Abstract

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) and poly(ε-caprolactone) (PCL) and a PHBV/PCL blend with a 75/25 composition (wt%) were processed by injection molding and then subjected to 50 and 100 kGy of gamma radiation. The crystallinity of pure PHBV and PCL and the PHBV/PCL blend was found to increase slightly after gamma radiation, suggesting that radiation in the doses studied here probably caused the scission of polymer chains. The slight increase in crystallinity sufficed to significantly augment the Young’s modulus and ultimate tensile strength of the materials and to decrease their elongation at break. The shifts in the Tg of pure polymers in the PCL/PHBV blend suggest that a chemical interaction was favored by exposure to gamma radiation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Blending two or more polymers together is a practical and economical way to develop new materials with unique properties unlike those of their pure constituents [1].

In the field of biodegradable materials, the combination of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) and poly(ε-caprolactone) has a promising potential for both automotive and biomedical applications, since these two polymers are biodegradable, biocompatible and nontoxic, and can be processed in equipment commonly used for synthetic polymers.

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) is a hydroxyvalerate (HV)-hydroxybutyrate (HB) copolymer that is synthesized by many types of bacteria that consume sugar in the presence of propionic acid or is produced directly from plants [2]. According to the conditions of the bioreaction, PHBV can be produced with units up to 30 %. The properties of the copolymer can be tailored by varying the HV content. For example, an increase in the ratio of HV to HB content increases the material’s impact strength and decreases its melting temperature, crystallinity [3], and tensile strength [4]. The practical application of PHBV has been limited by its brittleness, low impact strength and its narrower processing window than that of petroleum based-synthetic polymers [5, 6]. An interesting alternative is to blend PHBV with PCL, which is extremely flexible and biodegradable polyester. The mixture of these two polymers can result in materials with good properties.

The literature contains reports of studies focusing on blends of PHBV with poly(ε-caprolactone) (PCL). The miscibility and crystallinity of PHBV/PCL blends prepared by dissolution in solvents were examined by [7–9]. In these studies, the PHBV/PCL blends were found to be immiscible and their crystallinity was influenced by the blend’s composition. In another study, the preparation of PHBV/PCL blends in the melt state, in the presence of supercritical CO2, resulted in the development of miscibility between PCL and PHBV [10].

Gamma radiation is an interesting technique to improve the physical and mechanical properties of polymers and to sterilize medical devices made of polymers [11, 12]. Irradiation induces two molecular phenomena in a polymer. One phenomenon is main-chain scission, which decreases the polymer’s molar mass, and the other is chain crosslinking, which increases its molar mass and results in the formation of a network structure. The two phenomena may occur simultaneously and influence the final properties of materials [13]. These molecular changes depend on the radiation dose, temperature, and the polymer’s chemical structure. The effect of gamma radiation on the properties of PHBV and PCL has been investigated in several studies [14–17], but no studies have been published about the effect of gamma radiation on the PHBV/PCL polymer blend.

In this work, PHBV/PCL blends were gamma irradiated to compatibilize the polymers. The effect of gamma radiation on the thermal, mechanical and dynamic mechanical properties of PHBV/PCL blends was investigated.

Experimental

Materials

-

Poly(ε-caprolactone) (PCL) with MW: 50,000 g/mol was supplied by Union Carbide do Brasil (Cubatão, SP, Brazil).

-

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) with MW: 600,000 g/mol and 18 wt% of HV was donated by PHB Industrial S.A. (Serrana, SP, Brazil).

Processing of Polymers and Blends

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) polymers (in powder form) and PCL (in pellet form) were first dried in an air circulation drying oven at a temperature of 50 °C. The PHBV powder was processed into pellets in an IMACOM twin-screw extruder (L/D = 40 and D = 35 mm) operating at a screw speed of 200 rpm. The average temperature profile applied in different heating zones was 125/165/165/165/165/165.

The PHBV/PCL blends were prepared by premixing the pelletized PCL and PHBV polymers in ratio of 75:25 wt% (w/w) in a Henschel mixer to ensure proper homogenization. The resulting mixture was processed under the same conditions as those employed to pelletize the PHBV.

The PCL and PHBV polymers and extruded PHBV/PCL blends were injection molded in an Arburg 270 V 300–120 Allrounder machine. The injection conditions were: temperature profile of 155/160/170/170/170, molding temperature of 40 °C, injection pressure of 620 bar and injection speed of 20 cm/s.

After the process, the materials were stored in an atmosphere with 54 % relative humidity for 72 h to stabilize the morphological structure of the polymers.

Irradiation of Samples

The samples were irradiated out at IPEN-CNEN/SP, using a Co-60 Multipurpose Irradiator (GammaCell, model 220). The gamma radiation doses were 50 and 100 kGy, at a rate of 4.3 kGy/h, and air atmosphere and temperature of 25 °C. Table 1 describes the formulations and respective nomenclature of each formulation.

Characterization of Polymers and Blends

Soxhlet Extraction

Samples of approximately 1.0 g of dry irradiated and non-irradiated material were placed in a Soxhlet apparatus and extracted with 150 ml of chloroform for 30 min.

Differential Scanning Calorimetry (DSC)

Pure polymers (PHBV, PCL) and PHBV/PCL blends were analyzed by differential scanning calorimetry (TA Instruments Thermo DSC-Q100). For the DSC scans, the samples (Approximately 7 mg) were heated from 25º to 200 °C in a low pressure pan, applying a heating rate of 20 °C/min and a nitrogen flow of 50 ml/min. The melting temperature (Tm) and melting enthalpy (ΔHm) were determined from the smallest peak and the area of the melting peak in the DSC curves, respectively. The degree of crystallinity (XC) of the PHBV and PCL in the blends was calculated from the relationship between the values of ΔHm determined in the DSC curves and the data of the theoretical heat of fusion of the hypothetically 100 % crystalline PHBV (146 J/g) [18] and the hypothetically 100 % crystalline PCL (139.5/g) [19], using the following equation:

where ΔHm is the enthalpy of fusion in the DSC curves of pure polymer or PHBV/PCL blends, Wp is the mass fraction of the polymer in the blend, and \( \Updelta {\text{H}}_{\text{m}}^{^\circ } \) is the enthalpy of fusion of the 100 % crystalline polymer.

Dynamic Mechanical Thermal Analysis (DMTA)

This analysis was carried out using a TA Instruments DMA 2980 dynamic mechanical analyzer, in the 3-point bending mode, according to the ASTM D5023 standard. The conditions of the experiment were: temperature range of −80 to 40 °C, frequency of 1 Hz, and heating rate of 2 °C/min.

Mechanical Testing

The tensile tests were carried out in an Instron 5500R universal testing machine with a 50 kJ load cell, at constant cross-speed of 100 mm/min. The tensile strength tests were performed on specimens with dimensions specified by the ASTM D638 standard and following this standard’s analytical procedure. The results reported here represent the mean value of 7 samples.

Results and Discussion

The solubility test showed that the pure polymers and PCL/PHBV blends non-irradiated and irradiated with 50 and 100 kGy were completely soluble in chloroform. This suggests that crosslinking of the samples did not occur during their exposure to gamma rays.

Figure 1 depicts the DSC curves of the pure polymers (PHBV and PCL) and PHBV/PCL blends (75/25) before and after 50 and 100 kGy of gamma irradiation. Table 2 lists the melting temperatures (Tm) and degree of crystallinity (XC) of pure polymers and their values in the blends. Gamma radiation was found to have a minor effect on Tm, leading to a decrease of only 0.5–5 °C. The degree of crystallinity (XC) of pure PHBV and PCL and of the blends was slightly higher when compared with their respective non-irradiated samples. This behavior is attributed to chain scission, which releases macromolecular fragments that can rearrange into new crystalline structures, probably on existing crystals [20]. Other authors have reported similar behavior [14, 21–24], and attributed the decrease in Tm and the increase in crystallinity to main-chain scission caused by gamma radiation. Mitomo et al. [22] reported that PHBVwith 20 % of HV content showed chain scission when irradiated with doses of 50 and 100 kGy. Luo and Netravali [23] reported that no crosslinking reactions were observed in PHBV after up to 100 kGy of irradiation. According to Narkis et al. [21], the irradiation of PCL causes mainly chain scissions at doses below 250 kGy, leading to a 50–60 % increase in crystallinity in response to radiation doses varying from 0 to 250 kGy.

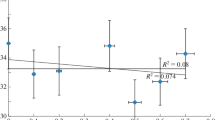

Figure 2 shows the results of the tensile tests of PHBV, PCL and PHBV/PCL blends (75/25) before and after 50 and 100 kGy of gamma irradiation. PHBV (0 kGy) showed rigid and brittle behavior, characterized by low elongation of the material, and sudden and severe rupture. On the other hand, PCL (0 kGy) showed ductile behavior characterized by high deformation. This behavior is associated with the glass transition temperature (Tg) of PCL (−60 °C), which is well below room temperature (25 °C). A comparison of the mechanical properties of the PHBV/PCL blends (0 kGy) (75/25) and those of the pure polymers (PCL (0 kGy) and PHBV (0 kGy)) indicated that the addition of 25 % of PCL to PHBV increased the elongation at break (εr) by approximately 700 % and decreased the ultimate tensile strength (σr) and Young’s modulus (E) by 52 and 20 %, respectively, compared to those of pure PHBV.

The mechanical properties of the pure polymers and the PHBV/PCL blend showed changes in response to irradiation. The values of E of the PCL and the PHBV/PCL blend increased significantly with irradiation, but did not vary significantly in pure PHBV. The σr values of PHBV and of the PHBV/PCL blend increased significantly in response to the increase in the irradiation dose from 50 to 100 kGy, whereas the PCL showed no significant change. The εr values decreased sharply in pure polymers and in the blends in response to gamma ray exposure. The σr values increased significantly in PHBV and the PHBV/PCL blends upon increasing the irradiation dose from 50 to 100 kGy, whereas the PCL showed no significant variation. The irradiated PHBV showed a significant increase in σr when compared to non-irradiated PHBV. The PHBV/PCL blend showed increases in the σr values of 360 % (50 kGy) and 650 % (100 kGy) over the non-irradiated blends.

Overall, the increase in E and σr and decrease in εr values can be explained by the increase in crystallinity caused by the chain scission phenomenon. Although the increase in crystallinity was slight, it may have had a significant effect on the mechanical properties. In the case of PHBV, due to its high stiffness (Tg above room temperature), the increase in crystallinity did not suffice to cause significant changes in the values of E.

Figures 3 and 4 illustrate the results of the DMTA of the different formulations. Tan δ curves for PHBV show a peak at about 13 °C, which is related to glass transition (Tg) but which was not detected in the DSC tests, probably due to the lower sensitivity of the technique. It was also found that the glass transition temperature (Tg) of the irradiated and non-irradiated PHBV samples showed no significant variation. This is an indication that doses of 50 and 100 kGy of gamma irradiation did not affect the amorphous phase. On the other hand, like the PCL, the Tg increased from −42 to −35 °C in response to 100 kGy of irradiation. The Tan δ peak of the irradiated samples also decreased when compared to that of non-irradiated PCL. The shift in Tg to higher temperatures and the decrease in the Tan δ peak indicates the diminished mobility of the amorphous phase, which may have been caused by scission in the amorphous regions, leading to increased crystallinity.

The Tan δ curves obtained for the PHBV/PCL blends showed two transitions: the first corresponding to the glass transition of PCL and the second to higher temperatures related to PHBV. Moreover, the non-irradiated blend showed no shift in such transitions compared to the transitions of pure polymers, indicating that these blends are immiscible and there is little interaction between them. In the case of irradiated blends, the PCL showed a minor increase in Tg while the PHBV showed a slight decrease in Tg. These shifts in glass transitions may be due to some degree of interaction resulting from chemical changes that occurred during gamma exposure.

Conclusion

The results showed that gamma exposure in doses of 50 and 100 kGy caused main-chain scissions, although no evidence of polymer chain crosslinking was found in the pure polymers or blends. The crystallinity of pure PHBV and PCL and of their blends increased slightly in response to gamma radiation, sufficing to cause a significant increase in the materials’ Young’s modulus and ultimate tensile strength and to decrease the elongation at break of PHV/PCL blends. The shifts in the Tg of the pure polymers in the PCL/PHBV blend suggested that some chemical interaction was favored during gamma exposure. Further studies are needed to analyze the effect of gamma radiation on PHBV/PCL blends at doses above 100 kGy, and to gain a better understanding of the mechanisms of degradation caused by gamma irradiation by evaluating the molar mass of PHBV/PCL blends.

References

Utracki LA (2002) Introduction to polymer blends in polymer blends handbook, vol 1. Kluwer Academic Publishers, Dordrecht

Yu L, Dean K, Li L (2006) Prog Polym Sci 31:576

Amass W, Amass A, Tighe B (1998) Polym Int 47:89

Kotnis MA, O’Brien GS, Willett JL (1995) J Env Polym Deg 3:97

Ha CS, Cho WJ (2002) Prog Polym Sci 27:759

Corradini E, Marconcini JM, Agnelli JAM, Mattoso LHC (2011) Carbohy Polym 83:959

Chun YS, Ki WN (2000) Polymer 41:2305

Qiu Z, Yang W, Ikehara T, Nishi T (2005) Polymer 46:11814

Lovera D, Márquez L, Balsamo V, Taddei A, Castelli C, Muller AJ (2007) Macromol Chem Phys 208:924

Jenkins MJ, Cao Y, Howell L, Leeke GA (2007) Polymer 48:6304

Chmielewski AG, Haji-Saeid M, Ahmed S (2005) Nucl Instrum Methods Phys Res B 236:44

De Paoli MA (2009) Polymers degradation and stabilization (in Portuguese), Artliber, São Paulo

Södergard A (2004) J. Bioact Compat Polym 19:511

Yang H, Liu J (2004) Polym Internat 53:1677

Kodama Y, Machado LDB, Giovedi C, Nakayama K (2007) Nucl Instrum Methods Phys Res B 265:294

Kodama Y, Machado LDB, Giovedi C, de Lima NB, Nakayama K (2009) Nukleonika 5:107

Luk JZ, Rondeau E, Trau M, Cooper-White J, Grondahl L (2011) Polymer 52:3251

Barham PJ, Keller A (1986) J Polym Sci, Part B: Polym Phys 24:69

Avella M, Errico ME, Rimedio R, Sadocco P (2002) J Appl Polym Sci 83:1432

Oliveira LM, Araújo ES, Guedes SML (2006) Polym Degrad Stabil 91:2157

Narkis M, Sibony-Chaouat S, Siegmann A, Shkolnik S, Bell JP (1985) Polymer 26:50

Mitomo H, Watanabe Y, Yoshii F, Makuuchi K (1995) Radiat Phys Chem 46:233

Luo S, Netravali AN (1998) J Appl Polym Sci 73:1059

Luk JZ, Rondeau E, Trau M, Cooper-White J, Grøndahl L (2011) Polymer 52:3251

Acknowledgments

The authors acknowledge the following Brazilian organizations: PHB Industrial, for supplying the PHBV polymer, IPEN (Institute for Energy and Nuclear Research), for irradiating the samples, and CNPq for its financial and technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosário, F., Corradini, E., Casarin, S.A. et al. Effect of Gamma Radiation on the Properties of Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/Poly(ε-Caprolactone) Blends. J Polym Environ 21, 789–794 (2013). https://doi.org/10.1007/s10924-013-0573-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-013-0573-3