Summary

Reactions of hexamethylcyclotrisiloxane, D3, with 1,1,3,3-tetramethyldisiloxane, HMMH, 1,1,1,3,3-pentamethyldisiloxane, HMM, phenyldimethylsilane and phenylmethylsilane catalyzed by tris(pentafluorophenyl)borane were studied. These reactions lead to ring opening of D3 by the SiH reactant producing open chain oligomers with hydrosilane functionality at one or both chain ends. The reactivity of the hydrosilanes toward D3 decreases in the series: PhMeSiH2 > HMMH > PhMe2SiH > HMM. Competitive self-oligomerization of HMMH and HMM also occurs. Primary products of these processes are able to enter into reactions with the SiH and D3 reactants; some also undergo cyclization. Thus, consecutive and competitive processes lead to a series of various oligohomologues. Gas chromatography in conjunction with chemical ionization mass spectroscopy permitted identification of structure and determination of the basic directions of these oligomerization processes. Polysiloxanes of higher molecular weight may be also formed in some of these systems. The reactions, which occur in the systems studied, are rationalized on the basis of the mechanism involving the hydride transfer from silicon to trivalent boron. This includes the transient formation of tertiary trisilyloxonium borate which decomposes by the hydride transfer to one of the silicon atoms of the trisilyloxonium center.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There has recently been a considerable interest in using tris(pentafluorophenyl)borane as a specific catalyst in organic and polymer chemistry. B(C6F5)3 is very efficient as a Lewis acid coinitiator of the polymerization of olefin, diene and vinyl monomers [1–4]. It is also broadly used as the catalyst in many organic reactions [5, 6], such as aldol condensations [6, 7], rearrangement processes [8, 9], Diels-Alder reactions [10], silylation [11, 12], stannylation [9] and others.

B(C6F5)3 is particularly active in the promotion of reductive processes by hydrosilanes. For example, alcohols and ethers may be reduced completely to hydrocarbons by R3SiH/B(C6F5)3 reagents [13, 14]. The organic compound is first transformed into alkoxysilane that as the result of the reaction with a second silyl hydride molecule yields hydrocarbon and disiloxane. The second step of this redox process has recently been used for the generation of the siloxane bonds in the synthesis of polysiloxanes. Two routes to those polymers were explored: heterofunctional polycondensation of dihydrosilanes with dialkoxysilanes [15] and polycondensation of dihydrosilanes with silanediols [16]. The mechanism of the silyl hydride reaction with alkoxysilane catalyzed by B(C6F5)3 has recently been studied [17]. The siloxane bond is usually resistant to cleavage by R3SiH/B(C6F5)3 reagents. However, we found that 1,1,3,3-tetramethyldisiloxane is easily cleaved by B(C6F5)3 which efficiently catalyzes its dismutation process producing Me2SiH2 and a series of α, ω-dihydrooligodimethylsiloxanes [18]. Products of these reactions include some cyclic siloxanes, mostly hexamethylcyclotrisiloxane, (D3), and octamethylcyclotetrasiloxane, (D4). We found that D3 is formed from linear tetrasiloxane according to reaction 1. This leads to a state of equilibrium which indicates that the rapid reverse reaction of D3 ring opening by dimethylsilane also occurs in the presence of B(C6F5)3.

This reverse reaction implies that the oligomerization of D3 with Me2SiH2 to α,ω-dihydrooligodimethylsiloxane promoted by B(C6F5)3 is possible. Similar reactions with other hydrosilanes should proceed as well. The reactions of triorganohydrosilanes with D3 were expected to yield oligomers having the Si–H function at one chain end. On the other hand, the reactions of Si–H terminated oligomers should lead to a chain extension, so they may produce higher molecular weight polymers. The purpose of this work is to explore these possibilities. The reactions of D3 with various hydrosilanes are included in this study to estimate the potential of these reactions in the synthesis of various linear siloxane oligomers and polymers terminated with reactive hydrosilane functional groups. Such oligomers and polymers are useful as reactive blocks in the synthesis of a variety of block and graft copolymers [19]. They are also attractive reagents for chemical modification of a variety of other materials.

Experimental

Basic Chemicals

1,3-Dihydro-1,1,3,3-tetramethyldisiloxane, 1-hydro-1,1,3,3,3-pentamethyldisiloxane, hydrodimethylphenylsilane products of ABCR GmbH, dihydromethylphenylsilane purchased from Gelest and hexamethylcyclotrisiloxane (GE Advanced Materials) were stored over CaH2 and distilled before use. Their purity, as confirmed by gas chromatography, was higher than 98%.

Tris(pentafluorophenyl)borane (Aldrich) was purified by resublimation. Toluene (POCH, Polskie Odczynniki Chemiczne), analytical grade, was shaken with concentrated H2SO4, washed with NaHCO3 water solution and dried over MgSO4 prior to distillation from sodium. n-Dodecane (Aldrich) was stored over CaH2 and distilled from it.

Reactions of Hexamethylcyclotrisiloxane (D3) with the H–Si Reagents

Reactions of D3 with hydrosilanes and hydrosiloxanes were performed using glass Schlenk type reactors equipped with a magnetic stirrer, three way gas tight stopcock connected to an inert gas flow system and a thermostate. A known amount of D3 was sublimed into the reactor on a high vacuum line. The reactor was filled with argon (or nitrogen), then known amounts of toluene, n-dodecane (standard for gas chromatography analysis), and the Si–H reagent were introduced through the stopcock under a flow of nitrogen using a gas tight precision Hamilton syringe. After stabilizing the temperature, a known amount of B(C6F5)3 in toluene solution was added in the same way. The reaction was performed at 25 °C. Samples were withdrawn for gas chromatography using a Hamilton syringe under nitrogen flow through the stopcock. Examples of the oligomerization and polymerization reactions are given below.

Oligomerization of D3 with HMMH

The following components of the reaction mixture were introduced into the reactor: D3 (2.92 g, 1.67 mol/kg), HMMH (1.73 g, 1.64 mol/kg), toluene (3.03 g), n-dodecane (0.17 g, 0.127 mol/kg) and finally B(C6F5)3 (9.06.10−3 mol/kg) in a toluene solution. Samples were drawn and introduced to Eppendorfer vessels containing an excess of 3-ethylpyridine acting as the reaction quencher. The gas chromatogram taken before the catalyst addition showed only peaks for the substrates, toluene, standard and quencher. The reaction started without an apparent induction period as a sample taken 26 s after the introduction of catalyst showed a decrease in HMMH concentration to 42% of its initial value. The concentration of D3 dropped down more slowly. After 13 min there was less than 2% of the initial amounts of HMMH and still as much as 55% of the initial D3. A relatively fast conversion of D3 was observed for the first 5 min, when HMMH was present; subsequently, the concentration of D3 dropped with lower rate. The sample taken after 13 h showed only 3% of D3 remaining. Assignment of product peaks was determined by a chemical ionization mass spectroscopy. The products, in addition to cyclic dimethylsiloxane, D4, were oligomers of HMD n MH series. Quantitative analyses of these oligomers were carried out by gas chromatography using the procedure described in Ref. [18].

Polymerization of D3 with HMMH

This reaction was similar to the oligomerization experiments. In a reactor were placed D3 (5.35 g, 2.41 × 10−2 mol), toluene (4 ml), n-dodecane and B(C6F5)3 catalyst. The concentration of catalyst was 2.4 × 10−2 mol/kg. The reaction was started by the introduction of HMMH (0.398 g, 0.296 × 10−2 mol). The mixture was kept for 4 days at room temperature before the catalyst was neutralized by an excess of 3-ethylpyridine. The gas chromatography analysis showed only small amounts of HMDnMH oligomer products. D3 was completely absent, but about 8% of D4 relative to all siloxane products and a small amount of larger ring homologs was estimated to be in the post reaction mixture. After evaporation of the solvent, the polymer product was dissolved in methylene chloride and precipitated into methanol. Size exclusion chromatography (SEC) indicated a M n = 19,700 Da, M w /M n = 1.72 of polydimethylsiloxane terminated by the OSiMe2H units.

The comparison of peak intensities of both substrates and the standard permitted a quantitative monitoring of reactants conversion for all reactions studied. Quantitative analysis of HMD n MH oligomers and D4 by gas chromatography using the procedure described in Ref. [18] facilitated determination of the concentration variation of these products in the reaction of D3 with HMMH. In the case of the reaction of D3 with HMM, PhMe2SiH and PhMeSiH2 oligomeric products were identified by chemical ionization GC-MS. In this case, quantitative analyses were not performed.

Analyses

Gas chromatography analysis was performed with a Hewlett Packard HP 6890 chromatograph equipped with thermal conductivity detector (TCD) and HP1 capillary column of 30 m length and 0.53 mm diameter. The carrier gas was helium at a flow rate of 5 ml/min. The detector temperature was 250 °C. Injector temperature was 250 °C. The temperature of the column was programmed, in most cases, as follows: 3 min, 40 °C isotherm, 40–250 °C increasing at 10 °C/min, 10–20 min 240 °C isotherm. N-dodecane was used as an internal standard.

Mass spectra were recorded with a GC-MS Finnigan MAT instrument using a chemical ionization technique. The reactive gas (H+ carrier) was isobutane at a pressure of 10−4 Torr. The mass-spectrometer worked in tandem with a gas chromatograph fitted with a standard capillary column DB-1 of length 30 m. The temperature program was configured to match the chromatogram with that obtained by the HP 6890 instrument. The ionization in the mass spectrometer occurred at mild conditions to limit the fragmentation of ionized species. Oligosiloxanes having no SiH functionality gave a strong M+1 signal of protonated species. These peaks, together with those of its direct fragmentation (M+1–16 for cleavage of methane; M+1–78 for cleavage of benzene), dominated the chromatograms. For Si–H containing oligomers, the signal was dominated by M+1-2 for the cation which lost H2. Intense peaks were observed for M+1–16 and M+1–78. Taking into account that most of the mass spectrogram showed very distinct M+1 or M-1 signals and all of them exhibited characteristic and limited fragmentation, the assignment of the chromatographic peaks was unambiguous.

Gel permeation chromatography was carried out with LDC analytical refractoMonitor instruments equipped with two Phenogel® columns covering the M w range 102–105 Da. Toluene was used as the solvent with polystyrene standards.

Results and Discussion

Four Si–H reagents were selected for studies of reactions with D3 catalyzed by B(C6F5)3: 1,1,3,3-tetramethyldisiloxane, HMMH, 1,1,1,3,3-pentamethyldisiloxane, HMM, dimethylphenylsilane, Me2PhSiH, and methylphenylsilane, PhMeSiH2. The reactions were performed in a concentrated toluene solution using various molar ratios of D3 to Si–H reagent. During the reaction, samples were withdrawn and analyzed by gas chromatography. Peaks on chromatograms were assigned by chemical ionization mass spectroscopy analysis.

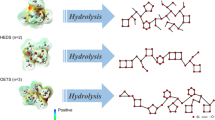

All the Si–H reactants used here were shown to react with D3 to open the ring and produce oligomeric open chain adducts with the SiH functionality at one or both chain ends (1st telomer). In general, the process occurs according to reaction 2.

The reactions were followed quantitatively by monitoring the conversion of reactants or, in the case of the reaction of HMMH, by following the formation of the D3 + HMMH adduct. The results permitted the comparison of the reactivity of various reactants with D3 (Table II). The ability of D3 to enter into reactions with Si–H reagents in the presence of B(C6F5)3 is due to the strain in the 6-membered ring which is the exceptional feature amongst cyclic oligodimethylsiloxane homologs. Unstrained D4 and presumably larger rings do not react at significant rates at conditions used here.

The D3 is also opened by oligomeric adducts which leads to extension of the chain (reaction 3) and, in some cases, could lead to polymer having relatively high molar mass.

Reactions 2 and 3 are accompanied by metathetic reactions (reactions 4 and 5) which are part of the hydrosiloxane dismutation described in our earlier paper [18]. The reaction of the Si–H chain end with starting reactant RR′R′′SiH (reaction 4) is typically relatively fast.

An analogous reaction between the SiH chain ends usually occurs more slowly and leads to chain coupling (reaction 5)

A competitive disproportionation reaction according to reaction 6 occurs more slowly than reactions 4 and 5.

In these metathetic reactions, the SiOSi bond is cleaved, but the salient feature is that only the siloxane group having hydrogen at the silicon atom is cleaved. The SiH functional reagents at conditions used here are not able to cleave hexamethyldisiloxane or the polydimethylsiloxane chain at any significant rates. Thus, when R, R′ and R′′ are not H, reactions 3–5 may, in principle, be considered irreversible. However, if R and/or R′ and/or R′′ are H, which is the case for HMMH and MePhSiH2, then the Si–H function appears at both chain termini of the products. Reaction 2 for this case is reversible and the metathesis may also occur intramolecularly [18] leading to a cyclic oligomer. Such unimolecular reactions occur particularly fast if the cyclic product is a six-membered ring.

Thus, many reactions occur in the D3+SiH/B(C6F5)3 system. Their relative rates are different for various RR′R′′SiH reactants, leading to different products. The course of the overall process for each of the selected reagents is discussed separately. All of the above mentioned component reactions are well understood assuming the mechanism involves a tertiary trisilyloxonium trispentafluorophenylborate intermediate. The transient formation of this intermediate as a diffusionally equilibrated or non-equilibrated species was considered in our previous papers [17, 18].

Oligomerization and Polymerization of D3 with 1,1,3,3-tetramethyldisiloxane, HMMH

In the oligomerization of D3 with HMMH experiments, the total amounts of both reactants were mixed with toluene and n-dodecane used as the gas chromatography standard. The catalyst was then introduced. Experiments with the addition of HMMH in various proportions to D3 and catalyst were also explored. A representative chromatogram of the reaction mixture is shown in Fig. 1. The reaction leads to series of linear chain polydimethylsiloxanes terminated at both ends with hydrosilane groups and cyclic oligodimethylsiloxanes, mostly octamethylcyclotetrasiloxane. The oligomer contents of both series were quantitatively determined which permitted following the change of concentrations in the reaction mixture (see Fig. 2).

Gas chromatogram of the reaction system of D3 with HMMH in concentrated toluene solution (Table I, entry 3) catalyzed by B(C6F5)3. HMMH was introduced successively in three equal portions. Chromatogram was taken 2300 s after beginning of reaction. Conversions of HMMH and D3 were 92 and 49% respectively.

Substrate conversion-time and main products formation-time dependences for the reaction of HMMH with D3 catalyzed by B(C6F5)3 in a concentrated solution in toluene (Table I, entry 2).

Results for the initial 1:1 molar ratio of reactants is shown in Fig. 2. HMMH is rapidly consumed. A rate of D3 conversion is relatively fast when HMMH is present in the system and it slows down considerably when HMMH is fully consumed. Two linear oligohomologs appear as primary products, i.e., 1,3-dihydrohexamethyltrisiloxane (HMDMH), and 1,7-dihydrodecamethylpentasiloxane (HMD3MH), reflecting two intensely competitive reactions that occur at the beginning of this process. The first is the dismutation of HMMH that was the subject of our previous publication [18]. It starts with the reaction of two HMMH molecules leading to HMDMH and Me2SiH2, which proceeds through a tertiary trisilyloxonium intermediate according to reaction 7.

The second process is the ring-opening of D3 by HMMH leading to HMD3MH according to reaction 8.

Concentrations of both products 2 and 3 rise to a sharp maximum after which there is a decrease, which means that consecutive processes leading to longer chain oligohomologs are proceeding. Generally, the secondary products are formed more slowly than primary products 2 and 3. Nevertheless, open chain tetrasiloxane HMD2MH 4 appears in a significant concentration initially as a result of a rapid consecutive reaction between Me2SiH2 formed in reaction 7 and D3, which contributes to the D3 consumption.

From the comparison of the initial rates of formation of homologues 2 and 3 and assuming a first order reactions in each of the reactants and in the catalyst, as was found for the analogous SiH + ROSi reaction [17], the ratio of catalytic constants for reactions 7 and 8 at 25 °C is 6.5.

Reactions 7 and 8 dominate the HMMH + D3 oligomerization pattern in its initial stage and are responsible for the formation of significant amounts of short chain oligomers HMD m MH m = 1–3 in the initial period of the oligomerization (Table I, entries 1–3). In the basic experiment performed at the molar ratio of substrates close to 1:1, the maximum yield of HMD m MH m = 1–3 was achieved when 92% of HMMH and about 30% of D3 was converted. At that point, these oligomers comprised 85% of the total product while those of m = 4–6 were only 8%. Cyclic D4 and D5 constitute only 3.5% of the total mass. Successive introduction of HMMH to a mixture of D3 with B(C6F5)3 improved the D3 conversion to about 50% when 85% of m = 1–3 oligomers were obtained, improving the overall yield of the process.

Longer linear chain oligomers are mostly formed by further dismutation of HMD m MH m = 1–3 oligomers, which also leads to the formation of Me2SiH2 and further consumption of D3 by the reverse of reaction 1. D3 is also consumed in analogous, although slower, reactions with higher linear Si–H terminated oligomers.

Small amounts of HMMH remain in the system as redistribution reactions are reversible. Higher cyclic oligodimethylsiloxanes are also formed (Fig. 3). Octamethylcyclotetrasiloxane, (D4), is produced in considerable amounts by conversion of HMD3MH, 3, which proceeds analogously to reaction 1.

Substrate conversion-time and main product formation-time dependences for the reaction of D3 with HMMH catalyzed by B(C6F5)3 in a concentrated toluene solution (Table I, entry 1) the HMDMH plot is omitted as it overlaps with the plot of HMD3MH.

The formation of D4 occurs more slowly than reaction 1 and proceeds irreversibly. More precisely, its equilibrium lies strongly toward D4 generation.

Reacting D3 with HMMH using a high molar ratio of reactants and a high catalyst concentration in order to obtain high molecular weight polymer was also explored. HMMH is almost completely consumed in the first stage of the process. Further consumption of D3 occurs by its reaction with longer linear oligomers, according to reaction 3, which contributes to the extension of the polysiloxane chain. The reaction occurs more slowly than that with HMMH and requires a higher concentration of B(C6F5)3catalyst to proceed to full conversion of D3. Polydimethylsiloxane of molecular mass M n = 19,700 Da, M w /M n = 1.72, terminated by Si–H was obtained (Table I, entry 5). The system contained about 8% by weight of D4 and negligible amounts of other cyclics. The molecular weight of the polymer is relatively high, which indicates that a significant contribution to the chain extension may come from metathetic reactions between reactive chain ends.

Oligomerization of D3 with 1,1,1,3,3-pentamethyldisiloxane, HMM Catalyzed by B(C6F5)3

Oligomerization of D3 with HMM occurs more slowly than with HMMH. A relatively high concentration of catalyst is used. Both reactants are converted more or less at the same rate, see Fig. 4, which suggests that they enter into the reaction in an equimolar ratio forming a 1:1 adduct. Indeed, in the initial period of the reaction when a 1:1 molar substrate ratio is used, the main product is the first HMM telomer of D3, i.e., 1-hydro-1,1,3,3,5,5,7,7,9,9,9-undecamethylpentasiloxane, (HMD3M), 4 generated according to reaction 9. Thereafter, other oligomers are formed.

Substrate conversion-time dependences for the reaction of D3 with MMH catalyzed by B(C6F5)3 in a concentrated toluene solution at 25 °C (Table I, entry 6).

The series MD n MH dominates the first stage. However, oligomers of the MD n M and HMD n MH series also appear (Fig. 5). This indicates that both processes occur, i.e., oligomerization of D3 with MMH and the accompanying metathesis of MMH according to reaction 10 which was described in Ref. [18]. The SiH containing products of reactions 9 and 10 undergo consecutive reactions.

Gas chromatogram of the reaction system of D3 with MMH in concentrated solution in toluene catalyzed by B(C6F5)3 (Table I, entry 6). Chromatogram was taken after 1 h of reaction time when the conversion of MMH and D3 were 70 and 67%, respectively.

The conversion of D3 proceeds according to a complex kinetic law. It is apparently lower than first order as indicated by the D3 conversion-time dependence plot shown in Fig. 4. It shows that D3 reacts even more readily with the Si–H containing products than with the HMM reactants.

Oligomerization and Polymerization of D3 with dimethylphenylsilane, Me2PhSiH

Since neither the Si–H reagent nor D3 alone may react at a significant rate in the presence of B(C6F5)3 catalyst, under conditions used in this study the expected reaction between these compounds was the telomerization of D3 with Me2PhSiH. Indeed, initially both reactants were consumed in a 1:1 molar ratio and the main product was the first telomer according to reaction 11.

Telomer 5 may react further with D3 producing the second telomer by an analogous mechanism to that presented in reaction 11. However, the second telomer appears in a significant quantity only if the molar ratio of D3 to Me2PhSiH is relatively large, e.g., 3:1 (Fig. 6). The first telomer 5 more readily reacts with Me2PhSiH according to reaction 12.

Gas chromatogram of the reaction system of D3 with PhMe2SiH in concentrated toluene solution catalyzed by B(C6F5)3 at 25 °C (Table I, entry 9). Chromatogram was taken 24 min after catalyst addition when the conversion of D3 and PhMe2SiH were 35 and 65%, respectively.

In reaction 12, route “a" is preferred. Thus, the main product of the oligomerization at a molar ratio of D3 to Me2PhSiH lower than 1 is oligomer 6 (Fig. 7).

Gel permeation chromatogram of the reaction system of D3 with PhMe2SiH in concentrated toluene solution catalyzed by B(C6F5)3 at 25 °C (Table I, entry 8).

The product of the reaction of the second telomer with Me2PhSiH is also seen in the gas-chromatogram. The by-product of reaction 12, Me2SiH2, is able to open the D3 ring (reverse reaction 1), which is responsible for the formation of small amounts of HMD2MH.

When D3 and Me2PhSiH are used in a molar ratio close to 1, D3 is converted according to first order kinetics (Fig. 8). This means that the rates of the D3 reaction with Me2PhSiH and with the SiH-containing oligomer products are comparable.

Substrate conversion-time dependences for the reaction of D3 with PhMe2SiH in concentrated toluene solution catalyzed by B(C6F5)3 at 25 °C (Table I, entry 7). The transposition of the kinetic curve for D3 into the first plot is shown in the right upper corner.

The experiment using a higher D3/PhMe2SiH molar ratio was performed. Polydimethylsiloxane having Si–H functionality at only one chain terminus could be produced as a result of the pure telomerization process. Since the PhMe2SiH is fully consumed in the first stage of the reaction giving mostly the first telomer, it is not available for subsequent undesired further reaction and telomerization dominates, as expected. However, the polymer obtained had a molecular mass more than twice that expected for the product of telomerization. Moreover, 1H NMR of the polymer showed no Si–H end-group resonance while the molecular mass calculated from the integration of the phenyl to methyl signals ratio and assuming phenyl groups at both chain ends was M n = 7200 Da which is close to the observed one of 7600 Da. The gel permeation chromatogram of this polymer is shown in Fig. 9. It can be concluded that the metathetic chain coupling according to reaction 5 accompanies the telomerization process.

Gel permeation chromatogram of the polymer PhMe2SiO(SiMe2)nOSiMe2Ph obtained by the polymerization of D3 with PhMe2SiH catalyzed by B(C6F5)3 in concentrated toluene solution at 25 °C (Table I, entry 10), M n = 7600, M w /M n = 1.70.

It is likely that reaction 5 is slower than the telomerization, as the polydispersity of the polymer M w /M n = 1.7 is relatively narrow. However, the difference in rates is not large enough to perform selective telomerization. On the other hand, it is possible to obtain polymer terminated at both ends with triorganosilyl moieties originating from the RR′R′′SiH reagent.

Oligomerization of D3 with Methylphenylsilane

A fast reaction of D3 with diorganodihydrosilanes was demonstrated in studies of the reaction of D3 with PhMeSiH2. The first step is the reversible formation of the linear chain adduct according to reaction 13.

The adduct 7 undergoes reversible cyclization forming 2-phenyl-2,4,4,6,6-pentamethylcyclotrisiloxane, 8, reaction 14. It may also be directly transformed to isomer 9 if route b of the decomposition of the oxonium intermediate is followed. However, the preferential route is that involving the hydride attack at the hydrogen bonded to exocyclic silicon.

Reversible formation of 9 from 8 occurs according to reaction 14, route a and b as well. Me2SiH2 also enters into the reaction with D3 leading to HMD2MH. Cyclic 8 reacts with PhMeSiH2 yielding three tetrasiloxane isomers 10, 11 and 12 (reaction 15) having two silicon atoms substituted with phenyl groups.

The cyclization of telomers 10, 11 and 12 produces two isomers E and Z of cyclotrisiloxane with two MePhSiO units and one Me2SiO unit according to reaction 16.

The formation of the above mentioned products is shown in Fig. 10(A–C) showing gas chromatograms of the reaction mixture at various stages of the reaction. Peaks on the chromatograms were assigned as a result of careful GC-MS analysis using the chemical ionization method.

Comparison of chromatograms of the reaction system of D3 with PhMeSiH2 in concentrated toluene solution catalyzed by B(C6F5)3 at 25 °C (Table I, entry 11). Chromatograms were taken as follows: A – 82 s, conv.: D3 39%, PhMeSiH2 54%; B – 300 s, conv.: D3 68%, PhMeSiH2 77%; C – 1900 s, conv.: D3 76%, PhMeSiH2 85%.

The MePhSiH2+D3/B(C6F5)3 reaction system is dominated by the ring formation and ring opening of cyclic trimers. Each of these cyclization – ring opening reactions leads to equilibrium between respective cyclic and linear species.

The equilibrium between the primary open chain product and the cyclic product of its interconversion is demonstrated in Fig. 11.

The formation of linear 1:1 adduct of D3 with PhMeSiH2 and the product of its cyclization

on the time scale of the reaction of D3 with PhMeSiH2 in a concentrated toluene solution at 25 °C catalyzed by B(C6F5)3 (Table I, entry 11).

on the time scale of the reaction of D3 with PhMeSiH2 in a concentrated toluene solution at 25 °C catalyzed by B(C6F5)3 (Table I, entry 11).

The cyclics – linear chain equilibrium is the reason the conversion of reactants is apparently stopped. It is seen in Fig. 12 that at a 1:1 molar ratio of reactants, D3 and PhMeSiH2 are consumed more or less in parallel. However, the reaction is arrested when the conversion of D3 achieves about 75% of its initial value and that of PhMeSiH about 85%.

Substrate conversion-time dependence for the reaction of D3 with PhMeSiH2 catalyzed by B(C6F5)3 in concentrated toluene solution at 25 °C (Table I, entry 11).

Conclusions

All the Si–H reactants studied herein open D3 rings in the presence of B(C6F5)3 catalyst producing 1:1 open chain adducts according to general reaction 2. Preliminary kinetic studies permitted the comparison of rates of these reactions for several representative Si–H reactants (Table II).

Since products of these reactions contain the Si–H terminal functional groups, they react with D3 in an analogous way. They also enter into metathetic reactions involving cleavage of the siloxane bond of the H–Si terminal units. This reaction may occur intramolecularly leading to a cyclosiloxane if SiH functions are at both ends of the oligomer chain. The cyclization leading to the formation of cyclotrisiloxane is particularly rapid. The equilibria of the ring closure and ring opening dominate the PhMeSiH2 with D3 reaction pattern. It also plays some role in the HMMH with D3reaction system. The reaction of the terminal Si–H group with D3 leads to chain extension and may produce a long chain polymer. Chains are also extended by metathetic coupling of the SiH terminated chains. All the reactions described above are rationalized on the grounds of mechanisms involving hydride transfer to boron with the transient formation of a trisilyloxonium borate intermediate. This intermediate is decomposed by the hydride transfer from the borate ion to one of the three silicon atoms of the oxonium center in a mechanism which has previously been presented [18].

References

You-Xian Chen E., Marks T. J.(2000) Chem. Rev. 100:1391

Coates G. W., Hustad P. D., and Reinartz S.(2002) Angew. Chem. Int. Ed. 41:2236

Yang Y. G., Choi D. S., and Han S.(2004) J. Polym. Sci., Part A, Polym. Chem. 42:1164

Ban H. T., Kase T., Kawabe M. et al.(2006) Macromolecules 39:171

Piers W.E (2005) Adv. Organomet. Chem. 52:1

G. Erker, J. Chem. Soc. Delton Trans., 1883 (2005)

Hassfeld J., Christmann M., and Kalesse M. (2001) Org. Lett. 3:3561

Chandrasekhar S., Reddy C. R., and Chandrasekhar G. (2004) Tetrahedron Lett. 45:6481

Marshall A. J., and Gill K.(2001) J. Organomet. Chem. 624:294

K. Ishihara, and H. Yamamoto Eur. J. Org. Chem. 527 (1999)

Blackwell J. M., Foster K. L., Beck V. H., and Piers W.E.(1999) J. Org. Chem. 64:4887

Blackwell J. M., Sonmor E. R., Scoccitti T., and Piers W. E.(2000) Org. Lett. 2:3921

Gevorgian V., Liu J. -X., Rubin M., Benson V, and Yamamoto Y.(1999) Tetrahedron Lett. 40:8919

Gevorgian V., Rubin M., Benson S., Liu J. -X., and Yamamoto Y.(2000) J. Org. Chem. 65:6179

Rubinsztajn S. and Cella J.(2005) Macromolecules 38:1061

Zhou D.Q., and Kawakami Y. (2006) Macromolecules 38:6902

Chojnowski J., Rubinsztajn S., Cella J., Fortuniak W., Cypryk M., Kurjata J., and Kaźmierski K.(2005) Organometallics 24:6077

Chojnowski J., Fortuniak W., Kurjata J., Rubinsztajn S., and Cella J.(2006) Macromolecules 39:3802

G. Belorgey, and G. Sauvet, in Silicon Containing Polymers, R. G. Jones, W. Ando, and J. Chojnowski, eds. (Kluwer Academic Publishers, Dordrecht, 2000), Chap. 2. pp 43–78.

Acknowledgments

The financial support from General Electric Company is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Footnote: This paper is dedicated to Professor Ian Manners in recognition of his significant contributions to the field of organometallic polymers.

Rights and permissions

About this article

Cite this article

Chojnowski, J., Rubinsztajn, S., Fortuniak, W. et al. Oligomer and Polymer Formation in Hexamethylcyclotrisiloxane (D3) – Hydrosilane Systems Under Catalysis by tris(pentafluorophenyl)borane. J Inorg Organomet Polym 17, 173–187 (2007). https://doi.org/10.1007/s10904-006-9083-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-006-9083-2