Abstract

Lignins in general have been extensively studied, while beech wood lignin in particular is rarely researched. In the present work, Organosolv isolated lignin from beech wood (OBL) has been characterized. The isolation was done by two methods: (a) by using sulfuric acid at 170 °C and a reaction time of 120 min and (b) at a temperature of 180 °C for 240 min. A range of analytical methods were applied including elemental analysis, FT-IR, UV–Vis, 31P NMR, SEC, Pyrolysis-GC/MS and HPLC to gain information about establish the purity, structure, molecular weight, thermal behavior and to determine carbohydrate residues according to the NREL protocol. FT-IR and UV–Vis spectra of OBL revealed expected typical absorptions for lignins. NREL analysis presented a carbohydrate-free lignin fraction which has not been achieved to date. TGA and DSC are used to study the thermal behavior of the isolated lignins and showed a relatively low glass transition temperatures (Tg: 123 °C) and decomposition temperatures of 348 and 381 °C. The pyrograms generated from the pyrolysis–GC/MS at 550 °C consisted mainly of fragments of syringyl, guaiacyl and hydroxyphenyl units, thereby confirming the results of the NMR analysis. Our findings support Organolsolv as an efficient method to isolate pure lignin fractions from beech wood with practical value in industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Besides cellulose and hemicellulose lignin is the most abundant organic natural raw material and expected to play a key role regarding the world-wide production of bio-based products. It is part of the cell walls of lignocellulosic plants, responsible for maintaining their rigidity and resistance against environmental conditions [1]. Pulp and paper industries produce large quantities of lignin (ca. 55 × 106 tons per year) as a side product of delignification via pulping processes [2]. The two most important industrial paper technologies are Kraft and sulphite pulping, leading to sulphur-containing degraded lignin fractions which are predominantly used as a secondary energy source. The utilization of lignin for the synthesis of high-value added materials is an issue of economic and environmental importance. There are studies of the utilization of lignins in phenolic-formaldehyde resins which show comparable properties to the commercial produced resins [3].

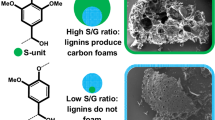

Lignin molecules are derived primarily from three phenylpropane units: p-coumaryl alcohol, coniferyl alcohol and synapsyl alcohol (Fig. 1). The resulting structure of lignin formed by dehydrogenative polymerization of these monolignols is an extremely complex three-dimensional macromolecule.

Among the various developed delignification methods mostly based on aqueous acids or bases, the Organosolv process provides an interesting alternative using organic solvents as delignification agents. It is a mild process resulting in lignins that differ significantly from those isolated via Kraft pulping. Via Organosolv pulping, the raw material is separated into a cellulose-rich fraction, a water-soluble fraction containing hemicellulose degradation products and a large fraction of dissolved sulphur-free lignin. During Organosolv treatment mainly β-aryl ether bonds are cleaved resulting in additional phenolic hydroxyl groups in the lignin macromolecule. Lora et al. [3] described the suitability of Organosolv isolated lignins for diverse applications such as dispersant, binder, copolymer, emulsifier etc.

Within the last 5 years, Organosolv lignins have been studied using various feedstocks such as Miscanthus giganteus [4], pine wood [5], switch grass, wheat straw, corn stover [6] and Eucalyptus [7]. However the applied characterization methods and resulting data are limited. Lignin derived from Miscanthus x giganteus was isolated under these conditions: T = 190 °C, t = 60 min, sulfuric acid = 1.2 % w/w, EtOH/H2O = 0.65 [4]. In this study 13C NMR, 31P NMR, FT-IR and UV–Vis spectroscopy were performed to characterize the structure of various lignins. Size exclusion chromatography was used to determine the molecular weight and polydispersity of the Organosolv isolated lignin fraction. Finally, the obtained results were discussed regarding the Organosolv process: it was shown that during Organosolv treatment β-O-4 linkages are cleaved as the main degrading process to a noticeable extent but it does not change the main core of the lignin structure (see Fig. 1). Organosolv isolated lignins of cord grass, switch grass and corn stover were isolated at following conditions: T = 140 °C, t = 20 min, sulfuric acid = 0.39–0.46 % w/w, ethyl acetate/EtOH/H2O = 36/25/37. They were determined for purity (Klason lignin and contaminants using NREL procedure), solubility, phenolic hydroxyl groups using UV–Vis spectroscopic methods and the presence of aromatic groups via 1H NMR spectroscopy. The results of this study show pure lignin fractions with low contents of carbohydrates. Proton NMR reveals mainly the presence of G and S units [5].

Wheat straw lignin was treated by Organosolv process (T = 200 °C, t = 60 min, 60 % w/w aqueous ethanol) and characterized applying NREL methods to determine ash contents and carbohydrates. Elemental composition, thermal analysis (TGA), molecular weight (SEC) and structure composition of wheat straw derived lignin were determined. The results also confirm a lignin of high purity and contents of monomeric units which are characteristic for wheat straw lignins [6]. Dominguez et al. [7] investigated the thermal stability and degradation kinetics of Organosolv-methanol lignins from Eucalyptus. These studies show an influence of methanol concentration and cooking time on thermal stability.

In our contribution we present new data regarding the physicochemical properties of Organosolv fractionated beech wood lignin. Two different fractions isolated from the same source are compared (OBL_1: T = 170 °C, t = 120 min, sulfuric acid 0.94 % w/w; OBL_2: T = 180 °C, t = 240 min). In general, beech wood exhibits an alternative with practical value over other examined sources due to its availability. A competitive situation in the pulp and wood-working industry can also be prevented by using this resource. A broad variety of characterization methods were performed for purity and structure analysis including spectroscopy (UV–Vis, IR, NMR), thermal analysis (TGA, DSC), solubility behavior and chromatography (SEC, Pyrolysis-GC/MS) to obtain extensive information. Morphology was investigated using SEM (Fig. 2).

Changes in lignin structure during Organosolv treatment [19]

Experimental Section

Lignins

The investigated Organosolv lignin fractions are products from a biorefinery pilot plant in Leuna, Germany [8]. The pulping process parameters for OBL_1 are a 50/50 ethanol/water mixture, a reaction temperature of 170 °C, a reaction time of 120 min and sulphuric acid as a catalyst with 0.94 % w/w. OBL_2 is a result of isolating beech wood with a 50/50 ethanol/water mixture at a temperature of 180 °C and a reaction time of 240 min.

Analytical Methods

Purity, Ash and Sugar Contents

The chemical composition (%, w/w) was performed according to National Renewable Energy Laboratory’s (NREL) standard analytical procedure [32]. A Macherey Nagel HPLC was used with a flow rate of 0.4 mL/min, a column (300 × 7.8 mm) of Macherey-Nagel at a temperature of 90 °C. This analysis was kindly performed by the biorefinery.de GmbH.

Solubility

Solutions were prepared in 5 mL volumetric flasks, using 0.1 g of lignin sample. The solutions were kept for 30 min in an ultrasonic bath and then filtered through a paper filter. The solid residue was dried and weighed. Comparison of the initial sample weight and the remaining solid residue after filtration is the percent solubility value.

UV–Vis Spectroscopy

UV–Vis spectra were recorded on a Hewlett-Packard 450 Diode Array spectrometer. Lignin sample (2.5 mg) was dissolved in 95 % (v/v) dioxane-water (10 mL). A 1 mL aliquot was diluted to 10 mL with 50 % (v/v) dioxane-water. Absorbances between 250 and 400 nm were measured.

FTIR Spectroscopy

FTIR spectra of the lignin samples were recorded on a Jasco FTIR 410 spectrometer in the range of 4000–400 cm−1 using a KBr disc containing 1 % finely ground samples. The spectrum recorded over 30 scans with a resolution of 4 cm−1.

31P NMR Spectroscopy

Quantitative 31P NMR spectra were performed on a Bruker DRX-400 spectrometer using pyridine-d5/CDCl3 (1.6:1 v/v) as the solvent, endo-N–hydroxy-5-norbornene-2,3-dicarboximide as the internal standard, chromium acetylacetonate as the relaxation reagent, and 2-chloro-4,4,5,5-tetramethyl-1,3,2-dioxapholane as the phosphitylation reagent.

SEC

The lignin sample was completely dissolved in THF (1 mg mL−1) at room temperature with gentle stirring at room temperature. Size exclusion chromatography was performed at room temperature with THF as the mobile phase (flow rate 1.0 mL min−1) and an UV detector (280 nm) using an Agilent 1100 instrument. Calibration was performed with polystyrene standards (PSS Standards).

TGA

TGA was performed with about 10 mg of lignin using a Netzsch TGA 209 F1 with a heating rate of 20 °C min−1 under nitrogen atmosphere. The temperature ranged from ambient to 800 °C.

DSC

Glass transition temperatures (Tg) were determined using a Perkin Elmer 8000 differential scanning calorimeter. The scans were run from a starting temperature of −30 °C hold for 3 min under a nitrogen flow rate of 10 mL min−1. The samples were then heated from −30 to 140 °C at 20 °C min−1. Before being tested, the samples were extensively dried for 24 h in an oven at 40 °C under vacuum.

Py–GC/MS

Approximately 1 mg of lignin sample was inserted without further preparation into the bore of the pyrolysis solids-injector and then placed with the plunger on the quartz wool of the quartz tube of the furnace pyrolyzer Pyrojector II™ (SGE Analytical Science, Melbourne, Australia). The pyrolyzer was operated at constant temperature of 550 °C. The pressure of helium carrier gas at the inlet to the furnace was 95 kPa. The pyrolyzer was connected to a Trace 2000 gas chromatograph (ThermoQuest/CE Instruments, Milan, Italy) with a quadrupole mass spectrometer Voyager (ThermoQuest/Finnigan, MassLab Group, Manchester, UK) operated in electron impact ionization (EI) mode. The fused silica GC capillary column DB-5 ms 30 m long, 0.25 mm I.D., 0.25 µm film thickness (J&W, Folsom, CA, USA) was used. The gas chromatographic conditions were as follow: programmed temperature of the capillary column from 60 °C (1 min hold) at 2.5 °C min−1 to 100 °C and then 10 °C min−1 to 280 °C (20 min hold at 280 °C). The temperature of the split/splitless injector was 250 °C and the split flow was 10 cm3 min−1. Helium, grade 5.0 (Westfalen AG, Münster, Germany) was used as a carrier gas at constant pressure of 70 kPa during the whole analysis. The transfer line temperature was 280 °C. The MS EI ion source temperature was kept at 250 °C. The ionization occurred with a kinetic energy of the impacting electrons of 70 eV. The current emission of the rhenium filament was 150 µA. The MS detector voltage was 350 V. Mass spectra and reconstructed chromatograms (total ion current [TIC]) were obtained by automatic scanning in the mass range m/z 35–455 u. Pyrolysis–GC/MS data were processed with the Xcalibur software (ThermoQuest) and the NIST 05 mass spectral library.

SEM

Lignin samples were sputtered with gold. Images were captured on SUPRA 55/Zeiss at 5 kV beam accelerating voltage and various resolving powers.

Results and Discussion

Purity and Fractional Yield of Lignin

The results of moisture, ash, elemental sugars, Klason (AIL) and acid-soluble (ASL) lignin contents (w/w %) are summarized in Table 1. They show a very high yield of lignin (91.4–94.0 %), low ash content (<1 %) and sugar content under quantification limit. These results can be attributed to the applied Organosolv treatment which leads to highly pure lignins. In comparison to other studies these results are unique. Mansouri and Salvado investigated lignosulfonates, Kraft, soda-anthraquinone, Organosolv and ethanol process lignins from different plant sources for the production of adhesives. Their characterizations of these lignins also show high contents of total lignin yield but all considered lignins exhibit sugar contents [9]. Sun et al. [10] investigated steam-exploded lignin with alkali post-treatment of Phyllostachyspubescens and their obtained yields of total lignins were between 63.45 and 73.35 % (w/w). The sugar contents were determined to 0.55–1.76 % (w/w). Erdocia et al. [11] studied different Organosolv conditions on olive wood. They used the Acetosolv, Formosolv and a mixture of both processes at a temperature of 130 °C and a reaction time of 90 min. The resulting lignin fractions had contents of Klason lignin between 69.05 and 79.01 % w/w. The sugar contents were between 1.88 and 5.87 w/w %.

Solubility

Due to the complex three dimensional lignin structure it is crucial to find appropriate solvents, especially for detailed structural analysis using spectroscopic or chromatographic methods. It is known that lignins are generally insoluble in water and most of the organic solvents, with the exception of Organosolv-processed lignins which show a higher solubility in organic solvents than conventional industrial lignins. Here, the solubility of OBL was examined in a variety of nonpolar to polar solvents and corresponding mixtures (Table 2) as classified by Reichardt [12]. Solvents are mainly divided in terms of their polarity and protic behavior. Organosolv lignin is insoluble in water but shows good solubility in protic polar such as methanol and ethanol and aprotic polar solvents like acetonitrile and acetone. The highest solubilites were observed in dioxane, tetrahydrofuran and pyridine which are aprotic apolar, protic polar and aprotic dipolar solvents, respectively. Cybulska et al. [5] investigated the solubility of Organosolv lignins derived from cord grass, switch grass and corn stover in DMSO, dioxane, methanol, ethanol, ethyl acetate and methyl isobutyl ketone MIBK. They found best solubility values in methanol as protic polar solvent and dioxane as aprotic apolar solvent and rather poor solubility in DMSO, ethyl acetate and MIBK as aprotic polar solvents in particular for cord grass lignin. Corn stover lignin isolated via Organosolv treatment showed better solubility in aprotic polar solvents and switch grass Organosolv lignin is poorly soluble in all applied solvents]. The solubility studies were significant to specify appropriate solvents for structurale analysis via UV–Vis spectroscopy (in 1,4-dioxane), SEC (in THF) and NMR spectroscopy (in pyridine). Due to rather high quantitative solubility values no further modifications (e.g. acetylation) were required.

UV–Vis Spectroscopy

UV–Vis spectroscopy studies were performed using 1,4-dioxane as solvent in a wavelength region of 260–400 nm (Fig. 3). Both lignin fractions show similar results: a typical UV absorption with maxima at 280 nm and 276 nm, respectively corresponding to electron excitation of conjugated phenolic groups. Xu et al. investigated sequential extractions of Eucommiaulmoides Olive to get G-rich and S-rich lignin fractions. They found small differences caused by lignin units: G-rich lignin fractions exhibit their absorption maximum at 280 nm, S-rich lignin fractions between 268 and 276 nm [13]. Studies specifying G and S lignin distribution in beech wood also show a maximum at 280 nm for G rich lignins, S rich lignins exhibit an absorption maximum at 274 nm [14]. The maximum absorption of OBL_1 is located at 280 nm, OBL_2 at 276 nm. This bathochromin shift of OBL_1 could be explained by higher content of S units. Thus, UV–Vis absorption spectroscopy could be used as an efficient and practical method for an initial qualitative study of lignin units.

Physicochemical Characteristics of Organosolv Derived Lignin

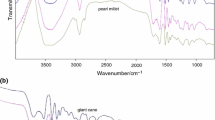

Fourier Transformation Infrared (FTIR) Spectroscopy

FTIR-spectra of Organosolv lignins are given in Fig. 5; the corresponding assignments and references are summarized in Table 4. According to former studies, the network of hardwood lignin is mainly composed by GS units. These units are mostly bonded via β-O-4-linkages. A broad absorption band at 3430 cm−1 is assigned to aromatic and aliphatic OH groups, bands at 2940, 2840 and 1460 cm−1 are related to C–H vibration of CH2 and CH3 groups, absorptions at 1600, 1515 and 1425 cm−1 are related to aromatic ring vibrations of the phenyl propane skeleton. The absorption at 1700 cm−1 can be attributed to non-conjugated carbonyl groups. The presence of phenolic OH groups is shown by absorption bands at 1330 and 1365 cm−1, whereas the one at 1030 cm−1 is related to primary alcohols. Absorptions at 1330, 1220 and 834 cm−1 are assigned to the syringyl units, while small shoulders at 1270, 1120 and 1153 cm−1 can be attributed to the guaiacyl units. The Organosolv process results in cleavage of the β-O-4-linkages which are mainly present in beech wood lignin generating both, phenolic hydroxyl (1365 cm−1) and carbonyl groups (1700 cm−1) [15].

31P NMR Spectroscopy

The beech wood lignin samples were phosphitylated with 2-chloro-4,4,5,5-tetramethyl-1,2,3-dioxaphospholane and analyzed via quantitative 31P NMR spectroscopy (with endo-N-hydroxy-5-norbornene-2,3-dicarboximide as internal standard) according to the method described by Granata and Argyropoulos [16]. The obtained spectrum (Fig. 4) provides information about the concentration of each hydroxyl group calculated in reference to the hydroxyl content (mmol g−1) of the internal standard.

According to the results obtained from 31P NMR spectra, Organosolv-isolated lignin samples exhibit considerable quantities of G and H units and rather low amounts of S units (see Table 3). It shows the presence of aliphatic hydroxyl groups (δ 146–149 ppm, 0.38 mmol g−1), amounts of syringyl units (δ 143–144 ppm, 0.12 mmol g−1), guaiacyl units (δ 142–143 ppm, 0.25 mmol g−1), hydroxyphenyl units (δ 139–140 ppm, 0.27 mmol g−1) and low amounts of carboxylic acid (δ 135 ppm, 0.02 mmol g−1). The high amount of guaiacyl hydroxyl units in OBL is a consequence of cleavages of β-O-4 linkages. The resulting ratios of monomeric units (H/G/S) were 32/49/19 for OBL_1 and 43/40/17 for OBL_2. The beech wood lignin data obtained by Faix et al. [17] show monomeric ratios of beech milled wood lignin of 4/56/40. El Hage et al. [4] investigated Organosolv lignin from Miscanthus and found hydroxyl amounts: aliphatic 1.19 mmol g−1, syringyl 0.13 mmol g−1, guaiacyl 1.33 mmol g−1 and hydroxyphenyl 0.61 mmol g−1. Regarding the results of Faix et al. our beech wood lignins show higher amounts of hydroxyphenyl units arising from Organosolv isolation method cleaving mainly the β-O-4 bonds. These results were also confirmed by pyrolysis-gas chromatography/mass spectrometry.

Thermogravimetric Analysis (TGA)

The thermal behavior of lignin was determined by thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). The thermogram of beech wood lignin (Fig. 7) shows that the thermal degradation of lignin occurs in a broad temperature range (100–700 °C). This can be explained by the fact that lignin represents a complex structure consisting of phenolic hydroxyl, carbonyl and benzylic hydroxyl functionalities. Several stages of weight-loss can be observed in the TG curves. Initially, the decrease in loss of weight was attributable to moisture present in the lignin sample and to the release of volatile products such as carbon dioxide and carbon monoxide up to 200 °C [7]. According to Wittkowski et al. [18] the degradation of propanoid side chains of lignin occurs between 230 and 260 °C with formation of methyl, ethyl, and vinyl guaiacol derivatives. Aryl ether bonds also have a low thermal stability, they can be cleaved at temperatures below 310 °C. According to the investigations of Nimz, more than 65 % of the monomer units of beech wood lignin are connected by β-O-4 linkages [15]. The major degradation occurs between 200 and 600 °C. The first derivative of the TG curves leads to the DTG curve which shows the corresponding rate of weight-loss. The curves are presented in Fig. 6 and show maximal values at 381 and 346 °C (DTGmax), respectively, with a weight-loss value of 0.4 % °C−1. This value expresses the decomposition temperature and can be used as reference to compare different lignins. In general, DTGmax values vary between 350 and 425 °C for softwood and hardwood lignins [19]. The decomposition temperature strongly depends on the molecular structure of lignin. Lignins with high contents of G units exhibit higher molecular weights caused by intermolecular C–C bonds, which have a high stability and are not cleaved during the pulping processes [20, 21]. This could be confirmed by our NMR results: OBL_1 offers a higher value of G units which leads to higher decomposition temperature. The presence of higher percentage of G units is also confirmed via pyrolysis-GC/MS. Dominguez et al. [7] investigated the thermal stability of Organosolv lignins from Eucalyptus. They obtained average DTGmax values of 340 °C. Nitsos et al. performed a systematic investigation of the hydrothermal pre-treatment of beech wood. Amongst other characterizations they used TGA to compare the DTG curves of untreated biomass and samples pre-treated by hydrothermal processes. The isolated beech wood lignin shows a DTGmax of 375 °C [22]. Research studies of Wen et al. on Organosolv birch wood lignin revealed a curve progression which is very similar to our obtained data. Their DTGmax is 355 °C with a rate of weight loss of 0.4 % °C−1 [23] (Table 4).

The final residual masses of the remaining charcoal are determined to be 35 % w/w for OBL_1 and 33 % w/w for OBL_2 (Figs. 5, 6 and 7).

Differential Scanning Calorimetry (DSC)

DSC is the most common method to determine thermal behavior and glass transition temperatures (Tg) of polymers, also used for various lignins [24]. The glass transition (a reversible phenomenon) is correlated to the viscoelastic behavior of amorphous polymers [25]. At temperatures below the glass transition viscoelastical materials are stiff and glassy. This stiffness decreases in the transition region; the material shows a rubber-like elasticity resulting from chain entanglements [26, 27]. Glass transitions are correlated local rotational or translational flowings of segments of the molecules at increasing temperature. Thermal expansion increases the free volume allowing these motions to take place. Glass transistions are also reported by Visthal et al. [28] for Organosolv lignin with Tg value of 97 °C; these studies were performed in order to study lignins as components in polymer blends. Softwood Kraft lignins show higher Tg values than Organosolv lignins derived from hardwoods [21]. The studied Organosolv beech wood lignin samples also show relative low Tg values of 123 °C (Figs. 8, 9).

Size Exclusion Chromatography (SEC)

The molecular weight of lignin has been analyzed through THF-eluted SEC. Due to polystyrene calibration standards the obtained data are discussed in comparison to literature studies performed under the same calibration conditions. Tejado et al. have investigated Kraft softwood lignins, Soda softwood lignins and Organosolv hardwood lignins. Technical Kraft lignins showed a weight average of 8700 g mol−1, Organosolv lignins from hardwood (tamarind) exhibited a molecular weight of 3100 g mol−1 [19]. Results of Kim et al. [28] show molecular weights of 4168 g mol−1 for Organosolv-treated poplar wood using an alkaline catalyst.

As confirmed by solubility tests a previous acetylation was not necessary as Organosolv lignins are very good soluble in THF (see Table 2). Figure 10 shows the chromatogram for the Organosolv-treated lignin samples.

Table 5 summarizes the determined average molecular weight Mw, number-average molecular weight Mn and the molecular weight distribution or polydispersity (Mw/Mn). Organosolv lignins show a low weight average compared to industrial lignins isolated via Kraft pulping. The rather low polydispersity value is most likely a result of significant degradation due to β-aryl-ether bond splitting during the Organosolv isolation process. These results are in line with low molecular weights reported in literature for Organosolv-isolated lignins using polystyrene standard [29]. The rather low polydispersity values indicate narrow molecular weight distributions.

The results of Erdocia et al. showed lower content of Klason lignin and higher sugar content. Their characterization methods also include SEC analysis. The results of the three different Organosolv processes exhibit molecular weights of about 16.400 g mol−1 for Acetosolv lignin and 7900 g mol−1 for Formosolv lignin. These values seem to be rather high for Organosolv lignins and might be caused by lower reaction temperature and shorter cooking time [8]. Zhang postulated a higher degree of cleavage of ether bonds and thus lower molecular masses with higher reaction temperatures and reaction times [30].

Pyrolysis-GC/MS

Among the different degradation techniques, pyrolysis in combination with gas chromatography and mass spectrometry detection allows an online degradation and fragment analysis of the samples. Today, pyrolysis-GC/MS is an established technique to determine decomposition characteristics and monomeric contents also for lignins. Pyrolysis decomposes a sample in the absence of oxygen into molecules of lower mass which can be detected by GC or MS. That results in a pool of fragments, a fingerprint, which is characteristic for each sample. There are basically two methods which are applied in pyrolysis research studies: the continuous mode and the pulse mode. In the continuous mode the sample is placed into a furnace and the temperature is kept fixed during the pyrolysis procedure. The pulse mode requires an introduction of the sample on a cold pyrolysis probe, which is then rapidly heated to the desired pyrolysis temperature (mainly applied: Curie-point pyrolysis). Curie-point pyrolysis of beech milled wood lignin has been investigated by Genuit, Boon and Faix [17]. Their results specifically show fragments of syringyl (S), guaicacyl (G) and p-hydroxyphenyl units (H) which is in line with the estimated SGH ratio on the basis of chemical degradation by Nimz [15]. The pyrogram also reveals fragments derived from carbohydrates. Lignin and polysaccharides are connected through covalent bonds to lignin carbohydrate complexes (LCC) [31]. Carbohydrates, which are not completely removed, can be detected by Py–GC–MS. So, pyrolysis coupled to GC/MS gives valuable information about the relative amounts of lignin and carbohydrates. The pyrograms of Organosolv lignins OBL_1 and OBL_2 are shown in Figs. 11 and 12. The nature and molecular weight of the released compounds after pyrolysis at a temperature of 550 °C are listed in Tables 6 and 7. Besides the fragments of SGH units there are small quantities of fragments originating from carbohydrate residues. Here, we found these small quantities of carbohydrates due to the lower detection limit of 1 ppb. The detection limit of HPLC is 10 ppb, so carbohydrates were not found. NMR results show a higher content of H and G units for OBL_2. These results are confirmed by pyrolysis and GC/MS fragment analysis.

Scanning Electron Microscopy (SEM)

The differences in morphology of Organosolv derived beech wood lignin can also be observed via SEM (see Figs. 13, 14). The SEM image of OBL_2 shows lignin of a rounded semispherical shape with open spaces on the rough surface. In contrast to OBL_1 the surface structure appears more homogenous most probably due to the milder pulping treatment without acidic catalysts.

Conclusions

Beech wood lignin isolated via Organosolv treatment has been characterized. The application of different process parameters mainly results in different molecular weights and decomposition temperatures. OBL_1 has been isolated using sulfuric acid as catalyst, whereas OBL_2 has been extracted without catalyst but at double process duration time. The fractionated lignins are found to be highly pure without carbohydrate residues. This enables conclusions to the pulping and isolation processes and the corresponding bond cleavages between lignin and carbohydrates. NMR studies revealed a HGS ratio of 32/49/19 for OBL_1 and 43/40/17 for OBL_2. Furthermore, the lignin showed a high solubility in the applied solvents like THF, pyridine and 1,4 dioxane. Concerning the three dimensional macromolecular structure the samples exhibit a rather low molecular weight and polydisperisty. Thermal analysis studies using TGA and DSC demonstrated typical thermal behavior for Organosolv-fractionated lignins. Organosolv-treated beech wood lignin samples exhibit decomposition temperatures (Td) of 381 and 348 °C and glass transition temperatures (Tg) of 123 and 124 °C. Pyrolysis studies presented an individual pyrogram with fragments that originated from HGS units which are in agreement with NMR analyses. Additional SEM studies show differences in morphology dependent on acid catalysts used for lignin isolation. In summary, the Organosolv process seems to be an efficient method to isolate pure lignin fractions. Resulting molecular weights are dependent on reaction time and catalysts used for lignin isolation. Thus, the presented study provides beneficial data for the utilization of beech wood lignin for chemical synthesis and material development.

References

Kamm B, Kamm M, Hirth T, Schulze M (2006) Lignocelluloses based chemical products and product family trees in biorefineries-industrial processes and products. Wiley-VCH, Weinheim

Gosselink RJA, de Jong E, Guran B, Abacherli A (2004) Ind Crops Prod 20:121–129

Lora JH, Glasser WG (2002) J Polym Environ 10:39

El Hage R, Brosse N, Chrusciel L, Sanchez C, Sannigrahi P, Ragauskas A (2009) Polym Degrad Stab 94:1632

Cybulska I, Brudecki G, Rosentrater K, Julson J, Lei H (2012) Bioresour Technol 118:30

de Wild PJ, Huijgen WJJ, Heeres HJ (2012) J Anal Appl Pyrolysis 93:95

Domínguez JC, Oliet M, Gilarranz MA, Rodríguez F (2008) Ind Crops Prod 27:150

Michels J, Wagemann K (2010) Biofuels Bioprod Bioref 4:263–267

Mansouri N, Salvado J (2006) Ind Crops Prod 24:9

Sun SN, Cao XF, Xu F, Sun RC, Jones GL, Baird M (2014) Carbohydr Polym 101:1191

Erdocia X, Prado R, Ángeles Corcuera M, Labidi J (2014) J Ind Eng Chem 20:1103–1108

Reichhardt C (2010) Solvents and solvent effects in organic chemistry. Wiley VCH, Weinheim

Xu F, Jiang JX, Sun RC, Tang JN, Sun JX, Su YQ (2008) Wood Sci Technol 42:211

Takabe K, Miyaucbi S, Tsunoda R, Fukazawa K (1992) IAWA bulletin 13:105

Nimz H (1974) Angew Chem 9:336

Granata A, Argyropoulos DS (1995) J Agric Food Chem 43:1538

Faix O, Genuit W, Boon JJ (1987) Anal Chem 59:508

Wittkowski R, Ruther J, Drinda H, Rafiei-Taghanaki F (1992) ACS Symp Ser 490:232

Tejado A, Pena C, Labidi J, Echevierra JM, Mondragon I (2007) Bioresour Technol 98:1655

El-Saied H, Nada AMA (1993) Polym Degrad Stab 40:417

Glasser WG, Jain RK (1993) Holzforschung 47:225

Nitsos CK, Konstantinos AM, Triantafyllidis KS (2013) ChemSusChem 6:110

Wen JL, Xue BL, Sun SL, Sun RC (2013) Chem Technol Biotechnol 88:1663

Glasser WG (2000) American Chemical Society 216

Irvine GM, Clayton V (1985) Wood Sci Technol 19:139

Kaelbe DH (1971) Physical chemistry of adhesion. Wiley Interscience, New York

Aklonis JJ, MacKnight WJ, Shen M (1972) Introduction to polymer viscoelasticity. Wiley Interscience, New York

Kim JY, Oh S, Hwang H et al (2013) Polym Degrad Stab 98:1671–1678

Vishtal A, Kraslawski A (2011) Bioresources 6:3547

Zhang J, Deng H, Lin L, Sun Y, Pan C, Liu S (2010) Bioresour Technol 101:2311–2316

Jung HG, Deetz DA (1993) Forage cell wall structure and digestibility. American Society of Agronomy, Crop Science Society of America, Soil Science Society of America, Wisconsin, pp 315–346

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D, Determination of structural carbohydrates and lignin in biomass, Laboratory Analytical Procedure (LAP) Issue Date: 4/25/2008, Technical Report NREL/TP-510-42618

Acknowledgments

Professor Bodo Saake (vTI Hamburg) is gratefully acknowledged for the kind delivery of lignin samples, FNR 22027405.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hansen, B., Kusch, P., Schulze, M. et al. Qualitative and Quantitative Analysis of Lignin Produced from Beech Wood by Different Conditions of the Organosolv Process. J Polym Environ 24, 85–97 (2016). https://doi.org/10.1007/s10924-015-0746-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-015-0746-3