Abstract

Effects of laser fluence on the characteristics of copper sulfide (CuS) nanoparticles (NPs), produced by laser ablation method have been investigated experimentally. CuS nanoparticles were synthesized by the pulsed laser ablation of a high purity copper bulk in dimethyl sulfoxide (DMSO). Pulses of a Q-switched Nd:YAG laser of 1064 nm wavelength at 7 ns pulse width and different fluences were employed to irradiate the Cu solid target in DMSO. The Effects of laser fluence on the size, morphology, and structure of produced nanoparticles have been studied. Results show that the size distribution of the generated CuS nanoparticles was augmented by increasing the laser fluence. The rate of CuS nanoparticles production was increased by increasing the laser fluence. The bandgap energy for CuS nanoparticles was calculated to be 3.77–3.94 eV.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the recent years, semiconductor nanomaterials with copper chalcogenides have attracted great interests due to their excellent properties and applications [1]. Among different copper chalcogenides such as CuO, Cu2O, Cu2S and CuS, CuS role is more important in the technology of p-type semiconductor. CuS nanostructure exhibits many significant properties and has great potential in a versatile range of applications such as high-capacity cathode material in lithium batteries, chemical sensors, surperionic materials, catalyst, nonlinear optical material, solar cell and solar radiation absorber [2,3,4,5,6,7].

There are multiple preparation methods to produce CuS nanostructures with different morphologies, such as hydrothermal, solvothermal, electrodeposition, chemical bath deposition, thermal decomposition, microwave, mechanochemical and laser ablation [8,9,10,11,12,13,14].

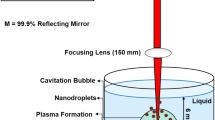

Laser ablation synthesis in liquid (LASIL) is a reliable approach for the synthesis of nanoparticles (NPs) in a variety of liquid solutions. In this method, NPs are produced during the condensation of a plasma plume formed by the laser ablation of a bulk metal plate dipped in a liquid solution. Recently, LASIL has become more popular because of its unique properties such as one step, simple procedure, low-cost, control of NPs size and size distribution [15] [16]. Characteristics of NPs including their size and shape can be controlled by laser pulse parameters alternation such as wavelength, pulse duration, laser fluence, and the media of ablation [17].

The liquid media is an effective parameter in the composition and the structure of nanoparticles produced by LASIL. Several different liquid medias are used for the production of metal sulfide by laser ablation method. Niu et al. [18] synthesized ZnS and PbS nanoparticles by employing laser ablation in β-mercaptoethanol, mercaptoacetic acid and dodecyl mercaptan/n-hexane. Due to adverse properties of mercaptan such as toxicity and having unpleasant odor characteristic of the sulfhydryl group, dimethyl sulfoxide (DMSO) can be a suitable media. Also Du et al. [14] used 1-dodecanethiol as the liquid media for the synthesis of CuS polycrystalline nanowires via laser ablation method.

According to the advantages of laser ablation method in comparison with other methods, this approach is suitable for the synthesis of CuS NPs. Furthermore, there are various liquid medium for synthesis the CuS NPs that have not been applied yet.

In the present investigation, CuS semiconductor NPs are synthesized by nanosecond pulsed laser ablation of a copper plate in DMSO. Experimental results on the formation of CuS NPs by changing the fluence of laser between 0.5 and 5 J/cm2 are presented which clearly demonstrate the effect of laser pulse energy on the nanostructure, morphology, and optical properties of CuS NPs at room temperature.

Experimental

Copper sulfide NPs was synthesized by ablation of a high purity Cu plate, using Nd:YAG laser operating at 1064 nm with pulse width of 7 ns, 10 Hz repetition rate and different fluences. Pure copper target with 0.3 mm thickness was cleaned ultrasonically in ethanol, acetone, and deionized water before the experiments. The target was ablated with 4000 laser pulses at laser fluence of 0.5, 2, 3.5, and 5 J/cm2 which are labeled as samples 1 to 5 respectively. The laser beam of 2 mm in diameter was focused exactly onto the surface of the target by means of a 100 mm focal length lens. The laser pulse hit the target at 10 mm depth in DMSO. Details of the samples preparation are presented in Table 1.

A variety of analytical techniques were applied for characterization the product. Immediately after ablation, the optical transmission and absorption spectrum of the NPs solutions in a 1 × 1 cm quartz covets was recorded at room temperature by UV–Vis–NIR spectrophotometer T80 from PG instruments Ltd. Size distribution of the NPs was characterized by dynamic light scattering (DLS) using Nano ZS (red badge) ZEN 3600 device. Morphology and size of NPs were imaged using Zeiss EM10C transmission electron microscopy (TEM). Crystalline structure of the samples was tested via X-PERTPRO MPD X-ray diffract-meter from the PANalitical. To investigate the molecular bonds in the suspensions, the infrared spectroscopy FTIR, NEXUS 870 FT-IR system was used. The PL spectroscopy was applied by means of a Cary Avaspec 2048 TEC system with 275 nm excitation wavelength.

Results and Discussion

The images of CuS NPs colloid are presented in Fig. 1. Their color is from light yellow to yellow. Color of NPs colloid, depends on the size and concentration of NPs. As shown in Fig. 1, by increasing the laser fluence, color of NP solutions was changed from light yellow to dark yellow, which means that we have different concentration of NPs with different size in the solutions.

XRD was applied to characterize the phase purity and crystallinity of CuS NPs. As shown in Fig. 2, the scanning regions are related to the diffraction angle (2θ) which was between 20° and 70° and Cu–Kα radiation was used to collect the spectrum. JCPDS Card No. 75-2233 XRD cards was used to characterize the peaks. Most peaks in the XRD pattern of samples was due to hexagonal phase of CuS. The main dominant peaks of CuS was identified at 2θ = 29.4°, 31.9°, 33°, 50.2° and 61.1°. In the XRD pattern of sample 4, two other peaks were observed at the angles of 27.3° and 47.7°. It can be concluded that with increasing the laser fluence, the crystallinity of CuS NPs was increased and new crystalline phase was formed in the lattice structure of produced NPs. High intensity and sharp diffraction peaks assert that the as-obtained products are well crystalline. The intensity of the sharpest peak increases as the laser fluence boosts. Therefore, the enhancement of the laser fluence indicates that the crystallization increases from samples 1–4. In most synthesis methods of CuS NPs, the sharpest picks are related to <110> crystalline lattice, as reported in several studies [19, 20] which we do not have it here.

The size distribution of copper sulfide NPs was measured by DLS method. The plots of size distributions of samples are presented in Fig. 3. The peaks of size distribution versus particles number are between 45 and 825 nm. The average size of produced NPs increased by increasing the laser fluence (Table 2). Rate of size increment of samples can be deduced from Fig. 4. The size distribution of particles is directly proportional to the laser fluence. Of course DLS method measures the hydrodynamic sizes of the synthesized NPs which is significantly larger than their real size [21].

TEM images of the NPs are shown in Fig. 5. As can be seen, the CuS NPs are almost spherical in all samples and the particle sizes was changed with the laser fluence. Figure 6 shows the particle size distribution of CuS NPs, obtained from TEM images. Here also with increasing the laser fluence, the average size of the spherical NPs was increased. The average particle sizes of samples obtained from TEM images is are shown in Table 2. In addition, TEM micrographs show that some NPs consist of a black core with grey shell (Fig. 5). If we consider the black cores as the non-sulfide Cu atoms, the grey shells indicate Cu sulfide in DMSO media. In all samples nanoparticles are aligned in a linear fashion forming chain. This may be due to several reasons [22]. Increasing the laser fluence is the main reason for such phenomena. With increasing the laser fluence the temperature of ablation environment increases which leads to melting the shell of particles and make an interconnection between the particles.

Figure 7 illustrates the UV–Vis–NIR spectra of the CuS NPs in DMSO solutions. The intensity of absorption peaks and their FWHMs are different for samples. The absorption peak for samples 1–4 was occurred at 265–312 nm due to CuS NPs exciton resonance absorption, which is presented in Table 3. Similar absorption feature was also reported by Chen et al. [23]. The most important property of semiconductor NPs is the size evolution of the optical absorption spectra. Therefore UV–Vis–NIR absorption spectroscopy is an efficient approach to characterize the optical properties of quantum-sized particles [24]. If the size of NPs increases, their resonance absorption spectrum peak will be shifted towards larger wavelength and vise-versa. In this case, for exciton resonance phenomenon to happen, the particle must be much smaller than the wavelength of incident light. A red shift in the absorption spectrum is due to increase of NPs size. The wavelengths corresponding to excitonic absorption peaks are presented in Table 3. A red shift was occurred for the excitonic peaks of samples 1–4, indicates that the size of NPs was increased with increasing the laser fluence. Furthermore, the intensity of peaks is a function of NPs concentration in the suspension. Results show that number of CuS NPs increased with increasing the laser fluence. On the other hand, The particle size distribution becomes nonuniform by increasing the excitonic peak FWHM [25]. The FWHM of excitonic peak of samples were increased by increasing the laser fluence. Therefore the most uniform CuS NPs were produced in sample 1.

The influence of nanocrystal size on the electronic structure of semiconducting material is represented by their bandgap energy. This effect is attributed to the so-called quantum confinement effect. Using absorption spectrum in Tauc equation, the bandgap energy of samples was calculated [26]. Tauc equation which governs the behavior of bandgap energy of materials at the absorption edge of semiconductor or insulator materials is as follows:

where α is the absorption coefficient, hν the photon energy, Eg refers to the bandgap energy and B is a factor that depends on the transition probability and can be assumed to be constant within the optical frequency range. The index n is related to the distribution of the density of states. The index n has discrete values like 1/2, 3/2, 2, more depending on whether the transition is direct or indirect and allowed or forbidden, respectively. Taking n = 1/2 corresponds to direct allowed transitions of CuS semiconductor and to calculate the Eg, the usual method is plotting (αhν)1/n versus the photon energy hν. The magnitude of the bandgap energy is the intersection of the tangent of the curve at the absorption edge with the horizontal axis. The values of the bandgap energies of samples are found to be 3.94, 3.91, 3.90, and 3.77 eV for samples 1–4 respectively. The bandgap energy of samples was decreased from sample 1–4, which indicates that the size of produced NPs was increased. This data is in very good agreement with the results obtained from other analysis.

The photoluminescence spectra of CuS NPs are shown in Fig. 8. The PL spectrum shows a strong peak at 550–556 nm which is the same in four samples. This peak was reported in several works [27, 28]. Since the PL emission is due to electronic transitions in the internal atomic levels of materials, narrow peaks show that the main atomic levels were formed in nanoparticles properly and number of defect levels is not noticeable. The positions of PL peaks are varied from 550 nm to 556 nm for samples 1–4 respectively. It is observed that the position of the PL peak purely depended on the size of nanoparticles [29]. Red shift of PL peak position is in good agreement with the results of UV–Vis–NIR spectra and particles sizes which were increased from S1 to S4. The peak intensity of CuS NPs with 0.5 J/cm2 is relatively higher compared to other samples. Such variation in PL intensity could be explained in terms of the size effects of the products. Increasing the size of particles decreases the intensity of peaks. This peak can be due to oxygen vacancy and defects level [30, 31]. Results confirm that with increasing the size of nanoparticles from sample 1 to 4 number of defect levels in the samples decreases. Another peak was occurred in the photoluminescence of samples at 880 nm. PL emissions in the range of λ > 600 nm are corresponding to the recombination with the donors and acceptors mechanism which was observed before by Takase. et al. [32].

Figure 9 shows the FTIR spectrum of CuS NPs synthesized by laser pulses with different fluence in DMSO. Data was recorded in the range of 600–4000 cm−1. Wavenumbers correspond to chemical bonds in the solutions are shown in Table 4. The valley in the curve of transmission spectra is actually an absorption peak. Several absorptions peaks in the range of 950 and 3500 cm−1 are due to chemical bonds in DMSO composition [33]. The absorption peak at about 660 nm is due to CuS bond. The intensity of CuS absorption peak for samples 3 and 4 is larger than samples 1 and 2. Results confirm that number of CuS bonds in samples 3 and 4 is larger than this number in sample 1 and 2.

Conclusion

Effects of laser fluence on the characteristics of CuS nanoparticles produced by laser ablation method in DMSO media has been studied experimentally. Results show that laser ablation method is a very simple and successful method to produce CuS NPs. There is not any by-products and wastes after the production and this method is environmental friendly method. Although the morphology of NPs does not be changed with changing the laser fluence, but laser fluence is an effective tool to control the size of NPs. With increasing the fluence of laser pulse, the number and the size of produced CuS NPs increases. Due to size increment of NPs, their bandgap energy decreases and the color of their suspension tends to yellow. Increasing the laser fluence during the ablation process leads to increasing the crystallinity of produced CuS NPs and also increases their size non-uniformity.

References

Y. X. Zhao and C. Burda (2012). Development of plasmonic semiconductor nanomaterials with copper chalcogenides for a future with sustainable energy materials. Energy Environ. Sci. 5, (2), 5564–5576.

H. Lee, S. W. Yoon, E. J. Kim, and J. Park (2007). In-Situ Growth of Copper Sulfide Nanocrystals on Multiwalled Carbon Nanotubes and Their Application as Novel Solar Cell and Amperometric Glucose Sensor Materials. Nano Lett. 7, (3), 778–784.

X. L. Yu, Y. Wang, H. L. W. Chan, and C. B. Cao (2009). Novel gas sensoring materials based on CuS hollow spheres. Microporous Mesoporous Mater. 118, (1–3), 423–426.

A. E. Raevskaya, A. L. Stroyuk, S. Y. Kuchmii, and A. I. Kryukov (2004). Catalytic activity of CuS nanoparticles in hydrosulfide ions air oxidation. J. Mol. Catal. A Chem. 212, (1–2), 259–265.

A. M. Malyarevich, et al. (2000). Nonlinear optical properties of CuxS and CuInS2 nanoparticles in sol–gel glasses. J. Appl. Phys. 87, (1), 212–216.

R. S. Mane and C. D. Lokhande (2000). Chemical deposition method for metal chalcogenide thin films. Mater. Chem. Phys. 65, (1), 1–31.

Y. Wang, X. Zhang, P. Chen, H. Liao, and S. Cheng (2012). In situ preparation of CuS cathode with unique stability and high rate performance for lithium ion batteries. Electrochim. Acta 80, 264–268.

F. Davar, M. R. Loghman-Estarki, M. Salavati-Niasari, and M. Mazaheri (2016). Controllable Synthesis of Covellite Nanoparticles via Thermal Decomposition Method. J. Clust. Sci. 27, (2), 593–602.

M. Salavati-Niasari, S. Alizadeh, M. Mousavi-Kamazani, N. Mir, O. Rezaei, and E. Ahmadi (2013). Surfactant-Free Fabrication of Copper Sulfides (CuS, Cu2S) via Hydrothermal Method. J. Clust. Sci. 24, (4), 1181–1191.

E. Godočíková, P. Baláž, J. M. Criado, C. Real, and E. Gock (2006). Thermal behaviour of mechanochemically synthesized nanocrystalline CuS. Thermochim. Acta 440, (1), 19–22.

M. Xin, K. Li, and H. Wang (2009). Synthesis of CuS thin films by microwave assisted chemical bath deposition. Appl. Surf. Sci. 256, (5), 1436–1442.

C. Wu, et al. (2008). Synthesis and optical properties of CuS nanowires fabricated by electrodeposition with anodic alumina membrane. Mater. Lett. 62, (6–7), 1074–1077.

K.-J. Huang, J.-Z. Zhang, and Y. Fan (2015). One-step solvothermal synthesis of different morphologies CuS nanosheets compared as supercapacitor electrode materials. J. Alloys Compd. 625, 158–163.

K. Y. Niu, J. Yang, S. A. Kulinich, J. Sun, H. Li, and X. W. Du (2010). Morphology Control of Nanostructures via Surface Reaction of Metal Nanodroplets. J. Am. Chem. Soc. 132, (28), 9814–9819.

V. Amendola and M. Meneghetti (2009). Laser ablation synthesis in solution and size manipulation of noble metal nanoparticles. Phys. Chem. Chem. Phys. 11, (20), 3805–3821.

D. Dorranian, S. A. Ahmadi Afshar, N. Tahmasebi, and A. Fotovat Eskandari (2014). Effect of Laser Pulse Energy on the Characteristics of Cu Nanoparticles Produced by Laser Ablation Method in Acetone. J. Clust. Sci. 25, (4), 1147–1156.

V. Amendola and M. Meneghetti (2013). What controls the composition and the structure of nanomaterials generated by laser ablation in liquid solution? Phys. Chem. Chem. Phys. 15, (9), 3027–3046.

K. Y. Niu, J. Yang, S. A. Kulinich, J. Sun, and X. W. Du (2010). Hollow Nanoparticles of Metal Oxides and Sulfides: fast Preparation via Laser Ablation in Liquid. Langmuir 26, (22), 16652–16657.

M. Saranya, et al. (2014). Hydrothermal growth of CuS nanostructures and its photocatalytic properties. Powder Technol. 252, 25–32.

R. Sahraei, S. Noshadi, and A. Goudarzi (2015). Growth of nanocrystalline CuS thin films at room temperature by a facile chemical deposition method. RSC Adv. 5, (94), 77354–77361.

E. Solati, M. Mashayekh, and D. Dorranian (2013). Effects of laser pulse wavelength and laser fluence on the characteristics of silver nanoparticle generated by laser ablation. Appl. Phys. A Mater. Sci. Process. 112, (3), 689–694.

V. S. Vendamani, A. Tripathi, A. P. Pathak, and S. V. Rao, “Laser ablation of natural micas: Synthesis of MgO and Mg (OH) 2 nanoparticles and nanochains,” Mater. Lett., 2017.

C. Chen, Q. Li, Y. Wang, Y. Li, and X. Zhong (2011). Room temperature synthesis of flower-like CuS nanostructures under assistance of ionic liquid. Front. Optoelectron. China 4, (2), 150–155.

M. Anpo (2004). Preparation, Characterization, and Reactivities of Highly Functional Titanium Oxide-Based Photocatalysts Able to Operate under UV–Visible Light Irradiation: approaches in Realizing High Efficiency in the Use of Visible Light. Bull. Chem. Soc. Jpn. 77, (8), 1427–1442.

D. Dorranian, E. Solati, and L. Dejam (2012). Photoluminescence of ZnO nanoparticles generated by laser ablation in deionized water. Appl. Phys. A 109, (2), 307–314.

R. Rusdi, A. A. Rahman, N. S. Mohamed, N. Kamarudin, and N. Kamarulzaman (2011). Preparation and band gap energies of ZnO nanotubes, nanorods and spherical nanostructures. Powder Technol. 210, (1), 18–22.

F. Li, J. Wu, Q. Qin, Z. Li, and X. Huang (2010). Controllable synthesis, optical and photocatalytic properties of CuS nanomaterials with hierarchical structures. Powder Technol. 198, (2), 267–274.

K. R. Nemade and S. A. Waghuley (2015). Band gap engineering of CuS nanoparticles for artificial photosynthesis. Mater. Sci. Semicond. Process. 39, 781–785.

S. Hamad, et al. (2014). Femtosecond ablation of silicon in acetone: tunable photoluminescence from generated nanoparticles and fabrication of surface nanostructures. J. Phys. Chem. C 118, (13), 7139–7151.

J. Liqiang, et al. (2006). Review of photoluminescence performance of nano-sized semiconductor materials and its relationships with photocatalytic activity. Sol. Energy Mater. Sol. Cells 90, (12), 1773–1787.

J. Zhou, F. Zhao, X. Wang, Z. Li, Y. Zhang, and L. Yang (2006). Template synthesis and luminescent properties of nano-sized YAG: tb phosphors. J. Lumin. 119–120, 237–241.

K. Takase, et al. (2002). Electrical resistivity and photoluminescence spectrum of layered oxysulfide (LaO)CuS. Solid State Commun. 123, (12), 531–534.

A. Awadhia and S. L. Agrawal (2007). Structural, thermal and electrical characterizations of PVA:dMSO:NH4SCN gel electrolytes. Solid State Ionics 178, (13–14), 951–958.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khademian, M., Zandi, M., Amirhoseiny, M. et al. Synthesis of CuS Nanoparticles by Laser Ablation Method in DMSO Media. J Clust Sci 28, 2753–2764 (2017). https://doi.org/10.1007/s10876-017-1257-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-017-1257-2