Abstract

Ciprofloxacin (CF) loaded biodegradable microspheres of Poly(lactide-co-caprolactone)-PF127 (a poloxamer block copolymer of Ethylene Oxide/Propylene Oxide) were prepared by using solvent evaporation technique. The microspheres were characterized by differential scanning calorimetry (DSC) and X-ray diffractometry (X-RD) technique to confirm the polymorphism of ciproflaxacin (CF) drug. The X-RD and DSC techniques indicated molecular level dispersion of CF in the microspheres. Scanning electron micrographic images (SEM) of the microspheres indicated smooth surfaces of the spherical microspheres. Cumulative release characteristics of the matrices for CF, the antibiotic drug, were investigated in pH 7.4 media. It was possible to release CF in controlled manner up to 72 h. The developed ciprofloxacin loaded Poly(lactide-co-caprolactone)-PF127 microspheres were evaluated for preliminary antibacterial applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Advantages of microspheres for the oral delivery of drugs over the conventional dosage forms have been reported [1]. A uniform distribution of multi-unit dosage form along the gastro-intestinal tract (GIT) could result in more reproducible drug absorption with a reduced risk of local irritations than the use of single-unit dosage forms [2]. These microspheres protect the liable compounds (e.g., proteins and peptides) from degradation in the GIT [3]. Several techniques were described in the literature for the preparation of microspheres, including solvent evaporation [4], phase separation [5], spray-drying [6] and in situ polymerization [7]. Among these, the solvent evaporation method is widely used due to its good reproducibility and versatility in offering the desired properties to the microspheres [8]. This method involves an emulsification step followed by the removal of solvent via extraction and evaporation.

One approach that address the drug delivery requirements is the use of biodegradable microspheres. Biodegradable microspheres may be produced from a variety of synthetic and natural polymers. Biodegradable polymers are the most widely studied systems in drug delivery applications [9, 10]. In the earlier studies, various biodegradable polymers, viz., poly(ε-caprolactone) (PCL), poly(3-hydroxybutyrate) (PHB), poly(glycolic acid) (PGA), poly(lactic acid) (PLA), and poly(lactide-co-glycolide) (PLAGA) have been explored in controlled release (CR) studies [11]. Broad interest in biodegradable and biocompatible polymers has led to the synthesis of an increasingly wide range of amphiphilic diblock copolymers. Various types of hydrophobic polymers, including poly L-lactic acid [12] (PLA) and poly ε-caprolactone [13] (PCL) and others [14, 15], were used as hydrophobic core blocks for micelles, micro and nanoparticles. Biodegradable particles (0.1–1,000 μm) prepared from poly(lactide-co-glycolide) polymers (PLAGA) have generated considerable interest in recent years for their use as delivery vehicles for various pharmaceutical agents. PLAGA is by far the most common biodegradable polymer that is used for the controlled delivery of drugs due to its early use and approval as a compatible biomaterial in humans. By varying the molecular weight and the lactide/glycolide ratio, the degradation time of the PLAGA, and thereby the release kinetics of the active agent, can be controlled [16].

The Pluronic PF127 (a poloxamer block copolymer Ethylene Oxide/Propylene Oxide) has high solubilizing capacity [17]. Aqueous pluronic dispersions (20–35%) are solutions at low temperatures and are converted into semisolid gel at higher or body temperature. These useful physico-chemical properties of pluronics have been evaluated for controlled release of drug for topical, rectal and ophthalmic routes [18–20].

Ciprofloxacin is 1-cyclopropyl-6-fluoro-1,4-dihydro-4-oxo-7-(1-piperazinyl)-3-quinolinecarboxylic acid. Its empirical formula is C17H18FN3O3 and its molecular weight is 331.4 g/mol. Ciprofloxacin is a synthetic chemotherapeutic antibiotic belonging to fluoroquinolone drug class [21, 22]. It is a second generation fluoroquinolone antibacterial. Ciprofloxacin is a broad-spectrum antibiotic that is active against both gram-positive and gram-negative bacteria. It functions by inhibiting DNA gyrase, type II topoisomerase, and topoisomerase IV, the enzymes necessary to separate bacterial DNA, thereby inhibiting cell division.

In view of the above discussion the present work involves the development of ciprofloxacin loaded biodegradable microspheres of Poly(lactide-co-caprolactone)-PF127 for antibacterial applications. Placebo and drug-loaded microspheres have been characterized by thermal analyses. The in vitro release was performed in phosphate buffer (PBS, pH 7.4) at 37 °C using dissolution tester.

Experimental

Materials and Methods

Ciprofloxacin (CF), Poly(lactide-co-caprolactone)(PLCL), Pluronic F127 were purchased from Sigma–Aldrich, USA. Analytical reagent grade samples of poly(vinyl alcohol)(PVA) (Mw 125,000 and 98% hydrolyzed) and dichloromethane (DCM) were purchased from S.D. Fine Chemicals (Mumbai, India). Dialysis membrane-110 was purchased from Himedia Laboratories (Mumbai, India). Double-distilled water was used throughout the work. All the chemicals were used without further purification.

Preparation of Ciprofloxacin Loaded Microspheres

Ciprofloxacin (CF) equivalent to 10% (w/w) dry weight of PLCL was dissolved in 10 mL of distilled water and serves as the aqueous phase. Totally, 1 g of PLCL and PF127 was dissolved in 100 mL of dichloromethane and serves as the oil phase. 10 mL of aqueous drug solution was added to the above PLCL-PF127 solution and emulsified by high-speed stirring (Remi Lab Stirrer, Remi Motors, Mumbai, India) for about 5 min to form stable w/o emulsion. This stable w/o emulsion was slowly added to 200 mL of aqueous solution containing 0.5 wt% PVA and this was further emulsified using Remi Lab Stirrer at 600 rpm speed to form w/o/w emulsion under ambient conditions. Hardening of the microspheres was done by continuously stirring the mixture for about 4 h along with evaporation of the solvent mixture. Microspheres were isolated by filtration and washed with distilled water several times to remove PVA. The produced microspheres were dried at ambient temperature (25 °C) for 24 h and dried in vacuum desiccators at room temperature for 12 h to remove any residual solvent.

Differential Scanning Calorimetry (DSC)

DSC curves of the placebo PLCL microspheres, placebo drug and drug-loaded microspheres were recorded using Rheometric Scientific Differential Scanning Calorimetry, (Model-DSC SP, UK). The analysis was performed by heating the samples at the rate of 10 °C/min in an inert atmosphere.

X-Ray Diffraction (XRD)

Crystalline nature of the placebo ciprofloxacin and ciprofloxacin-loaded microspheres were evaluated by powder XRD technique using Philips model PW-1710, UK diffractometer attached to the digital graphical assembly, and a computer with Cu-NF 25 kV/20-mA tube as Cu-radiation source.

Scanning Electron Microscopy (SEM)

SEM images of 10% CF-loaded microspheres were taken using JEOL model JSM-840A (Japan). Microspheres were sputtered with gold to make them conducting and placed on a copper stub. Thickness of the gold layer accomplished by gold sputtering.

Determination of Encapsulation Efficiency

Encapsulation efficiency of ciprofloxacin loaded microspheres was determined using UV spectrophotometer at a λmax of 274 nm. 10 mg of ciprofloxacin-loaded microspheres were dissolved in 10 mL of dichloromethane and extracted into 10 mL of 7.4 pH phosphate buffered solution. The aqueous solution was analyzed at a λmax of 274 nm using the UV spectrophotometer (New Brunswick Scientific Innova 4230, MN, USA). The % encapsulation efficiency was calculated using the Eq. 1. The results are listed in Table 1.

In Vitro Drug Release Studies

In vitro drug release from all the formulations was investigated in phosphate buffer solution (PBS) of pH 7.4. Microspheres (50 mg) were suspended in 1 mL of PBS and placed within the dialysis bag. The sample within the dialysis bag was placed in a conical flask containing 50 mL of PBS as the dissolution medium and kept on a shaker with a speed of 100 rpm at 37 °C (New Brunswick Scientific Innova 4230, MN, USA). The amount of drug released from the microspheres was determined by withdrawing 2 mL of aliquots at selected specific time intervals. The volume of withdrawn was replenished with an equal volume of fresh and pre-warmed PBS at 37 °C. Samples were analyzed by UV spectrophotometer (UV-1650 PC, Shimadzu, Duisburg) at a λmax value of 274 nm using PBS as the blank.

Antibacterial Activity

To carry out the antibacterial activity for these microspheres, nutrient agar medium was prepared using peptone (5.0 g), beef extract (3.0 g), and sodium chloride (NaCl) (5.0 g) in 1,000 mL distilled water and the pH was adjusted to 7.0 and agar (15.0 g) was added to the solution. The agar medium was sterilized in a conical flask at a pressure of 15 lbs for 30 min. This nutrient agar medium was transferred into sterilized petri dishes in a laminar air flow chamber (Micro Filt, Laminar Flow Ultra Clean Air Unit, Mumbai, India). After solidification of the media, bacillus culture was spread on the solid surface of the media. To this inoculated petri dish, one drop of microsphers solution (20 mg/10 mL distilled water) was added using 50-μL tip and incubated for 3 days at 37 °C in the incubation chamber.

Results and Discussion

Ciprofloxacin loaded microspheres were developed from water–oil-water (w/o/w) double emulsion by using solvent evaporation method and are very useful in terms of cost-effective. Notice that in the w/o/w method, PLCL, PF127 were dissolved in dichloromethane and the ciprofloxacin was dissolved in water. The dispersed organic phase was then emulsified into aqueous phase to produce droplets of regular shape and uniform size. To understand more about the finding of optimum formulation protocols, an investigation on the effect of drug ratio on encapsulation efficiency of the ciproflaxacin-loaded microspheres was done.

Differential Scanning Calorimetry

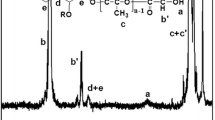

DSC images of placebo ciprofloxacin, ciprofloxacin-loaded PLCL-PF127 microspheres and placebo PLCL microspheres are displayed in Fig. 1. Melting peak of ciprofloxacin was observed at 199 °C. However, no characteristic peak of ciprofloxacin was observed in the drug-loaded microspheres, suggesting that the drug was molecularly dispersed in the polymer matrix.

X-Ray Diffraction

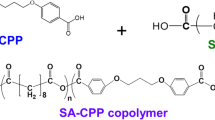

The crystalline nature of placebo ciprofloxacin and ciprofloxacin loaded microspheres was evaluated from the XRD data recorded for placebo ciprofloxacin and ciprofloxacin-loaded microspheres using powder XRD technique. XRD diffractograms of placebo ciprofloxacin and ciprofloxacin-loaded microspheres are presented in Fig. 2. Notice that ciprofloxacin has characteristic intense bands observed at 2θ of 22, 24 and 26, suggesting its crystalline nature; but these peaks have disappeared in ciprofloxacin-loaded PLCL microspheres. The XRD intensities depend on crystal size. But in the case of ciprofloxacin-loaded formulations, the characteristic intensities of ciprofloxacin have overlapped with the noise of the PLCL-PF127 itself. This observation suggests that ciprofloxacin was dispersed at molecular level in PLCL-PF127matrix and hence no crystals were found in ciprofloxacin-loaded matrices.

Scanning Electron Microscopy (SEM)

The SEM images of microspheres are shown in Fig. 3. Microspheres are spherical without much agglomeration with average size of 50–100 μM and their surfaces are smooth. However, few polymeric debris are seen around some particles and this is due to the method of particle production.

In Vitro Release

The in vitro release profiles of ciprofloxacin-loaded PLCL-PF127 formulations are presented in Figs. 4, 5 and 6. In general, drug release from biodegradable polymers like PLCL and PF127 can occur due to degradation followed by matrix erosion. In the present investigation the release of ciprofloxacin from PLCL-PF127 microspheres has appeared up to 72 h. A comparison of drug release from microspheres with varying weight percentage of PF127 was analyzed. It is observed that the release rates vary depending upon the amount of ciprofloxacin present in the PLCL-PF127 matrix, i.e., release is slower for those formulations having lower amount of ciprofloxacin, while release is higher in microspheres having higher amount of ciprofloxacin. However, the initial burst effect remains the same for all formulations, i.e., it occurred within 8 h, suggesting that nearly ~20% of ciprofloxacin has released due to hydrophilic nature of ciprofloxacin. Microspheres consisting of different PF127 ratio have released 98% of ciprofloxacin in about 72 h. In the case microspheres having 10 and 20% PF127 and keeping 5% CF, the drug release has shown the same trend, but there is difference in % release. 20% PF127 released more amounts CF than 10% PF127. This is due to increase in the hydrophilicity of the overall matrix, which makes the polymer to erode fast, which implicates on the release profile. The water-soluble ciprofloxacin might have migrated to aqueous dissolution medium, thereby sticking to the surface of microspheres. This inturn increased the chance for its initial quick release, thereby indicating that the high solubility of ciprofloxacin in water would favour its rapid migration to the dissolution medium.

Antibacterial Activity

The antibacterial effect of the plain Poly(lactide-co-caprolactone)-PF127 microspheres and ciprofloxacin loaded Poly(lactide-co-caprolactone)-PF127 microspheres was examined in the nutrient agar medium. Figure 7A illustrates that the plain Poly(lactide-co-caprolactone)-PF127 microspheres does not show any effect on the bacterial growth. Where as the ciprofloxacin loaded Poly(lactide-co-caprolactone)-PF127 microspheres have shown good bacterial inhibition in the nutrient agar medium (Fig. 7B, C). This is due to loading ciprofloxacin in the microspheres of Poly(lactide-co-caprolactone)-PF127 matrix. Therefore, it can be concluded that the ciprofloxacin loaded Poly(lactide-co-caprolactone)-PF127 matrix is excellent antibacterial material.

Conclusions

In present invention, biodegradable microspheres were prepared by solvent evaporation technique. The prepared ciprofloxacin-loaded PLCL microspheres ranging in size from 10 to 25 μm. Drug release showed the dependence on PF127 amount as well as amount of drug loading and encapsulation efficiency. In vitro release data of the formulations indicated longer period of release up to 72 h. Antimicrobial studies revealed that the release of ciprofloxacin over 72 h and inhibiting the microbial growth, which corroborated well with the in vitro results.

References

Abu-Izza K, Tambrallo L, Lu DR (1997) J Pharm Sci 86:554

Galeone M, Nizzola L, Cacioli D, Mosie G (1981) Curr Ther Res 29:217

Hagan DTO, Palin K, Davis SS, Artursson P, Sjoholm I (1989) Vaccine 7:421

Herrmann J, Bodmier R (1995) J Control Rel 36:63

Sveinsson SJ, Kristmundsdottir T, Ingvarsdottir K (1993) Int J Pharm 92:29

Bodmeier R, Chen H (1987) J Pharm Pharmacol 40:754

Shah SS, Pitt CG (1996) Relat Bioact Mater 23:357

Patrick BOD, McGinity JW (1997) Adv Drug Deliv Rev 28:25

Schwach-Abdellaoui K, Vivien-Castioni N, Gurny R (2000) Eur J Pharm Biopharm 50:83

Kenawy E, Bowlin GL, Mansfield K, Layman J, Simpson GD, Sanders EH, Wnek GE (2002) J Controlled Release 81:57

Soderquist RG, Sloane EM, Loram LC, Harrison JA, Dengler EC (2010) Pharm Res 27:841

Hagan SA, Coombes AGA, Garnett MC, Dunn SE, Davies MC, Illum L, Davis SS (1996) Langmuir 12:2153

Soo PL, Laibin L, Maysinger D, Eisenberg A (2002) Langmuir 18:9996

La SB, Okano T, Kataoka K (1996) J Pharm Sci 85:85

Cho CS, Nah JW, Jeong YI, Cheon JB, Asayama S, Ise H, Akaike T (1999) Polymer 40:6769

Lewis DH (1990) Controlled release of bioactive agents from lactide/gylcolide polymers. In: Chasin M, Langer R (eds) Biodegradable polymers as drug delivery systems. Marcel Dekker, New York, pp 1–41

Schmolka IR (1991) Polymer for controlled drug delivery. CRC Press, Boca Raton, pp 189–194

Chen CPC, Frank SG (1981) Int J Pharm 8:89–99

Miyazaki S, Yokonchi C, Nakamura T (1986) Chem Pharm Bull 34:1801–1808

Desai SD, Blanchard J (1998) J Pharm Sci 87:226–230

Nelson JM, Chiller TM, Powers JH, Angulo FJ (2007) Clin Infect Dis 44(7):977–980

Kawahara S (1998) Nippon Rinsho 56(12):3096–3099

Acknowledgments

The authors (KMR & SR) thanks the University Grants Commission (UGC-SAP), Government of India, New Delhi for the partial financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravindra, S., Varaprasad, K., Narayana Reddy, N. et al. Biodegradable Microspheres for Controlled Release of an Antibiotic Ciprofloxacin. J Polym Environ 19, 413–418 (2011). https://doi.org/10.1007/s10924-011-0290-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-011-0290-8