Abstract

Historical textiles suffer from deterioration as a result of exposure to uncontrolled environmental conditions in museums. To establish standard conditions for display of undyed and dyed silk fabrics in Egyptian museums, different artificial aging procedures (thermal, light and chemical) were applied to examine their effects on the physical, mechanical and chemical structure of the silk fiber. Samples of undyed silk and silk dyed with madder with different mordants, iron II sulphate; iron III chloride and copper sulphate were used for this purpose. These aged samples were examined for their surface morphology, color parameters (CIE Lab), mechanical properties, degree of crystallinity, secondary structure analysis and amino acids content.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Silk is a natural fiber which is susceptible to deterioration from environmental conditions. Raw silk produced by silkworms consists of protein fibers called fibroins, which are joined to one another by rubber-like proteins, known as sericin. Fibroin is a polypeptide, 90% of which consists of four amino acids: glycine, alanine, serine and tyrosine. Whereas formerly silk containing sericin was used for the production of silk fabrics, nowadays degummed silk, i.e. fibers devoid of sericin, is used. Fabrics produced from degummed silk are more susceptible to light induced destruction. Sericin protects fibers against light damage, but it readily turns yellow with time. Silk polymers may be considered to have the same composition as that of wool except that the silk polymer contains no disulphide bonds and its molecular chains not coiled but are aligned along the fiber axis forming the well-known β-sheets crystals [1–6].

Needles et al. investigated the effects of natural dyes and mordants on degradation in silk and wool subjected to xenon light and soil burial tests. Results showed that the mordanting agents improved the light fastness of the dyes but increased burial-induced color change. Many authors have studied the effect of light, temperature, humidity and washing on dyed silk with natural dyes [7]. Brigtti and David studied the effect of light from a fadometer lamp and they found that fustic dye was the most sensitive yellow dye, indigo and cochineal dyes have a moderate fastness to the light while madder and logwood dyes the most stable dyes [8, 9]. Researchers Garside et al.; Osman et al.; Kim and Wyeth; Kim et al.; and Leene et al., studied the effect of artificial aging on silk. These authors evaluated changes in the degree of polymerization, color measurements, acid content, fiber tenacity and elongation. They concluded that aging and deterioration resulted from a complex combination of degradation forces [10–14].

This research was undertaken to characterize physical and chemical degradation and changes in properties of artificially aged silk. Different aging procedures such as light, thermal and chemical were applied on undyed silk and on silk dyed with the natural dye madder mordanted with different mordants e.g., iron II sulphate, iron III chloride and copper sulphate. This information will aid in establishing standard conditions of light and temperature at which the archeological textile objects can be maintained to minimize deterioration. Methods of analysis included tests of surface morphology, color parameters (CIE Lab), mechanical properties, degree of crystallinity, secondary structure analysis, and content of amino acids. Figure 1 shows examples of textiles having exposure to uncontrolled environmental conditions in the Museum of Faculty of Archeology, Cairo University, Egypt.

Experimental

Materials

A silk fabric was degummed by a double treatment in a nonionic detergent (7 g L−1) at 95 °C for 30 min, washed twice with distilled water and extracted with petroleum ether. All sericin, representing 34% of the silk samples was removed by this treatment. The fabric, thus, contained only fibroin was then stored at 20 ± 2 °C and 65 ± 5% relative humidity [15].

-

Greek silk fabrics were supplied by TSIAKIRIS Co., Soufli—Greece.

-

Iron II sulfate FeSO4, Iron III chloride FeCl3 and Copper sulfate CuSO4·5H2O was purchased from Fluka.

-

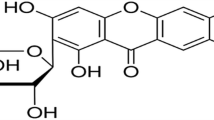

Madder dye was obtained from Wild Colours, Birmingham, UK. www.wildcolours.co.uk.

Dyeing

Extraction of Dye

The dyeing with madder dye 10% (w/v) was carried out according to the following steps:

-

Grinding the dye to be a fine powder.

-

Soaking the powder in the distilled water for 24 h to extract the color from the powder.

-

Heating the extract to boiling temperature for 2 h with continuous stirring. Water was added to compensate for the evaporated water during the heating process.

-

The extract was cooled and then filtered many times to get a clear colored solution.

Dyeing Procedure

The dyeing procedure was performed by the exhaustion method according to Bechtold [16] using a liquor ratio (LR) of 1:20 (For 1 g of goods a dye bath volume of 20 mL is applied). Ten grams of degummed silk fabric were used as protein fiber substrate. The dyeing experiments were performed in a beaker according to the temperature-dyeing diagram given in Fig. 2. In experiments with the addition of mordants, iron II sulphate, Iron III chloride and Copper sulfate were added as concentrated solution (50 g L−1) to give a final dye bath concentration of 2.5 or 5 g L−1 mordant. After dyeing, the unfixed dyestuff was removed by rinsing three times with cold water (5 min, room temperature, LR 1:20).

Thermal Aging

Silk dyed samples were hung in a temperature-controlled oven “Herous-Germany” on special frames. The samples were thermally aged separately at a temperature of 100 °C for different periods of 3, 6, 10, 12, 15, 18 days. Some studies refer that the thermal aging process of 100 °C for 3 days equals 25 years of aging in normal conditions. This is an experimental laboratory attempt for making the characteristics of modern samples similar to the old fabrics [17].

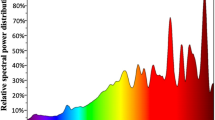

Light Aging

Irradiation of the silk samples, 5 cm width and 20 cm long, was carried by QUV Accelerated Weathering tester of the Q-Panel Lab Products; model QUV/spray that equipped with 500 watt MBTL lamp, 60 °C, 60% relative humidity (RH). The samples were mounted in the cells and irradiated for 36, 72, 108 and 154 h. To monitor temperature and relative humidity more accurately in the large chamber area, a number of temperatures and RH sensors were distributed throughout the interior of the chamber as well as in the interior of the panels. The temperature and RH sensor data were logged and stored via a data acquisition system and a desktop computer [17–19].

Chemical Aging

The silk samples were immersed in different concentrations of pure sulfuric acid purchased from Aldrich Co. Separate sample was immersed in the acid solution for chemical aging and the sulfuric acid concentration were 1, 2, 3 and 4% (v/v) for 1 h. After each immersion the samples were thoroughly washed and neutralized by using a calibrated Hanna pH-Meter [17].

Examinations and Analysis

X-ray Diffraction Analysis

Wide angle X-ray scattering (WAXS) measurements of unaged and aged samples were carried out with a SIEMENS X-Ray Diffractometer—D 5000, given 40 kV CU Ka, radiation of 30 mA. The diffractograms were recorded over 2θ = 50–300 continuously at a scan rate of 20/min. Crystallinity index (crystalline to amorphous ratio) can be calculated using the following equation [20]

Where I002 is the maximum intensity (in arbitrary units) of lattice diffraction, whileIam is the intensity of the lattic diffraction in the same units at 2θ = 20, the angle that represents the amorphous scatter of fiber.

Morphological Study

The morphology of the surface of the unaged and aged fabrics was investigated to show the changes to or the damage to the fibers. Small samples were taken from different areas of the fabric samples and investigated under Quanta 200 ESEM FEG from FEI scanning electron microscope SEM [21].

Color Measurement

The dyeing properties of the aged dyed silk fabrics were examined studying two main parameters; dyeability expressed as color strength (K\S) and fastness to light which was evaluated instrumentally by measuring the color difference parameter (ΔE). This gives more accurate and precise value for the actual amount of faded dye. The CIE-Lab values of the dyeing were measured using a double beam Optimatch spectrophotometer (Datacolor international Spectraflash SF450-UK). The colors are given in CIE Lab coordinates, L* corresponding to the brightness (100 = white, 0 = black), a* to the red–green coordinate (positive sign = red, negative sign = green), and b* to the yellow–blue coordinate (positive sign = yellow, negative sign = blue). The total color difference Δ E* between two color stimuli ΔE* = {(ΔL*)2 + (Δa*)2 + (Δb*)2}1/2 [22, 23].

Fourier Transform Infra Red Spectroscopy with Attenuation Total Reflection (FTIR-ATR)

The structural changes occurring in the fibers upon ageing procedures were monitored by BRUKER’S VERTEX 70—Fourier Transform Infra Red Spectroscopy with Attenuation Total Reflection (FTIR-ATR) with resolution of 4 cm−1. The vibrational bands that appear in the infrared spectra provide information about the secondary structure of silk fabrics and information about the chemical functional groups of a sample. This leads to a general characterization of the material or the identification of specific compounds [24, 25].

Amino Acid Analysis

Amino acids analysis was carried out by using Automatic Amino Acid Analyzer AAA400 INGOS Ltd. Acid hydrolysis was made according to the method of Block et al. [26].

Mechanical Measurements

Tensile strength and elongation at break for all the samples under test were measured and evaluated using Shimadzu Universal Tester of type S-500 Japan. The measurements are carried out according to ASTM 2000, D 3822-96 standard test method for tensile properties of single textile fibers.

Results and Discussions

Effect of Ageing Conditions on the Crystallinity

Silk is a semi-crystalline protein fiber. Therefore, a study of its crystallinity may lead to a more detailed knowledge of the degradation process. Any treatment with the potential to change fiber morphology may sometimes lead to crystallization or decrystallization. It was thought worthwhile to investigate changes due to different aging methods on the silk fibers. XRD results of aged silk samples are presented in two ways. The first way presents the percentage of the crystallinity index of unaged sample and those aged by different ageing methods such as thermal, light and acid aging. As shown in Table 1, there is a drastic decrease of crystallinity index for aged silk samples. The second way is the Wide angle X-ray (WAXS) diffractograms of unaged and aged silk samples. Figure 3 illustrates WAXS diffractograms of aged silk after thermal, light and acid aging showing the effect of the ageing method conditions on the silk crystallinity. There is a drastic difference between the diffractograms of the aged and unaged silk samples due to the action of the aging process. There were drastic changes on the size and shape of the crystalline area of the samples.

Morphological Study

The morphology of the surface of the silk samples was investigated using Scanning Electron Microscope (SEM). Scanning electron micrographs were taken of selected samples to assess fiber fracture patterns and the damaged aspects on these fibers. The surfaces of the unaged silk fibers were smooth with homogeneous appearances. Some types of fiber fracture patterns and damage were identified in the aged silks with examples shown in Fig. 4.

SEM photomicrographs of silk fiber fractures. a SEM photomicrographs (×3,000) of the aged silk undyed fabrics after acid ageing (4% sulphoric acid) showed V-shaped fiber fractures and roughness on the silk fibers; b SEM photomicrographs (×3,000) of the aged silk undyed fabrics after light ageing 154 h showed axial splits and fibrils with cracks and surface flaws

Color Changes

The results in Figs. 5a and 6a show that undyed silk fabrics with exposure to light radiation gave poor-light reflectance and higher color strength than the other aging methods. These results can be explained as photo radiation increases oxidation. On oxidation, the side groups of the amino acids turn into chromophoric groups (probably quinones) causing the material to develop yellow, brown, grey or light pink color [27]. The results in Figs. 5b–d and 6b–d can be explained that light through the photolysis process can break the chromophoric group of the dye producing two separated particles with different colors. The colors are usually lighter than the original colors which results in the fading of the dyed textile. Photo-oxidation, the next step in photodegradation reactions, can transform parts of the chromophoric systems on the dye molecule into non-chromophoric groups. This results in the production of a lighter color and, thus, a faded dye [28]. The results also clarify that the improvement in the dyeing properties (K\S) of madder dye mordanted with different mordants (iron II sulphate, iron III chloride and copper sulphate) applied on silk depends on the mordant metal and takes the order: iron III chloride > iron II sulphate > copper sulphate.

Reflectance of aged undyed and dyed silk mordanted with different mordants. a Refelctance of aged uncolored silk. b Refelctance of aged silk dyed with madder mordaned with FeCl3. c Refelctance of aged dyed silk with madder mordanted with FeSO4·H2O. d Refelctance of aged dyed silk with madder mordanted with CuSo4·5H2O

Fourier Transform Infrared Spectral Analysis (FTIR)

Infrared absorption spectra of silk show characteristic absorption bands assigned to the peptide bonds (-CONH-) that are known as amide I, amide II, and amide III. Amide I is useful for the analysis of the secondary structure of the proteins and is mainly related with the C=O stretching, and it occurs in the range of 1,700–1,600 cm−1. Amide II, which falls in 1,540–1,520 cm−1 range, is related with the N–H bending and C–N stretching vibration. Amide III occurs in the range of 1,430–1,450 cm−1, and it results from C–H bending vibration. In addition, the positions of these bands indicate the conformations of the protein materials: 1,650 cm−1 (random coil) and 1,630 cm−1 (β-sheet) for amide I, 1,540 cm−1 (random coil) and 1,520 cm−1 (β-sheet) for amide II. The results in Figs. 7, 8 and 9 showed that all the amide I and amide II appeared at ≈1,620 and ≈1,513 cm−1 respectively indicating that all the silk samples present are mainly in β-sheet structure. Hydrolysis of the polypeptide chain would be apparent as an increase in the OH stretching or bending frequencies found at ≈3,400 and ≈1,650 cm−1, respectively. Since the amide I band also occurs in the region 1,615–1,650 cm−1, an increase in the OH band at 1650 would result in an increase in the absorption intensity or height of the amide I band. By comparing the relative absorption intensities of the amide I band to that of the amide II, we found that the two bands are close to the same intensity in the spectrum for the reference silk sample, while in the spectrum of aged samples, the amide I band is much higher than the amide II [29]. These conclusions are clearly seen in Figs. 7a, 8c, 9a–c, Oxidation of the polypeptide chain can result in the formation of carbonyl compounds which would absorb in the 1,650–1,750 cm−1 region. This can be seen as a slight shoulder on the amide I carbonyl band and may result in the increase in area of the amide I band as shown in Figs. 7a, 8a–c [29].

Effect of light ageing, a and b The intensities of all the bands decreased compared with that of control. These results can be explained due to the solubility of the products resulting from photo-oxidation. c The intensities of all bands increased compared with that of control as a result of hydrolysis and photooxidation

Amino Acids Content

The amino acid composition of the silk molecule is shown in Tables 2 and 3. Glycine, alanine, and serine were the most abundant amino acids, together comprising 75.05–81.89 percent of the total amino acids present. The small side chain of these amino acid residues allow the polymer molecules to pack closely together into β-pleated sheet as confirmed by FTIR results. These results agreed with that of [30–32] who reported that glycine, serine, and alanine are the major amino acids and they are aligned in β-pleated sheet, crystal structure, with the remaining bulky side chain residues in amorphous regions.

Effect of Mordants on the Amino Acids Content of Dyed Silk

The results in Table 3 showed increase in both of acidic and basic amino acids. This can be explained as these mordants accelerate hydrolysis of silk’s polymer system. The results show an increase in the hydroxylated amino acids serine and tyrosine and decrease in glycine and alanine meaning the reduction in the crystallinity of the polymer.

Effect of Artificial Ageing on the Amino Acids Content of Undyed Silk

Kim et al. [13] suggested that thermal, heat, humidity and light promoted deterioration on fibroin at the molecular and microstructural levels. Their results establish that the acid content of fibroin increases upon ageing. As the fibroin protein which comprises silk, deteriorates it undergoes an inherent increase in acidity, due to the scission of the polymer in the amorphous regions with the resultant increase in accessibility of the bulky acidic amino acid residues [1].

Effect of Light on Undyed Silk

The results in Table 4 showed a high decrease in the percentage of tyrosine (2.72%) compared with that of the standard (6.16%). These results agreed with that of Gohl and Vilenski [5] who proved that silk has a low resistance to sunlight mainly because of the lack of covalent cross-links in the polymer systems and Koussoulou and Timár-Balászy [27, 28] who clarified that the susceptibility of silk to photo deterioration is due to presence of tryptophan, tyrosine and phenylalanine amino acid residues in its amorphous regions as tyrosine and tryptophan readily undergo photo-oxidation. The results also showed a decrease in basic amino acids (B) accompanied by an increase in the acidic amino acids (A). The Changes in the B/A ratio were shown to be a good measure for the average degree of oxidation (Kite and Thomson) [33]. The results showed that the amount of hydrolyzable ammonia increased suggesting deamination was also taking place [34]. Timár-Balászy and Eastop [27] also explained this increase as ammonia is one of the photo oxidation products.

Effect of Heat on Undyed Silk

The results showed a sharp decrease in basic amino acids and increase in acidic amino acids. These results can be explained as the most common effect of heat on silk is free radical thermal oxidation. The results showed also increase in neutral amino acids and hydrolyzable ammonia in addition to decrease in the hydroxylated amino acids serine and tyrosine. These results agreed with that obtained by Timár-Balászy and Eastop and Becker [27, 34].

Effect of Acid on Undyed Silk

The results showed a slight increase in both acidic and basic amino acids suggesting hydrolysis and breakdown of silk’s polymer system. These results were also accompanied by an increase in alanine, valine, leucine, tyrosine and phenyl alanine. The hydrolysis of silk with dilute acids causes one part of the polymer to dissolve relatively rapidly; hydrolysis of the remaining part requires a longer time or a higher temperature. This is due to the fact that amorphous region can be attacked more easily, because the peptide bonds, salt linkage and hydrogen bonds are more accessible which cause rupture of these bonds.

Effect of the Ageing Methods on Mechanical Parameters of the Samples

Changes in the mechanical properties reflect not only the changes in crystalline orientation and the chemical structure of the polymer system but also its morphology [35]. The silk samples that have been aged with different aging methods (thermal, light and acid aging) showed drastic decreases in both tensile strength and elongation properties over unaged samples as shown in Table 4. The change in the mechanical properties can be correlated with the change in chemical groups and amino acids with the ageing procedures as detected from FTIR-ATR spectra (Figs. 7, 8 and 9) and amino acids content (Table 3). The observed change in the mechanical properties can be related to the changes in both amino acids and carboxyl groups content as these are the basis for salt-links between adjacent fibroin chains [11]. These results can be also explained as photo radiation tends to accelerate the decomposition of silk. It increases oxidation and results in degradation and destruction of the fiber. This in turn leads to loss of strength and color [36]. As there are no covalent cross-links between silk polymers any acidic compound will cause breakdown of silk’s polymer system. Usually this is noted as a distinct weakening of the textile material and loss of its tensile strength [5].

Conclusion

Artificial aged dyed and undyed silk fabrics were evaluated and compared to unaged fabrics to determine the extent of degradation in relationship to the aging method and the results would help in establishing the standard conditions of light and temperature at which the archeological textile objects can be maintained without any deterioration. The results established that thermal, acid and light promoted deterioration on fibroin at the molecular and microstructural levels. The deterioration decreased the percentage of the crystallinity index and changed the size and shape of the crystalline area of the samples. Aging caused drastic decreases in both tensile strength and elongation properties over unaged samples. The change in the mechanical properties can be correlated with the change in chemical groups and amino acids with the aging procedures as detected from FTIR-ATR spectra and amino acids content. The amino acid content of the unaged and aged silk fabrics were similar; however, in all the aged samples the bulky acidic amino acid residues increased as a result of the scission of the polymer in the amorphous regions. Infrared absorption spectra showed that all the amide I and amide II appeared at ≈1,620 and ≈1,513 cm−1 respectively indicating that all the silk samples present mainly in β-sheet structure. Heat aged dyed samples using iron III chloride and copper sulphate as mordants are very stable to heat; the intensities of all the bands are unchanged. With the iron II sulphate mordant, the intensities of all bands and area of the amide I band increased compared with that of the control indicating the occurrence of hydrolysis and slight oxidation. In case of both light and acid aging, all the samples with various mordants without exception showed oxidation or/and hydrolysis of protein polymer in addition to increased solubility of acid aged silk samples. The research clearly shows that changes occur in silk fabrics due to chemical, light and temperature conditions so that possible uncontrolled environmental conditions need to be changed or adjusted to minimize damage and establish standard conditions for display of silk fabrics.

References

Garside P, Wyeth P, Zhang X (2010) e Preserv Sci 7:126–131

Szostak-Kotowa J (2004) Inter Biodet Biodeg 53:165–170

Becker M, Magoshi Y, Sakai T, Tuross N (1997) Stud Conserv 42:27–37

Kaplan D, Adams W, Farmer B, Viney C (1994) In: Kaplan D, Adams W, Farmer B, Viney C (eds) Silk polymers materials science and biotechnology. American Chemical Society, Washington, pp 252–269

Gohl E, Vilensky LD (1987) Textile science: an explanation of fibre properties, 2nd edn. Longman Cheshire Pty. Ltd., Melbourne

Guiyang L, Ping Z, Zhengzhong S, Xie X, Xin C, Wang H, Chunyu L, Tongyin Y (2001) Eur J Biochem 268:6600–6606

Needles H, Cassman V, Collins M (1986) Historic textile and paper materials: conservation and characterization. In: Needles HL, Zeronian SH (eds) Advances in chemistry series 212. American Chemical Society, Washington, pp 199–210

Brigitte O (1996) Stud Conserv 41:129–131

David D, Sinclair R, Sterling D (1977) Stud Conserv 22:166–167

Garside P, Wyeth P, Zhang X (2010) J Inst Conserv 33:179–193

Osman E, Michael M, Gohar H (2010) Inter J Chem 2:28–39

Kim J, Wyeth P (2009) e Preserv Sci 6:60–67

Kim J, Zhang X, Wyeth P (2008) e Preserv Sci 5:41–46

Leene J, Demeny L, Elema R, DeGraff A, Surtel J (1958) Proceed Int Council Museums 13:107–242

Massafra M, Seli E, Salsa S, Marcandalli H (1999) J DyPig 40:171–180

Bechtold T, Turcanu A, Ganglberger E, Geissler S (2003) J Clea Prod 11:499–509

Feller L (1994) Accelerated ageing, photochemical and thermal aspects, Marina Del Rey, The Getty Conservation Institute pp 91–114

Chin J, Forster A, Clerici C, Sung L (2007) Pol Deg Stab 92:1234–1246

Tera F (1981) Egyptian patent no. 15182

Segal L, Creely J, Martin J, Conrad C (1959) Text Res J 29:780–794

J. Batcheller (2005), Optical and scanning electron microscopy techniques for the identification of hair fibers from Romano—Egyptian textiles. In: Janaway R, Wyeth P (eds) Scientific analysis of ancient and historic textiles: informing preservation, display and interpretation, AHRC Research Center for Textile Conservation and Textile Studies, First Annual Conference, UK, 13–15, July 2005, pp 51–57

Booth J (1984) Principles of textile testing. Butterworth- Heinemann, USA, pp 118–169

Wyszecki G, Stiles W (2000) Color science concepts and methods, 2nd edn. Quantitative data and formulae, New York

Mary B, Dianne R, Nancie R (1989) The books and paper group annual 9. http://aic.stanford.edu/sg/bpg/annual/v08/bp08-01.html

Michele D (1989) J Ame Inst Cons 28:43–56

Block R, Durrum E, Zweig G (1958) A Manual of paper chromatography and paper electrophorsis, 2nd edn. Academic Press, New York

Timár- Balászy A, Eastop D (1998) Chemical principles of textile conservation. Butterworth-Heinemann, Oxford

Koussoulou T (1999) Papers from the Institute of Archaeology 10:75–88. http://pia-journal.co.uk/index.php/pia/article/viewFile/pia.135/265

Derrick M (1991) Book and paper group annual, The American Institute for Conservation. 10

Kim U, Park J, Li C, Jin H, Valluzzi R, Kaplan D (2004) Biomacromolecules 5:786–792

Lucas E, Shaw J, Smith S (1958) Adv Prot Chem 13:107–242

Yanagi Y, Kondo Y, Hirabayashi K (2000) Tex Res J 70:871–875

Kite M, Thomson R (2006) Conservation of leather and related materials. Butterworth-Heinemann, Oxford

Becker M (1993) The characterization of the initial degradative alterations of Bombyx mori silk fibroin: a comparative study of artificially aged silk fabric and silk fabrics from The First Ladies Collection, Smithsonian Institution, Washington DC’, PhD dissertation, Johns Hopkins University, U.M.I. Dissertation Services, Ann Arbor, Michigan, No. 9327568

Wyeth P, Greiff S, Kutzke H, Riekel C (2005) Surveying silk fiber degradation by crystallinity determination: a study on the tang-dynasty silk treasure from Famen Temple, China. In: Janaway R, Wyeth P (eds) Scientific Analysis of Ancient and Historic Textiles: Informing Preservation, Display and Interpretation AHRC Research Center for Textile Conservation and Textile Studies, First Annual Conference, UK, 13–15 July 2005, pp 38–43

Lee Y (1999) Silk reeling and testing manual, FAO Agricultural Services Bulletin, 136. http://www.fao.org/docrep/x2099E/x2099E00.htm

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmed, H.E., Darwish, S.S. Effect of Museum Conditions on Historical Dyed Silk Fabric with Madder Dye. J Polym Environ 20, 596–606 (2012). https://doi.org/10.1007/s10924-012-0421-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-012-0421-x