Abstract

In this work, novel titania (TiO2) nanoparticles were designed as a high performance photocatalyst. It was obtained by a simple method of dispersing nanofibrillated cellulose (NFC) onto the surface of titanium tetrachloride (TiCl4), inducing crystallization and removing NFC templates. Under UV light irradiation, The TiO2 nanoparticles displayed excellent photocatalytic activity for the decomposition of methyl orange solution. It was found that TiO2 after calcination had a more efficiency than that before calcination. The optimum calcination temperature for the removal of NFC templates was 300 °C. Methyl orange solution had been remarkably degraded by TiO2 nanoparticles when the mass ratio of TiCl4 and NFC was 12:1. These results indicate that the TiO2 nanopartilces can be easily applied in the field of wastewater treatment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Morphology controllable inorganic metal oxide has successfully obtained by natural materials as template, demonstrating excellent properties and development of composites for application in photocalysis, energy, medicines and so on [1,2,3,4,5]. A series of natural templates containing cellulose, lignin, chitosan and alginate are used to fabricate functional materials [6,7,8,9]. Recently, cellulose has been widely applied to template-directed synthesize functional nanomaterials of metal oxide [10, 11].

Nanofibrillated cellulose is made of d-glucose monomers linked by β-1,4 ether linkages containing abundant hydroxyl and carboxyl groups and ether bonds which support affinities and active sites to the dispersion and growth of inorganic nanoparticles [12, 13]. Moreover, the extensive hydrogen bond network of nanofibrillated cellulose builds up an ordered structure for providing enough space with formation of metallic oxide [14, 15]. These hydroxyl groups on the surface of cellulose acting as efficient hydrophilic active sites can accelerate the growth of metallic oxide particles [16]. Nanofibrillated cellulose template content had effects on the surface morphology of nanoparticles. To obtain the pure titanium dioxide with highly active crystal phase, proper calcination temperature could be required.

In this paper, TiO2 nanoparticles were successfully synthesized by using nanofibrillated cellulose as a template. The chemical composition, crystallinity and morphology of TiO2 were investigated by Fourier Transform Infrared Spectroscopy (FT-IR), Thermo Gravimetric Analyzer (TGA) and Scanning Electron Microscope (SEM), respectively. Effects of calcination temperature and template content on photocatalytic degrading methyl orange were investigated.

2 Experimental

2.1 Materials

Titanium tetrachloride, hydrochloric acid, ammonium sulphate, ammonia and absolute alcohol were of analytical grade and utilized without purification. Nanofibrillated cellulose (NFC) was obtained from Guilin Qihong Science and Technology Co., Ltd (0.6 wt%, average length: 6.8 nm, average width: 1000 nm).

2.2 Preparation of TiO2 Nanoparticles with Nanofibrillated Cellulose

Four milliliter TiCl4 (36 mmol) was added into 200 ml deionized water containing 1 g nanofibrillated cellulose (6.17 mmol) under continuous stirring in ice bath. After 1 h, 0.5 g (NH4)2SO4 (3.79 mmol) and 1.58 ml HCl (18.96 mmol) were added dropwise with further stirring for 1 h in ice bath. Moreover, the mixture was warmed in an oil bath at 70 °C for 2 h. Then, the pH of the mixture was regulated to nearly eight using ammonia and stirring at room temperature for further 24 h. The obtained products were washed with deionized water and absolute ethanol, respectively. The purified products were calcined at 300, 400, 500 and 600 °C in air atmosphere for 4 h, respectively.

2.3 Characterizations

The Fourier transform infrared spectra were carried out on a spectrophotometer (Bruker, VERTEX70, Germany). The chemical compositions of TiO2 and nanofibrillated cellulose template were measured by energy dispersive spectroscopy (HORIBA, XMX 1011, Japan). The morphologies of the products were observed using scanning electron microscope (Hitachi, SU8010, Japan). The thermal stabilities were evaluated using thermal gravimetric analysis (TA, Q500, USA). Samples were heated in an aluminum crucible to 700 °C at a heating rate of 10 °C/min. The crystal structure of TiO2 was characterized by using X-ray diffraction analysis (Rigaku, Ultima IV, Japan) with Cu Kα radiation. Antase to rutile ratio was estimated from integrated intensities of the reflection of (101) and (110) phases [17]. The crystallite size of anatase and rutile was calculated according to the Scherrer formula. BET surface area of TiO2 was characterized by nitrogen adsorption (Micromeritics, ASAP 2020, USA).

2.4 Evaluation of Photocatalytic Activity

The photocatalytic activity of TiO2 nanoparticles was estimated using methyl orange solution as target degradation molecule. The photocatalytic source was launched out by ultraviolet lamp with power about 36 W. A mixture containing 25 mg of TiO2 nanoparticles and 100 ml methyl orange (5 mg/l) was stirred for 30 min in the dark to reach adsorption equilibrium. Then, 3.5 ml of the mixture under UV irradiation was collected and filtered by 0.22 μm membrane at 15, 30, 60, 90 and 120 min, respectively. The absorbance of the filtrate was measured by UV–Vis spectrophotometer (Shimadzu, UVmini-1240, Japan).

3 Results and Discussion

3.1 Characteristics of TiO2 Nanoparticles Templated by Nanofibrillated Cellulose

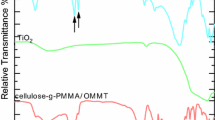

Obvious differences in wave numbers and intensities of the absorption bands can be observed between the spectra of TiO2 templated by NFC as shown in Fig. 1. The peak at 3430 cm−1 corresponds to stretching vibrations of hydroxyl groups of nanofibrillated cellulose. Loading TiO2 nanoparticles on the nanofibrillated cellulose, peak of hydroxyl groups shift to 3216 cm−1. After calcination, hydroxyl groups at 3373 cm−1 are stronger than nano cellulose, which indicates that hydroxyl groups of nano cellulose have some interactions with both Ti4+ and TiO2 nanoparticles. A similar phenomenon was observed for the in-plane OH deformation vibration (1609–1605, 1624 and 1627 cm−1, respectively).

The thermal properties of TiO2 templated by NFC were conducted with TGA. Figure 2 shows the thermal gravimetric curves for TiO2 with a heating rate of 10 °C/min under a nitrogen atmosphere. For NFC, the weight loss was 10.9% below 100 °C due to the moisture content in the NFC sample. NFC began with rapid chemical decomposition at 238 °C, leaving 23.5% quality content at 700 °C. Regarding to TiO2-FC, TiO2-TU and TiO2-TC, the weight loss below 100 °C were only 9.7, 7.7 and 5.7%, respectively. The quality content of TiO2-TU (29.4%) was higher than TiO2-FC (20.4%) and TiO2-TC (12.1%) at 700 °C, which indicated that much of organic compounds coming from NFC remained in the TiO2.

Figure 3 shows the SEM images of TiO2 free of template and TiO2 templated by NFC. From the SEM images, particle size of TiO2 was about 200 nm regardless of template. TiO2 free of template demonstrated that the TiO2 nanoparticles were spherical shape. While TiO2 templated by NFC showed that TiO2 particles agglomerated into linear shape.

3.2 Effect of Calcination Temperature on the Photocatalytic Activity of TiO2 Nanoparticles

The photocatalytic abilities of the obtained TiO2 nanoparticles at different calcined temperatures were investigated by decomposing the methyl orange solution with the concentration of 5 mg/l. The obtained TiO2 nanoparticles displayed superior photocatalytic activities, when the NFC template was removed. Residual concentration of methyl orange was reduced as the photocatalytic time. When the photocatalytic time was 60 min, the photodegradation efficiencies of the TiO2 samples calcined at 300, 400, 500, 600 °C are about 95.7, 69.5, 64.7, 60.0%, respectively. As the photocatalytic time extended to 120 min, the methyl orange was removed above 96% (Fig. 4).

XRD diffraction patterns of TiO2 nanoparticles calcined at different temperatures were shown in Fig. 5. The diffraction peaks at 2θ values of 25.3°, 27.4°, 37.0°, 37.8°, 41.4°, 48.1°, 53.9°, 55.1°, 62.7°, 68.8°, 70.4° and 75.0° correspond to the (101), (110), (101), (004), (111), (200), (105), (211), (204), (301), (112) and (215) planes of TiO2, respectively, and readily be indexed to the anatase phase (JCPDS card No. 21-1272) and rutile phase (JCPDS card No. 65–0191). Calcinaed temperature had not affected the peak positions at 25.3° and 27.4° of anatase and rutile, respectively. But the anatase/rutile ratio had been slightly reduced with the calcined temperature as shown in Table 1. At the same time, the crystallite size of TiO2 became larger with the calcined temperature. But the surface area of TiO2 nanoparticles was getting smaller with the calcination temperature.

3.3 Effect of Template Amount on the Photocatalytic Activity of TiO2 Nanoparticles

Photocatalytic activities of TiO2 templated by NFC with different mixture ratios were studied as shown in Fig. 6. After 120 min-UV irradiation, the decomposition ratio of methyl orange were all nearly 100% indicating that these TiO2 had very strong photocatalytic activities. When the UV irradiation time was 60 min, the concentration of methyl orange was only 1.7% under the UV irradiation by TiO2 (12:1). While other TiO2 displayed the weak photocatalytic activities as the following order: TiO2 (12:1) > TiO2 (100:1) > TiO2 > TiO2 (6:1) > TiO2 (3:1).

Figure 7 showed the X-ray diffraction data (XRD) of all the prepared materials which corresponded to TiO2 (anatase) (JCPDS card NO. 21-1272). The diffraction peaks at 2θ values of 25.3°, 37.9°, 48.0°, 54.2°, 62.7° and 75.3° correspond to the (101), (004), (200), (105), (204), and (215) planes of TiO2, respectively. From Table 2, the anatase/rutile ratio remained at 1, indicating that the TiO2 was made from pure crystal phase of anatase. Crystallite size of all the TiO2 nanoparticles was nearly 5 nm, while the surface area of TiO2 nanoparticles varied with the different ratio between TiCl4 and NFC. When the ratio between TiCl4 and NFC was 12:1, the surface area of TiO2 nanoparticles ran up to 88.3 m2/g.

3.4 Reusability of TiO2 Nanoparticles on Photocatalytic Activity

The reusability is an important parameter related to the application potential of photocatalysts. In this study, 25 mg of TiO2 nanoparticles were added into 100 ml of methyl orange solution (5 mg/l) to measure the concentration of methyl orange after 30 and 60 min UV irradiation. As seen from Fig. 8, the resulted TiO2 nanoparticles were used for five cycles. The concentration of methyl orange had been still reduced above 90% (60 min UV irradiation) and 65% (30 min UV irradiation) after five batches. Thus, it is believed that it can be recycled for many times.

4 Conclusions

TiO2 photocatalyst was synthesized by a hydrothermal approach with NFC as a template. The results showed that the catalytic activity of TiO2 templated by NFC was more superior than TiO2 free of template. When the calcination temperature was 300 °C, TiO2 nanoparticles achieved the higher content of anatase phase with larger surface area in favor of photocatalytic degrading pollutant molecules. TiO2 nanoparticles had the same content of anatase phase and crystallite size as the different ratios between TiCl4 and NFC. TiO2 templated by NFC exhibited a very good performance in removing methyl orange as well as a good reusability.

References

Y.Y. Kim, C. Neudeck, D. Walsh, Biopolymer templating as synthetic route to functional metal oxide nanoparticles and porous sponges. Polym. Chem. 1(3), 272–275 (2010)

B. Boury, S. Plumejeau, Metal oxides and polysaccharides: an efficient hybrid association for materials chemistry. Green Chem. 17(1), 72–88 (2015)

A. Ivanova, D. Fattakhova-Rohlfing, B.E. Kayaalp et al., Tailoring the morphology of mesoporous titania thin films through biotemplating with nanocrystalline cellulose. J. Am. Chem. Soc. 136(16), 5930–5937 (2014)

J.H. Kim, J.H. Kim, E.S. Choi et al., Colloidal silica nanoparticle-assisted structural control of cellulose nanofiber paper separators for lithium-ion batteries. J. Power Sources 242, 533–540 (2013)

F.Y. Fu, L.Y. Li, L.J. Liu et al., Construction of cellulose based ZnO nanocomposite films with antibacterial properties through one-step coagulation. ACS Appl. Mater. Interfaces 7(4), 2597–2606 (2015)

M.A. Mohamed, W. Salleh, J. Jaafar et al., Incorporation of N-doped TiO2 nanorods in regenerated cellulose thin films fabricated from recycled newspaper as a green portable photocatalyst. Carbohydr. Polym. 133, 429–437 (2015)

X.Y. Chen, D.H. Kuo, D.F. Lu et al., Synthesis and photocatalytic activity of mesoporous TiO2 nanoparticle using biological renewable resource of un-modified lignin as a template. Microporous Mesoporous Mater. 223, 145–151 (2016)

J. Liu, W.Y. Li, Y.G. Liu et al., Titanium(IV) hydrate based on chitosan template for defluoridation from aqueous solution. Appl. Surf. Sci. 293, 46–54 (2014)

M.C. Kimling, R.A. Caruso, Sol–gel synthesis of hierarchically porous TiO2 beads using calcium alginate beads as sacrificial templates. J. Mater. Chem. 22(9), 4073–4082 (2012)

A. Henry, S. Plumejeau, L. Heux et al., Conversion of nanocellulose aerogel into TiO2 and TiO2@C nano-thorns by direct anhydrous mineralization with TiCl4. Evaluation of electrochemical properties in Li batteries. ACS Appl. Mater. Interfaces 7(27), 14584–14592 (2015)

B. Boury, R.G. Nair, S.K. Samdarshi et al., Non-hydrolytic synthesis of hierarchical TiO2 nanostructures using natural cellulosic materials as both oxygen donors and templates. New J. Chem. 36(11), 2196–2200 (2012)

H. Ceylan, C. Ozgit-Akgun, T.S. Erkal et al., Size-controlled conformal nanofabrication of biotemplated three-dimensional TiO2 and ZnO nanonetworks. Sci. Rep. 3, 1–7 (2013)

D.H. Yu, X.D. Yu, C.H. Wang et al., Synthesis of natural cellulose-templated TiO2/Ag nanosponge composites and photocatalytic properties. ACS Appl. Mater. Interfaces 4(5), 2781–2787 (2012)

Z.D. Li, C.H. Yao, F. Wang et al., Cellulose nanofiber-templated three-dimension TiO2 hierarchical nanowire network for photoelectrochemical photoanode. Nanotechnology 25(50), 1–10 (2014)

Y. Lu, Q.F. Sun, T.C. Liu et al., Fabrication, characterization and photocatalytic properties of millimeter-long TiO2 fiber with nanostructures using cellulose fiber as a template. J. Alloys Compd. 577, 569–574 (2013)

N. Olaru, G. Galin, L. Olaru, Zinc oxide nanocrystals grown on cellulose acetate butyrate nanofiber mats and their potential photocatalytic activity for dye degradation. Indus. Eng. Chem. Res. 53(46), 17968–17975 (2014)

B. Tryba, A.W. Morawski, M. Inagaki, A new route for preparation of TiO2-mounted activated carbon. Appl. Catal. B 46(1), 203–208 (2003)

Acknowledgements

This work was supported by State Key Laboratory of Pulp and Paper Engineering (201617), Fujian Science and Technology of Education Department Fund (JAT160151), Fujian Innovation and Entrepreneurship Training Program (201610389083).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, H., Li, J. & He, B. Anatase-Titania Templated by Nanofibrillated Cellulose and Photocatalytic Degradation for Methyl Orange. J Inorg Organomet Polym 27, 1022–1027 (2017). https://doi.org/10.1007/s10904-017-0550-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-017-0550-8