Abstract

Icariin, a plant-derived flavonol glycoside, has been proved as an osteoinductive agent for bone regeneration. For this reason, we developed an icariin-loaded chitosan/nano-sized hydroxyapatite (IC–CS/HA) system which controls the release kinetics of icariin to enhance bone repairing. First, by Fourier transform infrared spectroscopy, we found that icariin was stable in the system developed without undergoing any chemical changes. On the other hand, X-ray diffraction, scanning electron microscopy and mechanical test revealed that the introduction of icariin did not remarkably change the phase, morphology, porosity and mechanical strength of the CS/HA composite. Then the hydrolytic degradation and drug release kinetics in vitro were investigated by incubation in phosphate buffered saline solution. The results indicated that the icariin was released in a temporally controlled manner and the release kinetics could be governed by degradation of both chitosan and hydroxyapatite matrix. Finally the in vitro bioactivity assay revealed that the loaded icariin was biologically active as evidenced by stimulation of bone marrow derived stroma cell alkaline phosphatase activity and formation of mineralized nodules. This successful IC–CS/HA system offers a new delivery method of osteoinductive agents and a useful scaffold design for bone regeneration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The treatment of serious osseous defects remains a great challenge in orthopedic surgery [1]. For the enhancement of bone regeneration and repair of bone defects, the implantation of biomaterials which can carry and efficiently release osteoinductive agents at the location is regarded as the best approach [2].

Among these osteoinductive agents, numerous growth factors (GFs) such as bone morphogenetic proteins (BMPs), platelet-derived growth factor (PDGF), transforming growth factor-β (TGF-β), and insulin-like growth factors (IGFs) have been extensively studied and employed [3, 4]. However the high cost and rapid degradation of such expensive GFs limit their widely use especially in clinic [5]. Therefore, there is an urgent need to develop some alternative bone formation stimulators with higher efficacies and lower costs than GFs [4].

Some flavonoids such as those from soybean that have successfully been used in bone regeneration applications. Soybean-based bone fillers have been tested in vitro and in vivo showing excellent bone regeneration properties [6–8]. Icariin (molecular formula: C33H40O15, molecular weight = 676.67) is also a flavonoid isolated from Epimedii herba and is considered to be the major (77%) bioactive component of this herba. Icariin was proved to have some positive effects on the proliferation of osteoblasts in many studies [9–11]. It also showed great promotion on the ossific differentiation of bone marrow derived stroma cells (BMSCs), which was proved to be relevant to a BMP and core binding factor alpha-1 (Cbfa-1) dependent manner [12]. Although icariin has showed promise as an alternative to GFs for the enhancement of bone regeneration, the controlled delivery system of icariin has not been study up to now.

Scaffolds for GFs or drug delivery should combine biocompatibility and controlled release capability. Besides, they should be resorbed and gradually replaced by newly formed bone [13]. Hydroxyapatite (HA), a major inorganic component of bone, has been used extensively for biomedical implant applications and GFs-loaded scaffold due to its bioactive, biodegradable and osteoconductive properties [14, 15]. However, the application of pure HA is very limited due to its slow degradation and brittleness. Since the natural bone is a composite mainly consisted of nano-sized, needle-like HA crystals and collagen fibers, many efforts have been made to modify HA by polymers, such as polylactic acid [16], collagen [14] and chitosan (CS) [15]. Among these polymers, CS has received much attention in the field of medical applications, due to its excellent biocompatibility and biodegradability. CS is a partially deacetylated derivative of chitin, which is the primary structural polymer in arthropod exoskeletons, shells of crustaceans, or the cuticles of insects [17]. As a semi-crystalline polysaccharide it is normally insoluble in aqueous solutions above pH 7. But in dilute acids (pH 6), its free amine groups are protonated and the molecule becomes soluble [18]. Most importantly, it degrades in the body to non-harmful and non-toxic compounds [19]. CS/HA composite combines the advantages of both CS and HA, and has great promising as a scaffold for the controlled release of GFs [15].

In this study, we hypothesized that the application of CS/HA can control the release kinetics of icariin. In order to test this hypothesis, we prepared an icariin-loaded chitosan/nano-size hydroxyapatite (IC–CS/HA) system. The phase, morphology, porosity and mechanical strength characteristics of this system were observed by Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscopy (SEM) and mechanical machine respectively. Subsequently the hydrolytic degradation and synthetic peptide release kinetics in vitro were investigated by incubation in phosphate buffered saline solution (PBS). Finally we specifically evaluated the in vitro bioactivity of this system by stimulation of BMSCs.

2 Materials and methods

2.1 Materials

Icariin (molecular formula: C33H40O15, molecular weight = 676.67) was purchased from the National Institute for the Control of Pharmaceuticals and Biological Products (Beijing, China). CS (molecular weight = 2.5 × 105, degree of deacetylation ≥90.0%, viscosity <100 cps, biomedical grade) was purchased from Shanghai Bo’ao Biological Technology Co. (Shanghai, China). Analytical grade acetic acid, calcium nitrate (Ca(NO3)2·4H2O), and potassium dihydrogen phosphate (KH2PO4) were purchased from Guangzhou Xinmei Chemical Industry Co. (Guangzhou, China). Dulbecco’s modified Eagle’s medium (DMEM) and fetal bovine serum (FBS) were purchased from the HyClone Co. (South Logan, USA). 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl-tetrazolium bromile (MTT) were purchased from the Gibco BRL (Grand Island, USA).

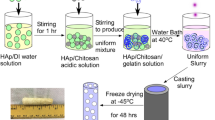

2.2 Preparation of IC–CS/HA composite

The composite was prepared according to Ref. [17–22]. Briefly, 200 mg icariin was first dissolved into 100 ml ethanol to prepare an icariin solution. Then the icariin solution was mixed with a CS solution which was prepared by dissolving CS in 2% (v/v) acetic acid aqueous solvent, at a ratio of 1:1 (v/v). Then the icariin–chitosan solution was stirred for 2 h, followed by the slow addition of Ca(NO3)2 and KH2PO4 (ratio of Ca/P = 1.67) to prepare IC–CS/HA solution precursor (concentration of CS was 2.5%, the final mass ratio of CS/HA was 1/2). Whereupon, the precursor was homogenized by 4 h vigorous stirring and centrifuged to remove the air bubbles. The resulting solution was cast by a glass mold (4 mm in diameter, 15 mm in length) and placed at 4°C for 6 h, −10°C for 3 h, then freeze–dried. After they were fully dried, composites of IC–CS/HA were soaked in 4% (wt/v) NaOH and icariin-saturated deionized water for 10 h, and then rinsed with icariin-saturated deionized water for several times to reach neutral pH. Finally, scaffolds were frozen and freeze–dried. Each IC–CS/HA contains about 2 mg of icariin. We also prepared CS/HA composite but without icariin as the controls. All the composites were sterilized with 20 kGy 60Co and stored in vacuum packages at room temperature before subsequent uses.

2.3 Characterization of IC–CS/HA composite

2.3.1 Phase and microstructure characterization

Infrared absorption spectra of icariin, CS/HA and IC–CS/HA were recorded by Fourier transform infrared spectroscopy (FTIR; Avatar 360, Nicolet Co., USA) in the 4,000–400 cm−1 range. XRD measurements of HA powder, CS/HA, and IC–CS/HA were conducted by a diffractometer (X’Pert Pro, PANalytical, Netherlands) with 40 kV and 50 mA using Co Kα radiation (λ = 0.154 nm). The scanning scope of 2θ was 5–50° and the scanning rate was 5°/min. The microstructure of the samples was examined by a scanning electron microscopy (SEM, S-3000N, Hitachi, Japan) after the samples were sputter coated with gold under vacuum.

2.3.2 Porosity measurement

The porosity of samples was measured by liquid displacement method [23]. The procedure of liquid displacement method was as follow: the volume (V 0) and weight (W 0) of the sample were measured. Then, the sample was immersed into ethanol for 5 min until it was saturated by absorbing ethanol. The sample was weighted again and noted as W 1. The porosity of the sample was calculated according to the formula: porosity (%) = (W 1−W 0)/(ρV 0) × 100 (ρ represents the density of the ethanol). The reported data was the average of five samples.

2.3.3 Test of mechanical properties

Resistance to mechanical compression of the samples was tested on a universal testing machine (Instron 5567, Instron Company, USA) at room temperature and humidity. The crosshead speed was set at 0.5 mm/min, and the load was applied until the sample was compressed to 70% of its original height. The compressive modulus was calculated as the slope of the initial linear section of the stress–strain curve. The compressive strength was determined by the maximum point of the stress–strain curve. The reported data was the average of five samples.

2.4 In vitro degradation and release experiments

2.4.1 Study of hydrolytic degradation

In degradability investigation of the samples, sterile PBS solution (pH 7.4) was used as a medium. The samples were placed in 10 ml vials, each containing 5 ml PBS solution. The vials were kept in a shaking incubator (37°C, 40 rpm) for various time periods of 0, 5, 10, 20, 30, 40, 50, 60, 70, 80 and 90 days. Each week the buffer solution was replaced by fresh solution. At the end of each time point, five samples for each composite were taken out, rinsed with distilled water, and vacuum dried at room temperature to constant weight. The weight loss was calculated as follows: Weight Loss (%) = (W 0−W 1)/W 0 × 100, where W 0 and W 1 were weights of the samples before and after hydrolytic degradation, respectively. The reported weight loss was the average of five samples.

2.4.2 In vitro release experiments

The release behavior of icariin from IC–CS/HA system was measured by ultra performance liquid chromatography (UPLC, Waters Co., Milford, USA). Briefly, samples of IC–CS/HA were soaked in 5 ml phosphate-buffered solution (PBS, pH 7.4, 37°C) and kept shaking gently at 10 rpm. At 0, 5, 10, 20, 30, 40, 50, 60, 70, 80 and 90 days, the 5 ml PBS was collected (stored at 4°C for UPLC examination) and replaced by adding the same amount of fresh PBS. For analysis of icariin concentration, all the samples were centrifuged (3,000 rpm) for 10 min and 0.5 ml supernatants were isolated, and after adding 0.5 ml of acetonitrile, the mixed solution were re-centrifuged (6,000 rpm) for 10 min and then 20 μl supernatants were applied for UPLC analysis. Data of peak area integration was done using Empower 2 software (Waters Co., Milford, USA). Icariin released from the sample was calculated according to standard curve and the percentage of icariin released was accumulated.

2.5 In vitro bioactivity

All animal experiments were approved by the Animal Ethical Committee of our university. BMSCs were obtained from BALB/c mice and expanded according to the method described in the Ref. [24]. And the BMSCs derived from the 3rd passage were used in the following experiments. Each BMSC experiment was repeated for three times.

2.5.1 Evaluation of cell adhesion and proliferation

BMSCs (the third passage, 5 × 105 cells/well) were cultured with the different composites respectively in 24-well plates, and incubated in vitro at 37°C in a humidified atmosphere with 5% CO2. After 6, 12 and 24 h of culture respectively, media were collected and non-attached cells were counted. The adhesion rates were calculated as percentage of attached BMSCs. Cell proliferation was detected by using a MTT method at 1, 3, 5 and 7 days. The absorbance was determined at 570 nm using an enzyme linked immunosorbent assay reader (Elx 800, Bio-Tek, USA).

2.5.2 Evaluation of osteogenic differentiation

The cells were plated at a density of 5 × 105 cells/well in 24-well plates containing the two different composites in a complete medium at 37°C in a humidified atmosphere with 5% CO2. After 7 and 14 days, cells were lysed in 100 μl deionized water and homogenized by ultrasound at 4°C. ALP activity and total protein content in cell lysates were measured using an alkaline phosphatase activity kit and a micro-BCA Assay kit (Beyotime Co., Haimen, China), respectively, and ALP activity was normalized for the corresponding total protein concentration (U/g). After 21 days of incubation under the same conditions, alizarin red staining was performed [4]. Cells cultured in an osteogenic medium (OM, consisting of DMEM supplemented with 10% FBS, 10−8 M DEX, 10−3 M β-glycerol phosphate, and 50 mg/ml l-ascorbic acid) were used as positive controls. Cells cultured without composite and OM were used as blank controls.

2.6 Statistical analysis

Statistical analyses were performed using SPSS software, version 12.0 (SPSS Inc, USA). The data were presented as the mean ± standard deviation and levels were compared by the one-way ANOVA and Student’s t test. P values less than 0.05 were considered significant.

3 Results and discussion

3.1 Characterization of IC–CS/HA composite

FTIR spectral data were used to confirm the chemical stability of icariin in CS/HA composite. FTIR spectra of pure icariin (a), CS/HA (b) and IC–CS/HA (c) were compared in Fig. 1 The characteristic peaks of icariin appeared at 2,923, 1,595 and 1,259 cm−1, corresponding to methylene (CH2), benzene ring and methoxyl (O–CH3) respectively. For CS/HA composite, the characteristic amide peak of CS shifted from 1,620 to 1,633 cm−1. Similarly the characteristic band corresponded to vibrations hydroxyl of HA also shifted from 1,634 to 1,633 cm−1. A small peak at 1,039 cm−1 appeared, corresponding to phosphate stretching vibration. When icariin was incorporated into the CS/HA, along with all the characteristic bands of the CS and HA, additional bands appeared due to the presence of icariin in the matrix. However, some bands of icariin, such as 1,595 and 1,259 cm−1, were not prominent in the IC–CS/HA composite due to identical stretching of the CS/HA and icariin at the same wave number. The characteristic band of icariin observed at 2,923 cm−1 still appeared in the icariin-loaded matrix without any change, which further indicates that icariin had not undergone any chemical change while producing IC–CS/HA composite.

The XRD spectra recorded for HA (a), CS/HA (b) and IC–CS/HA (c) were presented in Fig. 2. These studies were useful to investigate crystallinity of the samples. For HA powder, the existence of 2θ peaks at approximately 25.8°, 29.8°, 32.9°, 34.0°, 39.9°, 46.7° and 49.4° corresponded to the diffraction planes of (002), (112), (300), (130), (222) and (213) of the HA crystallites [17]. CS as a semi-crystalline biopolymer presented broad diffraction peaks at 10.2°, 19.8° and 21.9° [17]. For CS/HA composite, the typical crystalline peaks of both CS and HA still existed (19.9°, 25.9° and 32.1°), but the peaks became broader and weaker as compared to HA powder. Besides, not all diffraction planes were clearly identified. The molecular interaction between CS and HA led to hybridization and therefore influenced the diffraction peaks [25]. IC–CS/HA scaffold still exhibited similar peaks as the CS/HA composite, but peaks became broader. The XRD peak always depends on the crystal size, but in the present study the characteristic peaks of icariin overlap with the noise of the coated polymer (chitosan) itself. Further, the loaded drug (icariin) is amorphous, which is very difficult to measure at the detection limit of the crystal size in the present case. This indicated that icariin was dispersed at the molecular level in the polymer matrix and hence, no crystals were found in the IC–CS/HA composite.

All the samples showed a three-dimensional (3D) porous structure as shown in Fig. 3. It was observed that pores inside all the composites were interconnected in regular patterns and the pore size was uniformity at about 110 μm. SEM micrographs revealed that plenty of nano-sized HA crystal granules were dispersed on the pore wall of the composite at a high magnification. These cylinder-like granules were about 50 nm wide and 300 nm high. The microstructure of IC–CS/HA was similar to that of CS/HA.

The porosity of IC–CS/HA and CS/HA evaluated by a liquid displacement method was listed in Table 1. It was observed that the porosity of CS/HA scaffold was determined to about 88.701 ± 2.269%. The introduction of icariin in the CS/HA composite did not noticeably change the porosity. This finding was in agreement with the results of SEM observation.

The mechanical properties of IC–CS/HA and CS/HA composites evaluated by compressive measurements were summarized in Table 1. It was observed that the compressive strength of CS/HA scaffold was 1.496 ± 0.210 MP and compressive modulus was about 17.514 ± 3.425 MP. The mechanical properties of CS/HA composite decreased a little with the introduction of icariin (P > 0.05). These changes were so small that they didn’t influence their use as bone regeneration scaffolds.

For materials of bone regeneration, porosity and mechanical properties are two very important parameters. The material must have sufficient porosity for nutrition and gas exchange. Satisfactory porosity of more than 80% is a distinct symbol of a perfect scaffold [26]. In the present research we firstly dissolved icariin in ethanol and then mixed it with CS/HA precursor solution. Afterward homogeneous distribution of icariin was obtained by stirring. Therefore, after having been freeze–dried, icariin was absorbed by HA and encapsulated by CS, which had the lowest effect on the porosity of the composite. Moreover in situ composition with Ca(NO3)2 and KH2PO4 could get homogeneous dispersed nanometer HA (nano-HA), which is easily aggregated and hard scattered. Using water as a pore-forming agent, freeze–drying technique can produce satisfactory micropores. In the view of microstructure, in CS/HA composite, the combination of nano-HA and CS polymer, which conjugate with electrostatic interaction, van der Waals interaction, hydrogen bond and hydrophobic bond, load was transferred between mineral phase and organic phase, thus improving mechanical properties of the composite.

3.2 In vitro degradation

In order to study the degradability of IC–CS/HA composite scaffolds, in vitro hydrolytic degradation tests were carried out in PBS (pH 7.4) at 37°C. The weight loss for the samples was shown in Fig. 4. It could be observed that the weight loss for the CS/HA scaffold proceed slowly during the whole degradation period. After 90 days of incubation, the sample lost about 22% of its initial mass. With the introduction of icariin, the weight loss of IC–CS/HA samples increased (about 28%), indicating a preferential dissolution of the icariin component. Moreover, compared with the CS/HA scaffold, the IC–CS/HA gradually exhibited three-phasic weight loss. The weight loss increased much more quickly in the first phase due to the rapid release of icariin, which was encapsulated in superficial layer of the scaffold. After 20 days of experiment, about 9% of the original weight was lost. Subsequently, the degradation rate slowed down in the next 40 days. From 60 days, there was a second rapid weight loss. This corresponded to the mass loss of the control CS/HA scaffold and meant that the second weight loss is mainly attributed to the initial degradation of CS component.

3.3 In vitro release kinetics

The release behavior of IC–CS/HA composite in vitro was investigated by UPLC examination. The absorption peak of CS/HA was at 0.56 min, while the absorption peak of icariin was at 1.30 min. Icariin releasing from scaffolds was calculated based on standard curve and demonstrated as the accumulated percentage of icariin (Fig. 5). From 0 to 5 days, approximately 15% icariin was released; then the speed decreased and about 25% icariin was released by 20 days. Following a low-level continuous release was formed. From 60 days, there was a second rapid weight loss and 90 days later there was about 15% of icariin remaining in CS/HA scaffolds.

Compared to the results of Fig. 5 with the hydrolytic degradation of IC–CS/HA (Fig. 4), it could be found that the release profiles of icariin were in accordance with the mass loss of scaffolds. When contacted with water, CS expanded with water immersion, then the icariin encapsulated in superficial layer was released, and a quick release could be seen at the initial stage. Once the preferential dissolution of icariin was completed, the subsequent release kinetics was mainly controlled by the degradation of CS and HA component. Since CS is a semi-crystalline polymer and the degradation is caused by random scissions of ester linkages in its backbone, there was not obvious weight loss for CS/HA scaffold until 60 days of incubation. In addition, HA particles may affect icariin release behavior partially, because there was an adsorption–desorption process between icariin and surfaces of nano-particles. If the surface area of HA becomes larger, icariin cannot diffuse until greater intermolecular forces are surmounted, and therefore icariin releasing time is extended. As a result, the drugs were released in a sustained fashion during the period of 20–60 days. The second rapid release of GFs was corresponded to the collapse of CS/HA scaffolds after 60 days. Thinking that CS degrades in an autocatalytic process and the mass loss lags behind the change of molecular weight [26, 27], the actual molecular weight decrease might occur before 60 days. With the dissolution of low molecular weight CS degradation products, the structural integrity of CS/HA scaffolds was disappeared and thus the icariin incorporated inside the scaffolds were also dissolved into the PBS solution, resulting in another rapid release.

For the regeneration of bone tissue, an ideal drug-delivery system should serve two primary roles: as a delivery carrier to maximize the osteogenic effect of osteoinductive agents by maintaining its bioactivity and duration at implantation site with an optimal release profile; and as an osteoconductive scaffold with suitable pore structure for vascularization and bone formation [26, 28]. To achieve these two functions, we prepared this IC–CS/HA composite by a wet chemical coprecipitation approach. Based on our investigation we found that the introduction of icariin did not decrease the porosity of CS/HA scaffold during the scaffold preparation. Moreover the obtained IC–CS/HA composite can achieve sustained release of icariin for several months.

3.4 In vitro bioactivity

BMSCs were seeded onto the samples for 6 h and the percentage of adherent cells was measured. Adhesion rates on IC–CS/HA were significantly greater than those of CS/HA at each time point. The cells ceased to adhere virtually 12 h after the incubation and no difference in adhesion rate between 12 and 24 h (Fig. 6). The number of the BMSCs was on rise from 1 to the 7 days of the incubation, at which it reached a peak. The number of BMSCs on IC–CS/HA were significantly more than that on CS/HA (P < 0.05) (Fig. 7).

In order to test the bioactivity of the icariin, differentiated function of BMSCs was assessed by monitoring the expression of ALP activity after 7 and 14 days of culture. Figure 8 indicates the total ALP activity of BMSCs cultured with the IC–CS/HA containing the released icariin, the OM and blank control medium. In general, with the incubating time increased from 7 to 14 days, the ALP activity also increased in all three groups. The ALP activity of IC–CS/HA was significantly higher than that of either blank control or CS/HA (P < 0.05). Moreover, no statistical significant difference in bioactivity was found between IC–CS/HA and OM groups (P > 0.05), which meant that the icariin could preserve its biological function during the process of scaffold fabrication. Mineralized nodules that formed in IC–CS/HA dissolution products were also stained with alizarin red and showed positive staining (Fig. 9). No nodule formation was observed in the dissolution products of CS/HA or blank control. In Fig. 9, the cells looked to have a spindle-like morphology rather than the cuboidal morphology typical of osteoblast-like cells. The reason was unknown but by ALP activity measurement and calcium nodule staining, we found that, composite containing icariin could promote the osteogenic differentiation of MSCs. The ability of cells to produce mineralized matrix and nodules is important with regard to the development of materials for bone regeneration. Alizarin red is a common histochemical technique used to detect calcium deposits in mineralized tissues and cultures. In our study, numerous alizarin red positive nodules were observed, demonstrating extensive osteogenic differentiation of MSCs and indirectly supporting activation of icariin.

During the procedure of scaffolds preparation, how to preserve the bioactivity of bone formation stimulators is very important [29, 30]. Recently, it has been found that the icariin enhances the differentiation of BMSCs in a BMP and Cbfa-1 dependent manner [12]. The present study showed that the ALP activity is no significant difference for cells cultured in the released medium compared to the OM medium. Although the bioactivity assay used in this study detects only the differentiated function of BMSCs, this method may partially account for the maintenance of the biological function. Combining with the results of in vitro release, it is concluded that the icariin can be released not only in a controlled fashion but also in a bioactive form. The formation of mineralized nodules further confirmed this result.

4 Conclusions

This study showed that IC–CS/HA composite was a good system for the controlled release of icariin. Firstly the physical and biological properties of icariin were totally preserved in the composite developed without undergoing any chemical changes during the production. Secondly the introduction of icariin did not remarkably change the morphology, porosity and mechanical strength of the CS/HA composite. Thirdly in vitro degradation tests indicated that the icariin release kinetics from this IC–CS/HA composite could be governed by degradation of both CS and HA matrix, and could last for more than 90 days. We believed that this IC–CS/HA system could be a promising biomaterial for bone tissue engineering.

References

Kretlow JD, Mikos AG. Review: mineralization of synthetic polymer scaffolds for bone tissue engineering. Tissue Eng. 2007;13:927–38.

Lin ZY, Duan ZX, Guo XD, Li JF, Lu HW, Zheng QX, Quan DP, Yang SH. Bone induction by biomimetic PLGA-(PEG-ASP)n copolymer loaded with a novel synthetic BMP-2-related peptide in vitro and in vivo. J Control Release. 2010;144:190–5.

Lee JY, Seol YJ, Kim KM, Lee YM, Park YJ, Rhyu IC, Chung CP, Lee SJ. Transforming growth factor (TGF)-beta1 releasing tricalcium phosphate/chitosan microgranules as bone substitutes. Pharm Res. 2004;21:1790–6.

Bi L, Cheng W, Fan H, Pei G. Reconstruction of goat tibial defects using an injectable tricalcium phosphate/chitosan in combination with autologous platelet-rich plasma. Biomaterials. 2010;31:3201–11.

Okada M, Sangadala S, Liu Y, Yoshida M, Reddy BV, Titus L, Boden SD. Development and optimization of a cell-based assay for the selection of synthetic compounds that potentiate bone morphogenetic protein-2 activity. Cell Biochem Funct. 2009;27:526–34.

Santin M, Morris C, Standen G, Nicolais L, Ambrosio L. A new class of bioactive and biodegradable soybean-based bone fillers. Biomacromolecules. 2007;8(9):2706–11.

Giavaresi G, Fini M, Salvage J, Nicoli Aldini N, Giardino R, Ambrosio L, Nicolais L, Santin M. Bone regeneration potential of a soybean-based filler: experimental study in a rabbit cancellous bone defect. J Mater Sci Mater Med. 2010;21(2):615–26.

Morris C, Thorpe J, Ambrosio L, Santin M. The soybean isoflavone genistein induces differentiation of MG63 human osteosarcoma osteoblasts. J Nutr. 2006;136:1166–70.

Zhao J, Ohba S, Komiyama Y, Shinkai M, Chung UI, Nagamune T. Icariin: a potential osteoinductive compound for bone tissue engineering. Tissue Eng Part A. 2010;16:233–43.

Nian H, Ma MH, Nian SS, Xu LL. Antiosteoporotic activity of icariin in ovariectomized rats. Phytomedicine. 2009;16:320–6.

Qin L, Han T, Zhang Q, Cao D, Nian H, Rahman K, Zheng H. Antiosteoporotic chemical constituents from Er-Xian decoction, a traditional Chinese herbal formula. J Ethnopharmacol. 2008;118:271–9.

Zhao J, Ohba S, Shinkai M, Chung UI, Nangamue T. Icariin induces osteogenic differentiation in vitro in a BMP- and Runx2-dependent manner. Biochem Biophys Res Commun. 2008;369:444–8.

De la Riva B, Sánchez E, Hernández A, Reyes R, Tamimi F, López-Cabarcos E, Delgado A, Evora C. Local controlled release of VEGF and PDGF from a combined brushite–chitosan system enhances bone regeneration. J Control Release. 2010;143:45–52.

Venugopal J, Prabhakaran MP, Zhang Y, Low S, Choon AT, Ramakrishna S. Biomimetic hydroxyapatite-containing composite nanofibrous substrates for bone tissue engineering. Philos Transact A Math Phys Eng Sci. 2010;368:2065–81.

Liuyun J, Yubao L, Chengdong X. Preparation and biological properties of a novel composite scaffold of nano-hydroxyapatite chitosan carboxymethyl cellulose for bone tissue engineering. J Biomed Sci. 2009;14:65.

Hu Q, Li B, Wang M, Shen J. Preparation and characterization of nano-sized hydroxyapatite particles and hydroxyapatitechitosan nano-composite for use in biomedical materials. Biomaterials. 2004;25:779–85.

Han J, Zhou Z, Yin R, Yang D, Nie J. Alginate–chitosan hydroxyapatite polyelectrolyte complex porous scaffolds: preparation and characterization. Int J Biol Macromol. 2010;46:199–205.

Yamaguchi I, Tokuchi K, Fukuzaki H, Koyama Y, Takakuda K, Monma H, Tanaka J. Preparation and microstructure analysis of chitosan/hydroxyapatite nanocomposites. J Biomed Mater Res. 2000;55(1):20–7.

Yoshida A, Miyazaki T, Ishida E, Ashizuka M. Preparation of bioactive chitosan-hydroxyapatite nanocomposites for bone repair through mechanochemical reaction. Mater Trans. 2004;45:994–8.

Kong LJ, Gao Y, Cao WL, Gong YD, Zhao NM, Zhang XF. Preparation and characterization of nano-hydroxyapatite/chitosan composite scaffolds. J Biomed Mater Res A. 2005;75(2):275–82.

Oliveira JM, Rodrigues MT, Silva SS, Malafaya PB, Gomes ME, Viegas CA, Dias IR, Azevedo JT, Mano JF, Reis RL. Novel hydroxyapatite/chitosan bilayered scaffold for osteochondral tissue-engineering applications: scaffold design and its performance when seeded with goat bone marrow stromal cells. Biomaterials. 2006;27:6123–37.

Kong LJ, Gao Y, Lu GY, Gong YD, Zhao NM, Zhang XF. A study on the bioactivity of chitosan/nano-hydroxyapatite composite scaffolds for bone tissue engineering. Eur Polym J. 2006;42:3171–9.

Zhang R, Ma PX. Poly (alpha-hydroxyl acids)/hydroxyapatite porous composites for bone-tissue engineering. I. Preparation and morphology. J Biomed Mater Res. 1999;44:446–55.

Zheng J, Liang L. Intra-portal transplantation of bone marrow stromal cells ameliorates liver fibrosis in mice. Hepatobiliary Pancreat Dis Int. 2008;7(3):264–70.

Zhang Y, Venugopal JR, El-Turki A, Ramakrishna S, Su B, Lim CT. Electrospun biomimetic nanocomposite nanofibers of hydroxyapatite/chitosan for bone tissue engineering. Biomaterials. 2008;29:4314–22.

Niu X, Feng Q, Wang M, Guo X, Zheng Q. Porous nano-HA collagen PLLA scaffold containing chitosan microspheres for controlled delivery of synthetic peptide derived from BMP-2. J Control Release. 2009;134:111–7.

Gong YH, Zhou QL, Gao CY, Shen JC. In vitro and in vivo degradability and cytocompatibility of poly(l-lactic acid) scaffold fabricated by a gelatin particle leaching method. Acta Biomater. 2007;3:531–40.

Wei GB, Jin QM, Giannobile WV, Ma PX. The enhancement of osteogenesis by nano-fibrous scaffolds incorporating rhBMP-7 nanospheres. Biomaterials. 2007;28:2087–96.

Kim SE, Park JH, Cho YW, Chung H, Jeong SY, Lee EB, Kwon IC. Porous chitosan scaffold containing microspheres loaded with transforming growth factor-beta 1: implications for cartilage tissue engineering. J Control Release. 2003;91:365–74.

Lee J, Kim KE, Kwon IC, Ahn HJ, Lee SH, Cho HC, Kim HJ, Seong SC, Lee MC. Effects of the controlled-released TGF-beta 1 from chitosan microspheres on chondrocytes cultured in a collagen/chitosan/glycosaminoglycan scaffold. Biomaterials. 2004;25:4163–73.

Acknowledgments

This study was supported by Chinese Ministry of Science and Technology (973 Program No. 2009CB930003), NSF of China (Grant No. u0732003 and No. 30901532).

Author information

Authors and Affiliations

Corresponding author

Additional information

Junjun Fan, Long Bi, and Tao Wu are contributed equally to this work.

Rights and permissions

About this article

Cite this article

Fan, J., Bi, L., Wu, T. et al. A combined chitosan/nano-size hydroxyapatite system for the controlled release of icariin. J Mater Sci: Mater Med 23, 399–407 (2012). https://doi.org/10.1007/s10856-011-4491-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4491-4