Abstract

In the present study, Zinc Aluminium Carbonate Layered Double Hydroxides (ZAC-LDHs) with hydrotalcite like material are synthesized at different Zn2+/Al3+ molar ratios (R = 2:1, 3:1 & 4:1) by co-precipitation followed by hydrothermal method using cationic surfactant Cetyl Trimethyl Ammonium Bromide (CTAB) as a soft template at constant pH 9. The Calcined Zinc Aluminium Carbonate LDH (CZA-LDH) sample is prepared by calcination of Zn3Al Carbonate-LDH at 450 °C for about 2 h. The materials obtained ZAC-LDHs (R = 2, 3 & 4) and calcined sample (CZA-LDH) are characterized by a set of powder X-Ray Diffraction (PXRD), N2 adsorption and desorption isotherms (Brunauer–Emmett–Teller BET), Fourier Transform Infrared Spectroscopy, Field Emission Scanning Electron Microscope with Energy Dispersive Spectroscopy (FESEM with EDS), Thermogravimetric Analysis (TGA and DTA) and high Resolution Transmission Electron Microscope (HR-TEM). The increase in intensity and sharpness of the peak from the XRD pattern confirms that all the synthesized materials of ZAC-LDHs (R = 2, 3 & 4) are crystalline in nature. Owing to more advantageous property called “memory effect”, the CZA-LDH reconstruct its original LDH structure by intercalating anions present in aqueous solution. From the XRD and BET surface analysis of data, the formation of mesoporous and nano structured crystalline material of ZAC-LDHs and CZA-LDH through simple and synergistic methods of co-precipitation and hydrothermal method at 120 °C using CTAB as a soft template is confirmed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Layered Double Hydroxide (LDH) belongs to a class of ionic lamellar solids with positively charged layers consisting of two kinds of metallic cations (bivalent and trivalent) and charge balancing exchangeable hydrated gallery anions located in the interlayer region [1]. This compound is also referred to as anionic clay. The general formula of LDHs is [M2+1−xM3+x(OH)2]x+(An−)x/n·mH2O where M2+ is divalent metal (Zn2+, Mg2+, Fe2+ etc), M3+ is trivalent metal (Al3+, Fe3+ etc), and An− is interlayer anions (CO32−, Cl−, NO3−, SO42− etc.,) while m is the amount of water molecules present in layered structure [2,3,4]. Carbonates are the interlayer anions present in naturally occurring mineral hydroxide which is a member of this class of materials. On possessing some superior properties like anion exchange ability, large surface area and regeneration ability, LDH finds wide application in wastewater treatment as an adsorbent and photocatalyst [5].

LDH materials have gained great interest in many potential applications such as super capacitors [6], catalysis [7, 8], drug delivery [9, 10] wastewater treatment [11,12,13,14,15,16] and flame retardant epoxy formulation [17]. Especially, their application in water treatment as adsorbents have a great potential due to their low cost, high surface area, highly tunable interior architecture [18], non-toxicity [19, 20] and exchangeable anionic features [21]. Many researchers have reported the potential application of Mg/Al-LDHs in medical field as a carrier for anti-cancer drug [22], cardiovascular drug [23], osteotropicity [24], control release of salicylate, ibuprofen (IBU) and ciprofloxacin (CIPRO) [25, 26].

LDH or mixed metal oxides formed upon calcination can also be used to scavenge anions from solutions for recovering the layered structure [12, 27, 28]. Moreover, the functional LDHs as nano-sized systems and its calcined products have been largely developed and explored for various applications [29,30,31,32]. The combination of LDHs with materials such as carbon nano structures, anions, surfactants, iron nano-particles and polymers exhibit significant improvement in surface characteristics and adsorption performance. Indeed, these LDH-containing hybrids have increasingly diverted interest to investigate their adsorption performance of various hazardous pollutants from aqueous solutions.

In the present investigation, ZAC-LDHs of different molar ratios (R = 2:1, 3:1 & 4:1) with reduced interlayer distance and enhanced mesoporosity are prepared by using synergistic method of co-precipitation and hydrothermal employing CTAB as a soft template. CZ3A-LDH is also synthesized and characterized by PXRD, FTIR, TGA/DTA, BET, SEM, EDS and TEM analysis.

2 Materials and Methods

2.1 Preparation of ZAC-LDHs and CZA-LDH

All the materials used in the current study are AR grade and used without any purification. Zinc Aluminium Carbonate Layered Double Hydroxides (ZAC-LDHs) are synthesized by using aqueous solution of ZnSO4·7H2O and Al2(SO4)3·16 H2O. The aqueous solution of Zinc sulphate (1M) and Aluminium sulphate (1 M) are taken in the molar ratio of M2+/M3+ = 2:1, 3:1 & 4:1 and mixed in magnetic stirrer. Exactly 0.3 g of the CTAB is added to the solution and made as a homogeneous mixture with a magnetic stirrer. The mixture of sodium hydroxide (1 M) as precipitating agent and sodium carbonate (0.5 M) as intercalating carbonate anion source is added dropwise until the pH 9. The precipitate was poured into Teflon lined stainless steel autoclave and heated to about 120 °C and maintained for about 8 h. The material obtained is filtered, washed several times with double distilled water until the pH is neutral and dried at 80 °C in hot air oven. The three products obtained are named as ZAC-LDH (2:1), ZAC-LDH (3:1) and ZAC-LDH(4:1). CZA-LDH is obtained by heating the original ZAC-LDH (3:1) in a muffle furnace at 450 °C for 2 h in an air atmosphere with heating rate of 10 °C/min. All the prepared ZAC-LDHs and CZA-LDH samples are finely powdered and characterized by P-XRD, FTIR, TGA/DTA, BET, SEM, EDS and TEM analysis. The representation of ZAC-LDH is shown in Fig. 1.

2.2 Characterization of Synthesized ZAC-LDHs and CZA-LDH

Powdered X-Ray Diffraction (PXRD) pattern of the samples are characterized by using a Shimadzu XRD-6000 diffractometer, with Ni-filtered Cu-Kα radiation (λ = 1.54 Å) at 40 kV and 200 mA. Solid samples are mounted on alumina sample holder and basal spacing (d-spacing) is determined via powder technique. A sample scanning is carried out at 5°–80° range with a scanning rate of 1°/min.

Brunauer–Emmett–Teller (BET) surface area of the samples are measured by the N2 adsorption–desorption technique at − 196 °C on Micromeritics ASAP 2020 apparatus (United States of America) at a relative pressure (P/P0) range of 0.05–0.3. The nitrogen adsorption and desorption isotherm are utilized to determine pore size distribution through Barrett–Joyner–Halenda method. Pore volume and average pore size of the synthesized materials are obtained according to the nitrogen adsorption volume at P/P0 = 0.97.

The functional groups of the as-prepared samples are observed by the Fourier Transform Infra-Red spectroscopy (FTIR-Perkin Elmer, USA) using a KBr pellet over the range of 4000–400cm−1. To study the thermal stability of the samples, Thermogravimetric Analysis (TGA/DTA) is carried out on a Thermal Analyzer (Make/Model-Perkin Elmer STA 6000). The samples are heated in the temperature range from 40 to 750 °C at the heating rate of 20 °C min−1 under N2 flow.

Furthermore, the structural and morphological investigations of the samples are examined by a JEM-2100 High-Resolution Transmission Electron Microscope (HRTEM, JEOL, and Japan) operating at 200 kV voltage. The surface morphology and elemental composition of samples are analyzed by using Field Emission Scanning Electron Microscope (FESEM-ZEISS SIGMA GEMINI) with Energy Dispersive Spectroscopy (EDS). The samples are coated with a gold/palladium film, and the FESEM images are obtained using a secondary electron detector.

3 Results and Discussion

3.1 Powdered X-Ray Diffractogram Analysis

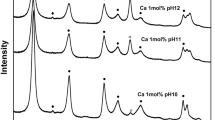

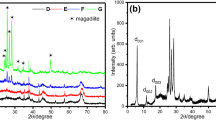

The PXRD pattern of the synthesized nanostructured ZAC-LDHs of different molar ratios Zn2+/Al3+ = 2:1, 3:1 & 4:1 are illustrated in Fig. 2a–c and CZA-LDH is shown in Fig. 2d. A strong basal reflection of (003),(006), (009) observed at lower 2 theta value and (110), (113) at higher 2 theta value agrees with the formation of the layered structure of LDH materials [33]. The basal reflections of planes hkl (003), (006), (009), (012),(015),(110) and (113) observed from XRD patterns for all the prepared ZAC-LDHs materials fit well to the regular layered structure [34, 35]. The 2 theta value for the appearance of the basal reflections corresponding to d(003) and d(006) of ZAC-LDHs(2:1) and (3:1) are more or less the same unlike the case of ZAC-LDH (4:1). This may be due to the increase in zinc content in LDHs. The crystalline nature of the synthesized LDH materials is confirmed by the appearance of sharp peak at lower 2θ value. Secondary phases ZnO and Al(OH)3 are also seen around the higher 2θ value in the range of 35°–60° along with brucite-like layer [36, 37]. The crystalline ZnO is mostly expected with brucite-like layer. All the ZAC-LDH samples are witnessed to have the rhombohedral 3R stacking sequence. The unit cell parameters ‘a’(= 2d110), ‘c’(3d003) and gallery height for all the LDH samples are calculated by using Brags equation and presented in Table 1. In this, ‘a’ is a function of the average radii of the metal cations and ‘c’ is the function of the average charge of the metal cations.

On calcination of ZAC-LDH at 450 °C for about 2 h, the original layered structure is collapsed with the loss of inter layer carbonate anion, hydroxyl ion and water molecule with the formation of mixed metal oxide. Figure 2d describes the disappearance of basal reflections of planes (003) and (006) confirms the loss of original layered structure with the formation of mixed metal oxides such as ZnO and ZnAl2O4 (ASTM card number 89-7102 and ASTM card number 82-1043 respectively). Table 1 reveals that the interlayer distance d (003) of ZAC-LDH (2:1) and (3:1) is more or less the same and contrast to ZAC-LDH (4:1). This may be attributed to the increase in the concentration of Zinc in LDH. According to Scherrer Eq. (1), the average crystallite size (D) for all the samples is calculated for high intensity peak appearing at d (003) and d(006) as illustrated in Table 1.

where \(K\) is the shape factor (0.94), \(\lambda\) is the wavelength of the X-ray (Cu- Kα) and \(B\) is the full width at half-maximum of the diffraction peak.

3.2 FTIR Analysis

The functional group of the synthesized and calcined samples are analyzed by FTIR spectrum and shown in Fig. 3a–d. A broad absorption band approximately centered at 3432 cm−1 for all ZAC-LDH (2:1, 3:1 and 4:1) is associated with the stretching mode of hydrogen bonded hydroxyl groups, both from metal hydroxide in brucite like layers and interlayer water molecules [38]. The sharp and intense band that appears at 1368 and 1044 cm−1 is associated with carbonate ion (CO32−) in the interlayer of all the synthesized ZAC-LDHs [39,40,41]. The appearance of band at 1640 cm−1 confirms the bending vibrations of water [42]. The low frequency region i.e., below 800 cm−1, confirms the presence of M–O vibration mode (M=Zn and Al) of LDH and the FTIR pattern is almost similar for all three ZAC-LDHs irrespective of the molar ratio. The absence of absorption band at 3432 and 1368 cm−1 in Fig. 3d confirms the destruction of LDH structure in CZA-LDH with the loss of water and interlayer carbonate molecule on calcination.

3.3 N2 Adsorption–Desorption Analysis

BET gas sorption measurements are performed to study the specific surface areas and the porous nature of three ZAC-LDHs and CZA-LDH. The BET surface area, pore volume and average pore width for all the ZAC-LDHs are recapitulated in Table 2. Likewise, the nitrogen adsorption/desorption isotherms and the pore size distribution (inset graph) plots for all three ZAC-LDHs and CZA-LDH samples are shown in Fig. 4a–d. According to the IUPAC classifications, pores can be classified into three types viz. micropores (d < 2 nm), mesopores (2 < d < 50 nm) and macropores (d > 50 nm).

It is evidenced from Fig. 4 that the relative pressure graphs are in accordance with the type IV isotherm accompanied by a type of H3 hysteresis loop attributes with the formation of aggregates of plate-like particles giving rise to slit shaped pores [43]. The mesoporous nature of all the samples is confirmed from the relative pressure graph where the adsorption and desorption curves increase from 0.6 to 1.0 and the pore diameters of all the samples are distributed in the range of 2–50 nm. Further, it is supported by the percentage of contribution of mesopore volume to the total pore volume (> 95%) in all the samples.The pore size distribution curves of the ZAC-LDHs and CZA-LDH are given as inset in Fig. 4a–d. From Table 2, the surface area and pore volume of the ZAC-LDHs samples are observed to increase with an increase in the molar concentration of zinc in the LDHs. As per the surface value in Table 2, after calcination of ZAC-LDH (3:1) at 450 °C for 2 h, the surface area of CZA-LDH is nearly the same as that of its precursor. In addition, the increase in pore volume and average pore size for CZA-LDH is noticed and it is contributed by the loss of interlayer CO32− ions on calcination. Additionally, the relative large pore size and mesoporosity make them a good adsorbent for wastewater treatment by allowing easy diffusion of the dye molecules [44]. The inherent surface area, pore size and mesoporosity make the ZAC-LDH and CZA-LDH materials as the futuristic materials in the field of material science.

3.4 Thermal Analysis

The thermal stability of all the ZAC-LDH has been studied by TGA. TGA and DTA curves for all the synthesized ZAC-LDHs and CZA-LDH are shown in Fig. 5a–d. LDH thermal behavior is usually observed by two main transition stages [45, 46]. The first stage is endothermic that corresponds to the loss of water molecules physisorbed on the surface and intercalated in the interlayer of LDH. This usually occurs without collapsing the lamellar structure in the temperature ranges from room temperature to 200 °C. Since the stage is reversible, the loss of water molecules may be rehydrated when it is in contact with aqueous solution. In the second stage, the complete destruction of LDH structure accompanied by dehydroxylation of the brucite-like layers and the decomposition of interlayer carbonate anions with oxide crystallization occur at the temperature range from 200 to 800 °C [47]. In this, dehydroxylation and loss of inorganic anions are endothermic processes whereas in the case of loss of organic anions in interlayer, they imply the exothermic process.

3.5 SEM with EDS and TEM Analysis

The elemental compositions of the synthesized ZAC-LDHs are determined qualitatively by EDS analysis. Table 3 clearly shows that the experimental elemental compositions (molar ratios) of synthesized LDHs are in good agreement with the proposed elemental composition in the experimental study. The morphology of the synthesized ZAC-LDHs (2:1, 3:1, 4:1) and CZA-LDH are examined by SEM and TEM and shown in Figs. 6a–d and 7A and a–D and d. The SEM images show the regular hexagonal shape platelet arrangements in all the ZAC-LDHs and on calcination, they lead to the aggregation of small particles overlapping with each other. The regular arrangement of hexagonal plate-like structures in all the synthesized ZAC-LDHs has been revealed by TEM images shown in Fig. 7a–d. Figure 7D and d shows the formation of some microspores in the calcined product due to the dehydroxylation and decomposition of interlayer CO32− anions [48,49,50,51]. The Selected Area Electron Diffraction (SAED) patterns of all the ZAC-LDHs in Fig. 7a–d reveals the uniform and crystalline nature of the sample by the formation of different concentric diffraction rings due to different characteristic lattice planes [52]. In addition, the spots exist in diffraction rings in SAED pattern of CZA-LDH as shown in Fig. 7d which confirms the formation of crystalline mixed metal oxides.

4 Conclusion

In the present study, ZAC-LDHs at different molar ratios are successfully synthesized with reduced interlayer distance and increased mesoporous nature by using co-precipitation followed by hydrothermal method at120 °C employing cationic surfactant CTAB as a soft template. The calcined sample CZA-LDH is formed by the calcination of ZAC-LDH (3:1) at 450 °C for about 2 h. The increased pore size of CZA-LDH may be due to the dehydroxylation and decomposition of carbonate anion of precursor. The structure and morphology is evidenced by XRD,SEM and TEM. The data obtained from BET surface analysis support the mesoporous nature of all the LDHs and CZA-LDH. Thus, the futuristic properties like mesoporosity, anion exchange ability and non-toxicity of the nanostructured ZAC-LDHs and CZA-LDH have attracted a great interest in many fields of material sciences and wastewater treatment.

References

J. Das, D. Das, K.M. Parida, Preparation and characterization of Mg–Al hydrotalcite-like compounds containing cerium. J. Colloid Interface Sci. 301, 569–574 (2006)

S. He, Y. Zhao, M. Wei, X. Duan, Preparation of oriented layered double hydroxide film using electrophoretic deposition and its application in water treatment. Ind. Eng. Chem. Res. 50, 2800–2806 (2011)

S. Mandal, D. Tichit, D.A. Lerner, N. Marcotte, Azoic dye hosted in layered double hydroxide: physicochemical characterization of the intercalated materials. Langmuir 25, 10980–10986 (2009)

D. Li, L. Qian, Y. Feng, J. Feng, P. Tang, L. Yang, Co-intercalation of acid red 337 and a UV absorbent into layered double hydroxides: enhancement of photostability. ACS Appl. Mater. Interfaces 6, 20603–20611 (2014)

Y. Yasin, A.H. Abdul Malek, S. Mariam Sumari, Adsorption of eriochrome black dye from aqueous solution onto anionic layered double hydroxides. Orient. J. Chem. 26, 1293 (2010)

X. Cai, X. Shen, L. Ma, Z. Ji, C. Xu, A. Yuan, Solvothermal synthesis of NiCo-layered double hydroxide nanosheets decorated on RGO sheets for high performance supercapacitor. Chem. Eng. J. 268, 251–259 (2015)

D. Tichit, B. Coq, Catalysis by hydrotalcites and related materials. Cattech 7, 206–217 (2003)

C. Li, M. Wei, D.G. Evans, X. Duan, Layered double hydroxide-based nanomaterials as highly efficient catalysts and adsorbents. Small 10, 4469–4486 (2014)

K. Ladewig, Z.P. Xu, G.Q. Lu, Layered double hydroxide nanoparticles in gene and drug delivery. Exp. Opin. Drug. Deliv. 6, 907–922 (2009)

M.H. Kim, D.H. Park, J.H. Yang, Y.B. Choy, J.H. Choy, Drug-inorganic-polymer nanohybrid for transdermal delivery. Int. J. Pharm. 444, 120–127 (2013)

J. Das, B.S. Patra, N. Baliarsingh, K.M. Parida, Adsorption of phosphate by layered double hydroxides in aqueous solutions. Appl. Clay. Sci. 32, 252–260 (2006)

K.H. Goh, T.T. Lim, Z. Dong, Application of layered double hydroxides for removal of oxyanions: a review. Water. Res. 42, 1343–1368 (2008)

D. Bharali, R.C. Deka, Preferential adsorption of various anionic and cationic dyes from aqueous solution over ternary CuMgAl layered double hydroxide. Colloids Surf. A 525, 64–76 (2017)

K. Abdellaoui, I. Pavlovic, M. Bouhent, A. Benhamou, C. Barriga, A comparative study of the amaranth azo dye adsorption/desorption from aqueous solutions by layered double hydroxides. Appl. Clay. Sci. 143, 142–150 (2017)

R.M. dos Santos, R.G. Gonçalves, V.R. Constantino, C.V. Santilli, P.D. Borges, J. Tronto, F.G. Pinto, Adsorption of acid yellow 42 dye on calcined layered double hydroxide: effect of time, concentration, pH and temperature. Appl. Clay. Sci. 140, 132–139 (2017)

W. Yao, S. Yu, J. Wang, Y. Zou, S. Lu, Y. Ai, N.S. Alharbi, A. Alsaedi, T. Hayat, X. Wang, Enhanced removal of methyl orange on calcined glycerol-modified nanocrystallined Mg/Al layered double hydroxides. Chem. Eng. J. 307, 476–486 (2017)

C.M. Becker, A.D. Gabbardo, F. Wypych, S.C. Amico, Mechanical and flame-retardant properties of epoxy/Mg–Al LDH composites. Compos. Part A Appl. Sci. Manuf. 42, 196–202 (2011)

Z. Gu, J.J. Atherton, Z.P. Xu, Hierarchical layered double hydroxide nanocomposites: structure, synthesis and applications. Chem. Commun. 51, 3024–3036 (2015)

M.I. Carretero, Clay minerals and their beneficial effects upon human health. A review. Appl. Clay. Sci. 21, 155–263 (2002)

C. Del Hoyo, Layered double hydroxides and human health: an overview. Appl. Clay. Sci. 36, 103–121 (2007)

X. Liang, Y. Zang, Y. Xu, X. Tan, W. Hou, L. Wang, Y. Sun, Sorption of metal cations on layered double hydroxides. Colloids Surf. A Physicochem. Eng. Asp. 433, 122–131 (2013)

S. Senapati, R. Thakur, S.P. Verma, S. Duggal, D.P. Mishra, P. Das, T. Shripathi, M. Kumar, D. Rana, P. Maiti, Layered double hydroxides as effective carrier for anticancer drugs and tailoring of release rate through interlayer anions. J. Controlled Release 224, 186–198 (2016)

H. Zhang, K. Zou, S. Guo, X. Duan, Nanostructural drug-inorganic clay composites: structure, thermal property and in vitro release of captopril-intercalated Mg–Al-layered double hydroxides. J. Solid State Chem. 179, 1792–1801 (2006)

D.A. Bedoya, C. Vasti, R. Rojas, C.E. Giacomelli, Risedronate functionalized layered double hydroxides nanoparticles with bone targeting capabilities. Appl. Clay. Sci. 141, 257–264 (2017)

S. Mondal, S. Dasgupta, K. Maji, MgAl-layered double hydroxide nanoparticles for controlled release of salicylate. Mater. Sci. Eng 68, 557–564 (2016)

M.J. Barnabas, S. Parambadath, C.S. Ha, Amino modified core–shell mesoporous silica based layered double hydroxide (MS-LDH) for drug delivery. J. Ind. Eng. Chem. 53, 392–403 (2017)

C. Forano, Environmental remediation involving layered double hydroxides, in Clay Surfaces: Fundamentals and Applications, ed. by F Wypych, KG Satyanarayana (Elsevier, Amsterdam, 2004), p. 425

M.A. Ulibarri, M.C. Hermosín, Layerd double hydroxides in water decontamination, in Layered Double Hydroxides: Present and Future, ed. by V Rives (NOVA Sci Pub Inc, New York, 2001), p. 251

Y. Zhao, H. Lin, M. Chen, D. Yan, Niflumic anion intercalated layered double hydroxides with mechano-induced and solvent-responsive luminescence. Ind. Eng. Chem. Res. 53(8), 3140–3147 (2014)

H. Zhang, J. Zhang, R. Yun, Z. Jiang, H. Liu, D. Yan, Nanohybrids of organo-modified layered double hydroxides and polyurethanes with enhanced mechanical, damping and UV absorption properties. RSC Adv. 6(41), 34288–34296 (2016)

R. Gao, D. Yan, Ordered assembly of hybrid room-temperature phosphorescence thin films showing polarized emission and the sensing of VOCs. Chem. Commun. 53(39), 5408–5411 (2017)

Z. Li, Y. Zhou, D. Yan, M. Wei, Electrochemiluminescence resonance energy transfer (ERET) towards trinitrotoluene sensor based on layer-by-layer assembly of luminol-layered double hydroxides and CdTe quantum dots. J. Mater Chem. C 5(14), 3473–3479 (2017)

S. Miyata, (1975) The syntheses of hydrotalcite-like compounds and their structures and physico-chemical properties I: the systems Mg2+-Al3+-NO3 −, Mg2+-Al3+-Cl−, Mg2+-Al3+-ClO4 −, Ni2+-Al3+-Cl− and Zn2+-Al3+-Cl. Clay Clay Miner. 23, 369–375

S. Kannan, A. Dubey, H. Knozinger, Synthesis and characterization of CuMgAl ternary hydrotalcites as catalysts for the hydroxylation of phenol. J. Catal. 231, 381–392 (2005)

Z.P. Xu, G.Q. Lu, Hydrothermal synthesis of layered double hydroxides (LDHs) from mixed MgO and Al2O3: LDH formation mechanism. Chem. Mater. 17, 1055–1062 (2005)

D. Carriazo, M. Del Arco, E. Garcia-Lopez, G. Marci, C. Martin, L. Palmisano, V. Rives, Zn, Al hydrotalcites calcined at different temperatures: preparation, characterization and photocatalytic activity in gas–solid regime. J. Mol. Catal. A 342, 83–90 (2011)

F.L. Theiss, M.J. Sear-Hall, S.J. Palmer, R.L. Frost, Zinc aluminium layered double hydroxides for the removal of iodine and iodide from aqueous solutions. Desalin. Water Treat. 39, 166–175 (2012)

R.R. Shan, L.G. Yan, Y.M. Yang, K. Yang, S.J. Yu, H.Q. Yu, B.C. Zhu, B. Du, Highly efficient removal of three red dyes by adsorption onto Mg–Al-layered double hydroxide. J. Ind. Eng.Chem. 21, 561–568 (2015)

B. Li, Y. Zhang, X. Zhou, Z. Liu, Q. Liu, X. Li, Different dye removal mechanisms between monodispersed and uniform hexagonal thin plate-like MgAl–CO3 2–-LDH and its calcined product in efficient removal of Congo red from water. J. Alloys Compd. 673, 265–271 (2016)

Z. Yan, B. Zhu, J. Yu, Z. Xu, Effect of calcination on adsorption performance of Mg–Al layered double hydroxide prepared by a water-in-oil micro emulsion method. RSC Adv. 6, 50128–50137 (2016)

K.M. Parida, L. Mohapatra, Carbonate intercalated Zn/Fe layered double hydroxide: a novel photocatalyst for the enhanced photo degradation of azo dyes. Chem. Eng. J. 179, 131–139 (2012)

J. Yu, G. Fan, Y. Yang, F. Li, Multi-level three-dimensional Mg–Al layered double hydroxide hierarchical microstructures with enhanced basic catalytic property. J. Colloid Interface Sci. 432, 1–9 (2014)

Y. Guo, Z. Zhu, Y. Qiu, J. Zhao, Enhanced adsorption of acid brown 14 dye on calcined Mg/Fe layered double hydroxide with memory effect. Chem. Eng. J. 219, 69–77 (2013)

H. Zaghouane-Boudiaf, M. Boutahala, L. Arab, Removal of methyl orange from aqueous solution by uncalcined and calcined MgNiAl layered double hydroxides (LDHs). Chem. Eng. J. 187, 142–149 (2012)

P. Monash, G. Pugazhenthi, Utilization of calcined Ni-Al layered double hydroxide (LDH) as an Adsorbent for removal of methyl orange dye from aqueous solution. Environ. Prog. Sustain. Energy 33, 154–159 (2014)

X. Yue, W. Liu, Z. Chen, Z. Lin, Simultaneous removal of Cu (II) and Cr (VI) by Mg–Al–Cl layered double hydroxide and mechanism insight. J. Environ. Sci. 53, 16–26 (2017)

V.R. Constantino, T.J. Pinnavaia, Basic properties of Mg2+ 1−xAl3+ x layered double hydroxides intercalated by carbonate, hydroxide, chloride, and sulfate anions. Inorg. Chem. 34, 883–892 (1995)

A.R. Auxilio, P.C. Andrews, P.C. Junk, L. Spiccia, The adsorption behavior of CI Acid blue 9 onto calcined Mg–Al layered double hydroxides. Dyes Pigm. 81, 103–112 (2009)

X. Cheng, X. Huang, X. Wang, D. Sun, Influence of calcination on the adsorptive removal of phosphate by Zn–Al layered double hydroxides from excess sludge liquor. J. Hazard. Mater. 177, 516–523 (2010)

J.Y. Dong, C.H. Lin, Y.J. Hsu, S.Y. Lu, D.S. Wong, Single-crystalline mesoporous ZnO nanosheets prepared with a green antisolvent method exhibiting excellent photocatalytic efficiencies. CrystEngComm 14, 4732–4737 (2012)

D. Fu, G. Han, Y. Chang, J. Dong, The synthesis and properties of ZnO–graphene nano hybrid for photodegradation of organic pollutant in water. Mater. Chem. Phys. 132, 673–681 (2012)

M.A. Ahmed, A.A. Mohamed, An efficient adsorption of indigo carmine dye from aqueous solution on mesoporous Mg/Fe layered double hydroxide nanoparticles prepared by controlled sol-gel route. Chemosphere 174, 280–288 (2017)

Acknowledgements

The authors gratefully acknowledge the financial support provided by the University Grants Commission (UGC), New Delhi, under the Minor Research Project scheme (Project Proposal Number: 1161) to carry out the present research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manjula Rani, K., Palanisamy, P.N. Synthesis and Characterization of Mesoporous, Nanostructured Zinc Aluminium Carbonate Layered Double Hydroxides (ZAC-LDHs) and Its Calcined Product (CZA-LDH). J Inorg Organomet Polym 28, 1127–1135 (2018). https://doi.org/10.1007/s10904-018-0796-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-018-0796-9