Abstract

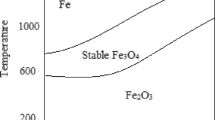

Iron (III) oxide magnetic nanoparticles have provided us a multitude of new tools to explore biological and other scientific systems on small length scales. The opening up of single cell or single molecule phenomena to experimental investigations present an important step forward and promises to yield new insights. This review depicts some important and most commonly used methodologies for the engineering of iron oxide magnetic nanoparticles including superparamagnetic iron oxide nanoparticles and ultra-small superparamagnetic iron oxide nanoparticles, important features of these synthesis methods and their applications in different fields of life proving it as an emerging material. Most important task in nanoscale synthesis of iron oxide is to control morphology and contain it within a narrow size distribution. These processes include sol–gel method, hydrothermal method, sonochemical method, co-precipitation and micro emulsion methods. These processes are essentially highly controlled to fabricate the desire material with appropriate properties. Synthesis of mono disperse nanometer-sized magnetic particles of metal alloys and metal oxides is an active research area because of their potential technological ramifications ranging from ultrahigh-density magnetic storage media, to biological imaging. Size, size distribution, shape, and dimensionality are important for the properties of these magnetic materials. Nanoparticles of various iron oxides (Fe3O4 and ç-Fe2O3 in particular) have been widely used in a range of biological applications. Iron oxide magnetic nanoparticles can be designed to exhibit novel and significantly improved physical, chemical and biological properties, phenomena and strategies as a result of the limited size of their constituent particles.

Graphical Abstract

Iron oxide nanoparticles can be designed to exhibit novel and significantly improved physical, chemical and biological properties, phenomena and strategies as a result of the limited size of their constituent particles by using various methodologies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Magnetic Nano spheres compromise attractive prospects in diverse fields of life due to their well-regulated size and magnetic properties [1]. Iron oxide magnetic nano spheres incline to be either paramagnetic or superparamagnetic with a size fluctuating from a few nanometers up to tens of nanometers. Magnetic nanoparticles are of pronounced curiosity for investigators from a wide range of disciplines, comprising magnetic fluids [2], catalysis [3, 4], biotechnology/biomedicine [5], magnetic resonance imaging [6, 7], data storage, [8] and environmental remediation [9, 10]. Functionalized nanoparticles are commonly used in catalysis, bio labeling, and bio separation [11]. Specifically in liquid-phase catalytic reactions, such small and magnetically separable particles may be useful as quasi homogeneous systems that combine the advantages of high dispersion, high reactivity, and easy separation [12]. The magnetic nanoparticles should also have high magnetic moment, and can be improved via surface chemistry reactions so that they are proficient of binding precisely to the biomolecules of interest and able to hold out numerous physiological conditions [12]. These nanoparticle materials often display very stimulating electrical, optical, magnetic, and chemical properties, which cannot be attained by their bulk counterparts [13]. Nanosized particles have physical and chemical properties that are characteristic of neither the atom nor the bulk counterparts [14]. Quantum size elects and the large surface area of magnetic nanoparticles radically change some of the magnetic properties and exhibit superparamagnetic phenomena and quantum tunneling of magnetization [15].

Superparamagnetic iron oxide structures have the general formula Fe2 3+O3M2+O, where M2+ is a divalent metal on like iron, nickel, cobalt etc. SPIO is magnetite if metal ion is ferrous ion. Superparamagnetic behavior occurs when crystals containing region of unpaired spin, are sufficiently large as they can be regarded as thermodynamically independent, single domain particles. Such particles process an overall magnetic dipole that is larger when compared to its unpaired electrons individually. In the absence of an applied magnetic field, and let the particles to rotate freely from a thermal motion of time scale that is shorter as compare to its time of observation. Ensembles of such particles are randomly oriented with no net magnetic field. However, an external magnetic field causes the magnetic dipole of the particles to reorient analogues to paramagnetic materials. The magnetic moment of such particles reflects the domain of interacting electrons that results in the form of magnetic moment greater than that of a paramagnetic substance. These single domain particles are named as magnetic domains [16,17,18,19].

In order to attain high throughput and high accuracy in bioscreening [20], the core MNPs must be rather large and their size should be precisely controlled with several dozen nanometers [21]. The stability of electronic and high density data storage devices made of magnetic nanoparticles is limited by their superparamagnetic transition [22]. Therefore, here is strong interest to understand the magnetization processes in the superparamagnetic region [23]. The current efforts are aimed at increasing the thermal energy barrier against the magnetic reversal in magnetic nanocomposite [24]. For applicability of magnetic nanoparticles it is also important to know, how the inter-particles interaction affects the physical properties of magnetic nanoparticles system [25]. The nanoparticles samples may exhibit glassy dynamics due to strong dipolar inter-particle interaction [26], but weak or non-interacting nanoparticles systems were observed after embedding into isolated matrix [6].

All these biomedical and bioengineering applications require that these nanoparticles have high magnetization values and size smaller than 100 nm with overall narrow particle size distribution, so that the particles have uniform physical and chemical properties [27,28,29,30]. In addition, these applications need special surface coating of the magnetic particles, which has to be not only non-toxic and biocompatible but also allow a targetable delivery with particle localization in a specific area [28,29,30,31]. To this end, most work in this field has been done in improving the biocompatibility of the materials, but only a few scientific investigations and developments have been carried out in improving the quality of magnetic particles, their size distribution, their shape and surface in addition to characterizing them to get a protocol for the quality control of these particles [32].

This review article deals with basic and general synthesizing routs for Fe3O4 and superparamagnetic iron oxide nanoparticles, and their applications in different fields. An outlook toward this emerging material reveals its dynamic contribution to society as well as science proving it a versatile material in different walks of life. In this article our main focus is on the simple Fe3O4 nanoparticles and superparamagnetic iron oxide nanoparticles [34].

Fe3O4 Magnetic Oxide Nanoparticles as an Emerging Material

Magnetite and maghemite nanoparticles are commonly studied magnetic iron oxides for clinical applications. The advantage of using iron oxide nanoparticles relies on their chemical stability in contrast to that of commonly used nanoparticles of pure Fe metal [32].

Methods of Preparation

To date, many approaches including reverse micelles method [35] and thermal decomposition route [32, 36,37,38,39,40,41] have been developed for the preparation of iron oxide nanoparticles. Wet-chemical syntheses, such as co-precipitation, sol–gel, hydrothermal and micro-emulsion techniques and a supercritical fluid [42] technique effectively control the morphology and chemical composition of prepared powders [43]. Particle synthesis by gel to crystalline conversion method helps to obtain final products at temperatures around 100 °C [44]. This method differs from the traditional sol–gel technique in two aspects: (1) no expensive alkoxide reactants are required, and (2) no need of higher temperature calcinations to produce final product [45,46,47]. Gold-coated iron oxide magnetic nanoparticles with a specific magnetic moment of 145 emu/g and a coercivity of 1664 Oe are being most intensively used for biomedical applications due to good corrosion resistance [48].

The synthesis of magnetic nanoparticles, covering a wide range of compositions and tuneable sizes, has made substantial progress, especially over the past decade [31]. Different kinds of monodisperse spherical nanocrystals with controllable particle sizes and compositions have been synthesized by a wide range of chemical synthetic procedures [49]: coprecipitation, reactions in constrained environments, thermal decomposition of metal–surfactant complexes, sol–gel reactions, polyol processes, flow injection synthesis, sonolysis, and electrochemical and aerosol methods [50].

Sol–Gel Method

Sol–gel methods, which have been found to be effective for dispersing small metal and oxide particles in nonmetallic matrixes, were also proposed for the preparation of iron magnetic oxide nanoparticles. Iron oxide-based porous solids were prepared by a sol–gel process using Fe(III) salts in various solvents [51].

Sol–gel methods generally refer to the hydrolysis and condensation of metal alkoxides or alkoxide precursors, leading to dispersions of oxide particles in a ‘‘sol’’. The ‘‘sol’’ is then dried or ‘‘gelled’’ by solvent removal or by chemical reaction [52]. The solvent used is generally water, but the precursors can also be hydrolyzed by an acid or base. Basic catalysis induces the formation of a colloidal gel, whereas acid catalysis yields a polymeric form of the gel [53]. The rates of hydrolysis and condensation are important parameters that affect the properties of the final products. Smaller particle sizes are obtained at slower and more controlled hydrolysis rates. The particle size also depends on the solution composition, pH, and temperature [53,54,55,56].

The rates of hydrolysis and condensation are important parameters that affect the properties of the final products [31]. Smaller particle sizes are obtained at slower and more controlled hydrolysis rates. The particle size also depends on the solution composition, pH, and temperature [24]. This compares with bulk maghemite values of 74–76 emu/g [57]. The low magnetization values suggest that the aerogels may not be suitable for magnetic applications, although they may still be useful in catalysis and other applications [58]. Disadvantages of the sol–gel methods include contamination from byproducts of reactions, as well as the need for post-treatment of the products [59].

In a typical experiment, 0.65 g of Fe(NO3)3·9H2O (1.6 mmol) was dissolved in 3.5 mL of 200 proof ethanol to give a clear red–orange solution that remained unchanged upon storage, under room conditions, for several months. If, instead, a 1.0 g portion of propylene oxide was added to the solution, there was rapid (<1 min color change as the solution became an intense dark red-brown color [25]. With the passage of time, the solution is transformed into a rigid red-brown gel. Gel formation usually occurred within several minutes [46, 60,61,62].

Aerogel samples were processed in a Polaron supercritical point drier. The solvent liquid in the wet gel pores was exchanged for CO2(l) for 3–4 days, after which the temperature of the vessel was ramped up to 45 °C, while maintaining a pressure of 100 bar [47]. The vessel was then depressurized at a rate of 7 bar/h approximately. For aerogel processing we preferred to use polyethylene vials to hold the gels during the extraction process [44]. This was done because much less monolith cracking was observed than when Fe2O3 gels were processed in glass vials. Xerogel samples were processed by drying in a fume hood at room temperature for 14–30 days. Under these conditions high vapor pressure solvents, like ethanol, were evaporated, and the wet gels were converted to xerogels [63,64,65].

Co-precipitation

In the co-precipitation process, two stages are involved: [32,33,34,35,36,37] a short burst of nucleation occurs when the concentration of the species reaches critical supersaturation, and then, there is a slow growth of the nuclei by diffusion of the solutes to the surface of the crystal. To produce monodisperse iron oxide nanoparticles, these two stages should be separated; i.e., nucleation should be avoided during the period of growth [51, 66,67,68]. Size control of monodispersed particles must normally be performed during the very short nucleation period, because the final particle number is determined by the end of the nucleation and it does not change during particle growth [69,70,71]. A wide variety of factors can be adjusted in the synthesis of iron oxide nanoparticles to control size, magnetic characteristics, or surface properties. A number of studies have dealt with the influence of these different factors. According to the thermodynamics of this reaction, complete precipitation of Fe3O4 should be expected at a pH between 8 and 14, with a stoichiometric ratio of 2:1 (Fe3+/Fe2+) in a non-oxidizing oxygen environment [52].

The Fe3O4 magnetic nanoparticles were prepared based on the co-precipitation of Fe3+ and Fe2+ under the aqueous ammonia (0.3 mol L−1) as precipitating agent. Briefly, ferrous chloride tetrahydrate and ferric chloride are dissolved in 100 ml deionized water were under vigorous stirring and with the protection of nitrogen to prepare total concentration of 0.015 mol-L−1 ferrite solution containing 1 g PEG4000 emulsifier. Aqueous ammonia (0.3 M) was dropped slowly into the mixture solution until the pH value was titrated to 11.0 [72]. It can be observed that the solution became black due to the formation of Fe3O4 particles. The sample was kept reacting in water bath at 50 °C for 30 min under vigorous stirring and dispersed in ultra sonicator for another 30 min. The black mixture was then aged at 80 °C for 1 h. After that, the product prepared was transferred to a large beaker and dissociated from liquor with the ferromagnet. Finally, the Fe3O4 magnetic nanoparticles were washed with distilled water until the pH value descended to 7.0, and were collected in vacuum drying chamber after being dried for 4 h at 60 °C. The main advantage of the co-precipitation process is that a large amount of nanoparticles can be synthesized. However, the control of particle size distribution is limited, because only kinetic factors are controlling the growth of the crystal [72,73,74,75,76,77].

Facile Hydrothermal Synthesis of Iron Oxide Nanoparticles

Hydrothermal synthesis is generally defined as crystal synthesis or crystal growth under high temperature and high pressure water conditions from substances which are insoluble in ordinary temperature and pressure (<100 °C, <1 atm). Since ionic product equilibrium (Kw) has a maximum value of around 250–300 °C, hydrothermal synthesis is usually carried out below 300 °C. The critical temperature and pressure of water are 374 °C and 22.1 MPa, respectively [78].

In a typical synthesis, FeCl2·4H2O (0.25 g) was dissolved in 12.75 mL water. Under vigorous stirring, ammonium hydroxide (1.25 mL) was added, and the suspension was continuously stirred in air for 10 min, allowing the iron(II) to be oxidized. The reaction mixture was then autoclaved in a sealed pressure vessel with a volume of 48 mL at 134 °C for 3 h under air with a gauge pressure of 2 bar and cooled down to room temperature. The black precipitate was collected and purified with water via a centrifugation-dispersion process. The final Fe3O4 NP suspension was lyophilized to obtain black dry powder [79]. The process of formation of nanospheres by this method is given as Fig. 1.

Diagrammatical illustration of mechanism of formation of metal oxide hollow nanospheres by hydrothermal approach [80]

Batch Hydrothermal Synthesis

In the batch reaction system, one of the advantages for synthesis of metal oxides in supercritical water is reducing alkaline concentration for the crystal phase formation [81].

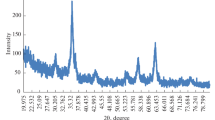

In the batch synthesis of Fe2O3 gel, hydrated iron (III) chloride (FeCl3·6H2O) was used as the precursor and 1,2-epoxybutane was used as the complexing agent. Alcohol was used as the solvent, and water was used as the gelation agent. FeCl3·6H2O (1.25 g) was added to 40 mL of absolute ethanol in a beaker and ultrasonicated for 20 min to obtain a clear yellow solution. To this mixture, 5 mL of epoxide and 1 mL of water were simultaneously added and the solution was stirred. The mixture was then allowed to sit until the solution formed a gel (time at which the solution could no longer flow). In the process of gel formation, the color of the solution gradually changes to reddish brown and the viscosity increases [55]. The morphology of the product obtained by hydrothermal/solvothermal method is given in Fig. 2.

Morphology of the iron oxide nanoparticles obtained by different hydrothermal strategies [82]

Solvothermal Synthesis

In this type of synthesis any other type of organic, inorganic or ionic liquids can be used as solvent replacing the water that is basic in hydrothermal process [ 83].

In a typical synthesis, into 13.0 mL (0.223 mol) of absolute ethanol 0.121 g (0.3 mmol) of Fe(NO3)3·9H2O was dissolved to form a dark red solution, and into it 1.3 g (0.024 mmol) of PVP (Mw = 58,000) was added under magnetic stirring. With the PVP dissolving, the solution gradually transformed into a viscous sol, which was poured into a Teflon-lined autoclave and heated at 240 °C for 4.0 h. After that the autoclave was cooled to room temperature, the as-obtained black suspension was mixed with an equal volume of ethanol, and the formed precipitate (γ-Fe2O3) was separated by centrifugation at 9500 rpm and washed with ethanol. Then it was redispersed into 13.0 mL (0.082 mol) of n-octanol to form a solution, and into it 0.5 g (8.6 × 10−3 mmol) of PVP and 0.2 mL (3.2 mmol) of hydrazine hydrate (80%) were added under stirring to form a homogeneous sol, which was transferred to an autoclave and heated a 180 °C for 6.0 h. After that the product (Fe3O4) was collected by centrifugation and washed with ethanol [84].

Green Synthesis of Nanoparticles

The use of toxic chemicals and non-polar solvents in synthesis limits the use of nanoparticles in clinical fields. Thus, it is needed to develop a clean, non-toxic, biocompatible and eco-friendly method for the synthesis of nanoparticles. Microbial synthesis of nanoparticles is a green chemistry approach that connects the fields of nanotechnology and microbial biotechnology. Biological synthesis of gold, silver, gold–silver alloy, platinum, palladium, selenium, tellurium, silica, titania, zirconia, magnetite and uraninite particles by bacteria, actinomycetes, fungi and yeasts have been reported worldwide [85]. Even though biological synthesis of nanoparticles is considered cost effective, safe, environment-friendly and sustainable, it has various drawbacks. The culturing of microorganisms is time-consuming and it is difficult to have fine control over shape, size and crystallinity. The particles are not monodisperse and the rate of production is slow. These are the various problems which have vexed the biological synthesis of nanoparticles. But optimization of factors involved like pH, temperature, metal ion concentration, and the strain of the microbe used has given hope for large scale application of biological synthesis. Moreover genetically engineered strains which express the reducing agent maximally can be used in the future which will provide better control over the shape and size of nanoparticles [86]. An example of green synthesis is biopolymer-assisted green synthesis of iron oxide nanoparticles.

Biopolymer-Assisted Green Synthesis of Iron Oxide Nanoparticles

To prepare Fe3O4 nanoparticles, 0.5 g of urea was added to 10 mL of aqueous solution containing 1.5 mmol of FeCl3, which was followed by the dropwise addition of 25 mL of a 25.4 mm sodium alginate aqueous solution (calculated by the repeating unit). Subsequently, the resulting solution was transferred into a 50 mL Teflon-lined autoclave and heated at 453 K for 24 h. A black solid product were collected, and then washed with distilled water several times, and finally dried in air [87].

Micro Emulsion

Microemulsion is a thermodynamically stable isotropic dispersion of two immiscible phases (water and oil) under the surfactant present, the surfactant molecules may form a monolayer at the interface between the oil and water, with the hydrophobic tails of the surfactant molecules dissolved in the oil phase and the hydrophilic head groups in the aqueous phase [87,88,89,90,91]

Water-in-oil (w/o) microemulsions consisting of nanosized water droplets dispersed in an oil phase and stabilized by surfactant molecules at the water/oil interface have been widely used to obtain iron oxide nanoparticles [92]. The surfactant-covered water pools offer a unique microenvironment for the formation of nanoparticles and for limiting their growth [93]. The size of the microemulsion droplets is determined by the water to surfactant ratio, although the eventual size of the nanoparticles may also be influenced by factors such as concentration of reactants (especially surfactant) and flexibility of the surfactant film [56, 94, 95].There are several ways to utilize microemulsions to produce nanoparticles. In one method, reactants A and B are dissolved in the aqueous phases of two identical w/o microemulsions and form an AB precipitate upon mixing (see Fig. 3a) [31]. In another method, nanoparticles are produced by the addition of a reducing or precipitating agent to a microemulsion containing the primary reactant dissolved in an aqueous phase (Fig. 3b). The reducing or precipitating agent can be a liquid such as hydrazine or a gas such as hydrogen [96]. Figure 3 depicts another method for the formation of oxide, hydroxide or carbonate precipitates by bubbling gases like O2, NH3, or CO2 through a microemulsion containing soluble salts of the cations [97].

Iron oxide nanoparticles were prepared by microemulsion mediated synthesis process [24]. This synthesis process was carried out at room temperature. The preparation of iron oxide nanoparticles was performed according to the following procedure. Ferrous chloride salt solution was prepared at a concentration of 0.2 M. The FeCl2 solution was stabilized by addition of a few drops of 0.5 M hydrochloric acid. 0.25 M NaOH salt solution was then prepared. Then, the microemulsion was prepared by dissolving HTAB in n-octane, followed by addition of 1-butanol and then FeCl2 aqueous salt solution. The system was stirred slowly until a transparent microemulsion suspension was obtained. The steps above were repeated to produce the second microemulsion that contained 0.25 M NaOH solution. This two microemulsion systems were then mixed at a volumetric ratio of 1:1. Immediately, a dark green precipitate was formed. It then transformed to black. The particles were recovered and then washed several times with deionized water and acetone. They were dried at room temperature and named as S1. The same procedure was repeated to produce a second sample with initial Fe2+ concentration of 0.1 M. The NaOH concentration was maintained at 0.25 M. The volumetric ratio of micoremulsion containing Fe2+ to microemulsion containing OH− was 2:1. This causes an increase of the total number of microemulsions [100]. The morphology of the product prepared by microemulsion method is described in Fig. 4.

Sonochemical Synthesis

As a competitive alternative, the sonochemical method has been extensively used to generate novel materials with unusual properties [58]. This method has been applied for the synthesis of various nanocomposites, and its versatility has been successfully demonstrated in iron oxide nanoparticles preparation [59]. The prepared Fe3O4 nanoparticles are superparamagnetic and its magnetization at room temperature is very low (1.25 emu/g) [25, 60, 103].

Although Fe3O4 has been synthesized through different approaches [24], the chemical co-precipitation process is the most common. However, in most cases, the particles formed are only just within the micrometer scale [104], and it is difficult to control the size distribution and scale in an ordinary chemical co-precipitation process [105]. The rapid progress of microelectronic technology and other fields of industry require continuous reduction of component size, stimulating the demand for synthesis of ultra-fine particles and functional materials. Much attention has been paid to ultrasound/chemical (sonochemical) methods for the production of nanomaterials [106]. The transmission of ultrasound in a liquid phase provides mixing conditions favorable for chemical reaction, and generates transient extreme temperature or high shear-rate through acoustic cavitations, which has a specific effect on a chemical reaction that is very suitable for the formation of nanoparticles. Several kinds of nanoparticles have been synthesized by this method [107].

The advantage of sonochemical synthesis is that one can obtain atomic level mixing of the constituent ions in the amorphous phase so that the crystalline phase can be obtained by annealing at relatively low temperatures [108]. The cavitation is a quenching process, and hence the composition of the particles formed is identical to the composition of the vapor in the bubbles, without phase separation [109].

A freshly prepared mixture of 1.5 mmol FeCl3·6H2O (97%, Aldrich) and 0.75 mmol FeCl2·4H2O (99%, Aldrich) in 5 mL of 0.05 M HCl was rapidly injected via a fine plastic tube to 40 mL of 2 M ammonia solution containing 0.01 M of hydrazine (98%, Aldrich) under power ultrasound at 3032 °C in an argon flow [110]. Hydrazine reduced the redox potential of solution preventing Fe(II) from oxidizing. The injection was performed into the active zone of the sonoreactor via a fine plastic tube. Solids with a distinctive black color of magnetite were precipitated immediately after injection [111, 112]. The mixture was sonicated for 5 min. The sediment was transferred to a nitrogen filled glovebox, separated with a permanent magnet, and washed twice with argon purged 0.1 M [113,114,115,116,117]. Flow sheet diagram for the sonochemical method of synthesis is given in Fig. 5.

Flow sheet diagram for the sonochemical method [118]

The sonochemical method requires expensive organometallic compounds as precursors, but offers better control of the size and size distribution of particles [119]. This facile synthetic process would be advantageous for the laboratory scale production of Fe3O4 nanoparticles having uniform morphology and narrow size distribution [120]. A comparison of nanoparticles obtained by different methods is given as Table 1.

Applications of Fe3O4 Nanoparticles and Superparamagnetic Iron Oxide Nanoparticles

Magnetic nanoparticles are playing an important role in a wide range of sophisticated bio-medical applications, such as targeted drug delivery [122], magnetic cell sorting and immunoassays [123], biochemical sensing [73], and ultra-sensitive disease detection [124]. Owing to its structure, magnetite is a typical semi-metallic material, which has been widely used in the fields of magnetism, photoelectric plot [125], biomedicine, high-gradient magnetic separation (HGMS) [126] and Efficient Surface-Enhanced Raman Scattering [127]. Especially, properly coated or surface- modified magnetite nanoparticles can be applied in clinical diagnosis and as a medicine transporter [128]. A complete overview of method of synthesis of nanoparticles, their size distributions and applications is given in Table 2.

Magnetite, Fe3O4, is a ferromagnetic material with Curie temperature of about 580 °C. It is known to be one of the most magnetic mineral with spin polarization close to 100% as per band-structure calculations. Thus, Fe3O4 is a promising material for many magnetic allied applications. The magnetic study of iron oxide nanoparticles provides a new insight into spin disorders and proton relaxivity that leads to imperative biomedical applications as well as in energy transfer devices [129]. The surface functionalization and modification of magnetic iron oxide NPs to bring in additional functionality is significantly important due to following reasons: (a) Improves the biocompatibility and chemical stability, and tailors the dispersibility and water solubility; (b) Endows the iron oxide new physico-chemical properties, such as magnet-optical properties, magnetic-electrical properties, magnetic-thermal properties, etc.; (c) Provides the iron oxide new functional end groups for the ensuing functionalized procedures or the subsequent applications, such as conjugation with the DNA, antibody, protein, etc. [130]. Applications avowed in this review include naked surface iron oxide magnetic nanoparticles as well as surface modified iron oxide nanoparticles.

The discovery of its gas sensing capability and applications in lithium-ion batteries has highlighted the need of a more effective fabrication approach [131]. Alignment, uniform dispersion, selective growth and diameter control are general parameters which play vital roles in the flourishing integration of nanostructures for the fabrication of bioelectronic sensing devices [132].

Success in each field has enthused multiple variations that prolong to drive the rapid evolution of the field. The high surface areas of nano structured materials are also valuable for chemical sensing [133]. Chemical sensors are extensively used for engineering process control and are experiencing growing use in security applications [134]. The nano-sized porous Fe3O4 particles with facile synthesis, good cycling performance and high capacity retention are promising candidate as anode materials for high energy–density lithium-ion batteries [135,136,137]. The magnetic Fe3O4 particles for the optimized DNA extraction procedure prove exceptional in effectiveness and it can be appropriate to extract plasmid DNA from agarose gel [138]. Fe3O4 novel fractal nanocrystals have been synthesized by a surfactant-assisted solvothermal process showing relatively high saturation magnetization (Ms) of 78.75 emu/g leads to new potential applications such as high-density recording media magnetic sensors [139]. Monodisperse magnetic-plasmonic Fe3O4-Au/porous silica core/shell nanoparticles, with nanoporous silica shells containing both primary and secondary amine groups, demonstrate a significant interest for coupling biomolecules. The multifunctional nanoarchitectures could also offer an ultimate platform to study the molecules with low fluorescence efficacies, and exhibit promising potential in practical applications such as multimodal imaging, bio sensing, or localized drug delivery [140]. Fe3O4–NH2/PEI-EDTA has been proven to be an effective, rapid and convenient nano-adsorbent for the removal of heavy metal ions (such as Cu2+, Pb2+and Cd2+) from aqueous solutions [141]. Magnetic sedimentation and magnetophoresis have been used for separation purposes, generally in combination with magnetically loaded colloids or cells in the micrometer range [142].

In data storage applications, the particles must have a stable, switchable magnetic state that is not be affected by temperature fluctuations [143]. For optimum performance in recording, the particles should exhibit both high coercivity and high remanence, and they should be uniformly small, and resistant to corrosion, friction, and temperature changes [144]. It was also found that the biotinylated PNIPAAm-coated iron oxide nanoparticles can still bind to the surface of a streptavidin-coated sensor chip with high affinity proving it valuable for therapeutic applications in biotechnology and biomedicines [110].

The NBR/nano-Fe3O4 composites show good anti-wear and friction-reducing properties. The nano-Fe3O4 is conducive to forming physical adsorption film and self-repairing film on the friction surface. It has the effect of improving the resistance to wear and friction. Clearly, the addition of nano Fe3O4 particles can improve friction and wear performance of NBR, and is helpful for its application in sealing [145].

Maghemite is useful in recording and data storage applications because of its chemical and physical stability [146]. It is often doped or coated with 1–5% cobalt in order to improve its coercivity and storage capacity. Coated nanoparticles have greater thermal stability than their doped counterparts and display uniaxial magnetic anisotropy [41].

Internalization of iron oxide particles strongly depends upon the size of the particles [147]. After administration, larger particles with a diameter higher than 200 nm are easily sequestered by the spleen and eventually removed by the cells of the phagocyte system, resulting in decreased blood circulation times. Magnetic drug targeting employing nanoparticles as carriers is a promising cancer treatment avoiding the side effects of conventional chemotherapy [148]. The incorporation of radioisotopes enables testing and describing the nanometerscale delivery vehicles for medical diagnostic and therapeutic purposes [149].

Layer-by-layer films of hemoglobin with magnetic Fe3O4 nanoparticles were successfully assembled on various solid surfaces mainly by electrostatic interaction between them. The good biocatalytic activity of Hb incorporated in multilayered {Fe3O4/Hb}6 films toward various substrates may establish a foundation for fabricating the new kind of biosensors or bioreactors without using chemical mediators [150].

Superparamagnetic iron oxide nanoparticles play an important role as MRI contrast agents, to better differentiate healthy and pathological tissues. Recent developments in MR imaging have enabled in vivo imaging at near microscopic resolution [151]. In order to visualize and track stem and progenitor cells by MR imaging, it is necessary to tag cells magnetically. Tat protein-derived peptide sequences have recently been used as an efficient way of internalizing a number of marked proteins into cells [152].

Some of the most important merits reported by different authors are given in the Table 2 given below.

Commercialized SPIONs

Superparamagnetic iron oxide nanoparticles (SPIO-NPs) have traditionally been used as MRI contrast agent for disease imaging via passive targeting [153]. However, there has been an increasing interest in the development of SPIO-NPs to cellular-specific targeting for imaging and drug delivery currently [32]. Due to rapidly growing applications in different fields of life different type of spions are commercially available [154]. Superparmagnetic magnetite nanoparticles can be applied to microbead applications of a biosensor [155].

Table 3 given below shows different SPIONs and its application with the reference of companies those are commercializing them [156].

Conclusion

In conclusion, Iron oxide magnetic nanoparticles can be designed to exhibit novel and significantly improved physical, chemical and biological properties, phenomena and strategies as a result of the limited size of their constituent particles by using above stated methodologies. This review reveals that Magnetic iron oxide NPs, especially superparamagnetic (SPM) NPs, is attractive magnetic probes for biological imaging and therapeutic applications. The examples illustrated in table further demonstrate that magnetic nanoparticles made from chemical synthesis with controlled size, surface chemistry and magnetic properties are indeed promising for further ultra-high density information storage, highly sensitive medical diagnostics and highly efficient therapeutic applications. The USPIONs appear to be nontoxic, are easy to manage, and provide substantial contrast enhancement, even on low tesla magnets. They may serve as complimentary agents to increase localization, characterization, and addition in different neurologic lesions. In CNS tumors, USPIONs may improve diagnosis and detection at early stages and will be of much significance in the future for monitoring therapeutic responses to antiangiogenic chemotherapies. There is a lot of activity in this field, and the future is bright, so long as we pay attention to the primary criteria for success, making sure that there is a clearly identified clinical need that can be addressed. It may also be prudent to carefully assess the potential applications for any new approach to see whether there is a simple, straightforward target that may be addressed in the short term.

References

A. Pankhurst, J. Connolly, S. K. Jones, and J. Dobson (2003). J. Phys. D Appl. Phys. 36, R167–R181.

C. B. Catherine and S. G. C. Curtis (2003). J. Phys. D Appl. Phys. 36, R198–R206.

S. Chikazumi, S. Taketomi, M. Ukita, M. Mizukami, H. Miyajima, M. Setogawa, and Y. Kurihara (1987). J. Magn. Magn. Mater 65, 245.

A.-H. Lu, W. Schmidt, N. Matoussevitch, H. Bönnemann, B. Spliethoff, B. Tesche, E. Bill, W. Kiefer, and F. Schüth (2004). Angew. Chem. 116, 4403.

A. C. Tsang, V. Caps, I. Paraskevas, D. Chadwick, and D. Thompsett (2004). Angew. Chem. 116, 5763.

A. K. Gupta and M. Gupta (2005). Biomaterials 26, 3995–4021.

S. Mornet, F. Vasseur, P. Grasset, G. Verveka, A. Goglio, J. Demourgues, E. Portier, E. Pollert, and E. Duguet (2006). Prog. Solid State Chem. 34, 237.

Z. Li, L. Wei, M. Y. Gao, and H. Lei (2005). Adv. Mater. 17, 1001.

T. Hyeon (2003). Chem. Commun. 8, 927.

D. W. Elliott and W.-X. Zhang (2001). Environ. Sci. Technol. 35, 4922.

M. Takafuji, S. Ide, H. Ihara, and Z. Xu (2004). Chem. Mater 16, 1977.

A. H. Lu, E. L. Salabas, and F. S. Angew (2007). Chem. Int. Ed. 46, 1222–1244.

C. Xu and S. Sun (2007). Polym. Int. 56, 821–826.

S. S. Lee, J. Park, Y. Chung, and H. B. Na (2001). J. Am. Chem. Soc. 123, 12798–12801.

B. H. Sohn and R. E. Cohen (1997). Chem. Mater. 9, 264.

D. K. Kim, Y. Zhang, W. Voit, K. V. Rao, and M. Muhammed (2001). J. Magn. Magn. Mater. 225, 30–36.

J. Gao, H. W. Gu, and B. Xu (2009). Acc. Chem. Res. 42, 1097–1107.

L. Wang, H. Y. Park, S. I.-I. Lim, M. J. Schadt, D. Mott, J. Luo, X. Wang, and C.-J. Zhong (2008). J. Mater. Chem. 18, 2629–2635.

Y. Lu, Y. Yin, B. T. Mayers, and X. Younan (2002). Nano Lett. 2, 183–186.

Q. A. Pankhurst, N. K. T. Thanh, S. K. Jones, and J. Dobson (2010). Acta Elct. Et. Info. 10, 39–42.

P. Berger, N. B. Adelman, K. J. Bechman, D. J. Campbell, A. B. Ellis, and G. C. Lisensky (1999). J. Chem. Educ. 76, 943.

C. Y. Wang, G. M. Zhu, Z. Y. Chen, and Z. G. Lin (2002). Mater. Res. Bull. 37, 2525.

B. Fang, G. Wang, W. Zhang, M. Li, and X. Kan (2005). Electroanalysis 17, 744–748.

S. Laurent, D. Forge, M. Port, A. Roch, C. Robic, L. V. Elst, and R. N. Muller (2008). Chem. Rev. 108, 2064–2110.

A. E. Gash, T. M. Tillotson, J. H. Satcher, J. F. Poco, L. W. Hrubesh, and R. L. Simpson (2001). Chem. Mater. 13, 999–1007.

M. N. Berger (2007). Acc. Chem. Res. 40, 793–800.

S. M. Moghimi, A. C. H. Hunter, and J. C. Murray (2001). Pharm. Rev. 53, 283–318.

J. M. Wilkinson (2003). Med. Device Technol. 14(5), 29–31.

R. K. Gilchrist, R. Medal, W. D. Shorey, R. C. Hanselman, J. C. Parrot, and C. B. Taylor (1957). Ann. Surg. 146, 596–606.

L. Babes, B. Denizot, G. Tanguy, J. J. Le Jeune, and P. Jallet (1999). J. Colloid Int. Sci. 212, 474–482.

W. Wu, Q. He, and C. Jiang (2008). Nanoscale Res. Lett. 3, 397–415.

Y. H. Zheng, Y. Cheng, F. Bao, and Y. S. Wang (2006). Mater. Res. Bull. 41, 525–529.

T. Ozkaya, M. S. Toprak, A. Baykala, H. Kavas, Y. Köseoğlu, and B. Aktas (2009). J. Alloys Compd. 472, 18–23.

J. Wang, J. Sun, Q. Sun, and Q. Chen (2003). Mater. Res. Bull. 38, 1113–1118.

S. Si, C. Li, X. Wang, D. Yu, Q. Peng, and Y. Li (2005). Cryst. Growth Des. 5, (2), 391–393.

H. W. Wang, H. Lin, Y. C. Yeh, and C. H. Kuo (2007). J. Magn. Magn. Mater. 310, 2425–2427.

Z. L. Liu and X. Wang (2004). J. Mater. Sci. 39, 2633–2636.

S. Ni, S. Lin, Q. Pan, F. Yang, K. Huang, and D. He (2009). J. Phys. D Appl. Phys. 42, 055004–0550016.

F. Dang, K. Kamada, N. Enomoto, J. Hojo, and K. Enpuku (2007). Ceram. Soc. J. 115(12), 867–872.

A.-L. Morel, S. I. Nikitenko, K. Gionnet, A. Wattiaux, J. Lai-Kee-Him, C. La-brugere, B. Chevalier, G. Deleris, C. Petibois, A. Brisson, and M. Simonoff (2008). ACSNANO. 5(2), 847–856. doi:10.1021/nn800091q.

N. Wang, L. Zhu, D. Wanga, M. Wang, Z. Lin, and H. Tang (2010). Ultrason. Sonochem. 17, 526–533.

A. Yan, X. Liu, G. Qiu, and H. Wu (2008). J. Alloys. Compd. 458, 487–491.

R. A. Mukh-Qasem and A. Gedanken (2005). J. Colloid Interface Sci. 284(2), 489–494.

R. A. Mukh-Qasem and A. Gedanken (2008). J. Phys. Chem. 112, 35–42.

M. N. Islam, L. V. Phong, J. Jeong and C. Kim (2011). Thin Solid Films in press.

Z. Mo, C. Zhang, R. Guo, S. Meng, and J. Zhang (2011). Ind. Eng. Chem. Res. 50, 3534–3539.

A. Zhua, L. Yuan, and T. Liao (2008). Int. J. Pharm. 350, 361–368.

M. Titirici, M. Antonietti, and A. Thomas (2006). Chem. Mater. 18, 3808–3812.

S. Sun* and H. Zeng (2002). J. Am. Chem. Soc. 124(28), 8204–8205.

A. B. Chin and I. I. Yaacob (2007). J. Mater. Proces. Technol. 191, 235–237.

R. Honga, J. Li, J. Wang, and H. Li (2007). China Particuol. 5, 186–191.

H. T. Chana, Y. Y. Doa, P. L. Huanga, P. L. Chienb, T. S. Chanc, R. S. Liuc, C. Y. Huangd, S. Y. Yangd, and H. E. Horngd (2006). J. Magn. Magn. Mater. 304, e415–e417.

H. Zeng, J. Li, Z. L. Wang, J. P. Liu, and S. Sun (2004). Nano Lett. 4(2), 187–190.

Y. Lu, Y. Yin, B. T. Mayers, and Y. Xia (2002). Nano Lett. 2(3), 3183–3186.

S. Santra, R. Tapec, N. Theodoropoulou, J. Dobson, A. Hebard, and W. Tan (2001). Langmuir 17, 2900–2906.

S. Park, S. Kim, S. Lee, Z. G. Khim, K. Char, and T. Hyeon (2000). J. Am. Chem. Soc. 122, 8581–8582.

R. Zboril (2002). Chem. Mater. 14, 969–982.

K. Woo, J. Hong, S. Choi, H.-W. Lee, J.-P. Ahn, C. S. Kim, and S. W. Lee (2004). Chem. Mater. 16, 2814–2818.

B. Bourlinos, A. Bakandritsos, V. Georgakilas, and D. Petridis (2002). Chem. Mater. 14, 3226–3228.

R. V. Kumar, Y. Diamant, and A. Gedanken (2000). Chem. Mater. 12, 2301–2305.

R. A. Mukh-Qasem and A. Gedanken (2005). J. Colloid Interface Sci. 284, 489–494.

M. N. Islam, L. V. Phong, J. R. Jeong, and C. G. Kim (2011). Thin Solid Films in press.

K. Nishioa, M. Ikedaa, N. Gokonb, S. Tsubouchia, H. Narimatsua, Y. Mochizukia, S. Sakamotoa, A. Sandhuc, M. Abe, and H. Handa (2007). J. Magn. Magn. Mater. 310, 2408–2410.

J. Qiu, H. Peng, and R. Liang (2007). Electrochem. Commun. 9, 2734–2738.

Z. Huang and F. Tang (2004). J. Colloid Interface Sci. 275, 142–147.

Z. Lu, G. Wang, J. Zhuang, and W. Yang (2006). Physicochem. Eng. Asp. 278, 140–143.

A. Jordan, R. Scholz, P. Wust, H. Fakhling, and R. Felix (1999). J. Magn. Magn. Mater. 201, 413–419.

E. E. Carpenter (2001). J. Magn. Magn. Mater. 225, 17–20.

Z. Z. Xu, C. C. Wang, W. L. Yang, Y. H. Deng, and S. K. Fu (2004). J. Magn. Magn. Mater. 277, 136–143.

M. Hofmann and B. V. Rechenberg (2005). J. Magn. Magn. Mater. 293, 483–496.

Y. C. Chang and D. H. Chen (2005). J. Colloid Interface Sci. 283, 446–451.

C. H. Peng, H. W. Wang, S. W. Kanb, M. Z. Shenb, Y. M. Weib, and S. Y. Chena (2004). J. Magn. Magn. Mater. 284, 113–119.

D. K. Kim, Y. Zhang, W. Voit, K. V. Rao, J. Kehr, B. Bjelke, and M. Muhammed (2001). Scr. Mater. 44, 1713–1717.

S. W. Kamau, S. Katja, P. F. Alke, H. Paul, H. Michael, H. Heinrich, and H. Margarethe (2005). Eur. J. Cell Mater. 10, 10.

J. Lim, C. Lanni, E. R. Evarts, F. L. Robert, and S. A. Majetich (2011). ACS Nano 5(1), 217–226.

Y. Lu, Y. Yin, B. T. Mayers, and Y. Xia (2002). Nano Lett. 2(4), 183–186.

F. Erogbogbo, K. T. Yong, R. Hu, W. C. Law, H. Ding, C. W. Chang, P. N. Prasad, and M. T. Swihart (2010). ACS 4(9), 5131–5138.

T. K. Jain, M. K. Reddy, M. A. Morales, D. L. Leslie-Pelecky, and V. Labhasetwar (2008). Mol. Pharm. 5(2), 316–327.

P. Sun, H. Zhang, C. Liu, J. Fang, M. Wang, J. Chen, J. Zhang, C. Mao, and S. Xu (2010). Langmuir 26, (2), 1278–1284.

C. Yee, G. Kataby, A. Ulman, T. Prozorov, H. White, A. King, M. Rafailovich, J. Sokolov, and A. Gedanken (1999). Langmuir 15, 7111–7115.

E. Taboada, E. Rodríguez, A. Roig, J. Oró, A. Roch, and R. N. Muller (2007). Langmuir 23, 4583–4588.

A. J. Rondinone, A. C. S. Samia, and Z. J. Zhang (1999). J. Phys. Chem. 103, 6876–6880.

H. Duan, M. Kuang, X. Wang, Y. A. Wang, H. Mao, and S. Nie (2008). J. Phys. Chem. C 112(22), 8127–8131.

D. Tang, R. Yuan, and Y. Chai (2006). J. Phys. Chem. 110, 11640–11646.

G. Zou, K. Xiong, C. Jiang, H. Li, T. Li, J. Du, and Y. Qian (2005). J. Phys. Chem. 109, 18356–18360.

S. Li, Y. C. Hong, H. S. Uhm, and Z. Li (2004). Jpn. J. Appl. Phys. 43(11A), 7714–7717.

M. Chen, S. Yamamuro, D. Farrell, and S. A. Majeticha (2003). J. Appl. Phys. 93(10), 7551–7553.

Y. Deng, D. Qi, C. Deng, X. Zhang, and D. Zhao (2008). J. Am. Chem. Soc. 130, 28–29.

Y.-W. Jun, Y.-M. Huh, J.-S. Choi, J.-H. Lee, H.-T. Song, and S. Kim (2005). J. Am. Chem. Soc. 127, 5732–5733.

S. X. Wang and G. Li (2004). J. Am. Chem. Soc. 126, 273–279.

S. Sun, S. Anders, H. F. Hamann, J.-U. Thiele, J. E. E. Baglin, T. Thomson, E. E. Fullerton, C. B. Murray, and B. D. Terris (2002). J. Am. Chem. Soc. 124(12), 2884–2885.

J.-P. Fortin, C. Wilhelm, J. Servais, C. Ménager, J.-C. Bacri, and F. Gazeau (2007). J. Am. Chem. Soc. 129, 2628–2635.

W. Zhao, J. Gu, L. Zhang, H. Chen, and J. Shi (2005). J. Am. Chem. Soc. 127, 8916–8917.

A. Dyal, K. Loos, M. Noto, S. W. Chang, C. Spagnoli, K. V. P. M. Shafi, A. Ulman, M. Cowman, and R. A. Gross (2003). J. Am. Chem. Soc. 125, 1684–1685.

S. D. Dickson, W. Chen, A. W. Griffioen, Z. A. Fayad, W. J. M. Mulder, and P. A. Jarzyna (2009). Biomaterials 30, 6947–6954.

S. A. Corr, P. Y. Rakovich, and Y. K. Gu’nko (2008). Nanoscale Res. Lett. 3, 87–104.

J. Gao, H. Gu, and B. Xu (2009). Acc. Chem. Res. 42(8), 1097–1107.

E. Alphandéry, Y. Ding, A. T. Ngo, Z. L. Wang, L. F. Wu, and M. P. Pileni (2009). ACS Nano 3(6), 1539–1547.

H. Zhang, M.-Y. Lee, M. G. Hogg, J. S. Dordick, and S. T. Sharfstein (2010). ACS Nano 4(8), 4733–4743.

M. Fröba, R. Köhn, and G. Bouffaud (1999). Chem. Mater. 11, 2858–2865.

B. K. Pradhan, T. Toba, T. Kyotani, and A. Tomita (1998). Chem. Mater. 10, 2510–2515.

G. Ennas, A. Musinu, G. Piccaluga, and D. Zedda (1998). Chem. Mater. 10, 495–502.

A. S. Teja and P.-Y. Koh (2009). Prog. Cryst. Growth Charact. Mater. 55, 22–45.

X. Zhao, Y. Cai, T. Wang, Y. Shi, and G. Jiang (2008). Anal. Chem. 80, 9091–9096.

F. M. Kievit, F. Y. Wang, C. Fang, H. Mok, K. Wang, J. R. Silber, R. G. Ellenbogen, and M. Zhang (2011). J. Control. Release in press.

J. Xie, K. Chen, J. Huang, S. Lee, J. Wang, J. Gao, X. Li, and X. Chen (2010). Biomaterials 31, 3016–3022.

F. Dilnawaz, A. Singh, C. Mohanty, and S. K. Sahoo (2010). Biomaterials 31, 3694–3706.

P. Girginova, A. L. Daniel-da-Silva, C. B. Lopes, P. Figueira, M. Otero, V. S. Amaral, E. Pereira, and T. Trindade (2010). J. Colloid Interface Sci. 345, 234–240.

I. Koh, X. Wang, B. Varughese, L. Isaacs, S. H. Ehrman, and D. S. English (2006). J. Phys. Chem. 110, 1553–1558.

Z. Yuanbi, Q. Zumin, and H. Jiaying (2008). Chin. J. Chem. Eng. 16(3), 451–455.

J.-I. Jo, I. Aoki, and Y. Tabata (2010). J. Control. Release 142, 465–473.

C. Xu, K. Xu, H. Gu, R. Zheng, H. Liu, X. Zhang, Z. Guo, and B. Xu (2004). J. Am. Chem. Soc. 126, 9938–9939.

C. Fan, W. Gao, Z. Chenc, H. Fan, M. Li, F. Deng, and Z. Chen (2011). Int. J. Pharm. 404, 180–190.

I. De Vicentea, A. Merino-Martos, L. Cruz-Pizarroa, and J. de Vicentec (2010). J. Hazard. Mater. 181, 375–381.

K. Chen, J. Xie, H. Xu, D. Behera, M. H. Michalski, S. Biswal, A. Wang, and X. Chen (2009). Biomaterials 30, 6912–6919.

N. Tran and T. J. Webster (2011). Acta Biomater. 7, 1298–1306.

O. Lunov, T. Syrovets, B. Büchele, X. Jiang, C. Röcker, K. Tron, G. U. Nienhaus, P. Walther, V. Mailänder, K. Landfester, and T. Simmet (2010). Biomaterials 31, e5063–e5071.

B. Zargar, H. Parham, and A. Hatamie (2009). Chemosphere 76, 554–557.

F. Yang, Y. Li, Z. Chen, Y. Zhang, J. Wu, and N. Gu (2009). Biomaterials 30, 3882–3890.

A. Azhari, F. Golestani-Fard, and H. Sarpoolaky (2009). J. Eur. Ceram. Soc. 29, 2679–2684.

A. Figuerola, R. D. Coratob, L. Manna, and T. Pellegrino (2010). Pharmacol. Res. 62, 126–143.

M. Mahmoudi, S. Sant, B. Wang, S. Laurent, and T. Sen (2011). Adv. Drug Deliv. Rev. in press.

S. Cheng, J.-H. Jang, B. A. Dempsey, and B. E. Logan (2011). Water. Res. 45, 303–307.

H. Lee, E. Lee, D. K. Kim, N. K. Jang, Y. Y. Jeong, and S. Jon (2006). J. Am. Chem. Soc. 128, 7383–7389.

R. Y. Honga, B. Feng, L. L. Chen, G. H. Liu, H. Z. Li, Y. Zheng, and D. G. Wei (2008). Biochem. Eng. J. 42, 290–300.

R. Narain, M. Gonzales, A. S. Hoffman, P. S. Stayton, and K. M. Krishnan (2007). Langmuir 23, 6299–6304.

N. A. Frey, S. Peng, K. Cheng, and S. Sun (2009). Chem. Soc. Rev. 38(9), 2532–2542.

D. Cao and N. Hu (2006). Biophys. Chem. 121, 209–217.

T. K. Jain, M. A. Morales, S. K. Sahoo, D. L. Leslie-Pelecky, and V. Labhasetwar (2005). Mol. Pharm. 2(3), 194–205.

F. Sonvico, S. Mornet, S. Vasseur, C. Dubernet, D. Jaillard, J. Degrouard, J. Hoebeke, E. Duguet, P. Colombo, and P. Couvreur (2005). Bioconjugate Chem. 16, 1181–1188.

J. Fuliu, Z. Shanzhao, and A. Binjiang (2008). Environ. Sci. Technol. 42, 6949–6954.

M. Mikhaylova, D. K. Kim, C. C. Berry, A. Zagorodni, M. Toprak, A. S. G. Curtis, and M. Muhammed (2004). Chem. Mater. 16, 2344–2354.

S. Q. Wang, C. R. Li, Y. M. Miao, Z. Y. Wu, and B. S. Zou (2005). J. Phys. D Appl. Phys. 38, 1342–1350.

P. Tartaj, M. P. Morales, S. Veintemillas-Verdaguer, T. González-Carreño, and C. J. Serna (2003). J. Phys. D Appl. Phys. 36, R182–R197.

H. Wei and E. Wang (2008). Anal. Chem. 80, 2250–2254.

G. K. Kouassi and J. Irudayaraj (2006). Anal. Chem. 78, 3234–3241.

A. Tsukamoto, K. Saitoh, D. Suzuki, N. Sugita, Y. Seki, A. Kandori, K. Tsukada, Y. Sugiura, S. Hamaoka, H. Kuma, N. Hamasaki, K. Enpuku, and I. E. E. E. Trans (2005). Appl. Supercond. 15(2), 656–659.

D.-L. Zhao, H.-L. Zhang, X.-W. Zeng, Q.-S. Xia, and J.-T. Tang (2006). Biomed. Mater. 1, 198–201.

J. Li and H. Gao (2008). Electroanalysis 20(8), 881–887.

A. Erdem, F. Sayar, H. Karadeniz, G. Guven, M. Ozsoz, and E. Piskinb (2007). Electroanalysis 19(7–8), 798–804.

I.-M. Hsing, Y. Xu, and W. Zhao (2007). Electroanalysis 19(7–8), 755–768.

B. Fang, G. Wang, W. Zhang, M. Li, and X. Kan (2005). Electroanalysis 17(9), 744–748.

Q. A. Pankhurst, N. K. T. Thanh, S. K. Jones, and J. Dobson (2009). J. Phys. D Appl. Phys. 42, 224001–224016.

M. Irama, C. Guo, Y. Guan, A. Ishfaq, and H. Liu (2010). J. Hazard. Mater. 181, 1039–1050.

S. Tanaka, C. Toriyabe, Y. Torii, Y. Hatsukade, T. Eki, S. Katsura, N. Ohnishi, J. Wan, S. Yang, and Y. Zhang (2007). Phys. C: Supercond Appl. 463–465, 1029–1033.

L. Zhou, R. Diao, T. Zhou, H. Wang, H. Kage, and Y. Mawatari (2010). Adv. Powder Technol. in press.

Z. M. Saiyed, C. Bochiwal, H. Gorasia, S. D. Telang, and C. N. Ramchand (2006). Anal. Biochem. 356, 306–308.

M. Xu, Y. Zhang, Z. Zhang, Y. Shen, M. Zhao, and G. Pan (2011). Chem. Eng. J. 168, 737–745.

Y. F. Shen, J. Tang, Z. H. Nie, Y. D. Wang, Y. Ren, and L. Zuo (2009). Sep. Sci. Technol. 68, 312–319.

Q. Wei, Z. Xiang, J. He, G. Wang, H. Li, Z. Qian, and M. Yang (2010). Biosens. Bioelectron. 26, 627–631.

B. Chertok, B. A. Moffat, A. E. David, F. Yu, C. Bergemann, B. D. Ross, and V. C. Yang (2008). Biomaterials 29, 487–496.

C. Sun, J. S. H. Lee, and M. Zhang (2008). Adv. Drug Deliv. Rev. 60, 1252–1265.

C. H. Dodd, H.-C. Hsu, W.-J. Chu, P. Yang, H.-G. Zhang, J. D. Mountz Jr., K. Zinn, J. Forder, L. Josephson, R. Weissleder, J. M. Mountz, and J. D. Mountz (2001). J. Immunol. Methods 256, 89–105.

Q. Wang, F. Yang, Q. Yang, J. Chen, and H. Guan (2010). Mater. Des. 31, 1023–1028.

U. T. Lam, R. Mammucari, K. Suzuki, and N. R. Foster (2008). Ind. Eng. Chem. Res. 47, 599–614.

X. F. Zhang, L. Clime, H. Q. Ly, M. Trudeau, and T. Veres (2010). J. Phys. Chem. C 114, 18313–18317.

J. Fang, H. Wang, Y. Xue, X. Wang, T. Lin, and A. C. S. Appl (2010). Mater. Interfaces 2(5), 1449–1455.

T. K. Jain, M. A. Morales, S. K. Sahoo, D. L. Leslie-Pelecky, and V. Labhasetwar (2010). Mol. Pharm. 2(3), 194–205.

H. Chen, X. Wu, H. Duan, Y. A. Wang, L. Wang, M. Zhang, H. Mao, and A. C. S. Appl (2009). Mater. Interfaces 1(10), 2134–2140.

V. Zelenak, A. Zelenakova, J. Kovac, U. Vainio, and N. Murafa (2009). J. Phys. Chem. C 113, 13045–13050.

U. O. Häfeli, J. S. Riffle, L. Harris-Shekhawat, A. Carmichael-Baranauskas, F. Mark, J. P. Dailey, and D. Bardenstein (2009). Mol. Pharm. 6(5), 1417–1428.

D. Ma, T. Veres, L. Clime, F. Normandin, J. Guan, D. Kingston, and B. Simard (2007). J. Phys. Chem. C 111, 1999–2007.

Y. Xu, A. Karmakar, D. Wang, M. W. Mahmood, F. Watanabe, Y. Zhang, A. Fejleh, P. Fejleh, Z. Li, G. Kannarpady, S. Ali, A. R. Biris, and A. S. Biris (2010). J. Phys. Chem. C 114, 5020–5026.

Z. Lei, N. Ren, Y. Li, N. Li, and B. Mu (2009). J. Agric. Food Chem. 57, 1544–1549.

S. Xuan, F. Wang, J. M. Y. Lai, K. W. Y. Sham, Y.-X. J. Wang, S.-F. Lee, J. C. Yu, C. H. K. Cheng, and K. C.-F. Leung (2011). ACS Appl. Mater. Interface 3, 237–244.

F. Bertorelle, C. Wilhelm, J. Roger, F. Gazeau, C. Ménager, and V. Cabuil (2006). Langmuir 22, 5385–5391.

M. A. M. Gijs, F. Lacharme, and U. Lehmann (2010). Chem. Rev. 110, 1518–1563.

Y. Zhai, J. Zhai, Y. Wang, S. Guo, W. Ren, and S. Dong (2009). J. Phys. Chem. C 113, 7009–7014.

S. T. Selvan, T. T. Yang Tan, D. K. Yi, and N. R. Jana (2010). Langmuir 26(14), 11631–11641.

N. Insin, J. B. Tracy, H. Lee, J. P. Zimmer, R. M. Westervelt, and M. G. Bawendi (2008). ACS Nano 2(2), 197–202.

E. S. M. Lee, J. Chan, B. Shutter, L. Tan, M. S. K. Chong, D. L. Ramachandra, G. S. Dawe, J. Ding, S. H. Teoh, O. Beuf, A. Briguet, K. C. Tam, M. Choolani, and S. Wang (2009). Stem Cells 27, 1921–1931.

S. Wang, Y. Tan, D. Zhao, and G. Liu (2008). Biosens. Bioelectron. 23, 1781–1787.

A. Erdem, F. Sayar, H. Karadeniz, G. Guven, M. Ozsoz, and E. Piskin (2007). Electroanalysis 19, 798–804.

E. Katz, I. Willner, and J. Wang (2004). Electroanalysis 16, 1–2.

W. Zhao, J.-J. Xu, and H.-Y. Chen (2006). Electroanalysis 18, 1737–1748.

J. Liu, J. Liu, L. Yang, X. Chen, M. Zhang, F. Meng, T. Luo, and M. Li (2009). Sensors 9, 7343–7364.

A. El-Ansary and L. M. Faddah (2010). Nano Technol. 3, 65–76.

A. Ansari, M. Alhoshan, M. S. Alsalhi, and A. S. Aldwayyan (2010). Sensors 10, 6535–6581.

G. Ning, W. Lu-Yan, L. Tian-Hua, Z. Lei, and W. Feng (2009). Chin. J. Anal. Chem. 37(8), 1125–1130.

U. Yogeswaran, S. Thiagarajan, and S.-M. Chen (2008). Sensors 8, 7191–7212.

K.-S. Loh, Y. H. Lee, A. Musa, A. A. Salmah, and I. Zamri (2008). Sensors 8, 5775–5791.

W. Wen, Y. Tan, H. Xiong, and S. Wang (2010). Int. J. Electrochem. Sci. 5, 232–241.

J. Wang, A. Munir, Z. Zhu, and H. S. Zhou (2010). Anal. Chem. 82, 6782–6789.

G. Zhao, J.-J. Feng, Q.-L. Zhang, S.-P. Li, and H.-Y. Chen (2005). Chem. Mater. 17, 3154–3159.

Z. Li, J. F. Godsell, J. P. O’Byrne, N. Petkov, M. A. Morris, S. Roy, and J. D. Holmes (2010). J. Am. Chem. Soc. 132, 12540–12541.

S. H. Gee, Y. K. Hong, D. W. Erickson, and M. H. Park (2003). J. Appl. Phys. 93(10), 7560–7562.

L. Machala, R. Zboril, and A. Gedanken (2007). J. Phys. Chem. 111, 4003–4018.

J. Zhou, X. Qiao, B. P. Binks, K. Sun, M. Bai, Y. Li, and Y. Liu (2011). Langmuir 27, 3308–3316.

T.-L. Zhang and B.-H. Han (2010). Langmuir 26(11), 8893–8900.

L. Yang, X. Ren, F. Tang, and L. Zhang (2009). Biosens. Bioelectron. 25, 889–895.

H. Zhu, J. Han, J. Q. Xiao, and Y. Jin (2008). J. Environ. Monit. 10(6), 685–784.

Q. Lan, C. Liu, F. Yang, S. Liu, J. Xu, and D. Sun (2007). J. Colloid Interface Sci. 310, 260–269.

R. Zhang, X. Wang, C. Wu, M. Song, J. Li, G. Lv, J. Zhou, C. Chen, Y. Dai, F. Gao, D. Fu, X. Li, Z. Guan, and B. Chen (2006). Nano. Technol. 17, 3622–3626.

B.-L. Lin, X.-D. Shen, and S. Cui (2007). Biomed. Mater. 2, 132–134.

H. Lee, M. K. Yu, S. Park, S. Moon, J. J. Min, Y. Y. Jeong, H.-W. Kang, and S. Jon (2007). J. Am. Chem. Soc. 129(42), 12739–12745.

H.-L. Duan, Z.-Q. Shen, X.-W. Wang, F.-H. Chao, and J.-W. Li (2005). World J. Gastroenterol. 11(24), 3660–3664.

Y. F. Shen, J. Tang, Z. H. Nie, Y. D. Wang, Y. Ren, and L. Zuo (2009). Sep. Purif. Technol. 68, 312–319.

J. Wang, Z. Zhu, A. Munir, and H. S. Zhou (2011). Talanta 84, 783–788.

V. Chandra, J. Park, Y. Chun, J. Woo Lee, I. Hwang, and K. S. Kim (2010). ACS Nano 4(7), 3979–3986.

Acknowledgements

The authors would like to acknowledge the support provided by the Deanship of Scientific Research (DSR) at King Fahd University of Petroleum and Minerals (KFUPM) for funding this work through project No. SR161009. Project No. SR161009 has been awarded to Dr. Muhammad Ramzan Saeed Ashraf Janjua who is working as a Principal Investigator (PI) in this project. He is also thankful to his parent university, University of Sargodha (UOS) where he has been working since November 2010 on regular basis at BPS 19. He has been doing his research in KFUPM as an Assistant Professor of Physical Chemistry since January 2016 after taking permission and Ex-Pakistan Extra-Ordinary Leave (EOL) from Department of Chemistry, University of Sargodha, Pakistan. This research publication is the result of joint venture of UOS and KFUPM.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jamil, S., Janjua, M.R.S.A. Synthetic Study and Merits of Fe3O4 Nanoparticles as Emerging Material. J Clust Sci 28, 2369–2400 (2017). https://doi.org/10.1007/s10876-017-1256-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10876-017-1256-3