Abstract

Mechanically robust and biomimicking scaffolds are needed for structural engineering of tissues such as the intervertebral disc, which are prone to failure and incapable of natural healing. Here, the formation of thick, randomly aligned polycaprolactone electrospun fibre structures infiltrated with alginate is reported. The composites are characterised using both indentation and tensile testing and demonstrate substantially different tensile and compressive moduli. The composites are mechanically robust and exhibit large strains-to-failure, exhibiting toughening mechanisms observed in other composite material systems. The method presented here provides a way to create large-scale biomimetic scaffolds that more closely mimic the composite structure of natural tissue, with tuneable tensile and compressive properties via the fibre and matrix phases, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Every year, more than 300,000 people in the US alone receive surgery to relieve back pain [1]. Low back pain is frequently linked to degeneration of the intervertebral disc (IVD), a cartilaginous tissue that separates the bony spinal vertebrae, permits a limited range of motion and protects the spine from shock loads [2]. The majority of degenerated discs do not cause long-term debilitating pain, but a minority will through direct mechanical impingement of the spinal cord or aberrant biochemical processes, leading to a severely degraded quality of life [3]. New treatments, which regenerate degenerated disc tissue, are needed. Tissue engineering, using scaffolds with similar structures to the IVD, has been particularly promising in regenerating functional IVD tissue and there is substantial interest in developing biomimetic materials that more closely mimic the native extracellular matrix [4].

Like most soft tissues, the IVD is a fibre-reinforced composite. Both the outer region (the annulus fibrosus; AF) and the inner region (the nucleus pulposus; NP) consist of collagen fibrils (AF: type I, NP: type II) embedded in a gel-like ground substance that consists largely of proteoglycans and water. Composites of polymer nanofibres and hydrogels, which mimic native extracellular matrix, have recently been investigated for tissue engineering applications. Networks of fibres with sub-micron diameters, similar to those found in vivo, can be formed using an electrospinning technique [5]. These fibres can then be infiltrated with hydrogel precursors that are polymerised [6, 7]. Multiple variants on this basic manufacturing process have been proposed, including stacking laminates of electrospun fibre networks together and concurrently spraying hydrogel into the electrospun fibres as they are formed [6, 7]. Thick porous electrospun PCL fibre structures can be fabricated by spinning the fibres into a low-surface tension liquid [8] and recently it was demonstrated that fibre networks can be formed with physiologically-relevant thicknesses using this method and then infiltrated with hydrogels to form truly 3D fibrillar composites [9, 10].

These 3D composites exhibit many of the desirable properties of electrospun fibre networks and hydrogels [6]. Electrospun fibre networks present structural cues to cells and offer improved mechanical strength, while hydrogels provide a full three-dimensional environment with comparable complex mechanical behaviour and nutrient transport. Furthermore, there are a number of characteristic mechanical properties that arise from the interactions between fibre and hydrogel, which are not present for purely electrospun fibre structures or hydrogels [4]. Existing materials developed by embedding 100 μm fibres into hydrogels have demonstrated tensile-compressive nonlinearities, anisotropy, and viscoelastic behaviour [11, 12]. As yet, many of these opportunities for electrospun fibre-hydrogel composites remain unexplored.

Here, we build on preliminary results [10] and investigate the wide range of mechanical behaviour and properties that are available with electrospun fibre-hydrogel composites. Thick 3D electrospun fibre structures are formed and infiltrated with alginate hydrogels of varying compositions. The composites are characterised using tensile and indentation testing. It is shown that the tensile modulus and failure properties of these fibre-reinforced composites is strongly influenced by the fibre network, while the indentation properties (which are representative of compressive properties) are largely influenced by the material properties of the hydrogel. The results presented here illustrate a methodology to create strong fibre-reinforced composites with varying degrees of tensile and compressive mechanical properties.

2 Methods

2.1 Sample preparation

2.1.1 Single phase materials

A mixture of 1:1 dimethylformamide and tetrohydrofuran, containing 14 % w/v PCL (M n = 80,000 g/mol; Sigma Aldrich, UK) was placed in a 50 ml plastic syringe that was connected to a blunt 18 G needle (BD Blunt Fill Needle, Cole-Parmer Instrument Co. Ltd., London, UK) via a PTFE tube. The needle was mounted 14 cm vertically above a glass Petri dish (with a diameter of 11 cm) containing an earthed copper plate. Ethanol was added to the Petri dish containing the earthed copper plate until the fluid was just covering the copper plate.

A voltage of 15 kV was applied between the needle and copper plate using a high voltage supply (EH20P5; Glassman Europe Limited, Hampshire, UK). The polymer solution was pumped through the needle at 0.02 ml min−1 with a Chemyx Fusion 100 Syringe pump (Stafford, TX, USA). During this process, ethanol was also pumped into the Petri dish at 1.5 ml min−1. The flow rate of the ethanol syringe was controlled using a Graseby 3150 syringe pump (Smiths Medical, Smiths Group PLC, UK). PCL fibre structures were collected after ~1 h of electrospinning into ethanol.

Fabricated PCL fibre structures then underwent a process to infiltrate the structures with water. After fully submerging the structures in ethanol, the structures were centrifuged at 500×g to release any trapped air. An orbital shaker was then used to agitate the structures in distilled water for at least 24 h until they were no longer buoyant; the distilled water was changed regularly over the 24 h period. The resultant PCL fibre structures were stored in water until testing or until use for composite manufacture.

Alginate hydrogels (1, 3, and 5 %) and fully-dense PCL samples were manufactured as controls. Solutions of alginate and water were poured into moulds, kept in a −20 °C freezer overnight to control their shape and then placed into a beaker containing 200 mM CaCl2 solution and crosslinked for at least 12 h. In order to make fully-dense PCL samples, PCL pellets were placed into a Petri dish and heated in an oven at 80 °C until molten. A smaller Petri dish was pressed into the molten PCL to form a flat sheet ~1.5 mm thick. The molten PCL was then cooled at room temperature.

2.1.2 Composite fibre-hydrogels

Composite PCL–alginate structures (PCL–Alg) were produced by placing PCL fibre structures into solutions of 1, 3 or 5 % alginate for 6 h. The solutions were gently agitated using a magnetic stirrer. The alginate-containing structures were then placed into 200 mM CaCl2 solution and crosslinked for at least 12 h while agitated using an orbital shaker. These composites were then stored in 200 mM CaCl2 solution until testing.

2.2 Characterisation

2.2.1 Scanning electron microscopy (SEM)

Two electrospun PCL fibre structures and one sample of each type of composite were examined using electron microscopy. Sections were obtained by cutting the samples with a scalpel while wet. Samples were then dried in a desiccator for one week. Finally, samples were coated in gold for imaging at 15 kV using a Carl Zeiss (UK) EVO LS scanning electron microscope.

2.2.2 Fourier transform infrared spectroscopy (FTIR)

Attenuated total reflection infrared spectra of wet samples over the wave number range 4,000–575 cm−1 were obtained using a Spectrum 100 FTIR spectrometer (Perkin Elmer, Waltham, MA, USA). The absorbance spectra were normalised to the largest peak (e.g. A norm = A/A peak, where A is the absorbance), to facilitate comparisons between samples. Spectra were obtained from multiple positions on a sample and averaged together.

2.2.3 Mechanical testing

Both indentation and tensile testing were performed to characterise the elastic modulus and tensile strain-to-failure of the composites and single phase materials using an Instron 5544 universal testing frame with both 5 N and 500 N load cells. Five samples of each composition were used for each test.

Samples for indentation were sliced into rectangular slabs at least 20 mm long and 7 mm wide. PCL fibre and PCL–Alg samples were indented in the through-thickness direction, which was perpendicular to the predominant fibre plane. Indentation tests were carried out using a stainless steel spherical tip with a radius (R) of 4.7 mm on all sample types except fully-dense PCL, for which a 1.5 mm radius tip was used. A small preload (0.5 mN) was applied to the test samples, followed by a 10 s ramp to a peak displacement, h max of 0.3 mm (for the 4.7 mm indenter) or 0.1 mm (for the 1.5 mm indenter). These displacements correspond to indentation strains (\(\epsilon=0.2\sqrt{h/R}\)) of 0.05.

Viscoelastic indentation responses were examined using an elastic–viscoelastic correspondence approach described previously [13, 14]. Briefly, a Boltzmann hereditary integral formulation based on the elastic Hertzian contact solution was used to relate time t, indentation load, P(t) and indentation displacement h(t), assuming a constant Poisson’s ratio ν, according to:

where u is a dummy variable for time. The viscoelastic relaxation function, G(t) was assumed to take the form of a Prony series [13], such that:

where C 0 and C i are amplitude coefficients with units of elastic modulus and τ i are time constants.

The viscoelastic relaxation function of all materials was determined assuming ν = 0.5, except for the fully-dense PCL samples, for which a value of 0.3 was assumed as is typical of a glassy polymer [15]. From G(t), the limiting instantaneous [E 0 = 2G(0)(1 + ν)] and equilibrium [\(E_{\infty}=2G(\infty)(1+\nu)\)] elastic modulus values were calculated, as well as the ratio \(E_{\infty}/E_{0}\), as a measure of the extent of viscoelastic deformation. The identified Prony series G(t) for viscoelastic indentation were also used to predict an equivalent tensile modulus, E pred, that would be measured during testing at a constant strain rate, \(\dot{\epsilon}\). This was determined as the measured stress, σ(t T) at time \(t_{\mathrm{T}} = \epsilon(t_{\rm T})/\dot{\epsilon}\) divided by the applied strain at that time, \(\epsilon(t_{\rm T})\) and was calculated using a Boltzmann hereditary integral formulation for a uniaxial stress in response to an applied strain [16]:

For tensile testing, all samples, except for fully-dense PCL specimens, were cut into rectangular bars ~20 mm × 7 mm in size with a scalpel. The thickness of the samples was determined as the mean thickness of three separate points, using Roebuck 150 mm digital callipers (Buck & Hickman, Coventry, UK). The gauge length (~15 mm) and width of the samples was determined from images of the sample clamped in the grips taken with a PixeLINK PL-B776F 3.1 megapixel camera (Ottawa, ON, Canada). A preload of 0.05 N was applied to the sample followed by an increasing tensile extension (0.1 mm s−1) until failure. Strain was determined as the cross-head displacement divided by the gauge length. The elastic modulus of the samples was calculated by fitting the stress–strain curve in the region of 0–0.1 strain with a straight line using Microsoft Excel (Microsoft, Richmond, VA, USA). The “toughness” of the fibre structures was estimated from the energy per unit volume absorbed prior to failure. The area under the stress strain curve was calculated using the trapezium rule.

Fully-dense PCL specimens were cut into 5 mm wide dog-bone shapes with a 20 mm gauge length using a steel die. Two small marks were made on the gauge length using a permanent marker. Samples were tested at the same displacement rate as the other materials, but with an initial preload of 0.5 N, as the overall load applied was substantially larger. A PixeLINK PL-B776F 3.1 megapixel camera was used to record images at 1 s intervals throughout the test. The sample strain was determined as the change in length between these marks divided by their original length, rather than from the cross-head displacement for improved strain measurement accuracy in the stiffer sample. The elastic modulus of the samples was only calculated from 0 to 0.05 strain as the stress-strain curve was nonlinear for larger strains.

Estimates of the porosity (ϕ) of the fibre structures were obtained from the mean tensile moduli of both the PCL fibre structure and fully-dense PCL materials. Two different estimates of porosity were obtained, one assuming a 3D cellular solid structure [17]:

and the other assuming a planar fibrous network structure:

using the two-dimensional Christensen and Waals [18] composite bounds for fibrous networks assuming a matrix with negligible stiffness. In both cases, it was assumed that the density of PCL fibres was the same as that of fully dense PCL, an assumption that may not always hold for electrospun fibres [19].

3 Results

3.1 Formation of polycaprolactone structures and composites

Thick PCL fibre structures with a thickness of 1.91 ± 0.76 mm were formed. The samples were not buoyant in water suggesting that the samples were completely infiltrated with water and large air-pockets did not remain. When electrospun PCL fibre structures were backfilled with alginate, the thickness of the samples increased from 1.91 ± 0.76 to 2.96 ± 0.45 mm for PCL–1%Alg composites and to 5.43 ± 1.06 mm for PCL–3%Alg composites. The thickness of the PCL–5%Alg composites was not measured as they swelled into a non-uniform shape and large volumes of alginate hydrogel remained attached to the composite, which had to be removed with a scalpel.

3.2 SEM

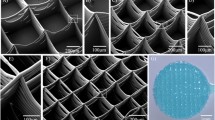

Samples were examined using an SEM. PCL electrospun fibres consisted of a planar layers of randomly-orientated fibres with a diameter of 0.786 ± 0.528 μm (Fig. 1). Both top-down and cross-sectioned micrographs revealed that the PCL structures were substantially porous, providing an opportunity to fill these structures with another material to create large hydrogel-electrospun composites.

Side by side comparison of SEM micrographs of a a PCL electrospun fibre structure and b a PCL–5%Alg composite (1,000× magnification). Although the dehydrated PCL–5%Alg composite still has a fibrillar structure when dried, the fibres are much larger than the electrospun PCL fibres and likely consist of a PCL fibre surrounded by a layer of dehydrated alginate

Examination of dehydrated PCL–Alg composites using SEM demonstrated that alginate had permeated throughout the original PCL fibre structure (Fig. 1). In the PCL–1%Alg system, fibres were clearly visible in a solid matrix. In the PCL–5%Alg system, objects resembling fibres where predominately visible, though the diameter of these objects was substantially larger (3.7 ± 1.7 μm) than the PCL fibres, suggesting that the fibres actually consisted of PCL fibres encased in a layer of alginate (Fig. 1). Minor differences in morphology in the composites was observed for different alginate concentrations, though these differences could be the result of sample-to sample variation.

3.3 FTIR spectroscopy

FTIR spectroscopy revealed that alginate and water had permeated throughout the PCL fibre structure (Fig. 2). The spectra of PCL–3%Alg composites mirrored that of a 3 % alginate hydrogel, with additional peaks at 1,720 and 1,166 cm−1, which are characteristic of the carbonyl and COC bonds found in PCL [20].

3.4 Mechanical characterisation

Fully-dense PCL had a tensile elastic modulus (E) of 219 ± 11 MPa, an instantaneous indentation modulus (E 0) of 245 ± 18 MPa and an equilibrium indentation modulus (\(E_{\infty}\)) of 174 ± 11 MPa . The agreement between the two measurement techniques is excellent: the equivalent predicted tensile elastic modulus (E pred, Eq. 3) determined from indentation was 210 ± 18MPa. Similarly, the elastic moduli of alginate hydrogels measured with tension and indentation were equivalent (Fig. 3). However, an order of magnitude difference between tensile and indentation elastic moduli was observed for electrospun PCL fibre structures.

Tensile elastic modulus and predicted equivalent elastic modulus (Eq. 3) determined from indentation for single phase materials

The modulus of alginate hydrogels increased with concentration (Fig. 4). Alginate was also significantly more viscous than PCL. Fully-dense PCL and electrospun PCL fibres demonstrated similar viscoelastic ratios (0.71 ± 0.01 vs. 0.61 ± 0.09), whereas alginate gels had a mean viscoelastic ratio of 0.18 ± 0.024. The viscoelastic ratio did not vary with alginate concentration.

Viscoelastic moduli of single phase materials and composites tested in a indentation and b tension. The predicted equivalent elastic modulus (E pred, Eq. 3) determined from indentation is also plotted in b for comparison

When electrospun fibre structures were backfilled with alginate hydrogels to form PCL–Alg composites, the indentation modulus increased. It can be seen from Fig. 4 that the indentation modulus of the PCL–Alg composites is dominated by the alginate phase. Little difference can be observed in both E 0 and \(E_{\infty}\) of the PCL–3%Alg composite and a pure 3 % alginate hydrogel. Similar behaviour was noted for the other composite systems. The viscoelastic ratio of the composites (0.22 ± 0.07) was much more similar to that of pure alginate hydrogels than that of PCL fibres. In contrast, the tensile moduli of PCL–Alg composites did not vary substantially from that of the electrospun fibre structures (Fig. 4). As the tensile modulus of the composites was similar to that of the PCL fibres and the indentation modulus was similar to that of the alginate phase, increasing the concentration (and hence modulus) of the alginate phase in the composites reduced the discrepancy between the measured tensile and indentation modulus.

PCL–Alg composites also demonstrated different failure behaviour to PCL and alginate (Figs. 5, 6). During tensile testing, alginate gels exhibited failure without post-yield deformation, with moderate strains-to-failure, regardless of concentration. In contrast, PCL fibre structures exhibited extremely large strains-to-failure (>300 %). Similar trends were noted for tensile strength. Energy per unit volume absorbed prior to failure exhibited the same trends, where average values were smaller than 20 kJ m−3 for all alginate concentrations, 450 kJ m−3 for PCL fibres in isolation, and declining from 300 kJ m−3 for PCL–1%Alg to 160 kJ m−3 for PCL–5%Alg. During tensile testing, stable necking of PCL fibre structures would occur until the structure appeared to be connected by a sole fibre bundle, which would eventually break. PCL–Alg composites exhibited behaviour in between these two extremes: PCL–1%Alg composites failed similarly to PCL fibre structures, PCL–3%Alg composites failed after the formation of a small number of fibre bundles and PCL–5%Alg composites failed after the formation of multiple fibre bundles throughout the matrix, although little visible macroscopic necking was observed (Fig. 6). As the concentration of alginate increased in the composites, the strain-to-failure decreased although it was still markedly greater than pure alginate even in the PCL–5%Alg system.

a Composite bounds calculated for two PCL–Alg composites from tensile elastic moduli plotted on a semi log scale. The upper and lower Voigt–Reuss bounds correspond to laminar composites undergoing equal stress and equal strain loading, respectively, while the Christensen and Waals [18] bounds represent random fibrous networks orientated in a two-dimensional plane or three-dimensional volume. Experimental data points for tension (solid markers) and indentation (E pred, hollow markers) are also plotted using approximate PCL volume fractions determined from the porosity estimates in Sect. 3.5. b The upper Voigt–Reuss and two-dimensional Christensen–Waals bounds are similar to the values observed in tension, while the lower Voigt–Reuss bound is similar to what was observed during indentation

3.5 Porosity

The porosity of the electrospun fibre structure was estimated from the tensile modulus of the PCL fibre structure (344 kPa) and the elastic modulus of fully-dense PCL (219 MPa). The porosity estimated assuming a two-dimensional planar fibre structure is 99.5 % (Eq. 5), while the porosity assuming a three-dimensional cellular solid structure is 96 % (Eq. 4). In either case, the fibre structures are extremely porous, which confirms their potential utility for infiltration with a hydrogel matrix.

When the composite structures were impregnated with alginate, they swelled in volume reducing the effective volume fraction of PCL. In the case of the PCL–1%Alg system, the total material volume increased by 155 %, assuming the length and width remained constant and only the thickness changed. During swelling the volume of PCL would remain constant. Hence, the volume fraction of PCL in these composites, post swelling, can be estimated from the porosity and swelling ratio as being between 0.03 and 2.5 %. Similarly, the total material volume of the PCL–3%Alg system increased by 280 % and the volume fraction of PCL can be estimated as 0.2–1.4 %. A swelling ratio was not calculated for the PCL–5%Alg system, but it is likely similar to the PCL–3%Alg composites. The fibres comprise an extremely small fraction of all of the composites. Nevertheless, because of the substantial modulus mismatch between dense PCL and alginate, the PCL dominates the tensile mechanical properties of the materials.

4 Discussion

In this work, thick and very porous 3D electrospun fibre structures were fabricated. The porosity of the structures was estimated, based on modulus comparisons between the modulus of the fibrous mats and modulus of fully dense PCL, to be in the upper ninetieth percentile, consistent with measured values for electrospun mats [21]. These structures were infiltrated with water and then with alginate gel in order to form solid fibre-reinforced hydrogels with varying tensile-compressive properties. On cross-sectioning the gels, fibres were visualised throughout the thickness, although the local fibre density did vary somewhat. These fibre-gel composites exhibit unique mechanical properties that are strongly influenced by their structure, with individual structural components dominating responses in different mechanical testing modes. The structure and composition of these composites can be altered to design tissue engineering scaffolds with targeted mechanical properties.

It was found that the tensile properties of the composites were largely dominated by the presence of the electrospun PCL fibres while the compressive properties (as determined with indentation) were dominated by the modulus of the hydrogel phase. It is unclear whether this behaviour results from a material tensile-compressive nonlinearity or the transverse isotropy of the structure (due to the dominantly planar orientation of the fibres). Both mechanisms have been used to characterize the compressive properties of articular cartilage. Further characterisation of the PCL–alginate composites will need to be performed to verify which description best applies.

Nevertheless, the observed trends can be predicted from the composite bounds for elastic modulus. Fig. 7 shows upper (E U) and lower (E L) Voigt–Reuss composite bounds on tensile elastic modulus for a PCL–1%Alg system and PCL–5%Alg system for PCL volume fractions of <5 % plotted on a semi-log scale.

where V 2 and E 2 are the volume fraction and elastic modulus of the PCL fibres and E 1 is the elastic modulus of the hydrogel matrix. The figure also shows the Christensen and Waals [18] bounds for two-dimensional and three-dimensional randomly orientated fibre networks:

For the small volume fractions of PCL considered here, the lower Voigt–Reuss bound, which represents a material where strains are applied perpendicular to the predominant fibre direction, is very sensitive to the modulus of the alginate phase but is not very sensitive to the volume fraction of PCL. In contrast, the upper Voigt–Reuss bound and both Christensen–Waals bounds are not very sensitive to the modulus of the alginate phase, but are linearly proportional to the volume fraction of PCL in the composite. Any increase in tensile modulus due to an increase in the modulus of alginate would likely have been offset by changes in the volume fraction of PCL due to swelling. This suggests that the tensile modulus of the fibre-reinforced hydrogels could potentially be increased or decreased by varying the volume fraction of the PCL, either by changing the initial electrospinning parameters, or by controlling the swelling of the composites. In preliminary experiments, it was demonstrated that PCL fibre structures (and composites) could be formed with tensile moduli of between 500 and 1,100 kPa [10]. Meanwhile, the compressive modulus, which is of primary importance for materials that mimic the NP, could be controlled by altering the concentration of the hydrogel matrix.

Fibre-reinforced hydrogels were also much more robust to failure than pure alginate hydrogels. Even the PCL–3%Alg system, for which the tensile modulus was comparable to 3 % alginate, had a strain-to-failure which was five times greater than that of pure alginate and an estimated toughness that was ten times greater. It has been observed that electrospun PCL fibre networks will reorient along the principle loading direction at large strains [22]. It is likely that the PCL fibre networks behaved similarly in tension tests. In the PCL–Alg composites, the alginate matrix would have resisted this fibre-reorientation, particularly for larger concentrations. This resulted in a more brittle failure, at a lower failure strain. Still, for the PCL–5%Alg system, fibre pull-out was observed throughout the matrix at failure. Fibre pull-out contributes to the toughness of a material, by absorbing fracture energy during crack advance [23]. While the compressive and shear strength of the material (which have not been investigated here) are equally important to the tensile strength for many applications, including NP tissue engineering, the presence of these strengthening mechanisms in tension is promising as it suggests an opportunity to create hydrogel-like materials with sufficient toughness to withstand the loading encountered during implantation and in vivo.

The fibre-reinforced hydrogels were slightly less time-dependent than pure alginate, but were much were much more time-dependent than PCL fibre structures. Cottenden and Oyen [24] used composite theory of viscoelastic materials to show that the viscoelastic ratio of a viscoelastic matrix reinforced with elastic fibres could be markedly different from the viscoelastic ratio of the matrix; the elastic fibres suppressed time-dependent behaviour in the matrix for moderate fibre volume fractions. Here, the PCL fibres were much more ‘elastic’ than the alginate matrix, though there was little suppression of viscoelastic response, despite the significant modulus mismatch between the phases. This could potentially stem from the extremely small volume fraction of PCL fibres. As the volume fraction increases the viscoelastic ratio of the composites may also increase, resulting in more 'elastic' materials.

However, the composites produced here are not purely viscoelastic. Experiments have demonstrated that ionically crosslinked alginate exhibits both poroelastic behaviour arising from fluid flow and viscoelastic behaviour arising from the time-deformation of the polymer network [25, 26]. In contrast to viscoelastic theory, theories of poroelasticity that incorporate a tensile-compressive nonlinearity (e.g. [27, 28]), such as would be found in a fibre-reinforced hydrogel, predict that the extent of relaxation under compressive loading will be greater than that of materials without a tensile-compressive nonlinearity. This occurs because the fibres constrain the radial expansion of the material, increasing fluid pressurisation. This behaviour has been observed in articular cartilage. Here, the time-dependent behaviour of the composites arises from the viscoelasticity of the electrospun fibre network, viscoelasticity of the alginate polymer network, and poroelasticity of fluid passing through the composite. Although the interacting effects are numerous, they could potentially be decoupled using an approach similar to Galli et al. [29], who investigated the PVE properties of particle-reinforced gelatin through homogenisation for viscoelastic parameters and intrinsic permeability.

It is is instructive to consider how the structure and properties of the biomimetic composites fabricated here compare to native tissue. Many soft tissues consist of collagen fibres embedded in a hydrogel-like matrix. The fibres provide stiffness and strength in tension, while also moderating the time-dependent response of the material in compression. The gel-phase swells and provides a mechanism to support and distribute compressive load, through fluid pressurisation. In the IVD, the AF consists of alternating laminates of type 1 collagen fibrils aligned at ±30 °C to the circumferential direction of the disc. The tensile circumferential modulus of multilaminate AF samples is ~17.4 ± 14.3 MPa [30], while the radial compressive aggregate modulus ranges from 0.27 to 0.44 MPa [31]. Here, electrospun fibres were randomly distributed in a plane, though they did still exhibit a tensile-compressive nonlinearity, with varying mechanical properties in the planar and through thickness direction. This nonlinearity could potentially be matched to that of the AF by increasing the concentration of fibres. Furthermore a laminated structure could potentially be created by following a method similar to that reported previously [32, 33].

Unlike previous studies of AF-like fibre composites where electrospun fibre laminates were wrapped around a hydrogel [32, 33], here the electrospun fibres were infiltrated with a hydrogel. This is likely to be important for the time-dependent behaviour of the material. One of the functions of the AF is to inhibit fluid flow away from the NP in order to maintain fluid pressurisation [34, 35]. Although the permeability of the composites was not measured here, the time-dependent behaviour of the composites was substantially different from that of the electrospun fibre structures. This could have been due to restricted fluid flow through through the alginate matrix. Infiltrating porous fibre structures with a semi-permeable hydrogel may be crucial to achieving a functional engineered IVD, with minimal culture time.

In contrast to the AF, the NP is thought to be isotropic and it is not known whether its network of randomly orientated collagen fibrils, which comprise 2 % of its wet weight [35], have a substantial mechanical function. Nevertheless, the compressive mechanical properties of the NP have been correlated with the mean diameter of the collagen fibrils [36]. Furthermore, the tensile properties of the NP (which have not been measured) may be important for a mechanically robust implant. Smolders et al. [37] implanted synthetic hydrogel implants into canine spines and found that 50 % of the retrieved implants were damaged. The authors proposed that the implants may have failed in tension due to tensile stresses applied from a “wedging” motion. Fibrous networks and fibre-reinforced hydrogels have only been investigated to a limited extent as NP scaffolds [38]. The NP is much thicker (7–12 μm; [39]) than what can be achieved using a conventional electrospinning process and these scaffolds lack compressive mechanical integrity. The work carried out here provides a method to produce composites of comparable thickness to the NP with a similar proportion of hydrogel and fibres.

5 Conclusions

In this work, the creation of large three-dimensional electrospun fibre-hydrogel composites has been demonstrated. The composites exhibit a differing tensile and compressive properties that can be tuned by varying the concentration and volume fractions of the constituent materials. Even with a very small volume fraction of fibres, the composites are much more mechanically robust than pure hydrogels. The method presented here can be used to fabricate materials that mimic the fibrous nature of natural tissue with combinations of mechanical properties optimised for tissue engineering applications.

References

Katz JN. Lumbar spinal fusion. Surgical rates, costs, and complications. Spine. 1995;20(24 Suppl):78S–83S.

Atlas SJ, Nardin RA. Evaluation and treatment of low back pain: an evidence-based approach to clinical care. Muscle Nerve. 2003;27(3):265–84.

Manchikanti L, Singh V, Pampati V, Damron K, Barnhill R, Beyer C, Cash K. Evaluation of the relative contributions of various structures in chronic low back pain. Pain Physician. 2001;4(4): 308–16.

Nerurkar NL, Han W, Mauck RL, Elliott DM. Homologous structure–function relationships between native fibrocartilage and tissue engineered from MSC-seeded nanofibrous scaffolds. Biomaterials. 2011;32(2): 461–8.

Teo WE, Ramakrishna S. A review on electrospinning design and nanofibre assemblies. Nanotechnology. 2006;17(14):R89–106.

Bosworth LA, Turner LA, Cartmell SH. State of the art composites comprising electrospun fibres coupled with hydrogels: a review. Nanomedicine. 2012;9(3): 322–35.

Shapiro J, Oyen M. Hydrogel composite materials for tissue engineering scaffolds. JOM. 2013;65(4):505–16.

Hong S, Kim G. Fabrication of size-controlled three-dimensional structures consisting of electrohydrodynamically produced polycaprolactone micro/nanofibers. Appl Phys A. 2011;103:1009–14.

Coburn J, Gibson M, Bandalini P, Laird C, Mao HQ, Moroni L, Seliktar D, Elisseeff J. Biomimetics of the extracellular matrix: an integrated three-dimensional fiber-hydrogel composite for cartilage tissue engineering. Smart Struct Syst. 2011;7(3): 213–22.

Strange DGT, Tonsomboon K, Oyen ML. MRS Proceedings. 2012:1417. doi:http://dx.doi.org/10.1557/opl.2012.742

Moutos FT, Freed LE, Guilak F. A biomimetic three-dimensional woven composite scaffold for functional tissue engineering of cartilage. Nat Mater. 2007;6(2):162–7.

Agrawal A, Rahbar N, Calvert P. Strong fiber-reinforced hydrogel. Acta Biomater. 2013;9(2):5313–8.

Mattice J, Lau A, Oyen M, Kent R. Spherical indentation load-relaxation of soft biological tissues. J Mater Res. 2006;21(8): 2003–10.

Strange DGT, Oyen ML. Composite hydrogels for nucleus pulposus tissue engineering. J Mech Behav Biomed Mater. 2012;11: 16–26.

Greaves GN, Greer AL, Lakes RS, Rouxel T. Poisson's ratio and modern materials. Nat Mater. 2011;10(11):823–37.

Lakes RS. Viscoelastic materials. Cambridge: Cambridge University Press; 2009.

Gibson L, Ashby M. Cellular solids: structure and properties. Cambridge: Cambridge University Press; 1999.

Christensen R, Waals F. Effective stiffness of randomly oriented fibre composites. J Composite Mater. 1972;6(4): 518–32.

Stachewicz U, Bailey RJ, Wang W, Barber AH. Size dependent mechanical properties of electrospun polymer fibers from a composite structure. Polymer. 2012;53(22): 5132.

Elzein T, Nasser-Eddine M, Delaite C, Bistac S, Dumas P. FTIR study of polycaprolactone chain organization at interfaces. J Colloid Interface Sci. 2004;273(2):381–7.

Stachewicz U, Modaresifar F, Bailey RJ, Peijs T, Barber AH. Manufacture of void-free electrospun polymer nanofiber composites with optimized mechanical properties. ACS Appl Mater Interfaces. 2012;4(5):2557–82.

Koh C, Strange D, Tonsomboon K, Oyen M. Failure mechanisms in fibrous scaffolds. Acta Biomater. 2013;9(7):7326–34.

Chawla K. Composite materials: science and engineering. Berlin: Springer; 1998.

Cottenden D, Oyen M. Quantitative modelling of viscoelasticity of isotropic fibrous composites with viscoelastic matrices. Theor Appl Mech Lett. 2011;1(5):052006.

Zhao X, Huebsch N, Mooney DJ, Suo Z. Stress-relaxation behavior in gels with ionic and covalent crosslinks. J Appl Phys. 2010;107(6):063509.

Strange DGT, Fletcher TL, Tonsomboon K, Brawn H, Zhao X, Oyen ML. Separating poroviscoelastic deformation mechanisms in hydrogels. Appl Phys Lett. 2013;102: 031913.

Cohen B, Lai W, Mow V. A transversely isotropic biphasic model for unconfined compression of growth plate and chondroepiphysis. J Biomech Eng. 1998;120(4): 491–6.

Soltz M, Ateshian G. A conewise linear elasticity mixture model for the analysis of tension-compression nonlinearity in articular cartilage. J Biomech Eng. 2000;122(6):576–86.

Galli M, Fornasiere E, Cugnoni J, Oyen ML. Poroviscoelastic characterization of particle-reinforced gelatin gels using indentation and homogenization.J Mech Behav Biomed Mater. 2011;4(4): 610–7.

Elliott DM, Setton LA. Anisotropic and inhomogeneous tensile behavior of the human anulus fibrosus: experimental measurement and material model predictions. J Biomech Eng. 2001;123(3): 256–63.

Best B, Guilak F, Setton L, Zhu W, Saed-Nejad F, Ratcliffe A, Weidenbaum M, Mow V. Compressive mechanical properties of the human anulus fibrosus and their relationship to biochemical composition. Spine. 1994;19(2):212–21.

Nerurkar NL, Baker BM, Sen S, Wible EE, Elliott DM, Mauck RL. Nanofibrous biologic laminates replicate the form and function of the annulus fibrosus. Nat Mater. 2009;8(12):986–92.

Nerurkar NL, Sen S, Huang AH, Elliott DM, Mauck RL. Engineered disc-like angle-ply structures for intervertebral disc replacement.. Spine. 2010;35(8):867–73.

Chiu E, MD P, Newitt D, Segal M, Hu S, Lotz J, Majumdar S. Magnetic resonance imaging measurement of relaxation and water diffusion in the human lumbar intervertebral disc under compression in vitro. Spine. 2001;26(19): E437–44.

Ohshima H, Tsuji H, Hirano N, Ishihara H, Katoh Y, Yamada H. Water diffusion pathway, swelling pressure, and biomechanical properties of the intervertebral disc during compression load. Spine. 1989;14:1234-44.

Aladin DMK, Cheung KMC, Ngan AHW, Chan D, Leung VYL, Lim CT, Luk KDK, Lu WW. Nanostructure of collagen fibrils in human nucleus pulposus and its correlation with macroscale tissue mechanics. J Orthop Res. 2010;28(4):497–502.

Smolders LA, Bergknut N, Kingma I, van der Veen AJ, Smit TH, Koole LH, Hazewinkel HAW, Meij BP. Biomechanical evaluation of a novel nucleus pulposus prosthesis in canine cadaveric spines. Vet J. 2012;192(2):199–205.

Nesti LJ, Li WJ, Shanti RM, Jiang YJ, Jackson W, Freedman BA, Kuklo TR, Giuliani JR, Tuan RS. Intervertebral disc tissue engineering using a novel hyaluronic acid-nanofibrous scaffold (HANFS) amalgam. Tissue Eng Part A. 2008;14(9):1527–37.

Gilad I, Nissan M. A study of vertebra and disc geometric relations of the human cervical and lumbar spine. Spine. 1986;11(2):154–157.

Acknowledgements

The authors would like to acknowledge Vera Malheiro, Oliver Armitage and Timothy Fletcher for helpful discussions. DGTS acknowledges the Cambridge Commonwealth Trust and the Nano Science and Technology Doctoral Training Centre Cambridge and KT acknowledges the Thai government for funding.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Strange, D.G.T., Tonsomboon, K. & Oyen, M.L. Mechanical behaviour of electrospun fibre-reinforced hydrogels. J Mater Sci: Mater Med 25, 681–690 (2014). https://doi.org/10.1007/s10856-013-5123-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-013-5123-y