Abstract

The morphological parameter of a thin film surface can be characterized by power spectral density (PSD) functions which provide a better description to the topography than the root mean square roughness and imparts several useful information of the surface including fractal and superstructure contributions. In the present work PSD spectra computed from atomic force microscopy (AFM) data were used for studying the morphology of three different titanium nitride thin films obtained by dc magnetron sputtering system. The power values of PSD for the AFM data were determined by the fast Fourier transforms algorithms. We investigate the effect of substrate temperature and crystallite sizes on the roughness of thin films surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently there is a great interest in designing and engineering thin films with morphologies tailored to specific requirements for various application fields. The connection between surface morphology of the films and functionality is especially important for optical applications, as surface microstructure generates scattering and stray light in optical components [1] Thus properties of the tin films are usually substantially influenced by their microstructure and surface morphology [2]. It has also long been recognized that the nature and structure of the substrate has a strong influence on the structure and morphology of the thin films [3–5]. The surface morphology, including surface roughness, of a thin film often determines the electrical or the optical properties that are crucial to the performance of a device. Amongst these techniques, atomic force microscopy (AFM) is an excellent tool for characterizing the surfaces and widely being used in studying optical thin film surfaces. However, AFM can be advantageously used with high vertical and spatial resolution to extract microroughness information of the surfaces [6, 7]. In an effort to understand and control film growth, it is important to characterize the surface during and after deposition. Such roughness information obtained from AFM can be advantageously employed to the successful development of low scatter optical multilayer coatings. In addition, such information about the surface roughness is extremely useful for the alternate optical characterization of thin films using ellipsometry or spectrophotometry. The most popular parameter characterizing the morphology of surfaces is the root mean square (RMS) roughness, which represents the root mean square height of a surface around its mean value. However, this statistical description, though simple and reliable, makes no distinction between peaks and valleys and does not account. A more complete description is provided by the power spectral density (PSD) of the surface topography, which performs a decomposition of the surface profile into its spatial wavelengths and allows comparison of roughness measurements over different spatial frequency ranges. PSD functions describe two aspects of the surface roughness such as the spread of heights from a mean plane, and the lateral distance over which the height variation occurs [8]. Hence, PSD explains a surface much better than the RMS roughness and provides very useful information on fractals and superstructures that may coexist in the microstructures. The power spectral density method is sensitive to data set size, sampling frequency and the spectral range [9]. This study focuses on titanium oxide, a material currently used as thin lm coating in optical applications due to its notable dielectric and optical properties. Because of their high thermal stability, excessive hardness, chemical stability, and low electrical resistivity, titanium nitride (TiN) has been widely used as a coating material, ranging from diffusion barrier in microelectronic industry, to the hard and protective coatings on mechanical tools and decorative coatings[10, 11]. Production of thin films on semiconductor surfaces has been widely applied in many fields ranging from electronic, microelectronic, nano electronic to optoelectronic [12].

Experiment

Three titanium nitride thin films were deposited by DC magnetron sputtering method in Ar + N2 atmosphere. The reactive sputter gas was a mixture of Ar (99.999%) and N2 (99.999%) with the ratio Ar (97%) and N2 (3%) by volume. The sputtered layers were grown at different temperatures. The experimental arrangement and deposition technique are described in [13].

The samples, denoted A1, A2 and A3, differ by substrate temperature during deposition and crystallite sizes, as shown in Table 1.

The investigations described in [13] showed that the deposited titanium nitride have a polycrystalline (TiN, Ti2N) structure. Results show that by increasing the substrate temperature, the crystal structure tends toward single crystalline of tetragonal Ti2N. The root mean square (RMS) values and the power spectral density (PSD) curves used throughout this work were calculated from selected AFM scans with the Nanotec off-line analysis software.

AFM Image Analysis

Treatment of the AFM data allows quantitative information to be extracted on surface roughness. A systematic description of various analytical methods used for roughness characterization can be found in [14]. Root-meansquare roughness, RRMS, which is defined as the standard deviation of the surface height profile from the mean height, is the most commonly reported measurement of surface roughness, and is given by:

Where N is the number of pixels in the image (or data points), h i is the height of the ith pixel, and h i is the mean height of the image. Although the RRMS evaluations are useful, they provide information only on the height variation, i.e., in the direction perpendicular to the substrate. Possible correlation between length scale of surface features and the roughness cannot be characterized using these values. For example, two images with exactly the same RRMS values may have different surface morphologies. One way to examine more closely how the roughness varies with length scale is through power spectral density (PSD) analysis. Fast Fourier transform (FFT) can be used to obtain frequency distribution of the profile over the entire frequency range. The resulting function is the PSD function and is defined as the square modulus of FT. This is accomplished by calculating the square magnitude of the coefficients of the fast Fourier transform \( \left| {F\left( {x,y} \right)} \right|^{ 2} \) of the digitized surface profile z(x,y). For a two dimensional (2D) isotropic surface profile, the PSD is obtained by performing 2D angular averaging of the \( \left| {F\left( {x,y} \right)} \right|^{ 2} \) using the radius in the reciprocal space as the spatial frequency. The calculation used in this work normalizes the PSD with the number of pixels of every frequency resulting in units of length. The power spectral density is then plotted as a function of spatial frequency or wavelength and therefore provides valuable information. Hence, PSD gives a more complete description than RRMS roughness alone.

There have been large numbers of publications dealing with PSD calculations from the surface profile data. The computation of PSD function adopted in this paper is given by [15],

where S 2 denotes the two-dimensional PSD, L 2 is the scanned surface area, N is the number of data points per line and row, Z mn is the profile height at position (m, n), f x , f y are the spatial frequency in the x- and y directions and ∆L = N/L is the sampling distance. PSD dependant on the spatial frequency f yields:

Where K has spatial length to the power and γ is the power of PSD. The γ is calculated as the inverse slope in the log–log plot of the high spatial frequency and the PSD.

The fractal dimension of a set of two dimensional (2D) images can be calculated from the slope of a log p(k)–log k plot. The relationship between the power spectral density p(k) and the frequency k is given as [9, 16]:

The fractal dimension D f is related to the slope γ in a log–log plot as

Results and Discussion

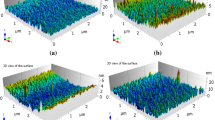

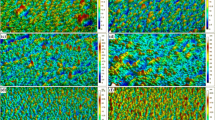

The AFM images showing the surface morphologies of the films are shown in Fig. 1. All of the AFM image sizes are of 1 μm × 1 μm areas.

It can be seen that the surface roughness is a function of substrate temperature, because mountains, valleys, and island clusters become bigger.

The RMS roughness and fractal dimension D f of TiN thin films were shown in Table 2. The interesting results (RMS) have been listed in Table 2, and also plotted in Fig. 2. It can be seen that the RMS roughness values increased as the substrate temperature is increased. This behavior is caused by the aggregation of the native grains into the larger clusters. This different cluster size affects the surface morphology of the thin films that confirmed by Table 1.

Several algorithms have been used to determine the value of fractal dimension D f based upon AFM images. In order to study the fractal features of TiN thin films, the PSD (power spectral density) functions of all the surface profiles of each film have been calculated and combined into a single PSD profile covering large spatial frequency band width. These algorithms have been described in previous section.

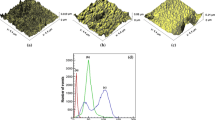

The calculated PSDs, for TiN thin films at different substrate temperatures are shown in Fig. 3. It can be seen from Fig. 3 that at the high spatial frequency the PSD function of the thin film deposited, by increasing of substrate temperature tend to converge and their PSD curves move away as the frequency lowers.

The PSDs of both the films exhibit inverse power law variation especially at the high spatial frequency region suggesting the presence of fractal components in the surface topographies.

It is well known that the low frequency components of the PSD spectrum represent the aggregates [17].

It is observed from lower spatial frequency region that aggregates contribute to the total film roughness to a large extent.

The slope γ of PSDs spectra of the thin films are in the range of 2.98–3.39. The variation of fractal dimension of samples deposited TiN thin film with substrate temperature is listed in Table 1. The fractal dimensions devotedly describe the evolution of surface morphology of TiN thin film. It is clear that the values of fractal dimension depend on the surface roughness (interface width w) of TiN thin film. It can be seen from Fig. 4 the values of fractal dimension of smooth surface are bigger than those of rough surfaces.

Conclusions

In order to obtain quantitative and qualitative morphology of three samples, we used from the AFM. The AFM results show that the roughness of films increases as the substrate temperature increases. The PSD studies have yielded several interesting information about fractal nature and intrinsic roughness. The effect of substrate temperature on the roughness of the films was characterized by the PSD. At the high spatial frequency the PSD function of the thin film deposited, by increasing of substrate temperature tend to converge. The computed fractal dimension value of these micrographs was used to describe the surface morphology of thin films.

References

R. Gavrila, A. Dinescu, D. Mardare, Romanian J. Inf. Sci. Technol. 10(3), 291–300 (2007)

T. Jiang, N. Hall, A. Ho, S. Morin, Thin Solid Films 471, 76–85 (2005)

A.A. Gewirth, B.K. Niece, Chem. Rev. 97, 1129 (1997)

D.M. Kolb, Electrochim. Acta 45, 2387 (2000)

O.M. Magnussen, F.A. Moller, A. Lachenwitzer, R.J. Behm, in Electrochemical Synthesis and Modification of Materials, Materials Research Society Symposium Proceedings, vol. 451 (1997), p. 43

G. Binnig, C.F. Quate, C. Gerber, Phys. Rev. Lett. 56, 930 (1986)

K.-S. Hwang, B.-A. Kang, Y.-S. Jeon, J.-H. An, B.-H. Kimb, K. Nishio, T. Tsuchiya, Surf. Coat. Technol. 190, 331–335 (2005)

J.M. Elson, J.M. Bennett, Appl. Opt. 34, 201 (1995)

B. Tayfun, D. Kayhan, Fractal 9, 105 (2001)

W.-J. Chou, G.-P. Yu, J.-H. Huang, Surf. Coat. Technol. 140, 206 (2001)

W.-J. Chou, G.-P. Yu, J.-H. Huang, Surf. Coat. Technol. 149, 7 (2002)

S.Shyan, W. Long, in Growth Behavior of Electroless Copper on Silicon Substrat, University of science and Technology Bejing 14, No. 1, 67–71 (2007)

M. R. Hantehzadeh, R. Bavadi, A.H. Sari, J. Fusion Energ. (springer) (2011)

J.M. Bennett, L. Mattson, Introduction to Surface Roughness and Scattering (Optical Society of America, Washington, DC, 1989)

J. Ferre-Borrull, A. Duparre, E. Quesnel, Appl. Opt. 40, 2190 (2001)

T. Babadagli, K. Develi, Theor. Appl. Frac. Mech. 39, 73 (2003)

M. Senthilkumar et al., Appl. Surf. Sci. 252, 1608–1619 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gelali, A., Ahmadpourian, A., Bavadi, R. et al. Characterization of Microroughness Parameters in Titanium Nitride Thin Films Grown by DC Magnetron Sputtering. J Fusion Energ 31, 586–590 (2012). https://doi.org/10.1007/s10894-012-9510-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10894-012-9510-z