Abstract

A new coordination polymer of lead(II) nitrate complexes with bridging trans-1,2-bis(4-pyridyl)ethene (bpe) ligand, [Pb(µ-NO3)2(bpe)(MeOH)]n (1), has been synthesized and characterized by elemental analysis, FT-IR, 1H, 13C-NMR, thermal analysis and single crystal X-ray diffraction. In compound 1, lead(II) ions are bridged by nitrate ligands forming linear chains, which are also further coordinated by neutral bpe and methanol ligands into a two-dimensional polymeric chain. This polymeric precursor has been used to prepare PbO nano-particles using two different method. The prepared lead(II) oxide nano-structure was characterized by scanning electron microscopy and X-ray powder diffraction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Chemists and materials scientists studied metal coordination polymers widely, as they have an important specific structures, properties, and reactivities that are not found in mononuclear compounds [1–10]. Nanometer-sized particles of metal coordination polymers are fascinating to explore, since their unique properties are controlled by the large number of surface molecules, which experience an entirely different environment than those in a bulk crystal. Controlling the growth of materials at the submicrometer scale is of central importance in the emerging field of nanotechnology [11–17]. Although considerable effort has been dedicated to the controlled synthesis of nano-scale particles of metals, oxides, sulfides, and ceramic materials, little attention was focused to date on nano-particles of supramolecular compounds such as coordination polymers [18–22]. This article focuses on the simple synthetic preparation of a new Pb(II) two-dimensional lead(II) coordination polymer, [Pb(μ-NO3)2(bpe)(MeOH)]n (1), bpe = trans-1,2-bis(4-pyridyl)ethene, and on its conversion into nano-structured lead oxide by direct calcination at moderately elevated temperature. PbO nano particles have many application such as usage in dye and glass industry (lead glasses), piezoelectric ceramics, supercapacitors and lead-acid batteries.

2 Experimental Section

2.1 Materials and Physical Techniques

All chemicals were of reagent grade from Merck company and were used as commercially obtained without further purification. IR spectra were recorded using Perkin-Elmer 597 and Nicolet 510P spectrophotometers. Microanalyses were carried out using a Heraeus CHN-O-Rapid analyzer. Melting points were measured on an Electrothermal 9100 apparatus and are uncorrected. The thermal behavior was measured with PL-STA 1500 apparatus. The luminescent properties were investigated with a Shimadzu RF-5000 spectrofluorophotometer. X-ray powder diffraction (XRD) measurements were performed using an X’pert diffractometer of Philips Company with monochromated Cukα radiation and since our samples were powder operator put them on holder and then system start to scan. Crystallographic measurements were made at 100(2) K using a Bruker AXS SMART APEX CCD diffractometer. The intensity data were collected using graphite monochromated Mo-Kα radiation (λ = 0.71073 Å). Accurate unit cell parameters and orientation matrices were obtained from least-squares refinements using the programs Smart and Saint, and the data were integrated using Saint. The structures have been solved by direct methods and refined by full-matrix least-squares techniques on F 2 using SHELXTL. The molecular structure plots were prepared using the ORTEP [23] and Mercury programs [24]. Crystallographic data and details of the data collection and structure refinements are listed in Table 1. Nano structures were characterized with a scanning electron microscope (SEM) (Philips XL 30) with gold coating and the centrifuge equipment that was used is Hettich ZENTRIFUGEN D-78532/EBA 20.

2.2 Synthesis of [Pb(μ-NO3)2(bpe)(MeOH)]n (1)

Ligand bpe (0.182 g, 1 mmol) was placed in one arm of branched tube and lead(II) nitrate (0.331 g, 1 mmol) in the other. Methanol was carefully added to fill both arms, then the tube was sealed and the ligand-containing arm immersed in a bath at 60 °C, while the other was at ambient temperature. After 5 days, yellow crystals were deposited in the cooler arm which was filtered off, washed with acetone and methanol and air dried. Yield 45%. decomp. p. 205 °C. Anal. Calcd. for C13H14N4O7Pb (%): C, 28.59; H, 2.56; N, 10.26; found: C, 28.90; H, 2.35; N, 10.80. IR (cm−1) selected bonds: 538(m), 820(m), 992(m), 1062(w), 1196(w), 1380(vs), 1410(w), 1588(s), 3200(w), 3350(w).

2.3 Synthesis of PbO Nanoparticles

The precursor [Pb(μ-NO3)2(bpe)(MeOH)]n (1) (0.1 mmol) was dissolved immediately in 1.58 ml oleic acid as a surfactant and formed light yellow solution. This solution was degassed for 20 min and then heated to 180 °C for 2 h. At the end of the reaction, a black precipitate was formed. A small amount of toluene and a large excess of EtOH were added to the reaction solution and PbO nanoparticles were separated by centrifugation in 60 rpm for 5 min. The solids were washed with EtOH and dried under air atmosphere. In other hand PbO nanoparticles had been synthesised from direct calcination of compound 1 at 600 °C for 4 h. The size and morphology of nanoparticles from two different methods was characterized by SEM and compared.

3 Result and Discussion

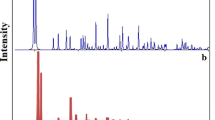

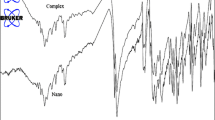

Reaction between trans-1,2-bis(4-pyridyl)ethene (bpe) ligand with lead(II) nitrate a new lead(II) coordination polymer, [Pb(μ-NO3)2(bpe)(MeOH)]n (1), in the crystalline form has been obtained. This compound is air-stable and high-melting solids that is soluble in DMSO. IR spectra of compound 1 display characteristic absorption bands for bpe and nitrate ligands. The relatively weak absorption bands at around 2,900 and 3,050 cm−1 is due to the C–H modes involving the ethane and aromatic hydrogen atoms, respectively. The IR spectrum of the compound 1 shows ν(NO3) at 1,380 cm−1. Determination of the structure of compound 1 by X-ray crystallography (Table 1; Figs. 1, 2, 3) showed that the lead(II) ions are bridged by nitrate ligands forming linear chains, which are also further coordinated by neutral bpe and methanol ligands into a two-dimensional polymeric framework. The lead(II) ions have eight-coordinate geometry with one N atom from bpe ligand, one oxygen atom of methanol and six oxygen atoms of nitrate anions (Fig. 3). The arrangement of the ligands in compound 1 exhibits holodirected geometry and coordination around the lead(II) ion is possibly occupied by a inactive lone pair of electrons. Solvent methanol molecules are found in the lattice of compound 1 and are involved in a hydrogen bonding network (Table 2). Consequently, hydrogen bonds grow the structure into a hybrid two-dimensional layer (Fig. 2). The methanol molecules are acting as hydrogen bond donors towards the uncoordinated N atoms of the bpe ligands. The thermal stability of compound 1 (Fig. 4) has been determined between 25 and 700 °C in a air atmosphere by thermogravimetric (TG) and differential thermal analyses (DTA). Compound 1 is stable up to 180 °C at which temperature the methanol molecules begin to be removed. The experimental mass loss of 5.83% is consistent with the calculated value of 5.86% for the elimination of one molecule of methanol. The solid residue formed at around 250 °C is suggested to be methanol-free compound, [Pb(μ-NO3)2(bpe)]n. At higher temperatures, the decomposition of the residue occurs with two exothermic effects at 250 and 295 °C. Mass loss calculations of the end residue show that the final decomposition product is PbO. The solid-state photoluminescent spectrum of compound 1 were recorded at room temperature and excited at 383 nm, compound 1 shows one broad emission spectrum centered at 430 nm (Fig. 5). The emission band of compound 1 may be assigned to the ligand-to-metal charge-transfer (LMCT) band.

PbO nano-particles were synthesized from the decomposition of the precursor 1 in oleic acid at 180 °C (Fig. 6) under air atmosphere. The morphology and size of the as-prepared PbO samples were further investigated using SEM. SEM photograph and histographs of PbO nanostructure showed regular shape of lead(II) oxide nano-particles with the diameter about 65 nm at 180 °C (Figs. 6, 8) but the prepared nano-size lead(II) oxide at 600 °C produce not regular shapes but smaller size about 45 nm (Figs. 7, 9). The final product upon by decomposing the compound 1 is, based on their XRD patterns (Fig. 10), orthorhombic PbO. The phase purity of the as-prepared orthorhombic PbO nano-particles are completely obvious and all diffraction peaks are perfectly indexed to the orthorhombic PbO structure with the lattice parameters of a = 5.4903 Å, c = 4.7520 Å, Z = 4 and S.G = Pcam which are in JCPDS card file no. 38–1,477. No characteristic peaks of impurities are detected in the XRD pattern.

4 Conclusion

A new Pb(II) coordination polymer, [Pb(μ-NO3)2(bpe)(MeOH)]n (1); bpe = trans-1,2-bis(4-pyridyl)ethene, has been synthesized using a thermal gradient. Compound 1 was structurally characterized by single-crystal X-ray diffraction. The crystal structure of compound 1 consists of a two-dimensional polymer and shows the coordination number in the Pb(II) ions is eight. Calcination of compound 1 under air produces nano-sized particles of PbO. This study demonstrates the coordination polymers may be suitable precursors for the preparation of nanoscale materials and it does not need special conditions like high temperature, long times and pressure controlling. This method may have some advantages such as: shorter reaction times, better yields and it also is likely to produce nano-sized particles of the coordination polymer [25–30].

5 Supplementary Material

Crystallographic data for the structures reported in the paper has been deposited with the Cambridge Crystallographic Data Centre as supplementary publication no, CCDC-773859. Copies of the data can be obtained on application to CCDC, 12 Union Road, Cambridge CB2 1EZ, UK [Fax: + 44–1223/336033; e-mail: deposit@ccdc.cam.ac.uk].

References

M.J. Zaworotko, B. Moulton, Chem. Rev. 101, 2619 (2001)

O.M. Yaghi, G. Li, H. Li, Nature 378, 703 (1995)

A. Morsali, M.Y. Masoumi, Coord. Chem. Rev. 253, 1882 (2009)

J.A. Ramsden, W. Weng, A.M. Arif, J.A. Gladysz, J. Am. Chem. Soc. 114, 5890 (1992)

A. Aumuller, P. Erk, G. Klebe, S. Hunig, J.U. von Schutz, H.-P. Werner, Angew. Chem. Int. Ed. 98, 759 (1986)

M.A.M. Abu-Youssef, A. Escuer, D. Gatteschi, M.A.S. Goher, F.A. Mautner, R. Vicente, Inorg. Chem. 38, 5716 (1999)

M. Aoyagi, K. Biradha, M. Fujita, J. Am. Chem. Soc. 121, 7457 (1999)

M. Fujita, Y.J. Kwon, S. Washizu, K.J. Ogura, J. Am. Chem. Soc. 116, 1151 (1994)

S. Kawaguchi, Coord. Chem. Rev. 70, 51 (1986)

G. Mahmoudi, A. Morsali, A.D. Hunter, M. Zeller, Cryst Eng Comm 9, 704 (2007)

A. Askarinejad, A. Morsali, Ultrason. Sonochem. 16, 124 (2009)

A. Askarinejad, A. Morsali, Chem. Eng. J. 150, 569 (2009)

A. Askarinejad, A. Morsali, Chem. Eng. J. 153, 183 (2009)

M. Sugimoto, J. Magn. Chem. Mater. 133, 460 (1994)

M. Martos, J. Morales, L. Sanchez, R. Ayouchi, D. Leinen, F. Martin, J.R. Ramos Barrado, Electrochim. Acta 46, 2939 (2001)

A.V. Murugan, R.S. Sonawane, B.B. Kale, S.K. Apte, A.V. Kulkarni, Mater. Chem. Phys. 71, 98 (2001)

S.-H. Yu, J. Yang, Z.-H. Han, Y. Zhou, R.-Y. Yang, Y.-T. Qian, Y.-H. Zhanga, J. Mater. Chem. 9, 1283 (1999)

C. Li, X. Yang, B. Yang, Y. Yan, Y.T. Qian, J. Cryst. Growth 291, 45 (2006)

J. Yang, J.H. Zeng, S.H. Yu, L. Yang, G.E. Zhou, Y.T. Qian, Chem. Mater. 12, 3259 (2000)

C. Bao, M. Jin, R. Lu, P. Xue, Q. Zhang, D. Wang, Y. Zhao, J. Solid State Chem. 175, 322 (2003)

S. Khanjani, A. Morsali, J. Mol. Struct. 935, 27 (2009)

A. Aslani, A. Morsali, Inorg. Chim. Acta 362, 5012 (2009)

L.J. Farrugia, Ortep-3 for windows. J. Appl. Cryst 30, 65 (1997)

Mercury 1.4.1, Copyright Cambridge Crystallographic Data Centre, 12 Union Road, Cambridge, CB2 1EZ, UK (2001/2005)

A. Spokoyny et al., Chem. Soc. Rev. 38, 1218 (2009)

H. Sadeghzadeh, A. Morsali, V.T. Yilmaz, T. Veysel, O. Bueyuekguengoer, Mat. Lett 64(7), 810 (2010)

H. Sadeghzadeh, A. Morsali, Polyhedron 29(2), 925 (2010)

M.J. Fard-Jahromi, A. Soltanian, Morsali. Ultrason. Sonochem. 17(2), 435 (2010)

Z. Rashidi, A. Morsali, J. Mol. Struct. 936(1–3), 206 (2009)

L. Hashemi, A. Morsali, J. Inorg. Organomet. Polym. 20(4), 856 (2010)

Acknowledgments

Support of this investigation by Tarbiat Modares University is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hashemi, L., Aslani, A. & Morsali, A. Synthesis of a New Lead(II) Coordination Polymers with N-donor Ligand as Precursor for Preparation of PbO Nano-structure; Spectroscopic, Thermal, Fluorescence and Structural Studies. J Inorg Organomet Polym 22, 867–872 (2012). https://doi.org/10.1007/s10904-012-9668-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-012-9668-x