Therefore, a study had been carried out on the possibility of using these wastes as alternative adsorbents for removal of heavy metal ion from aqueous solutions, which formed the motivation of this present study [22].

The aim of the present study was to investigate the dye adsorption potential of water bamboo leaves (WBL) for cationic dye methylene blue (MB) removal from aqueous solutions in batch system. The study included an evaluation of the effects of various operational parameters such as solution pH, initial concentration of the dye, adsorbent dose, contact time and temperature on the dye adsorption process. The adsorption kinetic models, equilibrium isotherm models, and thermodynamic parameters related with the process were also performed and reported.

Materials and Methods

Adsorbent and Adsorbate

Water bamboo leaves (WBL) used in this study was the wastes obtained from the local vegetable market in Zhenjiang, China. The samples were washed with tap water, distilled water, filtered out and dried in an oven at 50 °C for 48 h. The dried sample was mechanically crushed and sieved to obtain a particle size between 0 and 355 μm. The prepared WBL samples were stored in a desiccator for further use. No other chemical or physical treatments were used prior to adsorption experiments.

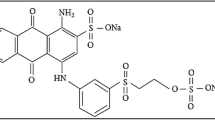

Methylene blue (MB) supplied by Sinopharm Chemical Reagent Co. Ltd. (Shanghai, China) was taken as the model adsorbate and used as received without further purification. The formula of MB is C16H18ClN3S·3H2O and its molecular weight is 373.9. Distilled water was used for preparing all solutions. Stock solutions of the test reagent were made by dissolving MB in doubly distilled water.

The concentration of the MB was determined at 666 nm using a Shimadzu UV-2550 spectrophotometer. A pH meter (model PHSJ-4F, Shanghai REX, China) was used to determine the pH of the solution. The surface morphological structure of the WBL was observed using scanning electron microscopy (S-3400N) under an acceleration voltage of 15 kV. The surface functional groups of WBL were detected by a Fourier transform infrared spectroscopy (FTIR, NEXUS 670 spectrometer) using the KBr method in a wave number range of 4000–400 cm−1.

Batch Adsorption Experiments

The adsorption of MB on the WBL was investigated in batch mode adsorption experiments. All batch adsorption experiments were carried out by adding a fixed amount of WBL into a series of 100 mL conical flasks filled with 50 mL diluted solutions at a known initial concentration (50–250 mg L−1) with adjusted pH. The solution pH was adjusted with 0.1 mol L−1 HCl and 0.1 mol L−1 NaOH solutions. The conical flasks were then sealed and placed in a water-bath shaker and shaken at 100 rpm with a required time at different temperatures. The influence of solution pH (2–12), initial dye concentration (50–250 mg L−1), adsorbent dose (0.05–0.30 g), temperature (283–333 K), and contact time (5–180 min) were evaluated during the present study. The flasks were then removed from the shaker, and 2–10 mL samples were drawn at each experiment. The samples were then centrifuged for 15 min at 3000 rpm and the left out concentration in the supernatant solution were analyzed at 666 nm using a Shimadzu UV-2550 spectrophotometer. Percentage of dye removal was calculated using the following equation:

where C 0 (mg L−1) and C t (mg L−1) are dye concentration initially and at time t, respectively.

Batch Kinetic and Equilibrium Studies

In an adsorption study, it is necessary to fit the equilibrium adsorption data using different adsorption isotherm models and kinetic equations in order to analyze and design an adsorption process. Therefore, batch kinetic and equilibrium studies were also investigated in batch mode adsorption experiments. For adsorption kinetic experiments, the amount of MB adsorbed at time t (q t (mg g−1)) was calculated by following equation:

where C 0 (mg L−1) is the initial dye concentration, C t (mg L−1) the dye concentration at any time t, V (L) the volume of the solution and m (g) is the mass of the adsorbent.

The procedures of equilibrium experiments were identical with those of kinetic tests. Equilibrium adsorption capacity was calculated from the following equation:

where q e (mg g−1) is the equilibrium adsorption capacity, C e (mg L−1) is the dye concentration at equilibrium, V (L) is the volume of solution and W (g) is the weight of adsorbent.

Results and Discussion

Adsorbent Characterization

SEM analysis is a useful tool for the analysis of the surface morphology of an adsorbent. Figure 1 showed the SEM micrographs of WBL sample at different magnifications. The micrographs in Fig. 1 showed convex structure on the surface of WBL and many pores and cavities of various dimensions in the internal of WBL. Furthermore, the surface and internal structures of the adsorbent were highly heterogeneous, which provided a large exposed area for the adsorption of MB and indicated that there was a good possibility for the dye molecules to be trapped and adsorbed onto the WBL.

The FTIR technique is an important tool to identify functional groups, which are capable of adsorbing dyes. The FTIR spectra of WBL before and after adsorption of MB dye in the range of 4000–400 cm−1 were taken to obtain information on the nature of functional groups at the surface of the adsorbent. The spectra presented in Fig. 2 showed broad and strong absorption peaks around 3400 cm−1, which was due to vibration of the hydroxyl group linked in cellulose and lignin and adsorbed water. The peak observed at 2922 cm−1 was assigned to the stretching vibration of C–H bond in methyl group. The peaks located at 1639 cm−1 were characteristics of carbonyl group stretching. The peak around 1384 cm−1 was due to bending vibration of C–H of methyl group. The C–O stretching band at 1261 cm−1 also confirmed the lignin structure of the adsorbents. The peak around 1100 cm−1 was due to C–O–C stretching of cellulose present in WBL. Characteristic changes were observed in the FTIR spectrum of WBL after adsorption of MB dye. The results indicated that the intensity of most peaks decreased and some peaks were shifted or disappeared. These changes observed in the spectrum indicated the possible involvement of these functional groups on the surface of the WBL in the adsorption process.

Effect of Solution pH

The pH of the aqueous solution has been recognized as one of the most important factors influencing any adsorption process [7]. The pH of the solution affects not only the surface charge of the adsorbents, the degree of ionization of the pollutants present in the solution and the dissociation of functional groups on the active sites of the adsorbent, but also the solution dye chemistry [23]. As the pH increases, it is usually expected that the cationic dye adsorption also increases due to increasing of the negative surface charge of adsorbents.

In this study, the initial pH of the MB solution was adjusted between pH values about 2.0 and 12.0 by adding various concentrations of HCl or NaOH. The variation of MB adsorption with the pH value of MB solution was studied at an initial MB concentration of 100 mg L−1 using adsorbent dosage 0.1 g at 10 °C for 1 h. The effect of pH on the adsorption of MB by WBL was shown in Fig. 3. It could be seen that adsorption of MB was strongly pH-dependent. The adsorption amount of dye increased notably with raising the pH from about 2.0 to 5.0. Above these levels, the adsorption amount did not change significantly up to pH 11.0. The maximum adsorption amount took place at about pH 10.42, and percent of adsorption of dye was 84.59 %. As well known, MB is a cationic dye, which exists in aqueous solution in the form of positively charged ions. As a charged species, the degree of its adsorption onto the adsorbent surface is primarily influenced by the surface charge on the adsorbent, which in turn is influenced by the solution pH. At low pH values, the protonation of the functional groups present on the adsorbent surface easily takes place, and thereby restrict the approach of positively charged dye cations to the surface of the adsorbent resulting in low adsorption of dye in acidic solution. With decrease in acidity of the solution, the functional groups on the adsorbent surface become deprotonated resulting in an increase in the negative charge density on the adsorbent surface and facilitate the binding of dye cations. The increase in dye adsorption amount at higher pH may also be attributed to the reduction of H+ ions which compete with dye cations at lower pH for appropriate sites on the adsorbent surface. However with increasing pH, this competition weakens and dye cations replace H+ ions bound to the adsorbent surface resulting in increased dye adsorption [24].

Effect of Initial Dye Concentration

The amount of adsorption for dye removal is highly dependent on the initial dye concentration. The effect of initial dye concentration depends on the immediate relation between the concentration of the dye and the available sites on an adsorbent surface. In general, the percentage of dye removal decreases with an increase in the initial dye concentration, which may be due to the saturation of adsorption sites on the adsorbent surface. On the other hand, the increase in initial dye concentration will cause an increase in the capacity of the adsorbent and this may be due to the high driving force for mass transfer at a high initial dye concentration [11].

Figure 4 showed the effect of initial MB concentration on the adsorption of MB using WBL. It was found that the amount of adsorption rised with increasing MB concentration from 50 to 250 mg L−1, but its increasing rate declined gradually. On the other hand, the percent of adsorption reduced significantly. It could be explained that the adsorbent for a given amount of the adsorbent had a limited number of active sites, which became saturated at a certain concentration. This indicated that the adsorption capacity would increase with the increase of initial dye concentration, which mainly due to the rise in the mass transfer from the concentration gradient. However, the concentration would inversely impact on the adsorption frequency because of the limited adsorption sites available for the adsorption of cationic dye.

Effect of Adsorbent Dose

Adsorbent dosage is another important process parameter to determine the capacity of an adsorbent at the operating conditions. Generally the percentage of dye removal increases with increasing adsorbent dosage, where the quantity of adsorption sites at the surface of adsorbent will increase by increasing the amount of the adsorbent. The effect of adsorbent dosage gives an idea for the ability of a dye adsorption to be adsorbed with the smallest amount of adsorbent, so as to recognize the capability of a dye adsorption from an economical point of view [7].

The effect of WBL dosages on the adsorption of MB was analyzed and shown in Fig. 5. Amount of adsorbent was varied from 0.05 to 0.30 g and equilibrated for 12 h at an initial MB dye concentration of 120 mg L−1. The percent of adsorption increased rapidly with increasing dosage from 0.05 to 0.15 g and then reached a plateau of up to about 93 % at the dosage above 0.15 g. However, unilaterally increasing the adsorbent dosage led to a monotonic decrease of the adsorption capacity and thus to a waste of adsorbent.

Effect of Temperature

To study the effect of temperature on the adsorption of MB dye adsorption by WBL, the experiments were carried out at temperatures of 10, 20, 30, 40, 50 and 60 °C at an initial MB dye concentration of 100 mg L−1. Figure 6 showed the influence of temperature on the adsorption of MB dye onto WBL. As observed, the percent of adsorption and the amount of adsorption MB onto WBL both decreased with increasing temperature. The results indicated that the lower temperature increased surface activity and the adsorption between MB and WBL was an exothermic process. This means the lower temperature was in favor of adsorption. Similar types of results for the MB adsorption at various temperatures have been reported for different adsorption systems [25–27].

Effect of Contact Time

One of the most important parameters that significantly describe adsorbent characteristics is contact time. Therefore,the effect of contact time on the adsorption of MB was investigated. Figure 7 showed the adsorption of MB by WBL as a function of contact time at different initial concentrations. It was seen that the adsorption of MB increased rapidly with rise in contact time up to 60 min, but its increasing rate declined gradually. Then it reached a plateau at the contact time above 60 min. Further increase in contact time did not enhance the adsorption greatly. Initially, the rate of adsorption was rapid due to the adsorption of dye molecules onto the exterior surface. After that the molecules enter into pores (interior surface), a relatively slow process. The initial faster rates of adsorption might also be attributed to the presence of large number of binding sites for adsorption and the slower adsorption rates at the end was due to the saturation of the binding sites and attainment of equilibrium.

Adsorption Kinetics Study

Adsorption kinetics is one of the most important characteristics which govern the solute adsorption rate. It represents the adsorption efficiency of the adsorbent and, therefore, determines its potential applications. Several adsorption kinetic models have been established to describe the reaction order of adsorption systems based on dye solution concentration. These include pseudo-first-order model, pseudo-second-order model, Weber and Morris adsorption kinetic model, first-order reversible reaction model, external mass transfer model, first-order equation of Bhattacharya and Venkobachar, Elovich’s model and Ritchies’s equation [28]. However, the pseudo-first-order and pseudo-second-order kinetic models are the most well-liked model to study the adsorption kinetics of dyes and have been widely used in the kinetic study of dye adsorption using various kinds of adsorbent materials. By acknowledging their wide application and usefulness in adsorption studies, the pseudo-first-order model, the pseudo-second-order kinetic model, the Elovich model, and the intraparticle diffusion model were used to study the kinetics of MB adsorption onto WBL in the present study.

The pseudo-first-order model is represented by the following equation [29, 30]:

where q e (mg g−1) is the amount of MB adsorbed per unit mass of adsorbent at equilibrium, q t (mg g−1) is the amount of MB adsorbed per unit mass of adsorbent at any time t (min) and k 1 (min−1) is the first-order rate constant adsorption. Values of k 1 and equilibrium adsorption density q e were calculated from the plots of log(q e − q t ) versus t for different initial concentrations of MB.

The pseudo-second-order kinetic model can be expressed as follows [30, 31]:

where k 2 (g mg−1 min−1) is the rate constant for the pseudo-second-order adsorption kinetics. Values of k 2 and q e for different initial concentrations of MB were calculated from the slope and intercept of the linear plot of t/q t versus t.

The k 1 values, the correlation coefficients R 2, and theoretical and experimental equilibrium adsorption capacity q e were given in Table 1. The R 2 values in Table 1 suggested that adsorption of MB onto WBL did not follow pseudo-first-order kinetics. In addition, the theoretical and experimental equilibrium adsorption capacities, q e obtained from these plots varied widely, confirming that the pseudo-first-order model was not appropriate for describing the adsorption kinetics of MB onto WBL. On the contrary, the kinetic data showed excellent fit to the pseudo-second-order equation at all initial MB concentrations studied. The plot of t/q t against t at different initial MB concentrations was shown in Fig. 8. The pseudo-second-order rate constant k 2, the calculated q e values and the corresponding linear regression correlation coefficients values R 2 were also given in Table 1. From Table 1, it was evident that the calculated q e values agreed with experimental q e values well, and also, the correlation coefficients for the pseudo-second-order kinetic plots at all the studied initial MB concentrations were higher (R 2 = 0.9999 > 0.99). It could thus be easily concluded that the ongoing reaction proceeded via a pseudo-second-order mechanism rather than a pseudo-first-order mechanism.

In addition, the initial adsorption rate, h (mg g−1 min−1) at different initial MB concentrations was calculated using Eq. (6) from the pseudo-second-order kinetic parameters [24], and were given in Table 1.

It could be seen in Table 1 that, the value of h was hardly increasing with increase in the initial MB concentrations.

The time required for the WBL to adsorption half of the amount adsorbed at equilibrium is the half-adsorption time of the dye. It is often considered as a measure of the rate of adsorption. So the adsorption data were further analyzed using the intraparticle diffusion model. The intraparticle diffusion model based on the theory proposed by Weber and Morris is represented by the following equation [32, 33]:

where C (mg g−1) is the intercept and k d (mg g−1 min−0.5) is the intraparticle diffusion rate constant. Value of k d was obtained from the slope of the linear plot of q t versus t 0.5. The R 2 values in Table 1 suggested that adsorption of MB onto WBL did not follow intraparticle diffusion kinetics. In fact, the plots for adsorption of MB on WBL at different initial MB concentrations were multimodal with three distinct regions. The initial curved region was attributed to the external surface adsorption in which the adsorbate diffused through the solution to the external surface of the adsorbent. The second stage related the gradual adsorption reflecting intraparticle diffusion as the rate limiting step. The final plateau region was referred to the gradual adsorption stage and the final equilibrium stage, in which the intraparticle diffusion started to slow down and level out. The present finding implied that although intraparticle diffusion was involved in the adsorption process, but it was not the sole rate-controlling step and that some other mechanisms also played an important role. In addition, values of intercept C gave an idea about the thickness of the boundary layer. The larger intercept indicated the greater the boundary layer effect [33]. The C values increased with the initial dye concentrations which indicated the increasing of the initial dye concentrations promoted the boundary layer diffusion effect.

The kinetic data was further fitted to the Elovich equation. The Elovich equation assumes that the solid surface active sites are heterogeneous in nature and therefore, exhibits different activation energies for chemisorptions. The Elovich kinetic model can be expressed as follows [34, 35]:

The Elovich plot (q t vs. ln t) at different initial MB concentrations can be plotted using relevant data. The values of the coefficients α and β were listed in Table 1. The correlation coefficients (R 2) determined from these plots reveal basically a linear characteristic. In Elovich model, α is related to rate of chemisorption (initial adsorption rate) and β is related to surface coverage (desorption constant). With the increase in initial MB concentrations, the constants α and β decreased showing that both the rate of chemisorption and the available adsorption surface would decrease.

Adsorption Equilibrium Study

The analysis of an adsorption process depends on the equilibrium relationship between the adsorbate concentration in the liquid phase and that on the adsorbent’s surface at a given condition, called an isotherm. An isotherm is a thermodynamic basis of an adsorption separation processes and determines the extent to which a material can be adsorbed onto a particular surface [36]. Generally, some simple information about adsorption equilibrium can be obtained by plotting adsorption isotherm (q e vs. C e ). In the Fig. 9a, it is clear that equilibrium adsorption capacity q e increases with the increase of equilibrium concentration C e and tends to achieve saturation value gradually. What’s more, a variety of isotherm models has been developed to describe equilibrium relationships. The parameters obtained from the different models provide important information on the surface properties of the adsorbent and its affinity to the adsorbate. However, no single model is universally applicable. All models involve assumptions which may or may not be valid in particular cases. In the present study, the Langmuir, Freundlich, Dubinin–Radushkevich and Tempkin isotherms are applied to study the adsorption process of MB onto WBL.

The Langmuir isotherm is based on the assumption that the adsorption process takes place at specific homogeneous sites within the adsorbent surface and that once a dye molecule occupies a site, no further adsorption can take place at that site, which concludes that the adsorption process is monolayer in nature. The Langmuir isotherm is expressed as [37, 38]:

where C e (mg L−1) is the equilibrium concentration, q e (mg g−1) the amount of adsorbate adsorbed per unit mass of adsorbate, and q m (mg g−1) and K L (L mg−1) are the Langmuir constants related to adsorption capacity and rate of adsorption, respectively. Plot of C e /q e versus C e was linear shown in Fig. 9b. The isotherm showed good fit to the experimental data with high correlation coefficients (R 2 = 0.9996), indicating that the adsorption of MB on WBL followed the Langmuir isotherm. The Langmuir isotherm constants K L and q m were calculated from the slope and intercept of the plot between C e /q e and C e , and the results were shown in Table 2. The maximum dye adsorption capacity of WBL was found to be 54.17 mg g−1.

The essential characteristics of Langmuir isotherm can be expressed by a dimensionless constant called equilibrium parameter R L, defined by [39]:

where K L (L mg−1) is the Langmuir constant and C 0 (mg L−1) is the highest dye concentration. The value of R L indicates the type of the isotherm to be either unfavorable (R L > 1), linear (R L = 1), favorable (0 < R L < 1) or irreversible (R L = 0). Values of R L were found to be 0.025 confirmed that the WBL was favorable for adsorption of MB dye under studied conditions.

The data was further analyzed by the linearized form of Freundlich isotherm model. The Freundlich isotherm assumes that adsorption process occurs on heterogeneous surfaces and the capacity of adsorption is related to the concentration of MB at the equilibrium [40]. The Freundlich equation is expressed as follows [41]:

where q e (mg g−1) is the amount of adsorption, K F (mg g−1) is the Freundlich constant related to adsorption capacity and 1/n is a constant related to energy or intensity of adsorption. This gives an expression encompassing the surface heterogeneity and the exponential distribution of activated sites and their energies. This isotherm dose not predict any saturation of the adsorbent surface. The Freundlich exponents K F and 1/n could be determined from the linear plot of ln q e versus ln C e . The values of the Freundlich constants K F and n were 18.48 and 4.36, respectively shown in Table 2. The slope 1/n ranging between 0 and 1 was a measure of adsorption intensity or surface heterogeneous, becoming more heterogeneous as its value got closer to zero. In addition, the value of 1/n less than 1 also represented a favorable adsorption.

The Dubinin–Radushkevich (D–R) model, which does not assume a homogeneous surface or a constant adsorption potential as the Langmuir model, is further used to test the experimental data. The linear form of Dubinin–Radushkevich isotherm equation can be expressed as [42]:

where q m (mg g−1) is the maximum adsorption capacity, β (mol2 kJ−2) is a constant related to the adsorption energy, ε is the Polanyi potential, R is the gas constant (8.314 J mol−1 K−1), and T is temperature (K). The values of constant q m and β determined from the linear plot of ln q e versus ε 2 were shown in Table 2. The D–R isotherm model constant β gives an idea about the mean free energy E (kJ mol−1) of adsorption per mole of the adsorbate which in turn can give information about the type of adsorption mechanism. E can be calculated using the relationship [43]:

If the magnitude of E is between 8 and 16 kJ mol−1, the adsorption process is supposed to proceed via chemisorption, while for values of E < 8 kJ mol−1, the adsorption process is of physical nature. The estimated value of E for the present study was found in the range expected for physical adsorption.

The Temkin equation was also fitted to the experimental data. Temkin isotherm assumes that the fall in the heat of adsorption is linear rather than logarithmic, as implied in the Freundlich equation, and its equation is given as [44, 45]:

where B T = RT/b, b (J mol−1) is the Temkin constant related to heat of sorption, T is the absolute temperature in K T , R the universal gas constant, 8.314 J mol−1 K−1, K T the equilibrium binding constant (L mg−1) corresponding to the maximum binding energy and B T is related to the heat of adsorption. The constants K T and B T determined from the intercept and slope of the plot between q e and ln C e were shown in Table 2. The small value of the Temkin constant B T for WBL suggested that adsorption of MB on this adsorbent was favorable and designated the process to be physiosorption.

The correlation coefficient (R 2) values of the four isotherms were also listed in Table 2. Based on the R 2 values, the applicability of the isotherms was compared. It could be concluded that the adsorption of MB onto WBL, best fitted to the Langmuir isotherm equation. The fitness of the adsorption data to the Langmuir isotherm implied that the binding energy on the whole surface of the adsorbent was uniform. It also indicated that the adsorbed dye molecules did not interact or compete with each other and that they were adsorbed by forming a monolayer. It can be concluded that WBL is an excellent adsorbent for MB.

Thermodynamic Study

Thermodynamic consideration of an adsorption process is necessary to conclude whether the process is spontaneous or not. The Gibbs free energy change is a critical factor for determining the spontaneity of a process and can be computed by the classical Van’t Hoff equation [46]:

where ∆G 0 is the standard free energy change (J mol−1), T the absolute temperature (K) and R gas constant (8.314 J mol−1 K−1). K C is the distribution coefficient for adsorption defined as:

According to thermodynamics, the Gibbs free energy change is also related to the enthalpy change as well as change in standard entropy according to the following equation:

where ∆H 0 is enthalpy change (J mol−1), ∆S 0 entropy change (J mol−1 K−1).

From Eqs. (16) to (18), it follows that

The plot of ln K C against 1/T shown in Fig. 10 yielded a straight line, from which ΔH 0 and ΔS 0 could be calculated from the slope and intercept, respectively. Once these two parameters were obtained, ΔG 0 was determined from Eq. (18). The thermodynamic parameters obtained at various temperatures investigated for 100 mg L−1 MB concentrations were represented in Table 3. The negative values of free energy ΔG 0 at all temperatures indicated the spontaneous nature and the feasibility of the adsorption process. Increase in value of ΔG 0 with increase in temperature suggested that at lower temperature the adsorption was easier. The negative value of standard energy change ΔH 0 implied that the adsorption was exothermic in nature. Moreover, the negative value of ΔS 0 reflected the decreased randomness at the solid/solution interface suggested that the process was enthalpy driven during the adsorption of MB on WBL. This was the normal consequence of the physical adsorption phenomenon, which took place through electrostatic interactions.

Conclusions

The present study showed that water bamboo leaves could be used as an adsorbent for removal of MB from aqueous solutions. The adsorption characteristics of MB in aqueous solution were shown to be influenced by several factors. Dynamic modeling analysis revealed that the adsorption data showed good agreement with the pseudo-second-order kinetic model for different dye concentration. The equilibrium process was better described by the Langmuir isotherm model than other models with maximum sorption capacity of 54.17 mg g−1, implying the binding energy on the whole surface of the adsorbent was uniform and the dye molecules onto the surface of the adsorbent were monolayer coverage. And through the thermodynamics analysis, it was found that the adsorption process was spontaneous and exothermic in nature. Taking into consideration all the above obtained results, it can be concluded that WBL can be an alternative economic material to more costly adsorbents used for dye removal in wastewater treatment processes.

References

Pearce CI, Lloyd JR, Guthrie JT (2003) Dyes Pigments 58:179

Lee JW, Choi SP, Thiruvenkatachari R, Shim WG, Moon H (2006) Dyes Pigments 69:196

Ali H (2010) Water Air Soil Pollut 213:251

Yagub MT, Sen TK, Afroze S et al (2014) Adv Colloid Interface 209:172

Gupta VK, Suhas (2009) J Environ Manag 90:2313

Crini G (2008) Dyes Pigments 77:415

Salleh MAM, Mahmoud DK, Karim WAWA et al (2011) Desalination 280:1

Demirbas A (2009) J Hazard Mater 167:1

Franca AS, Oliveira LS, Ferreira ME (2009) Desalination 249:267

Hameed BH, Ahmad AA (2009) J Hazard Mater 164:870

Bulut Y, Aydin HA (2006) Desalination 194:259

Han R, Wang Y, Han P et al (2006) J Hazard Mater 137:550

Ferrero F (2007) J Hazard Mater 142:144

Hameed BH, Mahmoud DK, Ahmad AL (2008) Colloids Surf A 316:78

Hameed BH, El-Khaiary MI (2008) J Hazard Mater 154:639

Oliveira LS, Franca AS, Alves TM et al (2008) J Hazard Mater 155:507

Gong R, Li M, Yang C et al (2005) J Hazard Mater 121:247

Demir H, Top A, Balkose D, Ulku S (2008) J Hazard Mater 153:389

Annadurai G, Juang R, Lee D (2002) J Hazard Mater 92:263

Shih YF (2007) Bioresour Technol 98:819

Shih YF (2007) Mater Sci Eng A-Struct 445:289

Asberry HB, Kuo CY, Gung CH et al (2014) Microchem J 113:59

Crini G, Peindy HN, Gimbert F et al (2007) Sep Purif Technol 53:97

Chowdhury S, Mishra R, Saha P et al (2011) Desalination 265:159

Yagub MT, Sen TK, Ang M (2014) Environ Earth Sci 71:1507

Kumar S, Ramalingam S, Senthamarai C et al (2010) Desalination 261:52

Nandi B, Goswami A, Purkait M (2009) Appl Clay Sci 42:583

Chowdhury S, Saha P (2010) Biorem J 14:196

Chairat M, Rattanaphani S, Bremner JB et al (2008) Dyes Pigments 76:435

Hu Z, Chen H, Ji F et al (2010) J Hazard Mater 173:292

McKay G, Ho YS (1999) Process Biochem 34:451

Weber WJ, Morris JC (1963) J Sanit Eng Div Am Soc Civ Eng 89:31

Hameed BH, Daud FBM (2008) Chem Eng J 139:48

Cheung CW, Porter JF, McKay G (2000) Sep Purif Technol 19:55

Önal Y (2006) J Hazard Mater 137:1719

Chowdhury S, Mishra R, Kushwaha P et al (2011) Biorem J 15:77

Langmuir I (1916) J Am Chem Soc 38:2221

Ergene A, Ada K, Tan S et al (2009) Desalination 249:1308

Weber TW, Chakravorti RK (1974) AIChE J 20:228

Kumar KV, Ramamurthi V, Sivanesan S (2006) Dyes Pigments 69:102

Freundlich HMF (1906) J Phys Chem 57:385

Dubinin MM, Radushkevich LV (1947) Proc Acad Sci USSR Phys Chem Sect 55:331

Chakraborty S, Chowdhury S, Saha PD (2011) Carbohydr Polym 84:1533

Temkin MI, Pyzhev V (1940) Acta Physiochim URSS 12:217

Gao J, Zhang Q, Su K et al (2010) J Hazard Mater 174:215

Chowdhury S, Saha P (2010) Chem Eng J 164:168

Acknowledgments

The authors gratefully acknowledge the Natural Science Foundation of Jiangsu Province (BK20130511), the National Natural Science Foundation of China (51274106), and the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, L., Wang, Y., He, T. et al. Assessment of Potential Capability of Water Bamboo Leaves on the Adsorption Removal Efficiency of Cationic Dye from Aqueous Solutions. J Polym Environ 24, 148–158 (2016). https://doi.org/10.1007/s10924-016-0757-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0757-8