Abstract

This study reports on the biocompatibility of 316 LVM steel blasted with small and rounded ZrO2 particles or larger and angular shaped Al2O3 particles. The effect of blasting on the in vitro corrosion behavior and the associated ion release is also considered. Surface of Al2O3 blasted samples was rougher than that of ZrO2 blasted samples, which was also manifested by a higher surface area. Compared to the polished alloy, blasted steels exhibited a lower corrosion resistance at the earlier stages of immersion, particularly when using Al2O3 particles. With increasing immersion time, blasted samples experienced an improvement of the corrosion resistance, achieving impedance values typical of passive alloys. Blasting of the alloy led to an increase in Fe release and the leaching of Ni, Mn, Cr and Mo. On all surfaces, ion release is higher during the first 24 h exposure and tends to decrease during the subsequent exposure time. Despite the lower corrosion resistance and higher amount of ions released, blasted alloys exhibit a good biocompatibility, as demonstrated by culturing osteoblastic cells that attached and grew on the surfaces.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Austenitic stainless steel 316 LVM (Low Vacuum Melting) is one of the most frequently used biomaterials for internal fixation devices because of a good combination of mechanical properties, biocompatibility and cost effectiveness [1]. One common failure encountered in stainless steel devices arises from corrosion attack, which may decrease the structural integrity of the implants and elicit adverse local and remote tissue responses mediated by corrosion products [2–4]. In fact, elevated serum Cr levels were found in patients treated with stainless steel modular femoral nails [5]. Retrieved modular nails presented signs of stainless-steel corrosion products adherent to the junction where osteolysis, periosteal reaction, or cortical thickening were detected. Thus, the failure of stainless steel implant devices has been associated to inflammatory reactions in peri-implant soft tissues [5–7]. Mechanical factors such as applied stress, wear and micro motion may accelerate electrochemical dissolution, leading to premature structural failure of the implant and accelerated metal ion release [8, 9]. Therefore, mechanical stability of implanted stainless steel in contact with bone tissue and body fluids is of fundamental importance to ensure the implant success.

Severe surface plastic deformation of 316 LVM by grit blasting is considered an attractive modification to improve fatigue strength of intramedullary nails for the proximal femur and diaphysary fractures, providing an optimal combination between high resistance during the consolidation period and a minimal invasive geometry. Besides roughening, this surface treatment modifies the mechanical properties of the surface and near surface region through the induced compressive residual stresses. Whereas a number of studies have addressed the blasting induced effects on titanium and titanium alloys [10–14], there are only a few reports concerning the effect of blasting on corrosion resistance of stainless steels [15] and cytocompatibility of surface-treated stainless steel with bone-forming cells [16].

This study deals with austenitic stainless steel 316 LVM modified by blasting of the surface with small and rounded ZrO2 particles or larger and angular shaped Al2O3 particles. The influence of surface blasting of austenitic stainless steel 316 LVM on osteoblastic cell adhesion and proliferation, functions that play a key role during cell colonization of the implant, was evaluated. Other surface dominated events such as corrosion behavior and ion release were also addressed. The effects of blasting on the subsurface residual stresses and mechanical properties have been reported elsewhere [17–19].

2 Experimental procedures

2.1 Materials

Austenitic stainless steel 316 LVM, which chemical composition (wt%) is Cr 17.48, Ni 14.13, Mo 2.87, Mn 1.62, Si 0.53, C 0.024, Cu 0.067, N 0.061, S 0.001 and Fe in balance, was supplied by the implant manufacturer (Surgical SL, Valencia, Spain). Discs of 20 mm diameter and 2 mm thick, hereafter PL samples, were grinded and polished by conventional metallographic techniques. A final finishing was applied with silica gel. A set of samples was blasted with small and rounded ZrO2 particles or larger and angular shaped Al2O3 particles, hereafter BL-ZrO and BL-AlO samples, under the same experimental conditions. Blasted and polished samples were finally passivated in citric acid (20%) at 40°C during 30 min. For cell culture and ion release studies, all the samples were routinely sterilized under UV light in a laminar flow hood for 12 h on each side and stored until use [18].

2.2 Surface characterization

Topographic surface analysis was performed with an interferometer optical profilometer NT1100 (Wyco-Veeco, Santa Bárbara, CA, USA) using a Vertical Scanning Interferometry mode. This experimental setting provides with a vertical resolution of <1 nm and a lateral resolution of 400 nm. Ra (μm), Rq (μm), Rz (μm), Rt (μm), and real surface area (mm2) were determined at 5X, 20X, and 50X magnifications, which yields fields of view of 1.092, 0.068 and 0.011 mm2, respectively. Surface Skewness, Ssk, which can be interpreted as the degree of asymmetry of a surface height distribution, was determined from 5X images. Average values correspond to ten fields of view.

The geometric surface area (A) was 6.41 cm2 for all the discs. The area increase after blasting corresponds to the area ratio (%) of measured surface/scanned surface and allows determining an index area.

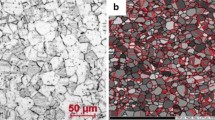

Microstructural characterization of surfaces and cross sectional views were performed by using a scanning electron microscope (SEM) Jeol JSM-6500F (Japan) equipped with a field emission gun (FEG) emitter coupled with an energy dispersive X-ray (EDX) system for chemical analysis. Depending of the analysis, secondary (SEI) or backscattered (BEI) electron images were selected.

2.3 Cell culture assays

In vitro biocompatibility of the samples was evaluated by using human osteoblastic Saos-2 cells (ECACC, Salisbury, Wiltshire, UK). Cells were grown in Dulbecco’s modified Eagle’s medium (DMEM) (Lonza, Barcelona, Spain) supplemented with 10% (v/v) heat-inactivated fetal bovine serum (FBS), 500 UI/ml of penicillin and 0.1 mg/ml of streptomycin and maintained at 37°C in 5% CO2 in a humidified incubator.

For adhesion assays, cells were seeded on the investigated surfaces in 12-well plates (5 × 104 cells/well) and incubated for 2, 4 and 6 h. Cell adhesion was assessed using the alamarBlue assay (Biosource, Nivelles, Belgium) which incorporates a redox indicator that fluoresces in response to cellular metabolic reduction. After washing extensively with PBS, attached cells were incubated in DMEM containing 10% alamarBlue dye for 4 h. After excitation at 530 nm, the fluorescence emitted at 590 nm was quantified using a microplate reader Synergy 4 (BioTek Instruments, Winooski, VT, USA). For viability assays, cells were seeded on the surfaces in 12-well plates (1.5 × 104 cells/well) and cultured for 1, 4 and 7 days. Cell viability was determined using the alamarBlue assay as described above. Cells cultured on tissue culture-treated polystyrene 12-well plates (PS) (Nunc, Roskilde, Denmark) were used as controls for cell adhesion and viability assays. All experiments were carried out at least twice, each in duplicate, with similar results.

2.4 Corrosion experiments

Electrochemical impedance spectroscopy (EIS) tests were performed in a conventional electrochemical cell filled with the Ringer’s solution (8.36 g of NaCl, 0.3 g of KCl, and 0.15 g of CaCl2 in each 1,000 ml of distilled water) and using the sample as working electrode. A counter electrode of platinum and a reference electrode of Ag/AgCl saturated in a potassium chloride solution were used. The EIS measurements were performed using a potentiostat/galvanostat AutoLab EcoChemie PGSTAT30 (Eco Chemie, Utrecht, The Netherlands) equipped with a FRA2 frequency response analyzer module. Frequency scans were carried out close to the corrosion potential. Sinusoidal wave perturbations of ±10 mV in amplitude were applied in the frequency range of 100 kHz to several mHz. Five impedance sampling points were registered per frequency decade. The EIS measurements were made after 5 min and 24 h of immersion. The impedance data were analyzed by using the ‘EQUIVCRT’ program [20].

2.5 Ion release

Samples were incubated in 30 ml of the Ringer’s solution in a humidified 5% CO2 atmosphere at 37°C for up to 4 days. At every 24 h period, 23 ml of solution were removed and replaced by fresh one, in order to simulate the fluid exchange of an adult human by the excretion of urine, as described elsewhere [21, 22]. Released ions in the solutions were quantitatively analyzed using an Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES Perkin–Elmer Model Optima 3300 DV, Palo Alto, CA, USA). Calibration solutions of Cr, Fe, Mn, Mo and Ni were prepared by appropriate dilution of 1,000 mg.L−1 multielemental CertiPur grade (Merck, Darmstadt, Germany) standards solutions. The solutions were prepared using the Ringer’s solution as matrix. All solutions were 1% (v/v) in nitric acid. All experiments were performed by triplicate. The amount of released ions was calculated as mass per volume unit (μg ml−1) or per unit area (μg·cm−2). Detection limits of the ICP for the investigated metals were <0.007 μg ml−1.

3 Results

3.1 Microstructural characterization

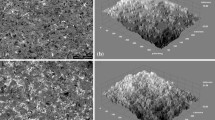

Blasting of the alloy causes a severe surface plastic deformation that leaves a rough surface (Fig. 1). A closer examination of the BL-AlO samples reveals the presence of embedded particles with polygonal edges, which are often broken forming agglomerates of fine particles. Particles found on the BL-ZrO samples, however, present soft edges and seems to be plastically deformed on the surface. EDX analysis revealed they are remnants of the particles used for blasting, thus Zr, Al and Si-rich oxides are found in sample BL-ZrO and Al-rich oxide in BL-AlO.

Topographic parameters shown in Table 1 reveal a higher roughness (Ra) for the samples blasted with alumina, which evidences the higher erosion and plastic deformation of this surface. The roughness increase is obviously accompanied with a significant increase in the surface area (up to about 170% for the BL-AlO sample). The observation of a number of irregular intrusions and protrusions with sharp ridges in the alumina blasted surfaces is consistent with their higher Rt values, which denotes the average distance between the higher tenth picks and the deeper tenth valleys. From the analysis of the Skewness parameter it follows that the polished surface, with an average values well above zero, is a flat surface with peaks. BL-AlO presents values well below zero, which indicates is a surface mainly composed with holes. The nearly zero value found for the BL-ZrO samples denotes a surface with holes having the most symmetric height distribution respect PL and BL-AlO samples. Since Ssk values are numerically below one, the presence of extreme holes or peaks on the blasted surfaces are not expected. All these parameters calculated from the three fields of view shows a strong consistency.

Cross sectional examination confirmed the presence of remnant of the blasting particles embedded at the surface and the development of a narrow zone (10–15 μm) with an ultrafine grain size (Fig. 2). Taking into consideration the gradients in hardness and compressive residual stresses, blasting affected zones of about 150 and 200 μm were determined for the BL-ZrO and BL-AlO samples, respectively [18].

3.2 Biocompatibility

Next, we investigated whether blasting of 316 LVM affects osteoblast-like Saos-2 cells adhesion and viability. The number of attached cells increased with time on the three tested surfaces (Fig. 3a). The process of grit blasting did not significantly affect the number of attached cells at any tested time. Cell growth increased over time on both polished and rough surfaces, as indicated by measurements of metabolic activity (Fig. 3b). Cell viability was similar on the three studied surfaces at days 1 and 4. At day 7, the number of viable Saos-2 cells on the BL-AlO samples was lower than on PL and BL-ZrO samples (Fig. 3b).

Cell attachment (a) and viability (b) on stainless steel surfaces. Saos-2 cells were cultured on polished ( ), BL-ZrO (

), BL-ZrO ( ) and BL-AlO (

) and BL-AlO ( ) samples for the indicated incubation periods. The results are expressed as the percentage of the fluorescence measured on PS at 2 h or 1 day, which was given the arbitrary value of 100. Each data represent the mean ± S.D. of four independent experiments. *P < 0.05 compared to PL specimens

) samples for the indicated incubation periods. The results are expressed as the percentage of the fluorescence measured on PS at 2 h or 1 day, which was given the arbitrary value of 100. Each data represent the mean ± S.D. of four independent experiments. *P < 0.05 compared to PL specimens

3.3 In vitro corrosion behavior

Figure 4 shows the Nyquist plots of the impedance data for the polished and blasted samples. After 5 min of immersion, all the impedance plots tended to describe a semicircle, approaching to the behavior of a non-passive alloy. With progressing immersion time, semicircles were also described but with larger diameter, which indicates that all samples reached a spontaneous passivation when they are exposed to the Ringer’s solution. Figure 5a, b shows the same impedance data plotted in the Bode format into the domain of 105–10−3 Hz and Fig. 5c shows a detail of the impedance modulus plots at low frequencies (1–10−3 Hz) using a linear–linear scale.

The experimental impedance data can be modeled using a complex non-linear least-square (CNLS) fit analysis and suitable electrical equivalent circuits (EECs). In a first approach, the EEC proposed by Mansfeld and Wang [23], Fig. 4d, was used. This circuit consists of a resistance R 1 and a parallel CPE-R 2 couple. R 1 corresponds to the electrolyte resistance and R 2 to the polarization resistance of the passive surface. In reference [23], C represented the capacitance of the passive surface but in this discussion C is implemented as a Constant Phase Element (CPE). The CPE should be used instead of a pure capacitance to account for a non-ideal capacitive response. This CPE arises because microscopic material properties are themselves often distributed. For example, the solid electrode/electrolyte interface on the microscopic level contains a large number of surface defects, local charge inhomogeneities, adsorbed species, variations in composition and stoichiometry, etc. [24] Following the equation used by Boukamp in the EQUIVCRT program [20], the impedance of CPE is defined by:

where j = √–1, ω is the angular frequency ω = 2πf, and f is the frequency in Hz. The exponential factor n is related to a non-uniform current distribution due to the surface roughness or other distributed properties, and varies between zero and one.

Table 2 shows the parameters obtained by using CNLS fit analyzes from the Boukamp program [20]. The Chi-square values and the error calculus describe the quality of the fitting. An exception is observed for the BL-ZrO samples, where the relative error found for the R 2 values after 1 day of testing was extremely high (506%). Moreover, the R 2 value obtained for this sample is also anomalous. It is believed that impedance spectra can be totally masked by experimental noise and uncertainties, thus the capacitance components of the response may not give exactly a CPE behavior [24].

A classification based on the values of polarization resistance of the passive surface (R 2 ) leads at the 5 min of immersion to values that are similar to those obtained with criteria based on the impedance modulus reached at the lowest frequencies. As can be seen, polarization resistance for polished samples is higher than that for BL-AlO samples. However, in the case of BL-ZrO samples this circuit leads to anomalous values when considering 24 h of immersion. Complexity of the blasted surfaces makes difficult to get more quantitative information for these samples.

3.4 Ion release

Figure 6 shows the accumulative amount of ions released from the surfaces along 24, 48, 72, and 96 h of immersion in the Ringer’s solution. We only detected small amounts of Fe released from polished samples within the first 24 h that remained constant over time. Blasting of the alloy led to elevated Fe ion release, but also the leaching of Ni, Mn, Cr, Mo and Al ions. In general, ion release increased with immersion time in both blasted surfaces. The total amount of ions significantly increases from 0.08 μg ml−1 for the polished condition to about 1.3 μg ml−1 for the blasted samples, being Fe preferentially released compared to Cr, Mn and Ni. The relative accumulative amounts of ions for BL-AlO samples was Fe ≫ Ni ≈ Mn > Cr > Al > Mo whereas for BL-ZrO samples was Fe ≫ Mn > Ni > Cr > Mo (P < 0.05). Al ion was only detected in BL-AlO while released amounts of Mo ion from both rough surfaces were very low. Besides surface contamination with Zr-particles, Zr ion released from BL-ZrO samples was below the detection limit (<0.007 μg ml−1).

4 Discussion

In this work, austenitic stainless steel 316 LVM was blasted with small and rounded ZrO2 particles or larger and angular shaped Al2O3 particles. As processing parameters were similar, differences in the topographic surface parameters between both types of samples are obviously related to the properties of the particles used for blasting. As expected, angular shaped alumina particles lead to more material removal than rounded ones [25], yielding a rougher surface and a higher real surface area. Roughness strongly depends on the magnification used, but in relative terms, surface parameters showed a consistent behavior with the roughness increase. However, complexity of the real “shape” of the surface, including remnants of broken blasting particles that are covering a relatively high fraction of the surface (up to about 10–15%), make difficult to correlate topographical parameters and blasting induced effects and, therefore, data of corrosion and ion release will be referred to the geometric surface, unless otherwise stated.

Blasting of stainless steel has been developed to provide roughness in a micrometrical range that bone cells can recognize. Biocompatibility tests were set to address the effect of surface roughness on osteoblastic behavior. Data presented herein show that blasted surfaces are biocompatible, irrespective of the particle used for blasting. However, some inconsistencies related to the roughness dependence observed on other metallic biomaterials are found. At first, it should be considered that changes in surface topography and chemistry of metallic materials may modulate cell behavior, such as initial cell attachment, proliferation or differentiation [16, 26–29]. In particular, a number of previous studies indicate that blasting of metallic materials produced a detrimental effect on initial osteoblast adhesion [27, 29, 30] but in other publications such effects have not been observed [31, 32]. Although the reason for these discrepancies remains unclear, multiple evidence indicates that cell attachment is strongly influenced by the process used to prepare the surface and hence by physicochemical surface characteristics [31]. Since initial attachment of Saos-2 cells was unaffected by surface roughness on stainless steel, we speculate that the effect exerted by blasting of 316 LVM surfaces do not affect short-term adhesion. In this regard, it has been suggested that initial non-specific electrostatic forces established between cells and substrates and passive formation of ligand-receptor bonds are more influenced by surface chemistry than by surface topography [31]. Moreover, it has been recently reported that nanograined/ultrafine-grained structure of the stainless steel enhances early interactions of fibroblasts [33]. Since blasting develops an ultrafine grain size at the outermost blasted affect zone of about 10–15 μm thick, with grain sizes ranging between 50 and 500 nm, we hypothesize that the detrimental effect of surface roughness on cell attachment can be circumvented by these ultrafine structures. However, the short-term adhesion does not always reflect the further behavior of cells on the substrates [28, 34]. In fact, we observed that Saos-2 viability decreased when cultured for 1 week on BL-AlO samples, with pronounced roughness (Ra higher than 5 μm), as compared to polished or BL-ZrO surfaces. In principle, this effect cannot be related to increased ion release that resulted in higher cell toxicity, as total ions released from both blasted samples were found to be rather similar. Micromolar doses of Al ion, which was released from BL-AlO surfaces, have been reported not to affect metabolic activity and proliferation of bone forming cells [35]. More likely, the effects observed on samples blasted with Al2O3 support the idea that changes of surface topography of metallic alloys in the micrometric range, also including 316 LVM, influence long-term cell adhesion and proliferation.

The corrosion resistance of biocompatible materials in body fluids is one of the essential factors in the determination of the lifetime of medical implants. Blasting the surface of stainless steel may affect its tendency to corrode when implanted. Figure 5a shows that the highest impedance modulus corresponds to the polished samples and the lowest to the blasted samples, which indicate a decrease in the corrosion resistance following blasting. Corrosion is a surface dominated process, thus it could be argued that this different behavior is an artifact related to the area increase of the surface. For sake of clarity it is worth mentioning that Fig. 5a shows the typical log-log plot, thus from his analysis it is difficult to assess the specific weight of the area increase for the blasted samples. Using a linear-log scale, Fig. 5c, it can be clearly seen that for a given frequency the difference in the impedance modulus between polished and blasted surfaces is nearly the same despite the area increase is much higher for the BL-AlO samples. Thus, the larger area increase following blasting cannot explain differences in the corrosion behavior between blasted surfaces and additional effects such as surface contamination, strain induced α′-martensite formation, residual stresses and grain size refinement are next considered.

On the one hand, remnant of blasting particles embedded at the surface would play a detrimental role since they are non-conducting and could act as cathodic zones, enhancing dissolution at the non-contaminated zones [36]. On the other hand, blasting with alumina particles (largest size, density and hardness) lead to more cumulative plastic deformation, which implies more strain hardening and formation of α′-martensite at deeper regions from the surface [18]. Since the plastically deformed subsurface region was constrained elastically by the material beneath the blasted affected zone, a compressive residual stress zone was developed. The angular shape of the alumina particles, however, causes severe erosion that grinds down the material and yields a more heterogeneous deformation forming large pits, as deduced from the Ssk values (Table 1). Besides partial removal of α′-martensite, magnitude of the maximum compressive residual stress for the BL-AlO samples (470 MPa) is lower than for the BL-ZrO samples (670 MPa) [18]. Interestingly, this value decreases both to the interior and to the blasted surface, likely changing into tensile residual stresses at a certain depth, as required to achieve a zero macroscopic residual stress on the specimen. At the sample surface, therefore, slight tensile stresses rather than compressive stresses are expected, which will make the surface more reactive [37]. Besides, it is known that the corrosion behavior of stainless steels can deteriorate substantially when the strain-induced α′-martensite is present because the structural non-homogeneities would increase the density of the localized states [38]. Magnetic measurements indicated that both type of samples have approximately the same quantity of α′-martensite [18].

Interestingly, impedance values increases with increasing the immersion time despite the high concentration of Cl– ions of the medium, which denotes an improvement of the corrosion protection likely due an increase in the thickness of the passive film as consequence of the equilibrium with the surrounded medium. The outermost ultrafine-grained layer would yield good corrosion resistance because the high amounts of grains boundaries would enable fast diffusion of Cr to the oxide passive film covering the surface [39]. However, although the impedance increase at the lowest frequencies for the BL-AlO samples (up to about 46%) approaches to the values found for the polished surfaces (about 56%), differences between both type of surface becomes slightly higher at 24 h. As the magnitude of the impedance achieved for blasted surfaces are typical of passive alloys, it could be concluded that blasting does not seriously challenge the passive behavior expected for an austenitic stainless steel.

While ion release from austenitic stainless steel 316 L have been investigated in various physiologic media and different surface conditions [40–43], studies on the blasted condition are almost lacking. Reliable data are relevant to assess whether there is any potential for risk of adverse effects arising from the element contained in the blasted alloy. Results for the polished steel agree with previous studies that found preferential Fe release for all exposure periods [40, 41, 43]. The Fe ion release is higher during the first 24 h exposure and tends to decrease during the subsequent exposure time.

Relevant for this investigation is that blasting of the alloy yields an increase in the Fe content but also the leaching of new ions, irrespective the immersion time. This fact correlates with the decrease in the corrosion resistance of the blasted samples. The thinner oxide films on the surfaces rather than their area increases may account for higher ion release from blasted surfaces. In fact, a direct correlation cannot be made between the surface area of blasted surfaces and the ion release increase. While real surface area increase from 8.2 cm2 for BL-ZrO to 13.3 cm2 for BL-AlO, total ion release per real area reveals values of 5.07 and 3.02 μg·cm-2 for the BL-ZrO and BL-AlO samples, respectively. The lower ion release from BL-AlO samples, exhibiting the worse corrosion behavior, is somewhat confusing and a more detailed analysis of the oxide film formed on each metal surface seems to be necessary. Ion release is a process related to the dissolution of elements forming the passive film and therefore its thickness, chemical composition and element distribution could be different. Determination of these features on a rough surface, however, would be rather complex.

Relevant for the intended application is the increase in the Ni release since the earliest stage of immersion, which agrees with results of a recent work of Reclaru et al. [44] that has shown that cold working (23%) of austenitic stainless steel significantly increases the release of Ni. Although every metal has its own intrinsic effect and potential toxicity, Ni ions are of particular interest since they may cause biological effects and also are the origin of the most widespread contact dermatitis [45]. Consequently, the European Union set from 2001 a regulation limiting the Ni release of utensil and jewellery items at 0.5 μg cm−2 during a week for at least 2 years [46]. This would equal 0.071 μg cm−2 on a daily basis, which is overcome by the BL-ZrO (0.112 μg cm−2) and the BL-AlO (0.095 μg cm−2) samples (values determined using the real areas). The results of this study should not be viewed as conclusive evidence since immersion times were rather short, thus more realistic average values would be obtained after longer times of immersion. Moreover, metal release is strongly influenced by the biological environment [47] and thus further experiments are needed to elucidate the influence of biomolecules contained in physiological fluids on the corrosion behavior of blasted steels.

5 Conclusions

-

Topographical analysis reveals that surface of the alumina blasted samples is rougher (Ra ~5 μm) than the zirconia blasted samples (Ra ~1 μm), which is also manifested by a higher surface area increase (~170%).

-

Corrosion tests reveal a lower corrosion resistance of the blasted surfaces at the earlier stages of immersion, particularly when using Al2O3 particles. With increasing immersion time, blasted alloys experience an improvement of the corrosion resistance achieving after 24 h exposure impedance values typical of passive alloys. The benefits of the ultrafine-grained structure beneath the blasted surfaces must balance the detrimental role played by the embedded blasting particles and the strain induced α′-martensite reaching the surface.

-

Blasting of the alloy yields an increase in the Fe release, but also to the leaching of new ions (Ni, Mn, Cr, Mo and Al).

-

Despite the lower corrosion resistance and higher amount of ions released, blasted alloys exhibit a good biocompatibility. As total ions released from both blasted samples were found to be similar, the slight decrease in the cell viability observed on the alumina blasted samples, having the highest roughness, support the idea that changes of surface topography in the micrometric range influence long-term cell adhesion and proliferation.

References

Disegi JA, Eschbach L. Stainless steel in bone surgery. Injury. 2000;31:2–6.

Sivakumar M, Dhanadurai KSK, Rajeswari S, Thulasiraman V. Failures in stainless steel orthopaedic implant devices: a survey. J Mater Sci Lett. 1995;14:351–4.

Amel-Farzad H, Peivandi MT, Yusof-Sani SMR. In-body corrosion fatigue failure of a stainless steel orthopaedic implant with a rare collection of different damage mechanisms. Eng Fail Anal. 2007;14:1205–7.

Savarino L, Maci GS, Greco M, Baldini N, Giunti A. Metal ion release from fracture fixation devices: a potential marker of implant failure. J Biomed Mater Res B Appl Biomater. 2008;86:389–95.

Jones DM, Marsh JL, Nepola JV, Jacobs JJ, Skipor AK, Urban RM, Gilbert JL, Buckwalter JA. Focal osteolysis at the junctions of a modular stainless-steel femoral intramedullary nail. J Bone Jt Surg Am. 2001;83:537–48.

French HG, Cook SD, Haddad RJ Jr. Correlation of tissue reaction to corrosion in osteosynthetic devices. J Biomed Mater Res. 1984;18:817–28.

Haynes DR, Crotti TN, Haywood MR. Corrosion of and changes in biological effects of cobalt chrome alloy and 316 L stainless steel prosthetic particles with age. J Biomed Mater Res. 2000;49:167–75.

Steinemann SG. Metal implants and surface reactions. Injury. 1996;27(Suppl3):SC16–22.

Guo HX, Lu BT, Luo JL. Interaction of mechanical and electrochemical factors in erosion-corrosion of carbon steel. Electrochim Acta. 2005;51:315–23.

Jiang XP, Wang XY, Li JX, Li DY, Man CS, Shepard MJ, Zhai T. Enhancement of fatigue and corrosion properties of pure Ti by sandblasting. Mater Sci Eng A. 2006;429:30–5.

Aparicio C, Gil FJ, Fonseca C, Barbosa M, Planell JA. Corrosion behaviour of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials. 2003;24:263–73.

Wennerberg A, Albrektsson T, Andersson B. Bone tissue response to commercially pure titanium implants blasted with fine and coarse particles of aluminum oxide. Int J Oral Maxillofac Implants. 1996;11:38–45.

Goldberg VM, Stevenson S, Feighan J, Davy D. Biology of grit-blasted titanium alloy implants. Clin Orthop Relat Res. 1995;319:122–9.

Aparicio C, Gil FJ, Thams U, Muñoz F, Padrós A, Planell JA. Osseointegration of grit-blasted and bioactive titanium implants: histomorphometry in minipigs. Key Eng Mater. 2001;254–256:737–40.

Bordji K, Jouzeau JY, Mainard D, Payan E, Delagoutte JP, Netter P. Evaluation of the effect of three surface treatments on the biocompatibility of 316 L stainless steel using human differentiated cells. Biomaterials. 1996;17:491–500.

Otsubo F, Kishitake K, Akiyama T, Terasaki T. Characterization of blasted austenitic stainless steel and its corrosion resistance. J Therm Spray Technol. 2003;12:555–9.

Multigner M, Frutos E, González-Carrasco JL, Jiménez JA, Marín P, Ibáñez J. Influence of the grit blasting of 316 LVM steel on the subsurface microstructure: implications on the magnetic and mechanical properties. Mater Sci Eng C. 2009;29:1357–60.

Multigner M, Ferreira S, Frutos E, Jaafar M, Ibáñez J, Marin P, Pérez-Prado T, et al. Superficial severe plastic deformation of 316 LVM stainless steel through grit blasting: effects on its microstructure and subsurface mechanical properties. Surf Coat Technol. 2010;205:1830–7.

Frutos E, Multigner M, González-Carrasco JL. Novel approaches to determine residual stresses by ultramicroindentation techniques: application to sand blasted austenitic stainless steel. Acta Mater. 2010;58:4191–8.

Boukamp BA. ‘Equivalent Circuit’ AC-Immittance Data Analysis System, Version 4.51, University of Twente, The Netherlands, 1993.

Yamamoto A, Hiromoto S. Effect of inorganic salts, amino acids and proteins on the degradation of pure magnesium in vitro. Mater Sci Eng. 2009;29:1559–68.

Guyton AC, Hall JE. Textbook of Medical Physiology, 11th Edition, Elsevier Sauders, 2006, p.292.

Mansfeld F, Wang Y. Development of ‘‘stainless’’ aluminum alloys by surface modification. Mater Sci Eng A. 1995;198:51–61.

Barsoukov E, Macdonald JR, editors. Impedance spectroscopy, theory, experiment, and aplications. 2nd ed. NJ: Wiley-Interscience; 2005.

Goodwin JE, Sage W, Tilly GP. Study of erosion by solid particles. Proc Inst Mech Eng. 1969;184:279–92.

Hao L, Lawrence J, Phua YF, Chian KS, Lim GC, Zheng HY. Enhanced human osteoblast cell adhesion and proliferation on 316 LS Stainless Steel by means of CO2 laser surface treatment. J Biomed Mater Res Part B Appl Biomater. 2005;73B:148–56.

Anselme K, Linez P, Bigerelle M, Le Maguer D, Le Maguer A, Hardouin P, Hildebrand HF, et al. The relative influence of the topography and chemistry of Ti6Al4 V surfaces on osteoblastic cell behaviour. Biomaterials. 2000;21:1567–77.

Rosa AL, Beloti MM. Effect of cpTi surface roughness on human bone marrow cell attachment, proliferation, and differentiation. Braz Dent J. 2003;14:16–21.

Saldaña L, González-Carrasco JL, Rodríguez M, Munuera L, Vilaboa N. Osteoblast response to plasma-spray porous Ti6Al4 V coating on substrates of identical alloy. J Biomed Mater Res A. 2006;77:608–17.

Kim HJ, Kim SH, Kim MS, Lee EJ, Oh HG, Oh WM, Park SW, et al. Varying Ti-6Al-4V surface roughness induces different early morphologic and molecular responses in MG63 osteoblast-like cells. J Biomed Mater Res A. 2005;74:366–73.

Anselme K, Bigerelle M. Statistical demonstration of the relative effect of surface chemistry and roughness on human osteoblast short-term adhesion. J Mater Sci Mater Med. 2006;17:471–9.

Saldaña L, Barranco V, González-Carrasco JL, Rodríguez M, Munuera L, Vilaboa N. Thermal oxidation enhances early interactions between human osteoblasts and alumina blasted Ti6Al4V alloy. J Biomed Mater Res A. 2007;81:334–46.

Misra RDK, Thein-Han WW, Pesacreta TC, Somani MC, Karjalainen LP. Biological significance of nanograined/ultrafine-grained structures: interaction with fibroblasts. Acta Biomater. 2010;6(8):3339–48.

Kunzler TP, Huwiler C, Drobek T, Vörös J, Spencer ND. Systematic study of osteoblast response to nanotopography by means of nanoparticle-density gradients. Biomaterials. 2007;28:5000–6.

Saldaña L, Barranco V, García-Alonso MC, Vallés G, Escudero ML, Munuera L, Vilaboa N. Concentration-dependent effects of titanium and aluminium ions released from thermally oxidized Ti6Al4V alloy on human osteoblasts. J Biomed Mater Res A. 2006;77:220–9.

Torralba JM, Jiménez-Morales A, Ruiz-Navas EM, Fogagnolo JB. Influence of the composition and processing conditions on the corrosion resistance of aluminium based composite materials. Bol Soc Esp Ceram V. 2002;43(2):196–9.

Mavrikakis M, Hammer B, Nørskov JK. Effect of strain on the reactivity of metal surfaces. Phys Rev Lett. 1998;81(13):2820–2.

Cigada A, Mazza B, Pedeferri P, Salvago G, Sinigaglia D, Zanini G. Stress corrosion cracking of cold-worked austenitic stainless steels. Corros Sci. 1982;22(6):559–78.

Mordyuk BN, Prokopenk GI, Vasylyev MA, Iefimov MO. Effect of structure evolution induced by ultrasonic peening on the corrosion behavior of AISI-321 stainless steel. Mater Sci Eng A. 2007;458:253–61.

Takada Y, Takahashi N, Okuno O. Electrochemical behaviour and released ions of the stainless steels used for dental magnetics attachments. In 6th International Conference on Magnetic Applications in Dentistry, March 1–20, 2007, S011.

Cieslik M, Reczynski W, Janus AM, Engvall K, Socha RP, Kotarba A. Metal release and formation of surface precipitate at stainless steel grade 316 and Hank’s solution interface-Inflammatory response and surface finisching effects. Corros Sci. 2009;51:1157–62.

Okazaki Y, Gotoh E. Comparison of metal release from various metallic biomaterials in vitro. Biomaterials. 2005;26:11–21.

Herting G, Walinder I, Leygraf C. Metal release from various grades of stainless steel exposed to synthetic body fluids. Corros Sci. 2007;49:103–11.

Reclaru L, Lüthy H, Ziegenhagen R, Eschler PY, Blatter A. Anisotropy of nickel release and corrosion in austenitic stainless steels. Acta Biomat. 2008;4:680–5.

Kanerva L, Förström L. Allergic nickel and chromate hand dermatitis induced by orthopedic metal implant. Contact Dermatitis. 2001;44:103–4.

Delescluse J, Dinet Y. Nickel allergy in Europe: the new European legislation. Dermatology. 1994;189(suppl 2):56–7.

Hanawa T. Metal ion release from metal implants. Mater Sci Eng C. 2004;24:745–52.

Acknowledgments

The authors wish to express their thanks for the financial support of Spanish’s Projects from Ministerio de Ciencia e Innovación (MAT2009-14,695-C04-02 and -04) and Fundación Mutua Madrileña. NV is supported by program I3SNS from Fondo de Investigaciones Sanitarias (Spain).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Galván, J.C., Saldaña, L., Multigner, M. et al. Grit blasting of medical stainless steel: implications on its corrosion behavior, ion release and biocompatibility. J Mater Sci: Mater Med 23, 657–666 (2012). https://doi.org/10.1007/s10856-012-4549-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4549-y