Abstract

New nonstoichiometric polyelectrolyte complex was prepared based on chitosan (CS) and Carboxymethyl cellulose (CMC) and the addition of ZnO nano particles prepared by green synthesis from Nettle leaf extract for increasing the antibacterial properties. The composites were prepared in different mass ratios and the physicochemical properties of the complexes were investigated by means of scanning electron microscopy, atomic force microscopy, FTIR analyzer, water absorption test, UV–Vis analyzer and thermal analyzer. The results indicated that the slow dropwise addition of CMC to chitosan allowed elaborating either anionic or cationic particles in the size range of 35.5–69.7 nm. The water uptake and the ash percentage of the nano composites increase by increasing the amount of CMC and the transparency and the opacity of Chitosan:CMC (75:25) is the best. The highest antibacterial activity related to the synthesised composite without nano ZnO for Escherichia coli and the best result achieved in prepared nano composite and adding nano ZnO (PCC3/ZnO) in Staphylococcus aureus medium.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Polyelectrolyte complexes (PECs) are the coalition complexes formed between oppositely charged particles and formed owing to the electrostatic interaction between oppositely charged ions [1,2,3]. This sidestep the use of chemical cross-linking agents, reducing the possible toxicity and other unpleasant effects of the reagents [3,4,5].

Chitosan is one of the most abundant polymers after cellulose [6, 7]. Chitosan is a biopolymer of d-Glucosamine and N-Acetyl, which is obtained from n-d-acetylation of chitin by alkaline solutions [8]. Chitin is a natural polysaccharide and is prominently found in shells of crustaceans such as shrimp, crabs, squid, and fungal cell walls [9,10,11]. The main parameters that have a direct effect on the properties of chitin and chitosan include molecular weight and the degree of de-acetylation [12,13,14]. The number of acetyl groups on the polymer chain, specify the differences between chitin and chitosan. The polymer, which hundred percent of amine groups, is acetylated, is called chitin and polymers that are free of amino groups are chitosan. Contiguously, the presence of 50% of amino groups is considered to be the boundary between chitin and chitosan, that is, polymer with a degree of de-acetylation of less than 50 is as chitin and more than 50% called chitosan [6]. Most polysaccharides in nature, including cellulose, dextrin and pectin, are neutral and acidic. While chitin and chitosan are available in the form of alkaline in nature. Chitin due to lipophilic properties is insoluble in water and many water solvents. Chitosan is soluble in dilute acids such as acetic acid, formic acid and lactic acid. In fact, chitosan is used in a variety of industries, including food packaging [13], sewage treatment [14], water engineering [15] and cosmetics [16], as well as in tissue engineering. Chitosan has a variety of promising pharmaceutical uses, is presently considered as a novel carrier material in drug delivery systems [17], and can be used to absorb heavy metal ions [18]. There are four main methods for making nano-chitosan: polyelectrolyte complex [19], ionotropic gelation [20], Micro emulsion [21] and Emulsification solvent diffusion [22]. Polyelectrolyte complex (PECs) on the base of natural and synthetic polymers evoke a particular interest. A complex polyelectrolyte method is an interaction between molecules with opposite loads, which in this method, chitosan, which is a natural cationic polymer, can be used [23,24,25]. Due to the presence of amine groups at its surface, recent use of large molecule complexes with opposite loads in nanoparticles has attracted a lot of attention which by this method the production of nano films with very favorable physical and chemical characteristics is allowed. This avoids the use of other chemical reagents. The use of materials such as gelatin, alginate and carboxymethyl cellulose [26], which are inexpensive and available biopolymers has been used to produce films and hydrogels, which has some interesting advancements in this field [27]. Polyelectrolyte complexes are formed by interactions between macromolecules that carry oppositely charged ionizable groups. During the last years, PECs on the base of natural and synthetic polymers evoke a particular interest because this process is simple, feasible, and can usually be performed under mild conditions [23]. The hydrogen bonds are involved in the intermolecular interactions even before dissolution in an aqueous medium. There are two ways in which hydrogen bonds are formed: Between the carbonyl containing acetyl groups and CH2OH groups between the hydroxyl groups and the deoxy of the neighboring molecules [28].

One of the important properties of chitosan is antibacterial properties that develop of its application [29].

The cationic nature of chitosan causes antimicrobial activity [30]. The interaction between positively site of chitosan and the opposite charge microbial causes the development of antibacterial properties. These days researchers attend to use nanotechnology in various industries and using this very small scale for antibacterial purposes have been done [31,32,33,34]. The inorganic antibacterial materials and metal oxide such as zinc oxide has great attention because they are very healthy for human and animal [33, 35, 36]. ZnO nanoparticle are important for variety of medical applications because of their antibacterial properties [32]. Currently, metal oxide nanoparticles are considered because of their availability, different usage include remediation, environmental, sensor, catalyst and antibacterial [37].

The synthesis of metal and metal oxide nanoparticle have been done by physical, chemical, biological and finally green method that green method is environmentally friendly alternative [38].

In this study, chitosan particles were prepared from the chitin of shrimp shells and then nano chitosan film was prepared by polyelectrolyte complex method using carboxymethyl cellulose. Furthermore, ZnO nanoparticles prepared by the green synthesis from Nettle leaf extract and added to the composites. The structure of the prepared films was proved by FT-IR, SEM, XRD, and AFM following by measurement of water absorption, ash and antibacterial properties.

2 Materials and Method

2.1 Materials

Chitosan prepared by chitin of shrimp (CS, the degree of deacetylation (DD) was 88%), Carboxymethyl cellulose (100%, Titrachem), Glycerol (85%), Acetic acid (glacial, 100%) and Zinc acetate dehydrate (98%) are from Merck company.

2.2 Leaf Extract

10 g of dried Nettle leafs was boiled in 70 cc of water and 30 cc of ethanol for 15 min, then the extracted filtered by filter paper following by centrifuging to achieve the liquid with no solid substances.

2.3 Preparation of Nano Zinc Oxide Particles

1 ml of Nettle leafs extract was added to 50 ml of 0.01 M zinc acetate dehydrate solution and the pH of the solution was adjust to 12. The solutions was stirred using magnetic stirrer at room temperature for 1 h. Changing the color of the solution into milky white indicates the particles formation. The solution was centrifuged at 10,000 rpm for 10 min, then the supernatant was discarded and the particles were collected. The resulting dried sample was crushed into powder and stored in airtight container for further analysis [39].

2.4 Preparation of Chitosan/Carboxymethyl Cellulose Nanocomposite

Chitosan–Carboxymethyl cellulose (CS–CMC) nanoparticles were prepared by mixing a positively charged CS, acetic acid solution and a negatively charged CMC solution at room temperature. For this purpose, 1 g chitosan was dissolved in acetic acid solution (1% w/w) and stirred for 24 h, then filtered by filter paper for future use. Then 1.0 g of CMC was dissolved in 100 g deionized water, stirred for 6 h and then filtered by filter paper. Afterward, the CMC solution was used as a base material and the CS solution was dropped into it in different ratio: 25:75 (PCC1), 50:50 (PCC2) and 75:25 (PCC3) at a dropping rate of one drop per second under magnetic stirring. The opalescent suspension was formed. The obtained suspension was then filtered by the filter paper, following the particle formation process, glycerin is added to the formed solution, and the material is poured into the container after mixing.

After preparation of nanocomposite chitosan/carboxymethyl films, the physical structure of the films were studied in terms of moisture absorption, then the best sample was selected, and the selected composite prepared again and at the final step of the preparation, 0.05 g of zinc oxide nanoparticles was added to its constituents.

2.5 Instrumentation

The FT-IR spectra obtained from chitosan and nano chitosan by FT-IR device model Thermo Nicolet Nexus 870. The scanning electron microscopy analysis was performed by SIGMA VP500 model. The Atomic force microscopy analysis was performed by DME-95-50E model. The XRD patterns was performed using Philips, PW1730 analyzer. The thermal degradation of the composites were recorded by using thermo gravimetric analyzer by NETZSCH TG 209 F1 Iris modle. The UV–Vis test was measured using a spectrophotometer model 2100 UWI.

2.6 Transparency and the Transmittance

The transparency and the Transmittance of the samples were calculated with the help of Eqs. 1 and 2 respectively. To achieve this purpose, a piece of the intact part of the bio composite without tear was selected and cut into strips (30 mm × 10 mm) and put it into dry glass cuvette and then the absorbance was measured at the several wavelength between 100 and 600 nm.

In which; A: absorption, T: transmittance.

2.7 Ash Percentage

To measure the amount of residual ash, 2 g of each chitosan composite film was put into crucible and the samples were burned by electrical furnace at 550 °C for 4 h. Then the residual ash content was calculated using Eq. 3 [40].

W1: Initial weight of the sample, W2: The final weight of the sample.

2.8 Hydrophilicity and Moisture Content

To measure the percentage of water absorption of the films, which is a mechanical property, a small piece of a film (1.5 × 1 cm2) was first dried in an oven at 40 °C for 24 h then immersed in a beaker containing 20 ml of water and kept for 10 min. Then the film was removed from the water and the surface was dried using filter paper and then weighed again and the water absorption was calculated by using Eq. 4 [40].

In which W1: Initial weight of the sample, W2: Final weight of the sample.

Measurement of the moisture content of composite is calculated using the following equations. To measure the moisture content of the prepared films, 0.5 g of the sample was put into a Chinese plant and placed in an oven at 110 °C for 1 h. The moisture content was calculated according to Eq. 5 [40]:

where W1: Initial weight of the sample (g), W2: Final weight of the sample (g).

2.9 Antibacterial Properties

For the antibacterial tests, S. aureus (PTCC 1112) and E. coli (PTCC 1270) representing gram-positive and gram-negative bacteria, respectively, were selected. Initially, three samples of gel materials were selected: chitosan hydrogel (CS), a chitosan with carboxymethyl cellulose hydrogel sample (PCC3), and a chitosan with carboxymethyl cellulose hydrogel sample with 0.05 g of zinc oxide nano particles (PCC3/ZnO). A dilution of 1.5 × 10–8 McFarland from the desired bacteria was prepared and 100 μl of the bacteria solution was poured into the prepared culture medium and uniformly spread using sterile cotton swab. Next, a pasture pipette was used to make three wells in each plate and the culture medium was removed from the wells. The wells were then filled with 30 μl of the selected samples. The plates were put inside the incubator at 37 °C for 24 h and eventually, depending on the amount of halo of the lack of bacterial growth, the inhibition zone was measured.

3 Results and Discussion

3.1 FT-IR Analysis

The interaction of composites were further assertion by Fourier-transform infrared (FTIR) spectroscopy. Figure 1 indicates the spectra of chitosan and nano chitosan composites.

The peaks appearing in the region of 3430 cm−1 represent the combination of NH2 and OH groups. The peak at 1160 cm−1 indicating the presence of the vibration of C–O–C group, and the peak at 1655 cm−1 indicates the presence of the CO group [41]. The difference between chitosan and nano chitosan film in the FTIR spectrum is that the peaks appearing in chitosan are more intense. The interaction between chemical groups on different natural polymers must shift to a peak of competitor groups. This evidences the formation of strong polyelectrolyte complex exist between chitosan and carboxymethyl cellulose and by changing the amount of substances it shows small gaps.

3.2 XRD Patterns

Synthesized ZnO nano particles were subjected to X-ray diffraction studies, to obtain the crystallinity and average particle size of the synthesized nanoparticles. The size of the nanoparticles was calculated from Debye-Scherr's equation (Eq. 6) [42].

where d is the average particle size (nm), k is 0.89, λ is 0.154060 nm for Cu Kα and β is the full width of half maximum (FWHM) of the peak.

The XRD pattern of the nano ZnO is shown in Fig. 2.

Following figure, reveal the XRD pattern of zinc oxide nanoparticles [43]. The peaks appear at 2θ = 31.77° (100), 34.44° (002), 36.27° (101), 47.62° (102), 56.73° (110), 62.96° (103), 68.06° (112), 69.13° (201) and 77.04 (202) are belong to ZnO nano particles [065121]. By using Debye-Scherr's equation, the mean crystal size of nano ZnO was calculated 30 nm.

3.3 SEM Images

Figure 3 shows the SEM images of the prepared nano chitosan film. The images show that the particles are regular and spherical structure. The image of scanning electron microscope indicate the composites were coalescence in somewhere. In natural polymer composites the voids have tendency to fill with the opposite ingredient. The SEM images indicate that the size of the particles change between 35.5 and 69.7 nm. The size of nano ZnO particles were measured by scanning electron microscopy that found to be 48–77 nm. These images showed that the particles are intersperse. Structural characteristics indicate that the particles are almost spherical [38].

3.4 AFM Analyses

AFM images of the prepared nanocomposites are shown in Fig. 4. Atomic force microscopy is high spatial and vertical resolution and has been applied to determined morphology and topography of the surface. The polyelectrolyte complex method is an usual method used to prepare chitosan nanoparticle. During the process the interaction between positively charged amino group on chitosan and oppositely charged carboxymethyl cellulose cause to be created crosslink in biocomposite. According to the following figures chitosan indicates mote and mound structure and uneven pores tophography. The surface roughness of pure chitosan film is less than other nano composite. According to the images obtained from the composite surface, it can be seen that by increasing the amount of carboxymethyl cellulose an increase in porosity on the surface happens. The topography patterns of nano particle include of heights from 0 to 70 nm.

3.5 Thermal Characterization of the Samples

Thermal studies of all the samples were performed in the temperature between 50 and 700 °C at the heating rate of 10 °C min−1.

Thermal studies are very important in these similar cases of polymers because they are applicated for packaging and the films perhaps expose to heat processes. TGA analysis of the effect of different ratios of carboxymethyl cellulose in natural polymer are shown in Fig. 5. The first step of decrease of weight happens between 0 and 100 °C by losing water. The lose of weight continues to 230 °C and also keep on to 400 °C. After 400 °C this process occurred very hurriedly.

As it said the initial reduction weight related by evaporation of water and the seconde step and the third and fourth stage related to dehydration of the polysaccharide. According to the figures as the temperature increases from 30 to 130 °C about 5wt% weight loss happens. The second step in above 100 °C until 280 °C have 96 wt% lossing weight by destruction of the chitosan structure [44].

3.6 Transparency and Transmittance of the Samples

Table 1 shows the absorbance of the samples in different wavelength. The transmittance and transparency of the samples were calculated using Eqs. 1 and 2 and shown in Tables 2 and 3 respectively.

The film with high light transmittance can be used in food industry and the contents can be clearly visible for packaging application.

The most transmittance and transparency were observed at wavelengths of 200 and 600 nm, respectively. Actually in 600 nm the lower the passage, the less corruption occurred. As the amount of transparency increases, the opacity is increased. So, in this experimental PCC1 shows the best transparency.

3.7 Ash Percentage

The quality of chitosan based composite films can be measurement of several parameter. One of them is the amount of minerals in the structure, which can be calculated by the percentages of ash (Eq. 3). The results of the ash test are presented in Fig. 6.

Chitosan and bio composite contain mineral elements such as calcium, sodium, potassium and magnesium. It is clear that calcium content is more than other minerals in chitin. This is because the main component of minerals in shrimp shell is calcium carbonate. Mild acid treatment after fermentation reduced the mineral content to permissible limits in the chitin. One of the factors determining the good quality of chitin is the low mineral content. The investigation of this experimental can be understood how much mineral material is in bio composite. The percentage of ash show that by adding the CMC in the structure of the composite the percentage of ash is increased.

3.8 Hydrophilicity and Moisture Content of the Films

The water absorption and moisture permeability coefficients of a film are related to the hydrophilicity of the molecules. The percentage of water uptake is also one of the important characteristics of the films that affect the quality of the films. It was suggested that it is affected by factors such as crystallinity, hydrophobic properties, and film thickness and integrity of the film components. All three-precursor molecules of the composite film contain a large number of hydrophilic hydroxyl groups, which significantly increases the permeability coefficients of all substrate combinations, thereby limiting the application of the film to packaging of food with lower water content. This is due to interaction between water and hydroxyl and amino groups in chitosan [45]. The amount of hydrophilicity is a parameter related to the total volume vacant occupied by water molecules in the microstructure of the film network, while the solubility is related to the water-solubility of the substance. According to Eqs. 4 and 5 the value of water absorption and moisture content are shown in Figs. 7 and 8 respectively. The percentage of water absorption related to the presence of carboxymethyl cellulose in the samples because CMC has a surface hydroxyl group and can easily adsorb water. The absorbance of water by CMC is not found to be so high [46]. It is reported by Othma et al. as well [47]. Furthermore, it showed that the hydrophilic acetyl group cause water absorption in chitosan films.

The results in this Figures show that the highest percentage of moistureis related to nano composite (PCC3) and the lowest absorption of water is related to chitosan film alone with no addition of carboxymethyl cellulose.

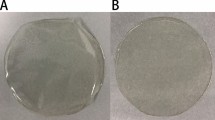

3.9 Antibacterial Activities of the Prepared Nano Composites

Thentibacterial activities and inhibition zone of the composites were shown in Fig. 9. Furtheremore, Table 4 shows the antibacterial results of the chitosan film alone, nano composite film and nano composite film with ZnO nano particles. According to the results of the microbial test and according to the results, it can be concluded that the nano composites have a better effect on gram positive bacteria than gram-negative bacteria.

With regard to the results obtained from the Table 4, in the case of S. aureus bacteria, according to the formation of bigger halo, the antibacterial property of PCC3/ZnO shows better activity and, in the case of E. coli, the best performance belongs to PCC3 which shows 20 mm of inhibition zone.

4 Conclusion

In this research, chitosan from shrimp skin with a degree of deacetylation of 88% was prepared. On the other hand ZnO nano particles was prepared from Nettle leafs extract by green synthesis method. Furthermore, nano composite films by using a polyelectrolyte complex method and adding carboxymethyl cellulose to chitosan solution were prepared as well. Three nano composite films were made in different mass ratios of chitosan and carboxymethyl cellulose and variety analysis were performed on them. FT-IR analyses show the interaction between chemical groups on different natural polymer matrix. XRD patterns prove the formation of ZnO crystals and the size of nano ZnO was calculated to be about 30–60 nm using SEM images. Furthermore, the mean size of the nano particles in the composite films were measured 48–77 nm.

According to the images obtained from the composite surface by AFM, it can be seen that by increasing the amount of carboxymethyl cellulose an increase in porosity on the surface happens. The percentage of ash show that by adding the CMC in the structure of the composite the percentage of ash is increased and UV–Vis test show that the transparency and the opacity of PCC1 is the best. Furthermore the water uptake of the composites increase by increasing the amount of CMC.

Antibacterial results show that all of the composites have antibacterial activities and the highest antibacterial activity related to the synthesized composite without nano ZnO (PCC3) in E. coli medium culture and the best result achieved in prepared nano composite with nano ZnO (PCC3/ZnO) in S. aureus medium. As a result chitosan/carboxymethyl cellulose composite films incorporation with zinc oxide nano particles can be a good alternative as the biodegradable coatings instead of synthetic ones in food industries.

References

S. Argin-Soysal, P. Kofinas, Y.M. Lo, Food Hydrocolloids 23, 202 (2009)

S.L. Patwekar, A.P. Potulwar, S.R. Pedewad, M.S. Gaikwad, S.A. Khan, A.B. Suryawanshi, IJPPR 5, 97 (2016)

N.G. Voron’ko, S.R. Derkach, Y.A. Kuchina, N.I. Sokolan, Carbohydr. Polym. 138, 265 (2016)

Y. Zheng, W. Yang, C. Wang, J. Hu, S. Fu, L. Dong, L. Wu, X. Shen, Eur. J. Pharm. Biopharm. 67, 621 (2007)

J.C. Roy, A. Ferri, S. Giraud, G. Jinping, F. Salaün, Int. J. Mol. Sci. 19, 2521 (2018)

C. Vasile, R.N. Darie, C.N. Cheaburu-Yilmaz, G.-M. Pricope, M. Bračič, D. Pamfil, G.E. Hitruc, D. Duraccio, Composites B 55, 314 (2013)

M. Kurniasih, T. Cahyati, R.S. Dewi, Int. J. Biol. Macromol. 119, 166 (2018)

D. Nataraj, S. Sakkara, M. Meghwal, N. Reddy, Int. J. Biol. Macromol. 120, 1256 (2018)

Y. Dun, Y. Li, J. Xu, Y. Hu, C. Zhang, Y. Liang, S. Zhao, Int. J. Biol. Macromol. 123, 420 (2019)

J. Brugnerotto, J. Lizardi, F.M. Goycoolea, W. Argüelles-Monal, J. Desbrieres, M. Rinaudo, Polymer 42, 3569 (2001)

G. Ru, S. Wu, X. Yan, B. Liu, P. Gong, L. Wang, J. Feng, Carbohyd. Polym. 206, 487 (2019)

H. El Knidri, R. Belaabed, A. Addaou, A. Laajeb, A. Lahsini, Int. J. Biol. Macromol. 120, 1181 (2018)

W. Lan, L. He, Y. Liu, Coatings 8, 291 (2018)

N. Devi, J. Dutta, Int. J. Biol. Macromol. 104, 1897 (2017)

F.W. Pontius, Am. J. Civil Eng. 4, 205 (2016)

I. Aranaz, N. Acosta, C. Civera, B. Elorza, J. Mingo, C. Castro, M.D.L. los Gandía, A. Heras Caballero, Polymers 10, 213 (2018)

O. Felt, P. Buri, R. Gurny, Drug Dev. Ind. Pharm. 24, 979 (1998)

G.Z. Kyzas, D.N. Bikiaris, Mar. Drugs 13, 312 (2015)

R. Sainitya, M. Sriram, V. Kalyanaraman, S. Dhivya, S. Saravanan, M. Vairamani, T.P. Sastry, N. Selvamurugan, Int. J. Biol. Macromol. 80, 481 (2015)

M.R. Avadi, A.M.M. Sadeghi, N. Mohammadpour, S. Abedin, F. Atyabi, R. Dinarvand, M. Rafiee-Tehrani, Nanomed. Nanotechnol. Biol. Med. 6, 58 (2010)

J. Zhi, Y. Wang, Y. Lu, J. Ma, G. Luo, React. Funct. Polym. 66, 1552 (2006)

J. Karnchanajindanun, M. Srisa-ard, Y. Baimark, Carbohyd. Polym. 85, 674 (2011)

S. Dakhara, C. Anajwala, Syst. Rev. Pharm. 1, 121 (2010)

N. Bhardwaj, S.C. Kundu, Carbohyd. Polym. 85, 325 (2011)

P. Coimbra, P. Ferreira, H.C. De Sousa, P. Batista, M.A. Rodrigues, I.J. Correia, M.H. Gil, Int. J. Biol. Macromol. 48, 112 (2011)

S. M. Azharuddin, Studies on Different Chitosan Polyelectrolyte Complex (Pec) Hydrogels for Modified Release of Diltiazem Hydrochloride, Thesis (2010)

W.L. Ng, W.Y. Yeong, M.W. Naing, Procedia CIRP 49, 105 (2016)

J.R. Rodríguez-Núñez, T.J. Madera-Santana, D.I. Sánchez-Machado, J. López-Cervantes, H.S. Valdez, J. Polym. Environ. 22, 41 (2014)

T.K. Sini, S. Santhosh, P.T. Mathew, Carbohydr. Res. 342, 2423 (2007)

D. Hu, H. Wang, L. Wang, LWT Food Sci. Technol. 65, 398 (2016)

M. Atef, M. Rezaei, R. Behrooz, Int. J. Biol. Macromol. 70, 537 (2014)

N. Padmavathy, R. Vijayaraghavan, Sci. Technol. Adv. Mater. 9, 035004 (2008)

S.E.-S. Saeed, M.M. El-Molla, M.L. Hassan, E. Bakir, M.M.S. Abdel-Mottaleb, M.S.A. Abdel-Mottaleb, Carbohyd. Polym. 99, 817 (2014)

H. Mu, Y. Chen, N. Xiao, Bioresour. Technol. 102, 10305 (2011)

A.A. Tayel, W.F. El-Tras, S. Moussa, A.F. El-Baz, H. Mahrous, M.F. Salem, L. Brimer, J. Food Saf. 31, 211 (2011)

Y. Liu, L. He, A. Mustapha, H. Li, Z.Q. Hu, M. Lin, J. Appl. Microbiol. 107, 1193 (2009)

T. Karnan, S.A.S. Selvakumar, J. Mol. Struct. 1125, 358 (2016)

S. Pal, S. Mondal, J. Maity, R. Mukherjee, Int. J. Nanosci. Nanotechnol. 14, 111 (2018)

Y. Li, W. Zhang, J. Niu, Y. Chen, ACS Nano 6, 5164 (2012)

F. Lukitowati, D.J. Indrani, Iran. J. Pharm. Sci. 14, 57 (2018)

A. Pawlak, M. Mucha, Thermochim. Acta 396, 153 (2003)

L. Hua Li, J.C. Deng, H.R. Deng, Z.L. Liu, L. Xin, Carbohydr. Res. 345, 994–998 (2010)

H. Sarma, K.C. Sarma, Int. J. Sci. Res. Publ. 4, 1 (2014)

H.N. Lim, N.M. Huang, C.H. Loo, J. Non-Cryst. Solids 358, 525 (2012)

Q. Cao, Y. Zhang, W. Chen, X. Meng, B. Liu, Int. J. Biol. Macromol. 106, 1307 (2018)

S. H. Othman, N. R. Kechik, R. A. Shapi’i, R. A. Talib, and I. S. Tawakkal, J. Nanomateri. 2019, (2019).

T. Kawasaki, T. Nakaji-Hirabayashi, K. Masuyama, S. Fujita, H. Kitano, Colloids Surf. B 139, 95 (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zahiri Oghani, F., Tahvildari, K. & Nozari, M. Novel Antibacterial Food Packaging Based on Chitosan Loaded ZnO Nano Particles Prepared by Green Synthesis from Nettle Leaf Extract. J Inorg Organomet Polym 31, 43–54 (2021). https://doi.org/10.1007/s10904-020-01621-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-020-01621-7