Abstract

Amorphous and crystallized poly(l-lactic acid) (PLLA-A and PLLA-C, respectively) films were prepared, and the proteinase K-catalyzed enzymatic degradation of UV-irradiated and non-irradiated PLLA-A and PLLA-C films was investigated for periods up to 10 h (PLLA-A) and 60 h (PLLA-C). The molecular weights of both the PLLA-A and PLLA-C films can be manipulated by altering the UV irradiation time. The enzymatic weight loss values of the UV-irradiated PLLA films were higher than or similar to those of the non-irradiated PLLA film, when compared with the specimens of same crystallinities. UV irradiation is expected to cause the PLLA films to undergo chain cleavage (a decrease in molecular weight) and the formation of C=C double bonds. It seems that the acceleration effects from decreased molecular weight on enzymatic degradation were higher than or balanced with the disturbance effects caused by the formation of C=C double bonds. After enzymatic degradation, a fibrous structure appeared on the spherulites of the UV-irradiated PLLA-C film. This structure may have arisen from chains containing or neighboring on the C=C double bonds, which were enzymatically undegraded and assembled on the film surface during enzymatic degradation. The results of this study strongly suggest that UV irradiation will significantly affect the biodegradation behavior of PLLA materials in the environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Among biodegradable polyesters, poly(l-lactic acid) (PLLA) has been attracting much attention, because it is producible from renewable resources at low cost, is non-toxic to the environment as well as to the human body and recyclable to its monomers with a high yield [1–14]. When PLLA materials are exposed to the environment, they are hydrolytically degraded to l-lactic acid and its oligomers and the formed products are bioassimilated. In addition to these types of degradation, they are also exposed to photodegradation through UV irradiation. UV irradiation causes PLLA materials to undergo structural changes, such as a decrease in molecular weight and the formation of C=C double bonds through the Norrish II mechanism [15], and thereby affects the biodegradation or hydrolytic degradation behavior of PLLA materials. The lowered molecular weight and the formation of C=C double bonds respectively are expected to enhance and disturb the biodegradation and hydrolytic degradation of PLLA materials [1–11].

The photodegradation of PLLA by UV irradiation was investigated mainly using gel permeation chromatography (GPC) and tensile testing [15–22], and the hydrolytic degradation behavior of PLLA was reported to be affected by simultaneous UV irradiation [22]. In that report, hydrolysis experiments were carried out under simultaneous UV irradiation, not after UV irradiation, although the conditions therein were very close to actual conditions, as in landfills, and the obtained information is useful for the environmental application of PLLA materials. To study the pure effects of UV irradiation on the hydrolytic degradation of PLLA, hydrolytic degradation should be performed after UV irradiation, not under simultaneous UV irradiation. Moreover, although one of the important structural parameters of PLLA, initial crystallinity, has crucial effects on hydrolytic degradation [1–11], the reports paid no attention to the initial crystallinity.

On the other hand, proteinase K (EC 3.4.21.14) is a well-known enzyme which catalyzes hydrolytic degradation of poly(lactic acid)s (PLAs), when PLA-based materials contain sufficiently long l-lactyl unit sequences in the amorphous phase [23–30]. The main factors affecting the enzymatic degradation rate of PLAs are (1) molecular characteristics, such as the molecular weight and the l-lactyl unit content [25–28, 31–39], the distribution [26–28, 31], hydrophilicity, and steric hindrance of the co-monomers [38], (2) highly ordered structures, such as the crystallinity [24–27, 29, 30, 39] and the crystallite size [29], (3) additives and polymer blending [31, 40–48], and (4) surface treatments [49, 50]. Despite these intensive studies [23–50], as far as we are aware, there has been no study of the UV irradiation effects on the enzymatic degradation of PLLA. Moreover, if the enzymatic degradability of PLLA films is altered by UV irradiation, it strongly suggests that UV irradiation will significantly affect the biodegradation behavior of PLLA materials in the environment.

The objectives of this study were to investigate the pure effects of UV irradiation on the enzymatic degradation of PLLA films and to compare the effectiveness of UV irradiation on the enzymatic degradation of amorphous and crystallized PLLA films. For these purposes, we prepared amorphous and crystallized PLLA films by thermal treatments from the melt and the prepared films were UV-irradiated for periods up to 60 h. Furthermore, the UV-irradiated and non-irradiated PLLA films were enzymatically degraded in the presence of proteinase K for periods up to 10 h (amorphous film) and 60 h (crystallized film), and the degraded films were investigated by the use of gravimetry, gel permeation chromatography (GPC), differential scanning calorimetry (DSC), and scanning electron microscopy (SEM).

Experimental

Materials

PLLA (LactyTM 5000) was kindly supplied by Shimadzu Co. (Kyoto, Japan) and was purified by precipitation using methylene chloride and methanol as the solvent and non-solvent, respectively. The purified polymers were dried in vacuo for at least 2 weeks. The films (100 μm thick) of the purified PLLA were prepared by solution casting using chloroform as the solvent. A PLLA solution with a concentration of 1.0 g dL−1 was cast onto a Petri dish, followed by solvent evaporation at room temperature for about one day. To prepare amorphous and crystallized PLLA films, the cast PLLA films were thermally treated by the following procedures. Each of the cast PLLA films was placed between two Teflon sheets and sealed in a glass test tube under reduced pressure ( < 3 mmHg). The sealed PLLA films were melted at 200 °C for 3 min and then quenched at 0 °C or crystallized at 140 °C for 600 min. The crystallized films were quenched at 0 °C to stop further crystallization. Thus prepared amorphous and crystallized PLLA films are abbreviated as PLLA-A and PLLA-C films, respectively.

UV Treatment

The UV treatment (irradiation) of thermally treated PLLA films was carried out according to ISO 4892-4 (Plastics-Method of exposure to laboratory light sources-Part 4: Open flame carbon-arc lamps) with an accelerated weathering chamber (S80H-B, Suga Test Instruments Co. Ltd., Tokyo, Japan) without using a water-spray system [51, 52]. The films were irradiated with UV rays [Filter: Type A, wave length: 300–700 nm, maximum intensity at 380 nm, 255 W m−2] for periods up to 60 h at a black-panel temperature of 63 °C (the temperature inside the chamber: 45 °C) and a relative humidity of 65%.

Enzymatic Degradation

Enzymatic degradation of the films (10 mm × 10 mm × 100 μm) was performed according to the procedure reported by Reeve et al. [25]. Namely, each of the films was placed in a vial filled with 5 mL of Tris–HCl buffer solution (pH 8.6) containing 1.0 mg of proteinase K (Sigma-Aldrich Co., Tokyo, Japan, lyophilized powder, 80% protein) and 1.0 mg of sodium azide (Nacalai Tesque Inc., Kyoto, Japan, the guaranteed grade). Enzymatic degradation of the films was performed at 37 °C in a rotary shaker for periods up to 10 h (PLLA-A films) and 60 h (PLLA-C films). The hydrolysis media were changed every 20 h to maintain enzymatic activity. During enzymatic degradation, the solution pH remained in the range of between 8.6 and 8.0, when the enzyme activity was reported to be practically constant [25].

The enzymatically degraded films were washed thoroughly with distilled water at 4 °C to stop further enzymatic degradation, followed by drying under reduced pressure for at least 2 weeks for weight loss measurements. The distilled water used for preparation of the Tris–HCl buffer solution and washing of the enzymatically degraded films was of HPLC grade (Nacalai Tesque Inc.). The experimental weight loss values represent averages of measurements from three replicate specimens. No significant weight loss was detected for any films when they were immersed in the Tris–HCl buffer solution without proteinase K for 10 h (PLLA-A films) and 60 h (PLLA-C films). This indicates that no significant amount of water-soluble components, such as low-molecular-weight oligomers and monomers, were eluted from the films, and that the weight loss observed for the films when degraded in the presence of proteinase K is ascribed to the enzyme-catalyzed chain cleavage and the subsequent elution of water-soluble oligomers and monomers into the surrounding media.

Measurements and Observation

The weight loss per unit surface area of the enzymatically degraded films [W loss (μg mm−2)] was calculated using the weights of a dried film before and after enzymatic degradation (W before and W after, respectively) and the surface area of the film before degradation (S before):

The weight- and number-average molecular weights (M w and M n, respectively) and the molecular weight distribution of the films were evaluated in chloroform at 40 °C by a Tosoh (Tokyo, Japan) GPC system (refractive index monitor: RI-8020) with two TSK Gel columns (GMHXL) using polystyrene standards.

The glass transition, cold crystallization, and melting temperatures (T g, T cc, and T m, respectively) and the enthalpies of cold crystallization (ΔH cc) and melting (ΔH m) of the films were determined with a Shimadzu DSC-50 differential scanning calorimeter. The films were heated at a rate of 10 °C min−1 under a nitrogen gas flow at a rate of 50 mL min−1 for the DSC measurements. The T g, T cc, T m, ΔH cc, and ΔH m values of the films were calibrated using benzophenone, indium, and tin as standards. The crystallinity (X c) values of the films were evaluated according to the following equation:

where ΔH m(100%) is the ΔH m value of a PLLA crystal having infinite thickness. The ΔH m(100%) value of PLLA is reported to be 135 J g−1 (Miyata and Masuko) [53]. By definition, ΔH cc and ΔH m are negative and positive, respectively. The molecular characteristics and thermal properties of typical UV-irradiated and non-irradiated PLLA films before and after enzymatic degradation are summarized in Table 1.

The surface morphology of the films was studied with a Hitachi (Tokyo, Japan) S-2300 scanning electron microscope. The films for SEM observation were coated with carbon to a thickness of about 20 nm.

Results and Discussion

UV Treatment

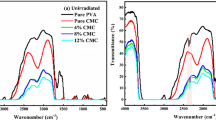

The photodegradation of PLLA was reported to proceed via the Norrish II mechanism, as shown in Fig. 1 [15]. This mechanism causes chain cleavage and the formation of C=C double bonds at newly formed chain terminals, as monitored by the GPC and IR methods, respectively[15]. On the other hand, our previous study revealed that the photodegradation of biodegradable polyesters such as PLLA and poly(ɛ-caprolactone) with UV irradiation proceeds via a bulk erosion mechanism, not via a surface erosion mechanism and thereby the molecular weight distribution curves of the specimens shift to a lower molecular weight as a whole with UV irradiation time [51, 52]. Also, the molecular weight distribution curves of the crystallized PLLA films contain no specific low-molecular-weight peaks ascribed to crystalline residues after UV irradiation [51, 52]. This reflects the fact that the chains in the crystalline regions are photodegradable, in marked contrast with the results for the hydrolytic degradation at the initial stage, when only the chains in the amorphous regions are degraded [1–11].

Figure 2 shows the time changes of M n and M w/M n of the PLLA-A and PLLA-C films caused by UV irradiation. The slightly lower initial M n of PLLA-C film (compared to that of PLLA-A film) may be partly due to the thermal degradation of PLLA-C film during crystallization. The M n of the PLLA-A and PLLA-C films decreased gradually with UV irradiation time, meaning that the M n of PLLA can be manipulated by altering the UV irradiation time. The decrease rate in M n was higher for the PLLA-A film than for the PLLA-C film, confirming the reported fact that the chains in the crystalline regions are less photodegradable than those in the amorphous regions [51, 52]. The M w/M n of the PLLA-A and PLLA-C films increased slightly with UV irradiation time and leveled off at around 1.9 for UV irradiation time exceeding 20 h.

Weight Loss

Figure 3 gives the weight loss change of the PLLA-A and PLLA-C films induced by proteinase K-catalyzed enzymatic degradation. The final values of percentage weight loss were ca. 80% and 10% for PLLA-A and PLLA-C films at 10 h and 60 h, respectively. The weight loss values of the UV-irradiated PLLA-A films were higher than or similar to those of the non-irradiated PLLA-A films (Fig. 3a). As stated above, UV irradiation induces the formation of C=C double bonds at newly formed chain terminals as well as chain cleavage (a decrease in molecular weight). Our previous study showed that for amorphous PLLA films, the contribution of exo-cleavage toward overall proteinase K-catalyzed enzymatic degradation is significant and thereby the decrease in molecular weight of PLLA films accelerates or enhances enzymatic degradation [31]. On the other hand, the formation of C=C double bonds is expected to disturb the enzymatic degradation of the chains containing or neighboring on the C=C double bonds. Probably, the chains containing or neighboring on the C=C double bonds are undegraded, and accumulated on the film surface. Thus, accumulated undegradable chains will disturb the absorption or cleavage process of proteinase K, resulting in a lowered enzymatic degradation rate at a late stage of enzymatic degradation of UV-irradiated PLLA-A films.

Molecular Weight Change

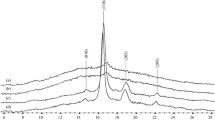

After enzymatic degradation for 10 h, no significant change was observed for the molecular weight distribution curves of the UV-irradiated and non-irradiated amorphous PLLA-A films (data not shown here). This is attributable to a surface erosion mechanism of the amorphous PLLA-A films, as reported earlier [30, 31, 38]. In the surface erosion mechanism, low-molecular-weight water-soluble oligomers and monomers formed by degradation, which will induce the decreased average molecular weights, are released from the film surface. The chains containing or neighboring on the C=C double bonds, which are expected to be enzymatically undegraded and accumulated on the surface of the UV-irradiated PLLA-A films, were not traced by GPC, probably due to a very small amount of the accumulated chains compared with that of the whole film. In contrast, as shown in Fig. 4, after enzymatic degradation for 60 h, low-molecular-weight specific peaks were noticed at a molecular weight of around 1 × 104 g mol−1 for both the UV-irradiated (60 h) and non-irradiated (0 h) PLLA-C films. These specific peaks are due to crystalline residues formed as a result of selective enzymatic cleavage and subsequent removal of the chains in the amorphous regions, leaving the chains in the crystalline regions on the surface of the PLLA-C films [10, 29, 30]. The molecular weights of the two specific peaks of the UV-irradiated PLLA-C film are identical with those of the non-irradiated PLLA-C film. The reason for the difference in molecular weight of the main peaks between the UV-irradiated and non-irradiated PLLA-C films is that the UV-irradiated PLLA-C film had a lower initial molecular weight (Table 1 and Fig. 2) and the core parts of the films remained undegraded after enzymatic degradation.

Figure 5 shows the M n changes of the UV-irradiated (60 h) and non-irradiated (0 h) PLLA-A and PLLA-C films caused by enzymatic degradation. No significant change in M n was observed for the amorphous PLLA-A films, as expected from no change in the molecular weight distribution curves, while the M n of the crystallized PLLA-C films decreased gradually with enzymatic degradation time. The latter M n changes can be ascribed to the fact that the relative fraction of crystalline residues remaining on the film surface increased with enzymatic degradation time. In the case of the PLLA-C films, the decrease rate of M n was higher for the non-irradiated film than for the UV-irradiated film. Figure 6 gives the M w/M n changes of the UV-irradiated (60 h) and non-irradiated (0 h) PLLA-A and PLLA-C films caused by enzymatic degradation. The M w/M n values of the PLLA-A films remained unchanged, whereas those of the PLLA-C films increased from 2 to 4 within 60 h. This again confirms that formed crystalline residues had accumulated on the surface of the PLLA-C films. The increase rate of M w/M n was higher for the non-irradiated PLLA-C film than for the UV-irradiated PLLA-C film. One probable reason for the seemingly rapid decrease of M n and increase of M w/M n of the non-irradiated PLLA-C film compared to those of the UV-irradiated PLLA-C film is that the initial molecular weight was higher for the non-irradiated film. However, we cannot explain why the M n values of the non-irradiated PLLA-C film at enzymatic degradation periods of 30 h and 40 h were lower than those of the UV-irradiated PLLA-C film.

Highly Ordered Structural Change

Figure 7 depicts the DSC thermograms of UV-irradiated (60 h) and non-irradiated (0 h) PLLA-A and PLLA-C films before enzymatic degradation and after enzymatic degradation for 10 h (PLLA-A) and 60 h (PLLA-C). The peaks observed at 60 °C–70 °C, 110 °C–130 °C, and 170 °C–180°C are due to the glass transition, cold crystallization, and melting phenomena of PLLA, respectively [1–11]. The thermal properties estimated from this figure are tabulated in Table 1. As seen in Table 1, after enzymatic degradation, no significant changes in T cc and T m were observed for the PLLA films, excluding the non-irradiated PLLA-A film. The T cc and T m of the non-irradiated PLLA-A film shifted to lower and higher temperatures, respectively, during enzymatic degradation, which is attributable to the fact that the nuclei of crystallites were formed during low-temperature annealing in the presence of water. In the case of the amorphous PLLA-A films, no significant information can be obtained from the changes in the melting peak shape or T m, because the monitored crystallites were those formed during DSC scanning. The X c values of both the UV-irradiated and non-irradiated PLLA-A films remained unchanged after enzymatic degradation.

No significant change in T m of the PLLA-C films during enzymatic degradation (Table 1) suggests that the crystalline regions were not degraded. However, as shown in Fig. 7, after enzymatic degradation, the melting peak widths of both the UV-irradiated and non-irradiated PLLA-C films increased or a shoulder appeared at a lower temperature of the melting main peak. This can be closely correlated with the appearance of melting subpeaks of PLLA films by enzymatic degradation in our previous study, where thinner crystallized PLLA films were used for enzymatic degradation and thereby the melting subpeaks were more clearly observed at a lower temperature. The reason for the appearance of the melting subpeak or the shoulder is the surface structural change of the crystalline regions during enzymatic degradation [54, 55]. Before enzymatic degradation, the surface of crystalline regions is connected with three types of amorphous chains, i.e., tie chains, folding chains, and chains with a free end. Proteinase K can catalyze the chain cleavage of tie chains and chains with a free end. As a result, after enzymatic degradation, the “fold surface” of crystalline regions is connected with two types of amorphous chains, i.e., folding chains and very short chains with a free end. Such structural change by enzymatic degradation must increase the free energy at the “fold surface”, and thereby will result in the formation of a crystalline species with a low melting temperature compared with that of the undegraded core part of the films. As seen in Fig. 7, the temperature of the newly formed melting subpeak for the UV-irradiated PLLA-C film was very close to the melting main peak compared to that for the non-irradiated PLLA-C film. It is probable that the presence of the chains containing or neighboring on the C=C double bonds disturbed the enzymatic chain cleavage, resulting in the imperfect removal of amorphous chains (or in a small increase of the free energy at the “fold surface”) in the UV-irradiated PLLA-C film compared to that for the non-irradiated PLLA-C film. On the other hand, the X c values of both the UV-irradiated and non-irradiated PLLA-C films were significantly increased by enzymatic degradation, confirming the fact that the selective removal of the amorphous chains and the accumulation of the crystalline residues occurred, as traced by GPC measurements (Figs. 4–6).

Morphological Change

Figures 8 and 9 respectively show SEM photographs of the UV-irradiated and non-irradiated PLLA-A and PLLA-C films after enzymatic degradation and SEM photographs of the UV-irradiated PLLA-C film before enzymatic degradation for reference. We show only the SEM photographs of the UV-irradiated PLLA-C film before enzymatic degradation, because other PLLA films before enzymatic degradation have a similar surface morphology. Slightly rough surfaces observed for the PLLA-C film before enzymatic degradation (Fig. 9) must be due to the surface shape of the Teflon sheets used for the thermal treatment. As seen in Fig. 8, after enzymatic degradation, numerous pores were formed on the surface of both the UV-irradiated and non-irradiated PLLA-A films. This reveals that some specific points are susceptible to enzymatic degradation even for completely amorphous specimens. Such pore formation was reported by Li et al. [28] for enzymatically degraded amorphous PLA films. On the other hand, a spherulitic structure appeared on the non-irradiated PLLA-C film after enzymatic degradation (Fig. 8), as reported previously [29]. Interestingly, in addition to the spherulitic structure, a fibrous structure was noticed in the UV-irradiated PLLA-C film after enzymatic degradation. The formation of such a fibrous structure may be related to the chains containing or neighboring on the C=C double bonds, which were enzymatically undegraded and assembled on the film surface.

Conclusions

The following conclusions can be derived from the aforementioned experimental results in regard to the effects of UV irradiation on enzymatic degradation of the PLLA-A and PLLA-C films.

-

(1)

The molecular weights of both the PLLA-A and PLLA-C films can be manipulated by altering the UV irradiation time.

-

(2)

The enzymatic weight loss values of the UV-irradiated PLLA films were higher than or similar to those of the non-irradiated PLLA films, when compared with the same X c values. UV irradiation is expected to cause the PLLA films to undergo chain cleavage (a decrease in molecular weight) and the formation of C=C double bonds. It seems that the acceleration effects by decreased molecular weight on enzymatic degradation were higher than or balanced with the disturbance effects by the formation of C=C double bonds.

-

(3)

After enzymatic degradation, a fibrous structure appeared on the spherulitic structure of the UV-irradiated PLLA-C film. This structure may have arisen from the chains containing or neighboring on the C=C double bonds, which were enzymatically undegraded and assembled on the film surface during enzymatic degradation.

-

(4)

The results of this study strongly suggest that UV irradiation will significantly affect the biodegradation behavior of PLLA materials in the environment.

References

Kharas GB, Sanchez-Riera F, Severson DK (1994) In: Mobley DP (ed) Plastics from microbes. Hanser Publishers, New York, pp 93–137

Doi Y, Fukuda K (eds) (1994) Biodegradable plastics and polymers (Studies in Polymer Science 12). Elsevier, Amsterdam

Coombes AGA, Meikle MC (1994) Clin Mater 17:35

Vert M, Schwarch G, Coudane J (1995) J Macromol Sci, Pure Appl Chem A32:787

Hartmann MH (1998) In: Kaplan DL (ed) Biopolymers from renewable resources. Springer, Berlin, Germany, pp 367–411

Ikada Y, Tsuji H (2000) Macromol Rapid Commun 21:117

Albertsson A-C (ed) (2002) Degradable aliphatic polyesters (Advances in polymer science, vol 157). Springer, Berlin, Germany

Södergård A, Stolt M (2002) Prog Polym Sci 27:1123

Scott G (ed) (2002) Biodegradable polymers. Principles and applications, 2nd edn. Kluwer Academic Publishers, Dordrecht, The Netherlands

Tsuji H (2002) In: Doi Y, Steinbüchel A (eds) Polyesters III (Biopolymers, vol 4). Wiley-VCH, Weinheim, Germany, pp 129–177

Auras R, Harte B, Selke S (2004) Macromol Biosci 4:835

Tsuji H, Daimon H, Fujie K (2003) Biomacromolecules 4:835

Noda M, Okuyama H (1999) Chem Pharm Bull 47:467

Fan Y, Nishida H, Mori T, Shirai Y, Endo T (2004) Polymer 45:1197

Ikada E (1997) J Photopolym Sci Technol 10:265

Ikada E (1998) J Photopolym Sci Technol 11:23

Ikada E (1999) J Photopolym Sci Technol 12:251

Ikada E (1999) J Environ Polym Degrad 7:197

Ho K-LG, Pometto AL III (1999) J Polym Environ 7:93

Sakai W, Sadakane T, Nishimoto W, Nagata M, Tsutsumi N (2002) Polymer 43:6231

Copinet A, Bertrand C, Longieras A, Coma V, Couturier Y (2003) J Polym Environ 11:169

Copinet A, Bertrand C, Govindin S, Coma V, Couturier Y (2004) Chemosphere 55:763

Williams DF (1981) Eng Med 10:5

Cai H, Dave V, Gross RA, McCarthy SP (1996) J Polym Sci: Part B: Polym Phys 34:2701

Reeve MS, McCarthy SP, Downey MJ, Gross RA (1994) Macromolecules 27:825

MacDonald RT, McCarthy SP, Gross RA (1996) Macromolecules 29:7356

Li S, McCarthy SP (1999) Macromolecules 32:4454

Li S, Tenon M, Garreau H, Braud C, Vert M (2000) Polym Degrad Stab 67:85

Tsuji H, Miyauchi S (2001) Polym Degrad Stab 71:415

Tsuji H, Miyauchi S (2001) Polymer 42:4463

Tsuji H, Miyauchi S (2001) Biomacromolecules 2:597

Shirahama H, Mizuma K, Umemoto K, Yasuda H (2001) J Polym Sci: Part A: Polym Chem 39:1374

Shirahama H, Tanaka A, Yasuda H (2002) J Polym Sci: Part A: Polym Chem 40:302

Tsutsumi C, Shirahama H, Yasuda H (2002) Macromol Biosci 2:223

Tsutsumi C, Nakagawa K, Shirahama H, Yasuda H (2003) Polym Int 52:439

Watanabe Y, Shirahama H, Yasuda H (2004) React Funct Polym 59:211

Teramoto Y, Nishio Y (2004) Biomacromolecules 5:407

Tsuji H, Tezuka Y (2005) Macromol Biosci 5:135

Tsuji H, Tezuka Y, Yamada K (2005) J Polym Sci: Part B: Polym Phys 49:1064

Sheth M, Ananda Kumar R, Dave V, Gross RA, McCarthy SP (1997) J Appl Polym Sci 66:1495

Nagata M, Okano F, Sakai W, Tsutsumi N (1998) J Polym Sci: Part A: Polym Chem 36:1861

Tsuji H, Muramatsu H (2001) Polym Degrad Stab 71:403

Gajria AM, Dave V, Gross RA, McCarthy SP (1996) Polymer 37:437

Gan Z, Yu D, Zhong Z, Liang Q, Jing X (1999) Polymer 40:2859

Liu L, Li S, Garreau H, Vert M (2000) Biomacromolecules 1:350

Tsuji H, Ishizaka T (2001) Macromol Biosci 1:59

Fukuda N, Tsuji H, Ohnishi Y (2002) Polym Degrad Stab 78:119

Fukuda N, Tsuji H (2005) J Appl Polym Sci 96:190

Tsuji H, Ishida T, Fukuda N (2003) Polym Int 52:843

Tsuji H, Ishida T (2003) Macromol Biosci 3:51

Tsuji H, Echizen Y, Nishimura Y (2006) Polym Degrad Stab 91:1128

Tsuji H, Echizen Y, Saha SK, Nishimura Y (2005) Macromol Mater Eng 290:1192

Miyata T, Masuko T (1998) Polymer 39:5515

Tsuji H, Ikarashi K, Fukuda N (2004) Polym Degrad Stab 84:515

Tsuji H, Ikarashi K (2004) Polym Degrad Stab 85:647

Acknowledgments

The authors thank Ms. Mikiko Fujita, Textile Research Center, Aichi Industrial Technology Institute (AITEC) for the irradiation experiments. This research was supported by a Grant-in-Aid for Scientific Research on Priority Area, “Sustainable Biodegradable Plastics”, No. 11217209, and The 21st Century Centers of Excellence (COE) Program, “Ecological Engineering for Homeostatic Human Activities”, from the Ministry of Education, Culture, Sports, Science and Technology (Japan).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsuji, H., Echizen, Y. & Nishimura, Y. Enzymatic Degradation of Poly(l-Lactic Acid): Effects of UV Irradiation. J Polym Environ 14, 239–248 (2006). https://doi.org/10.1007/s10924-006-0023-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-006-0023-6