Abstract

The purpose of this study was to investigate the photocatalytic/antimicrobial properties of biodegradable film based on wheat gluten/zinc oxide nanocomposites (WG/ZnO) for the active packaging of food products. In this study, central composite design (CCD) was used to study the effect of gluten percent (15, 22.5 and 30%) and ZnO percent (0, 2 and 4%) on the photocatalytic, mechanical and physicochemical properties of WG/ZnO film. Some properties of films, including antimicrobial, antioxidant, FT-IR, SEM, solubility, water absorption, thickness, moisture, colorimetric (L*, a* and b*) and opacity were investigated. Antibacterial and antifungal properties of films based on photocatalytic activity were investigated in three wavelengths of 500, 365 and 254 nm on the Escherichia coli and Aspergillus Niger. The results of the photocatalytic/antimicrobial activity of the films showed that pure gluten film had no effect on bacteria and fungi at three wavelengths, but films containing zinc oxide nanoparticles showed a significant inhibitory effect on bacteria and fungi at 365 and 254 nm. Antibacterial and anti-fungal inhibitory effects were observed at 254 nm stronger than 365 nm (p < 0.05). This result showed that at lower wavelengths the photocatalytic activity was induced to the film. The results of the antioxidant test showed that pure gluten had no antioxidant activity, but antioxidant activity increased with increasing zinc oxide nanoparticles significantly (p < 0.05). The results of the FT-IR analysis showed that new interactions between zinc oxide nanoparticles and gluten polymer of wheat were created. The results showed that when the ZnO particle concentration was low, these particles were distributed uniformly, but high concentration of zinc oxide in the film leaded to agglomeration of these particles.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, there has been a significant expansion in the use of biodegradable technologies in the world. Biodegradable materials and products create a clean, healthy and stable environment. Synthetic plastics are not biodegradable and cannot be recycled in the environment. There are compounds that reduce the environmental hazards of synthetic plastics and can be substituted with these compounds [1]. Wheat gluten is a by-product of starch production and ethanol production as biofuel, and is available at a low cost [2]. Generally gluten films are pure and clear, the more purity the film causes of production of more transparent and stronger films. Gluten films are a good barrier to oxygen and carbon dioxide, but the mechanical resistance of gluten film is lower than other films. The strength of the gluten film is increased by adding a cross-link-agent. The biggest barrier to using gluten films is that the water is penetrating easily from these films. Gluten is used to cover peanuts and to encapsulate colors and flavors [3]. The gluten based biodegradable films are flexible and transparent, but do not have enough mechanical strength. Gluten films in low relative humidity have excellent oxygen and carbon dioxide inhibitions. Gluten film can also act as an ingredient carrier of antioxidants, antimicrobial agents and flavoring agents, and can help maintain the quality of food [2]. Di-sulfide bonds play an important role in forming a gluten film. Di-sulfide bonds between two polypeptide rings increase the power of the film. Di-sulfide bonds in gluten film are disconnected during the heating and when the film is formed, a new Di-sulfide bandings are formed. Due to the high intermolecular forces, the film will be crisp. Therefore, the addition of softening agents such as glycerol to improve mechanical properties and increase the flexibility of the film is necessary [4]. Zinc oxide nanoparticles induce many properties into the biodegradable films such as: high transparency against visible light, high absorption of UV rays and low dielectric constant. Consequently, polymer films containing zinc oxide nanoparticles can be used for various purposes such as UV protection, catalysts, gas detection, and thermo-electric cells. When zinc oxide nanoparticles are embedded in the polymeric composition, they modify the mechanical and optical properties of the compound, which is due to interactions between organic and inorganic groups [5, 6].

Biodegradable films with antimicrobial properties play a very important role in protecting food against microbial contamination and improve its shelf-life [7]. In recent years, attention has been paid to increasing the shelf life of food products such as fresh fruits and vegetables and ready-to-eat meat through active packaging. Antimicrobial packaging is obtained using antimicrobial polymer material or the addition of antimicrobial agents to a polymer compound to prevent the spread of pathogenic and microbial agents [8]. Many researchers have studied the antimicrobial role of zinc oxide nanoparticles for use in food packaging and enhancement of its sustainability [9]. Recently, the antimicrobial properties of silver, zinc oxide and titanium oxide nanoparticles (at sizes smaller than 100 nm) have been reported by UV radiation, due to the small size of the particles and the high level of zinc oxide nanoparticles. Also, under the influence of UV light, ZnO, Ag and TiO2 nanoparticles have a strong oxidizing power, which causes the nanoparticle to be destructive to organic compounds in the structure of microorganisms [9,10,11]. In the present study, the photocatalytic and antimicrobial properties of biodegradable film of gluten-zinc oxide nanocomposite was studied. In fact the photocatalytic activity of the WG/ZnO film was activated by UV irradiation at wavelengths of 500, 365 and 254 nm for 90 min to produce a biodegradable antimicrobial film for use in the packaging of food products. Also some properties of WG/ZnO films including antioxidant, solubility, water absorption, thickness, moisture, colorimetric (L*, a* and b*) and transparency, FT-IR and SEM were investigated.

2 Materials and Methods

2.1 Materials

Wheat Gluten was provided by the Nano Novin Polymer Company (Iran, Sari). Zinc oxide nanoparticles, DPPH, PDA culture media and nutrient agar and other solutions and compounds used in this study were obtained from Merck, Germany.

2.2 WG/ZnO Film Preparation

In this study, based on the central composite design (CCD), according to Table 1, 13 different films were prepared. To prepare the film, a solution was initially prepared by mixing a specific amount of wheat gluten powder (15, 22.5 and 30 g, according to the design of Table 1) and 9.9 g of glycerol in 135 ml of ethanol. Then this solution was homogenized by a magnetic stirrer and 90 ml of deionized water was added to it slowly. Sodium hydroxide (0.1 N) was used to adjust the pH of the solution. Then, ZnO nanoparticles were added to the solution at 3 levels (0, 2 and 4%) and the solution was heated to 75 °C for 20 min and was kept at 75 °C for 10 min. Finally, the solution was dispersed into Teflon containers (20 × 20 cm) and dried at room temperature for 48 h.

2.3 SEM Study

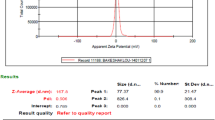

The microstructure of the films was analyzed by scanning electron microscope (TescanVegan-3, Japan). For this purpose the films were covered with gold. Imaging was done at 15 kw in different magnitudes [12].

2.4 FT-IR Study

To perform IR spectrometry, thin films with a thickness of less than 1 mm were obtained by mixing the film sample with bromide potassium in a ratio of 1:20 and applying a pressure of about Kpa60 in a tablet machine. The spectra of samples were recorded by FT-IR instrument (Perkin Elmer, USA) in the range of t 500 to 4000 cm−1 with a resolution of 0.5 cm−1 [3].

2.5 WG/ZnO Film Properties Analysis

2.5.1 Thickness Determination

To determine the thickness of films, micrometers were used with a precision of 0.01 mm. Measurements were performed in 10 different film regions and then their average was calculated. The average thickness was used for calculation of tensile strength [13].

2.5.2 Moisture Determination

To determine the moisture content, the films were cut in 2 × 2 cm2 and were weighted (m1). After initial weighing the films were dried for 24 h at 100 °C and were weighted again (m2). Moisture content of the films was obtained using the following equation [14].

where MCwb is moisture content of film, m1 is sample weight (g) before drying and m2 is sample weight (g) after drying.

2.5.3 Solubility Determination

For this test, the films were cut in 2 × 2 cm dimensions and placed in an oven (100 °C) for 24 h and then weighed (M1), and then placed in a beaker containing 50 ml of distilled water, and beaker was placed in a shaker incubator (25 °C) for 24 h. Finally the remaining pieces were placed in an oven (100 °C) for 24 h and weighed again (M2). The solubility of films was calculated using following equation [14].

where M1 is the initial weight of film and M2 is film weight after dissolving in water.

2.5.4 Water Absorption Determination

For this test, the films were cut in 2 × 2 cm dimensions and were weighed. Then they were placed in 30 ml of distilled water at room temperature for 2 h. After 2 h soaking with distilled water, the samples were gently cleaned and weighed again. The water absorption rate of the samples was obtained using the following equation.

where Wf is the final weight of the film and W0 is the initial weight of the film [4].

2.5.5 Antioxidant Activity Determination

Byun et al. (2010) method was used to determine the antioxidant activity of films. Films (2 × 2 cm) were immersed in ethanol at and shaken for 10 min. Films were digested in ethanol and antioxidant compounds released into the solution. After centrifugation for 10 min at 3000 RPM the solids were separated and ethanol solution was used for determination of antioxidant activity. For this purpose 1 ml of ethanol solution (obtained from film sample) was mixed with 2 ml of DPPH (0.06 mM) and 1 ml of ethanol. The mixture was placed in a dark place at 25 °C for 30 min, and then its absorbance was measured at 517 nm by a UV–Vis spectrophotometer. The control sample was prepared by mixing 2 ml of ethanol and 2 ml of DPPH (0.06 mm). The antioxidant activity was calculated using following equation [15].

Abscontrol: Control sample absorption at 517 nm.

Abssample: Film solution absorption at 517 nm.

2.5.6 Opacity Determination

The film opacity was determined using the (2014) Han method by the UV–Vis spectrophotometer (UV-2100, USA). For this purpose, the films were cut in 1 × 4 cm dimension and their thickness measured at 5 points along the film, and then the films were placed in a transparent wall inside the quartz cell and the film absorption was recorded. The opacity was calculated by the following equation [16].

where A600 is film absorbance in 600 nm and X is the average of film thickness (millimeter).

2.5.7 Color Determination

Colorimeter (Minolta, CR-410; Japan) was used to measure color of films. For this purpose first, the instrument was calibrated using standard white pages. The films were then placed on a white paper and their color was measured using a colorimetric device. The color properties including L*, a* and b*, which respectively indicate the brightness (from L = 0 for black to L = 100 for white), green to red (a = -60 for Green to a = 60 for red) and blue to yellow (from b = − 60 blue to b = 60 for yellow) were recorded [17].

2.5.8 Mechanical Properties Determination

Mechanical tests were performed using the texture analyzer (TA.XT Plus, Stable Micro Systems UK) according to the standard method [ASTM D882]. Before analysis, samples were conditioned in a desiccator (saturated calcium nitrite) for 24 h at a relative humidity of 55%. Then, three samples from each of the films were cut with dimensions of 0.5 × 8 cm and placed between two jaws of the instrument. The initial distance between the jaws and the jaw moving rate was 30 and 30 mm/min, respectively, and data were recorded using computer software. The tensile strength (TS) and strain to break (STB) were calculated by the following equations [3].

where Maximum Load is the maximum force input to the film (N), Cross sectional area is primary cross-sectional area of the film (m2), Elongation at break point is elongation amount of film to break (mm), Original length is initial length of film (millimeter), TS is the amount of stretch resistance in (MPa) and STB is the strain of film to break (%).

2.5.9 Photocatalytic Activity and Antibacterial Activity Determination

2 ml of Escherichia coli culture medium and Aspergillus niger fungus containing 105 − 106 cfu/ml of bacteria and fungi were prepared. To cultivate Escherichia coli and Aspergillus nutrient agar and PDA medium were used. After culture of bacteria and fungi, the films (in circle shape with a diameter of 5 mm) were placed on the culture media. The culture media was storage for 48 h at 37 °C, then the lack of growth areas around the film were measured (Fig. 1a and b) [18]. To activate the photocatalytic properties of films and study the photocatalytic effect of films on bacteria and fungi, a system was designed such as Fig. 1c. The films were exposed to UV rays for 24 h in three wavelengths of 500, 365, and 254 nm in a designed system.

2.6 Statistical Analysis

In this study, CCD was used to study the effects of wheat gluten percent (15 to 30 g) and ZnO percent (0 to 0.4%) on the film properties including antimicrobial, antioxidant, solubility, water absorption, thickness, moisture, colorimetric properties (L*, a* and b*) and opacity (Table 1). Design-Expert (Version 7) software was used for data analysis. Significant levels of data were considered at the 5% probability level (p < 0.05).

To study gluten (15 to 30%) and ZnO (0 to 4%) effects on the mechanical properties of the film, a factorial design with three replications was used. Minitab (Version 17) software was used for data analysis and Tukey’s test was used to compare the means. Also, significant levels of data were considered at the 5% probability level (p < 0.05). Meanwhile, the data in tables and forms were considered as a mean standard deviation (SD).

3 Result and Discussion

In this study, the response surface method (RSM) was used to study the effect of independent factors such as wheat gluten amount and ZnO concentration on the physicochemical properties of WG film, including thickness, water absorption, moisture, antioxidant activity, photocatalytic/antibacterial activity and color preoperties. The obtained results were studied in mathematical models and the mathematical relations between independent factors and the obtained responses were investigated. Table 2 shows the mathematical relation between independent factors and dependent factors.

3.1 Thickness, Water Absorption, Solubility, Moisture and Antioxidant Activity Study

Thickness is one of the important factors in films, which directly affects the properties of water vapor and oxygen permeability, as well as the mechanical properties of the film. Figure 2a shows the three-dimensional curve of the simultaneous effect of two variables of zinc oxide nanoparticles and the gluten amount in the film characteristics. The results showed that increasing the amount of gluten in the composition increased the thickness of the films and the amount of zinc oxide nanoparticles did not affect the thickness of the films (p < 0.05). The results are consistent with Girard et al. [19].

Water absorption and high moisture content limit the application capability of a biodegradable film in packaging. Also, reducing the amount of water absorption and moisture content of the film can prevent the destruction of the film. Therefore, the water absorption in the films should be at its minimum. Figure 2b shows the 3-D curve of water absorption of films. According to the results, with the increase of gluten content, water absorption increases, while by increasing the percentage of zinc oxide, water absorption in the films is reduced (p < 0.05). It is well known that the water absorption capacity in the film depends on its morphology and chemical structure. Decrease of water absorption in the film by adding of ZnO can be relate to the filling the pores of gluten film by zinc oxide nanoparticles. Kim et al. had reported that water absorption of films was decreased by adding zinc oxide, that their results confirmed the results of our study [9].

Solubility in water can be one of the most important properties for films due to resistance against water, especially in wet environments. This property demonstrates film’s effectiveness in protecting foods with high water activity and fresh and frozen food. Figure 2c shows the 3-D curve of the effect of gluten and zinc oxide on the film solubility. The results showed that the solubility of films decreased with increasing gluten and zinc oxide nanoparticles (p < 0.05). The reason for reducing the solubility of the film can be related to this fact that the glycerol and other components in water can be absorbed on the surface of zinc oxide nanoparticles. The results are consistent with the Rafieian et al. report [4].

Figure 2d shows the 3D curve of the effect of gluten and zinc oxide on the moisture content of films. Results showed that decreasing the percentage of gluten and increasing the amount of zinc oxide nanoparticles decreased the moisture content of films (p < 0.05). The present study is consistent with Shahabi-Ghahfarrokhi and Babaei-Ghazvini’s research [20].

The basis of the antioxidant test is based on the reduction of the DPPH radical resonance in the presence of antioxidants. In this test, the presence of antioxidants results in the conversion of DPPH radicals into a yellow compound called diphenylhydrazil. Figure 2e shows the 3-D curve of the simultaneous effects of zinc oxide and gluten on the antioxidant activity. According to result, the antioxidant properties of the films increased with increasing zinc oxide, and the gluten had no effect on the antioxidant activity (p < 0.05). The results of Nagajyothi et al. research on the antioxidant activity of zinc oxide nanoparticles are consistent with our study [21].

3.2 Opacity and Color Study

Light irradiation is one of the most important factors that causes of food corruption. Some food products are so sensitive to light that their color, odor and taste are changed extremely with oxidation from the effects of light. Figure 3a shows the 3-D curve of the effect of gluten and zinc oxide on the opacity. The results showed that the zinc oxide had no effect on the opacity and film opacity was increased by increasing the gluten content (p < 0.05). The reason for the increase of turbidity is the increasing of gluten and increasing of film thickness.

Wu et al. reported that the optical properties of the films were affected by some parameters such as the internal structure of the polymer, the phase mixing capacity, the color of the added materials, the type of dispersion and the size of the dispersed particles, and film thickness [22]. Color and transparency of packaging films are one of the important and influential factors in terms of consumer acceptability. Color is one of the most important features of a packaging film that plays an important role in its appearance and marketability. In general, the biodegradable films that have more similarity to synthetic polymers, have more acceptance and application. Figure 3b, c and d, respectively, show the 3-D curves of gluten and zinc oxide effects on the L*, a*, b* index. The results showed that the decrease of gluten resulted in an increase in the L*, indicating an increase in the whiteness of the produced films. Also, by increasing the zinc oxide nanoparticles and reducing the gluten, the factor a* increased. With the increase of the gluten, the b* increased significantly (p < 0.05). The zinc oxide nanoparticles, not affected significantly the L* and b* factors [23].

3.3 Photocatalytic, Antibacterial and Antifungal Study

The photocatalytic property of ZnO makes this nanoparticle an antimicrobial compound. Under the influence of UV light, ZnO nanoparticles exhibit strong oxidizing power, which makes the nanoparticle more harmful to organic compounds in the structure of microorganisms. In this test, the films were cut in 5 mm in diameter and placed in the vicinity of UV rays at wavelengths of 500, 365 and 254 nm for 90 min. After 90 min, the films were placed in the Escherichia coli and Aspergillus Niger culture plates (Fig. 1).

Figure 4a, b, c and d illustrate 3-D curves of gluten and zinc oxide on the antibacterial/antifungal properties of film at 256 and 365 nm. The results showed that the gluten had no effect on the antibacterial/antifungal property of the films. Also, the results showed that the antibacterial/antifungal effects had a direct correlation with the concentration of zinc oxide nanoparticles and increasing of ZnO increased the antibacterial/antifungal effects. The antibacterial/antifungal effect at wavelengths of 254 nm were higher than 365 nm. The Halo of lack of growth in Escherichia coli bacteria was observed more than the Aspergillus Niger fungi. Also, the results showed that wavelength of 500 nm did not active antibacterial/antifungal property of the films, so at 500 nm the Halo of lack of growth around the film against bacteria and fungi were not observed. The exact mechanism for the antimicrobial activity of zinc oxide nanoparticles is not known at this time. It has been accepted that the antimicrobial activity of zinc oxide nanoparticles is due to the photocatalytic properties of zinc oxide nanoparticles. This work results are consistent with Roy and Wan Rhim and Pirsa et al. results [24, 27].

3.4 Mechanical Properties Study

Mechanical properties are important factors in choosing the type of packaging in food industry. The package should be protected against physical stress and changing environmental conditions during storage until it is consumed. The role of plasticizers is the destruction of intra and intermediate molecular bonds of hydrogen, and the reduction of hydrogen bonds between polymer chains, which increases the distance between polymer molecules and molecular motions and increases the flexibility of the polymer.

In this test, tensile strengths (TS) and strain to break (STB) factors were measured in four films (F6, F7, F9 and F11) with three repetitions. The results of TS (Fig. 5a) showed that the TS increased with increasing gluten, and zinc oxide nanoparticles did not have a significant effect on the TS (p > 0.05). The results of the STB (Fig. 5b) showed that both gluten and zinc oxide nanoparticles were effective in this factor, and with increasing the amount of both variables, the film STB increased (p < 0.05). The reason for increasing the TS and STB factors due to the increase in gluten percentage can be attributed to a better gluten polymerization and an increase in free space between the gluten chains. The present study is consistent with the results of Vaezi et al. and Sartori et al. [5, 25]. Sartori et al. reported that increasing of gluten increased the TS of film and Vaezi et al. reported that increasing of ZnO increased the STB.

3.5 SEM and FT-IR Study

Figure 6a shows the SEM images of zinc oxide nanoparticles (Fig. 6A-a), pure gluten film (Fig. 6A-b), and gluten-zinc oxide (Fig. 6A-c) film. Figure 6A-a shows nanoparticles of zinc oxide at a size of 30 to 100 nm in a spherical shape. Figure 6A-b shows the pure gluten film, which is composed entirely uniformly and without pore. Figure 6A-c the film of gluten-zinc oxide shows that nanoparticles of zinc oxide are heterogeneously distributed within the film, and the presence of these particles in the film creates empty spaces on the film’s surface. According to SEM figures, pure gluten film is homohen and uniform and no agglomeration is observed, it also has a smooth surface without bulging, but in the film of gluten-zinc oxide by adding zinc oxide nanoparticles the agglomeration process has happened. The results of this study are consistent with Saral Sarojini et al., Chiou et al. reports [7, 26].

The FT-IR spectrum of pure gluten and gluten-ZnO films are shown in Fig. 6B-a and B-b. The FT-IR spectrum was recorded in the 500 to 4000 cm−1. The results of the pure gluten spectra show that peaks at 759, 1033, 1250, 1444 and 1630 cm−1 are related to tensile vibrations of C–O. Also, the peaks at 2930 and 3434 are related to the tensile vibrations of C–H and O–H. The results of gluten-ZnO spectra show that the peaks at 1039, 1244, 1441 and 1630 cm−1 are related to the tensile vibrations of the C–O. The peaks at 2080 and 2369 cm−1 are related to the tensile vibrations of the C–C and C–N. Also, the peaks at 2932 and 3437 are related to the tensile vibrations of C–H and O–H. By comparing the two pure gluten and gluten-ZnO spectra, it is observed that the peak at 759 cm−1 contained in the pure gluten is covered by C–C vibrations and is not observed in the gluten-ZnO spectrum. Also, peaks at 1039, 51244, 1441, 1630, 2932, and 3437 have been shifted to higher wavelengths in the gluten-ZnO spectrum and have become wider. This results show that vibrations stretching C–H and O–H have been created after adding zinc oxide nanoparticles to the film compound [27]. In general, no significant difference has been observed between pure gluten and gluten-ZnO spectra, which appears to be due to the weak vendrorase bond between gluten and zinc oxide nanoparticles. The results of this study are consistent with Kim et al. and Farshchi et al. results [9, 28].

4 Conclusion

In this study, the photocatalytic/antimicrobial properties of biodegradable film based on gluten-zinc oxide nanocomposites were investigated for the active packaging of food products. In this study, using the CCD, the effects of two variables of gluten percent (15, 22.5 and 30%) and percentage of ZnO nanoparticles (0, 2 and 4%) were studied. The film properties such as mechanical, antimicrobial and antioxidant properties, FT-IR, SEM, solubility, water absorption, thickness, moisture content, colorimetric properties (L*, a*, b*) and opacity of films were investigated. According to result, the antioxidant properties of the films increased with increasing zinc oxide, and the gluten had no effect on the antioxidant activity. With the increase of gluten content, water absorption increases, while by increasing the percentage of zinc oxide, water absorption in the films is reduced. The solubility of films decreased with increasing gluten and zinc oxide nanoparticles. The results of the STB showed that both gluten and zinc oxide nanoparticles were effective in this factor, and with increasing the amount of both variables, the film STB increased. According to the results, by increasing the percentage of nanoparticles of zinc oxide in the presence of UV rays, the antimicrobial properties of films increased and this factor was more effective against Escherichia coli than the Aspergillus Niger fungi. The effect of gluten on the antioxidant property was meaningless but it was increased by increasing zinc oxide nanoparticles percent. The results of the FT-IR analysis showed that new weak interactions between zinc oxide nanoparticles and gluten polymer were created. The results of the SEM analysis showed that the addition of high percentage of zinc oxide nanoparticles into the wheat gluten polymer caused agglomeration of nanoparticles on the film from. According to the results, biodegradable/photocatalytic gluten-ZnO nanocomposite can be used in packaging of food products that are sensitive to bacteria.

References

A.P. Bilck, M.V. Grossmann, F. Yamashita, Biodegradable mulch films for strawberry production. Polym. Test. 29, 471–476 (2010)

T. Sartori, G. Feltre, P. Sobral, R. Cunha, F. Menegalli, Biodegradable pressure sensitive adhesives produced from vital wheat gluten: effect of glycerol as plasticizer. Colloids Surf. A 560, 42–49 (2019)

R. Liu, X. Cong, Y. Song, T. Wu, M. Zhang, Edible gum–phenolic–lipid incorporated gluten films for food packaging. J. Food Sci. 83, 1622–1630 (2018)

F. Rafieian, M. Shahedi, J. Keramat, J. Simonsen, Mechanical, thermal and barrier properties of nano-biocomposite based on gluten and carboxylated cellulose nanocrystals. Ind. Crops Prod. 53, 282–288 (2014)

K. Vaezi, G. Asadpour, H. Sharifi, Effect of ZnO nanoparticles on the mechanical, barrier and optical properties of thermoplastic cationic starch/montmorillonite biodegradable films. Int. J. Biol. Macromol. 124, 519–529 (2019)

S. Daikh, F.Z. Zeggai, A. Bellil, A. Benyoucef, Chemical polymerization, characterization and electrochemical studies of PANI/ZnO doped with hydrochloric acid and/or zinc chloride: differences between the synthesized nanocomposites. J. Phys. Chem. Solids 121, 78–84 (2018)

K.S. Sarojini, M.P. Indumathi, G.R. Rajarajeswari, Mahua oil-based polyurethane/chitosan/nano ZnO composite films for biodegradable food packaging applications. Int. J. Biol. Macromol. 124, 163–174 (2019)

S. Shankar, L.F. Wang, J.W. Rhim, Preparations and characterization of alginate/silver composite films: effect of types of silver particles. Carbohydr. Polym. 146, 208–216 (2016)

D. Kim, K. Jeon, Y. Lee, J. Seo, K. Seo, H. Han, S. Khan, Preparation and characterization of UV-cured polyurethane acrylate/ZnO nanocomposite films based on surface modified ZnO. Prog. Org. Coat. 74, 435–442 (2012)

C. Fasciani, M.J. Silvero, M.A. Anghel, G.A. Arguello, M.C. Becerra, J.C. Scaiano, Aspartame-stabilized gold–silver bimetallic biocompatible nanostructures with plasmonic photothermal properties, antibacterial activity, and long-term stability. J. Am. Chem. Soc. 136(50), 17394–17397 (2014)

S. Sarkar, S. Chakraborty, C. Bhattacharjee, Photocatalytic degradation of pharmaceutical wastes by alginate supported TiO2 nanoparticles in packed bed photo reactor (PBPR). Ecotoxicol. Environ. Saf. 121, 263–270 (2015)

A. Casariego, B. Souza, M.M. Cerqueira, J. Texeira, R. Diaz, A. Vicente, Chitosan clay films properties as affected by biopolymer and clay micro/nanoparticales concentration. Food Hydrocolloid. 23, 1895–1902 (2009)

B. Peng, H. Fan, Q. Zhang, A giant electrocaloric effect in nanoscale antiferroelectric and ferroelectric phases coexisting in a relaxor Pb0.8Ba0.2ZrO3 thin film at room temperature. Adv. Funct. Mater. 23(23), 2987–2992 (2013)

C. Muller, F. Yamashita, B. Laurindo, Evaluation of the effects of glycerol and sorbitol concentration and water activity on the water barrier properties of cassava starch films through a solubility approach. Carbohydr. Polym. 72, 82–87 (2008)

Y. Byun, Y.T. Kim, S. Whiteside, Characterization of an antioxidant polylactic acid (PLA) film prepared with α-tocopherol, BHT and polyethylene glycol using film cast extruder. J. Food Eng. 100, 239–244 (2010)

J.H. Han, Edible films and coatings: a review, Innovations in food packaging, 2nd edn. (Academic Press, Massachusetts, 2014), pp. 213–255

M. Abdollahi, M. Alboofetileh, R. Behrooz, M. Rezaei, R. Miraki, Plasticizers forzein: their effect on tensile properties and water absorption of zein films. Cereal Chem. 81, 1–5 (2013)

S. Ruiz, J. Tamayo, J. Ospina, D. Porras, M. Zapata, J. Hernandez, C. Valencia, F. Zuluaga, C. Tovar, Antimicrobial films based on nanocomposites of chitosan/poly(vinyl alcohol)/graphene oxide for biomedical applications. Biomolecules 9, 109–126 (2019)

A. Girard, T. Teferra, J. Awika, Effects of condensed vs hydrolysable tannins on gluten film strength and stability. Food Hydrocolloid. 89, 36–43 (2019)

I. Shahabi-Ghahfarrokhi, A. Babaei-Ghazvini, Using photo-modification to compatibilize nano-ZnO in development of starch-kefiran-ZnO green nanocomposite as food packaging material. Int. J. Biol. Macromol. 124, 922–930 (2019)

P. Nagajyothi, S. Cha, I. Yang, T. Sreekanth, K. Kim, H. Shin, Antioxidant and anti-inflammatory activities of zinc oxide nanoparticles synthesized using Polygala tenuifolia root extract. J. Photochem. Photobiol. B. 146, 10–17 (2015)

H. Wu, H. Liu, G. Chen, R. Chang, Y. Chen, P. Anderson, Structure and properties of starch/zirconium phosphate nanocomposite films. Carbohydr. Polym. 77, 358–364 (2009)

T. Bourtoom, M.S. Chinnan, Preparation and properties of rice starch chitosan blend biodegradable film. LWT 41(9), 1633–1641 (2008)

S. Roy, W. Rhim, Carrageenan-based antimicrobial bionanocomposite films incorporated with ZnO nanoparticles stabilized by melanin. Food Hydrocolloid. 90, 500–507 (2019)

T. Sartori, G. Feltre, P. Sobral, R. Cunha, F. Menegalli, Properties of films produced from blends of pectin and gluten. Food Packag. Shelf Life. 18, 221–229 (2018)

B. Chiou, G. Robertson, L. Rooff, T. Cao, H. Jafri, K. Gregorski, S. Imam, G. Glenn, W. Orts, water absorbance and thermal properties of sulfated wheat gluten films. J. Appl. Polym. Sci. 116, 2638–2644 (2010)

S. Pirsa, T. Shamusi, E.M. Kia, Smart films based on bacterial cellulose nanofibers modified by conductive polypyrrole and zinc oxide nanoparticles. J. Appl. Polym. Sci. 135(34), 46617 (2018)

E. Farshchi, S. Pirsa, L. Roufegarinejad, M. Alizadeh, M. Rezazad, Photocatalytic/biodegradable film based on carboxymethyl cellulose, modified by gelatin and TiO2–Ag nanoparticles. Carbohydr. Polym. 216, 189–196 (2019)

Acknowledgements

The financial support of the Research Council of Urmia University and Afagh Higher Education Institute is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rezaei, M., Pirsa, S. & Chavoshizadeh, S. Photocatalytic/Antimicrobial Active Film Based on Wheat Gluten/ZnO Nanoparticles. J Inorg Organomet Polym 30, 2654–2665 (2020). https://doi.org/10.1007/s10904-019-01407-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-019-01407-6