Abstract

We are developing a superconducting camera based on microwave kinetic inductance detectors (MKIDs) to observe 100-GHz continuum with the Nobeyama 45-m telescope. A data acquisition (DAQ) system for the camera has been designed to operate the MKIDs with the telescope. This system is required to connect the telescope control system (COSMOS) to the readout system of the MKIDs (MKID DAQ) which employs the frequency-sweeping probe scheme. The DAQ system is also required to record the reference signal of the beam switching for the demodulation by the analysis pipeline in order to suppress the sky fluctuation. The system has to be able to merge and save all data acquired both by the camera and by the telescope, including the cryostat temperature and pressure and the telescope pointing. A collection of software which implements these functions and works as a TCP/IP server on a workstation was developed. The server accepts commands and observation scripts from COSMOS and then issues commands to MKID DAQ to configure and start data acquisition. We made a commissioning of the MKID camera on the Nobeyama 45-m telescope and obtained successful scan signals of the atmosphere and of the Moon.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Nobeyama 45-m radio telescope is a well-established facility for mm-wavelength astronomy up to 150-GHz band. The telescope, with its large aperture size, can detect and survey small radio sources (\(\sim 15^{\prime \prime }\)) like distant galaxies if a powerful continuum camera is installed. For this purpose, a background-limited detector array of \(\sim 100\) pixels at 100-GHz band is desired so that their beams fill the field of view (FoV) of the telescope (\(\sim 3^{\prime }\)).

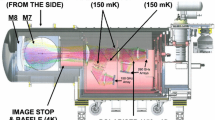

We are developing such a camera for 100-GHz bands with microwave kinetic inductance detectors (MKIDs) [1]. MKIDs can be multiplexed in a single readout line and are suitable for large detector arrays (e.g., [2,3,4]). The MKID made of aluminum is a lens antenna-coupled 1/4-wavelength coplanar waveguide (CPW) resonator on a 3-inch silicon (Si) substrate [5]. Each MKID pixel is fed by a double slot antenna coupled with a 5.7-mm-diameter Si lens[6]. The Si lens array and its anti-reflection coating based on the epoxy are fabricated at Advanced Technology Center (ATC) of NAOJ by an ultraprecision cutting machine and a high speed spindle [7, 8]. The cryostat of the MKID camera consists of a dilution refrigerator (Taiyo Nippon Sanso Co.) and a Gifford-McMahon refrigerator (Sumitomo Heavy Industries, Ltd.) as a cooling system, and a refractive optical system with 154-mm and 300-mm Si lenses so that the beams are coupled with the 45-m telescope relay optics. The readout system is based on FFTS [9, 10] with frequency sweeping [11]. The characteristics of MKIDs, especially its high sensitivity and ease of frequency multiplexing, are suitable for application as a radio continuum camera.

When the MKID camera is installed on the Nobeyama 45-m radio telescope, the readout system of the MKIDs has to work with the telescope control system, COSMOS [12]. Since all the data taken with the MKID camera are to be analyzed with the telescope information, such as the pointing in azimuth and elevation, the state of beam switch, the state of calibration loads, the whole data acquisition (DAQ) system is required to collect and save the information synchronously. We designed and integrated a DAQ system to operate the MKID camera with the telescope. The components and their relation are explained in this report.

2 Design of Data Acquisition System

Major requirements for the DAQ system are as follows. The DAQ system makes the MKID camera work harmoniously with COSMOS. The system is also required to record the reference signal of the beam switch for the demodulation by the analysis pipeline. The system has to be able to merge and save all data acquired both by the camera and by the telescope, including the cryostat temperature and vacuum pressure and the telescope pointing. In addition, the system is desired to provide quick-look data that observers would check.

An important point is the synchronization between the telescope and the MKID camera. The telescope scans can be done in on-the-fly (OTF) mode [13] with a sampling rate of 10 sps. A beam switch is equipped to suppress the effect of the sky fluctuation for radio continuum observations, whose switching rate is set to be 10–15 Hz. The requirement of synchronization, thus, is better than 10-ms precision.

A schematic figure of the system is shown in Fig. 1. One workstation can connect the camera system and telescope system. A collection of software implements these functions and works as a TCP/IP server on a workstation. The server accepts commands and observation scripts from COSMOS and then issues commands to MKID DAQ to configure and to start data acquisition. The workstation is placed in the lower cabin of the telescope, near to the port of the MKID camera. Observers use COSMOS workstations and a computer for MKID camera quick-look in the observing building. All the computers are connected in a local area network (LAN) as shown in Fig. 2.

2.1 MKID Readout System

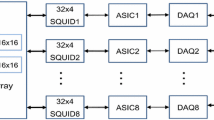

The key component of MKID readout system, shown in Fig. 3, is a prototype frequency-sweeping probe (FSP) circuit [11]. The FSP circuit has a pair of a digital-to-analog (D/A) converter and an analog-to-digital (A/D) converter to measure scattering parameter \(S_{21}\) for MKIDs on the feedline with probe tones. The both converters have a sampling rate of 4096 Msps and a bit width of 10 bit. The D/A converter generates a specified set of probe tones whose frequency is a multiple of 250 kHz below 1 GHz. The time-ordered data from the A/D converter are transformed into the frequency domain by fast Fourier transformation (FFT), and the complex amplitudes at the probe tone frequencies are selected to save in the hard disk drives (HDDs).

The probe tones from the FSP circuit are up-converted to the frequency range of the MKIDs (3–4 GHz) with a local oscillator (LO) signal of frequency about 3 GHz. To sweep the probe tone frequencies at the MKIDs by changing the LO frequency, a ramp signal generated by another A/D converter is sent to the external input port for frequency modulation of the synthesizer (Agilent Technologies, Inc., E8663D). These operations are done by four field-programmable gate arrays (FPGAs).

The FSP circuit has an embedded Linux system, and the data acquisition is controlled through an application software on the system (MKID DAQ). In order to control the FSP circuit from remote, a simple interface of remote control via TCP/IP is added to MKID DAQ. The available commands are only three: a command to start a data acquisition with a specified time, a command to stop the data acquisition immediately, and a query to check whether data are being acquired or not. File transfer and other remote operations can be done through Secure Shell (SSH).

2.2 Camera Control Workstation

The workstation runs processes to control data taking and to collect and store all data and runs the analysis pipeline (see Fig. 1). The ‘Command Receiver’ process receives commands as TCP/IP server from COSMOS, which triggers a data taking. Then, ‘DAQ Control’ sends commands to MKID DAQ on the FSP circuit.

The workstation also monitors the device status and the beam switch status through hardware interfaces, as shown in Fig. 4. The cryostat temperatures are collected through a temperature monitor (Lake Shore Cryotronics, Inc., Model 218) and a temperature controller (Model 350), and the cryostat pressure is measured with a vacuum gauge (Pfeiffer Vacuum, TPG 361). Their serial interface is converted to Universal Serial Bus (USB) and connected to the control workstation. A digital input and output (DIO) device (National Instruments Corporation, USB6211) is also connected to the control workstation to record the beam switch reference signal and the 1PPS signal in a sampling rate of 80 ksps. These information is collected by the ‘Status Monitor’ process.

2.3 Synchronization

Since the components have each internal clock, keeping synchronization and correcting timing offset between the components are the task in system integration. For this purpose, a clock pulse 1PPS and a 10-MHz reference signal provided from the telescope are used. The 10-MHz reference is received by the synthesizer and distributed to the FSP circuit. The 1PPS signal is distributed to the DIO device of the control workstation and the FSP circuit. The FSP circuit generates an internal 1PPS signal from the 10-MHz reference signal.

Computer system clocks (COSMOS, the control workstation, and the FSP circuit) are synchronized with NTP servers of the observatory. The control workstation and the FSP circuit gives the timestamp on the 1PPS signal by using the system clock. The timing of the beam switch reference signal is determined by the 1PPS data obtained by the DIO device. The timing offset of the FSP circuit between the external and internal 1PPS signals is measured before operation. These offsets are corrected in the pipeline analysis, which gives an accuracy better than 0.1 ms. Thus, this method satisfies our requirement (\(< 10\) ms). Still the synchronization of 1-s scale is need to be checked during operation because the time tagging for 1PPS could shift by \(\pm 1\) s among the instruments.

2.4 Data Flow and Analysis Pipeline

The data flow of the acquisition system is shown in Fig. 5a. The data sources are COSMOS and Camera DAQ, i.e., the MKID DAQ and ‘Status Monitor’. The data are generated in real time, merged in near real time, and analyzed as batch process.

The steps of the analysis pipeline are summarized in Fig. 5a. A desired output is OTF data in Flexible Image Transport System (FITS) file format, suitable for existing analysis tools, such as Nobeyama OTF Software Tools for Analysis and Reduction (NOSTAR). The pipeline does all process to obtain NOSTAR files of radiation temperature.

3 Test Measurements

The functions of the camera workstation, communication with COSMOS and operations of beam switching, were tested on the 45-m telescope before MKID camera installation. The continuum output was taken from a receiver (H22) instead of the MKID camera. Beam-switched data of a celestial point source (NRAO 530) and its demodulated signals are obtained successfully.

For the first commissioning, the MKID camera was installed on the 45-m telescope on 22 December 2016. A test device with 19 MKIDs (19 beams) was used. After 5 days of cooling, the device temperature reached 65 mK. The test measurements were taken 5 days from December 30, 2016, to January 5, 2017, 4 h each day. The optical response of the device was confirmed by the shift of the MKID resonance frequencies induced by beam chopping by a hot-load. Tipping scans for atmospheric opacity were done, and the Moon was observed for the first light. Measurements both with and without beam switching were taken. Basic functionality of the DAQ system was checked during these measurements.

The Moon was observed with go-and-return scan. Each scan is \(1^{\circ }\) in length and 60 s in duration. Signals of the Moon were obtained successfully. Figure 6 shows an example of resonance frequency data for the Moon signal of azimuth scan without beam switching. We also checked that the off-resonance data shows no response to the Moon. The azimuth offset (dAz) in horizontal axis was taken from the antenna log. The position difference in the Moon signal between go scan and return scan is less than 0.02 degree. This corresponds to the timing offset between the telescope motion and the MKID data less than 1 s. Thus, we found no significant time difference between the telescope and the camera system and confirmed that the time tagging for 1PPS is correct during the observation.

MKID response for go-and-return scan of the Moon. The resonance frequency of an MKID (#10) at the A/D converter is plotted to the azimuth offset of the telescope direction from the center of the Moon. The Moon signal appears in the same position in go scan (purple) and return scan (green), which indicates the time difference between the telescope and the camera is small (Color figure online)

In Fig. 6, the sky levels obtained by go scan and return scan are different, and those of the east side and the west side are also different. These differences are likely to be due to the time and spatial variation of atmospheric radiation, though we could not exclude the possibility that there is systematic drift of the camera response. Intensity calibration by the chopper-wheel method and beam switching are expected to remove these effects.

4 Summary

A data acquisition system has been developed to operate the MKID camera with the Nobeyama 45-m telescope. The system connects the readout system of MKIDs based on FFTS with frequency sweeping and the telescope control system COSMOS. We made the first commissioning of the MKID camera on the Nobeyama 45-m telescope and obtained successful scan signals of the atmosphere and of the Moon.

For the next step, a 109-pixel MKID camera is being developed. The design of the DAQ system is scalable on the number of MKIDs, and the scalability will be demonstrated in the next commissioning. On the other hand, the data rate will reach the limitation by the hardware of the prototype FSP circuit; upgrades of its hardware and/or firmware to improve the effective data rate are practical for larger MKID arrays.

References

P.K. Day, H.G. LeDuc, B.A. Mazin, A. Vayonakis, J. Zmuidzinas, Nature 425, 817 (2003). https://doi.org/10.1038/nature02037

K. Hattori, S. Ariyoshi, M. Hazumi, H. Ishino, A. Kibayashi, S. Mima, C. Otani, N. Satoh, T. Tomaru, M. Yoshida, H. Watanabe, J. Low Temp. Phys. 167, 671 (2012). https://doi.org/10.1007/s10909-012-0506-x

O. Bourrion, C. Vescovi, J.L. Bouly, A. Benoit, M. Calvo, L. Gallin-Martel, J.F. Macias-Perez, A. Monfardini, J. Instrum. 7, 7014 (2012). https://doi.org/10.1088/1748-0221/7/07/P07014

J. van Rantwijk, M. Grim, D. van Loon, S. Yates, A. Baryshev, J. Baselmans, IEEE Trans. Microwave Tech. 64, 1876 (2016). https://doi.org/10.1109/TMTT.2016.2544303

Y. Sekimoto, T. Nitta, K. Karatsu, M. Sekine, S. Sekiguchi, T. Okada, S. Shu, T. Noguchi, M. Naruse, K. Mitsui, N. Okada, T. Tsuzuki, A. Dominjon, H. Matsuo, Millimeter, submillimeter, and far-infrared detectors and instrumentation for astronomy VII. Proc. SPIE 9153, 915 (2014). https://doi.org/10.1117/12.2055666

T. Nitta, M. Naruse, Y. Sekimoto, K. Mitsui, N. Okada, K. Karatsu, M. Sekine, H. Matsuo, T. Noguchi, Y. Uzawa, M. Seta, N. Nakai, IEEE Trans. Terahertz Sci. Technol. 3, 56 (2013). https://doi.org/10.1109/TTHZ.2012.2235123

K. Mitsui, T. Nitta, N. Okada, Y. Sekimoto, K. Karatsu, S. Sekiguchi, M. Sekine, T. Noguchi, J. Astron. Telesc. Instrum. Syst. 1(2), 025001 (2015). https://doi.org/10.1117/1.JATIS.1.2.025001

T. Nitta, S. Sekiguchi, Y. Sekimoto, K. Mitsui, N. Okada, K. Karatsu, M. Naruse, M. Sekine, H. Matsuo, T. Noguchi, M. Seta, N. Nakai, J. Low Temp. Phys. 176, 677 (2014). https://doi.org/10.1007/s10909-013-1059-3

S.J.C. Yates, J.J.A. Baselmans, A.M. Baryshev, Y.J.Y. Lankwarden, L. Swenson, A. Monfardini, B. Klein, R. Güsten, in American Institute of Physics Conference Series, vol. 1185, ed. by B. Young, B. Cabrera, A. Miller, American Institute of Physics Conference Series, vol. 1185 (2009), pp. 249–252. https://doi.org/10.1063/1.3292325

K. Karatsu, M. Naruse, T. Nitta, M. Sekine, S. Sekiguchi, Y. Sekimoto, T. Noguchi, Y. Uzawa, H. Matsuo, H. Kiuchi, J. Low Temp. Phys. 176, 459 (2014). https://doi.org/10.1007/s10909-014-1115-7

H. Kiuchi, T. Okada, K. Karatsu, Y. Sekimoto, IEEE Trans. Terahertz Sci. Technol. 5, 456 (2015). https://doi.org/10.1109/TTHZ.2015.2413751

K.I. Morita, M. Nakai, T. Takahashi, K. Miyazawa, M. Ohishi, T. Tsutsumi, S. Takakuwa, H. Ohta, K. Yanagisawa, in Astronomical data analysis software and systems XII, Astronomical Society of the Pacific Conference Series, ed. by H.E. Payne, R.I. Jedrzejewski, R.N. Hook, Astronomical Society of the Pacific Conference Series, vol. 295 (2003), p. 166

T. Sawada, N. Ikeda, K. Sunada, N. Kuno, T. Kamazaki, K.I. Morita, Y. Kurono, N. Koura, K. Abe, S. Kawase, J. Maekawa, O. Horigome, K. Yanagisawa, Publ. Astr. Soc. Jpn. 60, 445 (2008). https://doi.org/10.1093/pasj/60.3.445

Acknowledgements

This work was supported by JSPS KAKENHI Grant Numbers JP25247022, JP26247019, and JP17H01115, and was achieved using the grant of Joint Development Research (FY2014, FY2017) supported by the Research Coordination Committee, National Astronomical Observatory of Japan (NAOJ), National Institutes of Natural Sciences (NINS). The Nobeyama 45-m radio telescope is operated by Nobeyama Radio Observatory, a branch of National Astronomical Observatory of Japan. The authors would like to thank the operation team of the Nobeyama 45-m radio telescope.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nagai, M., Hisamatsu, S., Zhai, G. et al. Data Acquisition System of Nobeyama MKID Camera. J Low Temp Phys 193, 585–592 (2018). https://doi.org/10.1007/s10909-018-1961-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10909-018-1961-9