Abstract

An easy to use and robust approach for amino acid type selective isotope labeling in insect cells is presented. It relies on inexpensive commercial media and can be implemented in laboratories without sophisticated infrastructure. In contrast to previous protocols, where either high protein amounts or high incorporation ratios were obtained, here we achieve both at the same time. By supplementing media with a well considered amount of yeast extract, similar protein amounts as with full media are obtained, without compromising on isotope incorporation. In single and dual amino acid labeling experiments incorporation ratios are consistently ≥90% for all amino acids tested. This enables NMR studies of eukaryotic proteins and their interactions even for proteins with low expression levels. We show applications with human kinases, where protein–ligand interactions are characterized by 2D [15N, 1H]- and [13C, 1H]-HSQC spectra.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

For numerous NMR experiments with biological systems it is necessary to produce biomolecules in stable isotope labeled form. Escherichia coli is the expression host of choice for such isotope labeling. However, contemporary research is increasingly targeting eukaryotic and especially human proteins, and many eukaryotic proteins are not expressed in functional form in E. coli. The reasons can be incorrect protein folding and/or lack of important post-translational modifications like disulfide formation. Insect cells have been well-established as a eukaryotic expression host for heterologous proteins and have become the expression method of choice for structural studies if expression in E. coli is not feasible (Suppl. Fig. 1). Insect cells are relatively easy to handle and do not need expensive or highly specialized infrastructure.

Several NMR studies based on stable isotope labeling in insect cells have been published. The ability of insect cells to perform posttranslational modifications was exploited in a study of the 117 amino acid glycoprotein Thy-1 (Walton et al. 2006). Here, besides partial 15N labeling of the protein backbone, 13C labeling of the sugar moieties was achieved, opening the possibility to study glycosylated proteins. In another publication, the solution conformations and dynamics of the 32 kDa protein Abl Kinase in complex with different inhibitors was studied. Backbone assignments were achieved to a completeness of 96%, using a combination of uniform 13C, 15N labeling and selective labeling of 15 amino acids in insect cells. This was the basis for characterizing the different binding modes and protein dynamics induced by different ligands of clinical relevance (Vajpai et al. 2008a, b).

Studies like the ones above require procedures for stable isotope labeling in insect cells. The difficulty compared to E. coli comes from the much more complex media required for insect cell culture, which also renders them more expensive (35–100 USD/l for unlabeled media). Insect cell media typically contain more than 50 ingredients: different carbohydrates (1–10 g/l), all amino acids in pure form (0.1–2 g/l of each), large amounts of yeast extract (4–6 g/l), vitamins, salts, optimized lipid mixtures, and for certain experiments up to 10% fetal calf serum (O’Reilly et al. 1994). In summary, the media contain defined pure ingredients but also complex ones, like yeast extract, which is a mixture in itself. Yeast extract is essential for long term reproducible and robust growth of insect cells and attempts to replace it with defined components have not been successful (O’Reilly et al. 1994). This represents a difficulty for designing media for isotope labeling, where defined minimal media are desired. For the purpose of isotope labeling, except for the salts, all of the ingredients mentioned above represent carbon and/or nitrogen sources. Thanks to the reduced metabolism of insect cells, for 15N labeling only the pure amino acids and the yeast extract need to be taken into account, whereas for 13C labeling also the carbohydrates need to be considered.

There are protocols for uniform labeling, where the important nitrogen and/or carbon sources are replaced by labeled ones (Strauss et al. 2005; Walton et al. 2006), but this remains prohibitively expensive for most laboratories and is not the subject of this work. Nevertheless, in many instances uniform labeling is not necessary and the experimental question can be solved by only labeling selected sites in a protein. Generally, two main approaches for amino acid selective isotope labeling in insect cells have been described. (1) Preparation of media from individual components and adding labeled amino acids (Brüggert et al. 2003) and (2) ordering custom made media lacking one or several amino acids and adding labeled amino acid (Strauss et al. 2003). Strategy (1) is work intense and bears the risk of batch to batch variations. This protocol yields lower amounts of protein than commercial media and isotope incorporation ratios can be low, as relative levels of individual unlabeled amino acids above 30% are present in the medium. Strategy (2) has been successfully applied in the studies of Abl kinase mentioned above (Vajpai et al. 2008a, b). Incorporation ratios of the labeled amino acid are above 90% and isotope scrambling to other amino acids is rarely observed. However, protein yields are reduced to 0–40% compared to expression in non-labeled full media and batch to batch variations are observed, due to individually prepared media for each experiment.

We have developed a robust protocol for isotope labeling in insect cells based on a simple new formulation, allowing preparation of the media in less than 1 h. This procedure is based on strategy (2) described above, but overcomes the problems in yields and reproducibility of these previous protocols without compromising isotope incorporation ratios, i.e. similar yields as in commercial full media can be obtained and typical isotope incorporation ratios are above 90%. Further, our approach can be used with different commercial base media. Therefore, adaptation of insect cell strains to special media or time consuming preparation of media from pure components, as required in strategy (1), are no longer needed. We tested our method with two different media and different proteins for expression yields, reproducibility and isotope incorporation ratios. These experiments include 13C and 15N labeling of different amino acids, as well as labeling of multiple amino acids. Here, we show applications in drug discovery research with kinases. With amino acid selective labeled protein samples, ligand binding experiments are performed, which allow unambiguous determination of specific binding based on chemical shift perturbations of the protein spectrum.

Materials and methods

Preparation of media

Growth media were prepared from amino acid free base media, four concentrated amino acid stock solutions, Tyrosine in powder form and a yeast extract stock solution (Table 1). The amounts of amino acids were adjusted in order to match the composition of full medium containing 6 g/l of yeast extract. The amino acid free base media were purchased from the respective vendors: SF-4 w/o amino acids w/o yeast extract (Bioconcept# 9-02538-l) and ExCell420 w/o amino acids w/o yeastolate (SAFC# 82371C-1,000 ml). All amino acids and yeast extract (Fluka# 70161-500G) were purchased from Fluka. Isotopically labeled amino acids were bought from Cambridge Isotope Labs and Spectra Stable Isotopes.

Amino acid (AA) stock solutions were prepared in the respective amino acid free base medium with subsequent pH adjustment. The aqueous stock solutions contain 4 or 5 amino acids which are grouped according to their solubility (CRC 1977). AA stock solution 1 contains amino acids R, G, H, K and S at 40× concentration, AA stock solution 2 (40×): A, C, P, T and V; AA stock solution 3 (10×): L, I, F and M; AA stock solution 4 (5×) D, N, E, G and W. Due to its low solubility, Tyrosine was added as powder to the final medium. The stock solutions were stored protected from light at 4°C and no deterioration of expression yields could be detected even after 1 year of storage. The exact composition of the amino acid stock solutions is listed in the supplementary material section.

The detailed protocol is available in the supplementary material section. In summary, amino acid stock solutions, except the one containing the amino acid to be labeled, were added to 740 ml of amino acid free base medium. The amino acid to be labeled and the remaining 3 or 4 amino acids in the same stock solution as well as Tyrosine were added as powder. Finally, 10 ml of 6% yeast extract filtrate were added to the medium and it was filled to 1 l with amino acid free based medium (Table 1). The mixture was stirred for 30 min at 30°C until all components were dissolved. A 5 ml sample was removed for measuring the pH offline. Offline pH measurement was carried out to minimize the possibility of contamination with baculovirus from the pH electrode. If needed, the pH was adjusted to 6.2 by titration of the 5 ml sample with NaOH or HCl. A proportional amount of base or acid was added to 1 l of medium and the pH of an aliquot was again measured. The medium was finally filtered through a 0.22 μm Steritop filter (Millipore). In a sterile hood, culture flasks were filled with medium and pre-warmed to 27°C.

Recombinant baculovirus preparation and cell culture

Highly concentrated baculovirus (BV) suspensions of ≥108 plaque forming units per ml (pfu/ml) as determined by plaque assay (O’Reilly et al. 1994) were prepared. Classical BV amplification protocols (O’Reilly et al. 1994) did not yield high enough titers needed for efficient isotope labeling, therefore the protocol of Strauss et al. (2003) was used.

Well-growing pre-cultures of sf9 or sf21 cells were prepared in full SF-4 or ExCell420 medium without serum. The target cell count for the expression culture was 1.5 × 106 cells per ml. To this end, an appropriate volume of pre-culture, typically 250–350 ml for 1 l of expression culture, was transferred into sterile 250 ml centrifuge bottles (Corning) and cells were spun down for 3 min at 300–400×g at room temperature. Centrifugation time was kept to a minimum, as cell viability decreased with the centrifugation time. Under this condition, the pellet is not compact, but enough so, to be able to decant the supernatant. The supernatant medium was carefully decanted immediately after centrifugation and discarded. The cells were immediately resuspended in 50–100 ml of labeling medium from the culture flask and transferred into the culture flask. The centrifuge bottle was rinsed with labeling medium if needed. To the culture flask, virus was added to obtain the desired multiplicity of infection (MOI). Here, the volume of viral stock solution was kept to a minimum (<2% v/v) by using highly concentrated virus (≥108 pfu/ml), as the virus solution contains unlabeled amino acids. Cells were cultured for expression for 72 h and harvested by centrifugation for 10 min at 400×g. The optimal expression time and MOI were assessed previously in small scale experiments.

Analysis of expressed protein

All purification steps were carried out at 4°C. Cells were lysed by sonication and centrifuged at 50,000×g for 30 min. Cleared lysates were purified over Ni–NTA columns (Qiagen) and buffer exchange was carried out using a desalting column. For quantification of protein amounts, the purified protein was analyzed by reverse phase HPLC and quantified by online UV absorption measurement at 215 nm. The HPLC–UV system was previously calibrated with IL-6 standard protein. Molecular mass was determined by LC–MS and incorporation rates were calculated from it. For NMR studies, samples were purified according to an established protocol (Vajpai et al. 2008a) and concentrated to 50 μM. Spectra were recorded at 23°C with a Bruker Avance I 600 MHz spectrometer equipped with a TCI cryoprobe.

Results

We have developed an isotope labeling protocol with improved reproducibility and twofold to threefold higher yields on average than previously published (Strauss et al. 2003). At the same time this procedure only requires about 1 h additional worktime than for unlabeled expression. The protocol is based on commercial serum-free insect cell media (SF-4 or ExCell420) that were ordered without amino acids. To limit the work dedicated to preparation of the media, pure amino acids were added from four concentrated stock solutions with corrected pH value. These solutions were used for several experiments and were tested previously to ensure optimal reproducibility. The target amino acid for labeling was added in powder form.

A factor negatively impacting reproducibility in the earlier protocols were the individual ordering of custom media for each experiment with different amino acids, because batch-to-batch variations of the media had a significant impact on the expression yields, even including failure of expression. In our approach, media were prepared from the same stock solutions, regardless of the amino acid targeted for labeling. A large batch of amino acid free (i.e. also yeast extract free) medium was ordered and supplemented with amino acids from previously tested stock solutions. Pre-cultures of insect cells that were used in our protocol were maintained in the corresponding full medium from the vendor. Thereby costs were generally reduced and no work for preparing custom pre-culture media was needed. For transferring the cells from the full medium to the labeling medium, cells were gently centrifuged, the non-labeled supernatant was decanted and the cells were re-suspended in the labeling medium.

The key to improved yields and reproducibility compared to older labeling protocols, was supplementing the media with ~10% of the normal amount of yeast extract (Fig. 1). The increase in yields was fourfold to fivefold in our experimental series (Fig. 1), and twofold to threefold compared to literature (Strauss et al. 2003), where a different virus stock was used. For Abl Kinase, expression levels of 33 mg of purified protein were assessed for cultures in full SF-4 medium. Using the procedure of Strauss et al. (2003) resulted in average yields of 6 mg/l, ranging from 0 to 11 mg/l. Previous experiments reported in literature with different batches of media and other virus stock yielded 9 mg/l in average (Strauss et al. 2003). With the present approach, including supplementing the media with 0.6 g/l of yeast extract, the yields recovered to 29 mg (25–31 mg/l), which are comparable to the ones obtained when using full medium. For ExCell420 the yields for the present protocol were 27 mg/l, compared to 5 mg/l without addition of yeast extract (Fig. 1).

Protein yields in different insect cell media. SF-4 and ExCell420 media were used as base media for comparing yields of expressed Abl Kinase. Full medium and two labeling media with 15N-Phe were tested: the standard labeling medium (std) (Strauss et al. 2003) and the optimized medium discussed here (opt). Western blots of the soluble fraction of each expression are shown. Abl Kinase was detected using an anti-Abl kinase antibody. Average yields after Ni-purification are shown as columns, the average values, as determined by HPLC–UV215, are indicated below in mg/l. Error bars represent values of 3 to 5 experiments, omitting experiments with no expression at all that occurred with the (std) medium. For ExCell420 only one experiment was performed for each medium

Isotope incorporation ratios

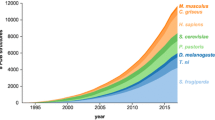

With the addition of yeast extract, non-labeled amino acids are added to the medium and the isotope incorporation ratio is potentially lowered. The incorporation ratio depends on the ratio of labeled amino acids (added to the medium as pure powder) and unlabeled amino acids (added from yeast extract). We therefore calculated the maximum amount of yeast extract that can be added to the medium still allowing incorporation ratios ≥90% for all amino acids. We used the amino acid composition of IPL-41 medium (O’Reilly et al. 1994) for the amounts of pure amino acids in the medium and we have determined the amino acid composition of yeast extract (Suppl. Fig. 2). Using 0.6 g of yeast extract per liter of medium results in relative amounts of unlabeled amino acids below 5% for all amino acid types (Fig. 2). This low level of unlabeled amino acids theoretically enables incorporation rates consistently above 90% for all amino acid residues.

Relative content of amino acids in labeling medium: from pure powder (blue) and from yeast extract (red). The fraction from yeast extract (red parts of the bars) will be unlabeled in a labeling experiment for a given amino acid. The amount of yeast extract in the medium was adjusted to 0.6 g/l such that the unlabeled fraction is below 5% for each amino acid, as indicated by the dashed horizontal line

The amino acids with the potentially highest reduction in isotope incorporation due to unlabeled amino acids from yeast extract are Valine and Leucine (Fig. 2). We demonstrated experimentally that even for these amino acids incorporation rates of 90% or higher are achieved (Table 2; Fig. 3). From this experiment, higher incorporation ratios can be anticipated for other amino acids, provided that they are not subject to metabolic scrambling. For Methionine, Leucine, Lysine, Phenylalanine, Tyrosine and Valine our experiments confirmed this assumption.

NMR spectra of amino acid selective labeled Abl Kinase produced with the presented protocol. a 2D [15N,1H]-HSQC spectrum of 15N-Val labeled Abl Kinase. 15 of the expected 18 signals are visible. b [15N,1H]-correlations of an HNCO spectrum of 15N-Val, 13C1-Leu labeled Abl Kinase (blue) are shown, superimposed on the 2D [15N,1H]-HSQC spectrum of 15N-Val labeled Abl Kinase (grey, same as in a). The three expected HNCO correlations are visible

Dual 13C′-AAy/15N-AAx labeling

High incorporation ratios are particularly important for dual labeling of sequential backbone carbonyl and nitrogen atoms (Weigelt et al. 2002). Here we tested the most unfavorable combination of amino acids, concerning the relative amount from yeast extract, Valine and Leucine. For Abl-kinase, combined incorporation ratios were 92 and 90% for SF-4 and ExCell420 medium, respectively (Table 2). In an HNCO experiment, where the signal strength depends on the product of the incorporation ratios of both involved amino acids, an efficiency of more than 80% was therefore reached. In the resulting spectrum, the three signals were observed that were expected from the amino acid sequence of Abl-kinase. These signals therefore unambiguously identified the Valine resonances with Leucine as the preceding residue (Fig. 3).

An alternative approach for single amino acid labeling

In selected cases of single amino acid labeling, knowledge of the approximate amounts of individual amino acids in the medium allowed an alternative even simpler procedure. It was followed in cases where incorporation ratios were not the highest priority. For this approach, a sufficiently high excess of labeled amino acid was added to regular full media, yielding partially labeled protein (Table 3; Fig. 4). Knowledge of the approximate amounts of individual amino acids in the medium, from yeast extract and from pure amino acids, allowed rough calculation of the expected incorporation of the labeled amino acid. In the example of 15N-Leucine shown here, we assumed 0.5 g of total unlabeled amino acid per liter, and added 2 g of 15N-Leucine in excess. This lead to 84% label incorporation, which was above the expected 80%. We attributed this to lower amounts of Leucine in commercial SF4 medium than in IPL41, and depletion of Leucine in the in the pre-culture medium, which contributed 24% of the final culture volume. Depending on the target amino acid, large amounts of labeled amino acid are required, which may be toxic to the insect cells. Therefore the viability of cells in such a medium with one amino acid in large excess was tested beforehand in a separate experiment.

2D [15N,1H]-HSQC spectrum of 15N-Leu labeled Abl Kinase, produced using full medium and adding 15N-Leu in excess. Twenty five of the expected 26 signals are visible (Table 3)

Ligand binding studies

The capability of selective labeling of proteins with intrinsically low expression yields enables several applications. Here, examples of ligand binding confirmation and determination of the binding site of ligands are shown.

Detection of changes of chemical shifts in the protein spectrum is a reliable experiment for confirming that a ligand binds to a protein in a specific manner. Such changes are often difficult to assess in 1D 1H experiments because of spectral crowding and/or line broadening for large proteins. With 15N- or 13C-labeled protein, 2D spectra with higher resolution can be obtained and chemical shift changes between free protein and protein in the presence of ligand can be precisely monitored.

In Figs. 5 and 6, examples of a kinase from an active drug discovery program are shown—kinase B. The protein was labeled with 15N-Phenylalanine in insect cells using the present protocol. Protein yields were 6 mg/l, similar to expression in full medium, and label incorporation was 93% as judged by mass spectrometry. In 2D [15N, 1H]-HSQC spectra the exact number of expected signals was observed. In these 2D HSQC spectra, specific compound binding to this kinase was clearly demonstrated. Further, a striking difference between spectra of inactive and active form of the kinase could be observed (Fig. 5). This was used to distinguish between compounds that bound to the active (Fig. 5b, c) and inactive conformation of the protein (Fig. 5d), respectively.

Identification of specific ligand binding using 15N-Phe labeled kinase B. The 2D [15N,1H]-HSQC spectrum of the apo form of the protein is shown in panel A. The exact number of expected signals is visible in the spectra of the inactive form of the kinase (a). Specific binding of different compounds is evidenced by chemical shift perturbations of the resonances, compared to the apo spectrum in black (b, c). The compound Dasatinib binds to the active state of this kinase (Das et al. 2006), leading to a qualitatively different spectrum due to internal dynamics (d). Spectra were recorded using 50 μM protein samples with 200 μM compound in 4 h

Identification of ligands using 13Cε-Met labeled kinase B (33 kDa). 2D [13C,1H]-HMQC spectra of the protein with two different ligands (a blue, b red) are shown, individually superimposed on the spectrum of apo protein (grey). Specific binding can be proven by chemical shift perturbations. Spectra were recorded using 50 μM protein samples with 200 μM compound in 30 min

In a different experiment we studied kinase B using a sample that was produced in insect cells with specific 13Cε -Methionine labeling. Here, the incorporation ratio was 94% as determined by mass spectrometry. Despite the size of 33 kDa of the protein, [13C, 1H]-HMQC spectra of high quality were obtained in only 30 min at 50 μM protein concentration. The number of signals agrees with the expected number. Specific binding could be demonstrated for a number of compounds based on clear chemical shift perturbations. As examples, two of them are shown in Fig. 6.

Discussion

We have presented a general protocol for amino acid specific isotope labeling, which is highly reproducible and yields similar protein amounts as expression in full media without reduced isotope incorporation ratio. A further advantage is the limited amount of work needed to prepare the media, as it relies on commercial media. We have applied the approach with the two commercial media that are used in our laboratory, SF-4 and ExCell420. The protocol is easily extendable to other media, provided the vendor offers the media without amino acids and yeast extract or yeastolate. Also yeast extracts from other vendors should be usable, as the amino acid composition of different yeast extracts found in literature (Martini et al. 1979) correlate well with our analysis (Suppl. Fig. 2).

To apply this approach, no changes in the cell cultivation laboratory infrastructure are needed, as cell maintenance and pre-culture can be carried out in standard commercial media. The amino acid free variants of the media were purchased at twice the price of the respective full media, which is still 1–2 orders of magnitude lower than commercial custom prepared isotope labeling media or full labeling media. As all labeling experiments can be carried out with the same basic reagents, the speed of this method is increased compared to approaches based on custom prepared media, which generally require relatively long waiting times upon ordering. Further, the minimal amount for ordering of custom media was 10 l, of which in most cases only a small fraction thereof was used, rendering this procedure less cost effective.

The main improvement over other protocols resulted from the addition of low amounts of non-labeled yeast extract. As we showed, this increases protein yields and improves reproducibility, without compromising the isotope incorporation ratio. The highest ratio of unlabeled amino acid incorporated was 10% for the Valine labeling experiment in ExCell420 medium, which is still low enough for most NMR applications. The incorporated unlabeled amino acids stem from yeast extract, the virus stock solution, the pre-culture and from the endogenous amino acid pool of the cells. However, since it takes 6–8 h for virus infection and start of target protein production, a large fraction of the endogenous amino acid pool is consumed during this time and not incorporated into the target protein. The carry over from the pre-culture is reduced to a neglectable minimum by centrifugation and the use of high tittering recombinant Baculovirus suspension helps to keep this source of unlabeled amino acids below 2%.

We have not further investigated whether the effect of the addition of yeast extract can be reduced to one or a few important components. Several, unsuccessful attempts have been made to replace the yeast extract in insect cell media by defined components, i.e. nucleic acids, fatty acids, etc. (O’Reilly et al. 1994). To our knowledge, to date there is no fully defined medium available in which cells can be cultured for several passages. In the media described here, cell viability started dropping at 4–6 passages, compared to 1–2 in yeast extract free medium. We speculate that components of the yeast extract not only improve cell viability but also facilitate virus infection. Cell diameters at the end of an expression experiment are consistently 1–2 μm larger than diameters of cells grown in yeast extract free cultures. Large cell diameters correlate with efficient viral infection (O’Reilly et al. 1994). Apparently, the components that are important for these effects work similarly well at lower concentrations of yeast extract.

There are, however, possibilities for optimizing the amount of yeast extract used in the medium. The 0.6 g/l suggested here is the amount suited for a general approach for obtaining incorporation ratios ≥90% for any amino acid. However, this concentration can be increased for selective labeling of amino acids that are only present in very low amounts in yeast extract. Therefore, for labeling of e.g. Methionine the original amount of 4–6 g/l yeast extract could be used, bringing the yields to the same level as in full medium. On the other hand, even the use of full medium supplemented with an excess of labeled amino acid can lead to acceptable incorporation ratios, as shown here with the alternative labeling protocol for 15N-Leucine (Fig. 4). With this alternative protocol, the higher yields obtainable with full ExCell420 medium could be exploited. However, toxic effects of high concentrations of individual amino acids or economical considerations limit the general applicability of this approach.

As for other published methods for amino acid specific labeling there are limitations imposed by the metabolism of the cells. The amino acid metabolism of insect cells is much reduced compared to E. coli. For example, labeling of Phenylalanine is not subject of scrambling of the isotopes to other amino acids, which occurs extensively in E. coli cells. However, we do not expect specific and efficient labeling of amino acids with direct roles in the citric acid cycle like glutamic acid and asparagine to be metabolically stable in insect cells. For 15N-Glycine (Strauss et al. 2003) and 15N-Glutamic acid (Strauss, unpublished), cross-labeling to other amino acids was in fact observed.

For most other amino acids incorporation ratios ≥90% should be achievable. High incorporation ratios are of special importance for experiments with dual labeling. As shown in Fig. 3, even for a combination of 15N-Val and 13C1-Leu, such a high ratio is obtained with our approach. This enables HNCO experiments that are indispensable for assigning individual amino acids in a protein, i.e. amino acids directly involved in ligand binding or modulation of protein activity (Vajpai et al. 2008b).

In conclusion, we have shown here an easy to use and robust protocol for amino acid type selective stable isotope labeling in insect cells. It relies on inexpensive commercially available media and can be implemented in laboratories without sophisticated infrastructure. Similar yields as with full media are obtained, yielding isotope incorporation ratios ≥90% for all amino acids tested. This enables NMR studies of eukaryotic proteins and their interactions even for proteins with low expression levels.

References

Brüggert M, Rehm T, Shanker S, Georgescu J, Holak TA (2003) A novel medium for expression of proteins selectively labeled with 15N-amino acids in Spodoptera frugiperda (Sf9) insect cells. J Biomol NMR 25:335–348

CRC (1977) CRC handbook of chemistry and physics. CRC Press Inc., Cleveland

Das J, Chen P, Norris D, Padmanabha R, Lin J, Moquin RV, Shen Z, Cook LS, Doweyko AM, Pitt S, Pang S, Shen DR, Fang Q, de Fex HF, McIntyre KW, Shuster DJ, Gillooly KM, Behnia K, Schieven GL, Wityak J, Barrish JC (2006) 2-aminothiazole as a novel kinase inhibitor template. Structure-activity relationship studies toward the discovery of N-(2-chloro-6-methylphenyl)-2-[[6-[4-(2-hydroxyethyl)-1-piperazinyl)]-2-methyl-4-pyrimidinyl]amino)]-1,3-thiazole-5-carboxamide (dasatinib, BMS-354825) as a potent pan-Src kinase inhibitor. J Med Chem 49:6819–6832

Martini AEV, Miller MW, Martini A (1979) Amino-acid composition of whole cells of different yeasts. J Agric Food Chem 27:982–984

O’Reilly DR, Miller LK, Luckow VA (1994) Baculovirus expression vectors: a laboratory manual. Oxford University Press, Oxford

Strauss A, Bitsch F, Cutting B, Fendrich G, Graff P, Liebetanz J, Zurini M, Jahnke W (2003) Amino-acid-type selective isotope labeling of proteins expressed in Baculovirus-infected insect cells useful for NMR studies. J Biomol NMR 26:367–372

Strauss A, Bitsch F, Fendrich G, Graff P, Knecht R, Meyhack B, Jahnke W (2005) Efficient uniform isotope labeling of Abl kinase expressed in Baculovirus-infected insect cells. J Biomol NMR 31:343–349

Vajpai N, Strauss A, Fendrich G, Cowan-Jacob SW, Manley PW, Grzesiek S, Jahnke W (2008a) Solution conformations and dynamics of ABL kinase-inhibitor complexes determined by NMR substantiate the different binding modes of imatinib/nilotinib and dasatinib. J Biol Chem 283:18292–18302

Vajpai N, Strauss A, Fendrich G, Cowan-Jacob SW, Manley PW, Jahnke W, Grzesiek S (2008b) Backbone NMR resonance assignment of the Abelson kinase domain in complex with imatinib. Biomol NMR Assign 2:41–42

Walton WJ, Kasprzak AJ, Hare JT, Logan TM (2006) An economic approach to isotopic enrichment of glycoproteins expressed from Sf9 insect cells. J Biomol NMR 36:225–233

Weigelt J, van Dongen M, Uppenberg J, Schultz J, Wikström M (2002) Site-selective screening by NMR spectroscopy with labeled amino acid pairs. J Am Chem Soc 124:2446–2447

Acknowledgments

We thank Sylvie Antz and Sébastien Rieffel for maintaining cell stocks, Sihame Haddad and Arun Bhat for helpful feedback on the experimental protocol and René Knecht for the analysis of the amino acid content of yeast extract.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gossert, A.D., Hinniger, A., Gutmann, S. et al. A simple protocol for amino acid type selective isotope labeling in insect cells with improved yields and high reproducibility. J Biomol NMR 51, 449–456 (2011). https://doi.org/10.1007/s10858-011-9570-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10858-011-9570-9