Abstract

In this study, a good combination consisting of electrospun titanium dioxide (TiO2) nanofibers incorporated with high purity hydroxyapatite (HAp) nanoparticles (NPs) and antimicrobial silver NPs is introduced for hard tissue engineering applications. The synthesized nanofibers were characterized by various state of art techniques like; SEM, XRD, TEM, TEM EDS and XPS analyses. SEM results confirmed well oriented nanofibers and good dispersion of HAp and silver NPs, respectively. XRD results demonstrated well crystalline feature of three components used for electrospinning. Silver NPs were having a diameter in range of 5–8 nm indicated by TEM analysis. Moreover, TEM EDS analysis demonstrated the presence of each component with good dispersion over TiO2 nanofiber. The surface analyses of nanofibers were investigated by XPS which indicated the presence of silver NPs on the surfaces of nanofibers. The obtained nanofibers were checked for antimicrobial activity by using two model organisms E. coli and S. aureus. Subsequently, antimicrobial tests have indicated that the prepared nanofibers do posses high bactericidal effect. Accordingly, these results strongly recommend the use of obtained nanofiber mats as future implant materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In present years, implant engineering has gained tremendous attention due to well established results from experimental animal models. However, the scientific community is still facing a major challenge to facilitate the perfect strategy for formation of a new bone tissue for the patients suffering from various bone and dental defects. For this aesthetic purpose different designs to formulate a material of choice which will used as perfect implant are still under investigation. Therefore, lots of materials are utilized among them, titanium dioxide (TiO2) have been widely used as orthopedic and dental implant because of its good biocompatibility [1]. Although the use of TiO2 as implant materials is commonly adopted but it still lacks long-term maintenance is which plays a post vital role for osseointegration [2]. In order to facilitate osseointegration between the implant surface and its surrounding bone tissue, varied surface modification has been performed. Such modifications include as roughening by sand blasting, formation of TiO2, natural organic compounds and other chemical treatments [3–6]. Among them most commonly used surface modifications include by using hydroxyapatite (HAp) on the surfaces of titanium implants. Owing to its excellent biocompatibility, bioactivity, nonimmunogenicity, noninflammatory behavior and osteoconductive nature it has been most frequently used [7]. It is also believed that HAp, the most ubiquitous family of bioceramics which mimic the mineral composition of bone and forms a direct bond with neighboring bone resulting to induce mesenchymal cells which can further on differentiate toward osteoblasts [8, 9]. Therefore, use of HAp is widely adopted for implant materials.

It is noteworthy to mention that in order to improve patient outcomes to use TiO2 and HAp based materials there are lots of other parameters controlling the rejection rate of implants. Among them infection is a major cause for removal of prosthesis or significant delay in healing which overall results in postoperative infections. The systemic treatment of infected implant with antibiotics is often impossible due to the poor accessibility of applied organic antibiotics at the infection site. For this purpose implants materials are modified with antimicrobial coatings containing silver which can be beneficial for efficient recovery after implant replacement. Silver is a powerful inorganic antibiotic being used since ancient times for the purpose of wound healing. When silver comes in contact with microorganisms, it leads to sudden distortion of cell wall which later on causes death of these organisms, therefore, progressive steps are made for future use of the silver based materials [10]. Formation of super-bugs has become a main problem due to frequent use of the antibiotics. Generally, due to genetic transformation of microbial strains had created resistance against the present antibiotics which hamper their use on implant surfaces [11]. In order to have complete removal of pathogenic strains during wound healing process, there is a need to have an alternate strategy. Silver is also considered to be active against multiple drug resistant microbial strains. Surprisingly, there are minimal chances for development of bacterial resistance due to immediate death of microorganisms upon contact with silver ions. The mechanism for development of minimal resistance against silver has been well reported [12].

Electrospinning technique have been drawn attention due to their web like nature which exactly mimic the topology of extracellular matrix present in human body therefore, are used as scaffolds in tissue engineering [13]. Therefore, use of electrospinning in implantology has also been suggested by modifying various materials [14]. Knowing about the aforementioned facts present work reports the modification of TiO2 nanofibers as a base containing HAp and silver nanoparticles by electrospinning process. Moreover, evaluation of the obtained nanofiber matrices for morphological properties and crystalline structure were investigated. Antimicrobial activities for two test microorganisms have been evaluated. According to the obtained results, the prepared TiO2 nanofibers containing HAp and silver nanoparticles could serve a multiple functions with material character present in them. So as to be used as recommended strategy in terms of bone inducing and antimicrobial effect showing formulation for future implant materials. Further a detailed future study of nanofiber hybrids with osteoblast cells and certain aspects with respect with cell viability and cell-cytotoxicity are on the way of progress.

2 Experimental section

2.1 Materials

Poly (vinyl acetate) (PVAc, Mw = 500,000 g/mol) was obtained from Sigma-Aldrich USA. Titanium (IV) isopropoxide (Ti(Iso)), 98% assay) and silver nitrate (AgNO3) 99.8% assay were purchased from Junsei Co. Ltd., Japan. N,N-dimethylformamide (DMF) Showa Chemicals Ltd., Japan were used as solvents without further purification. Dialysis tubing’s (MWCO 12,000–14,000, Membrane Filtration Products Inc., USA) was used for checking the release of silver NPs from nanofibers. Difco Mueller–Hinton Broth and Difco Mueller–Hinton Agar were purchased from Becton, Dickinson and Co., Spark, MD 221 Ltd., USA. Phosphate buffer saline (PBS) 0.1 M, pH 7.4 was purchased from Aldrich Co., USA. For checking antimicrobial activity two microbial strains as E. coli (ATCC 43890) and S. aureus (CCARM 3-423) were used as model organisms.

2.2 Characterization

The morphology of the nanofiber mats had been analyzed by JEOL JSM-5900 scanning electron microscope, JEOL Ltd., Japan. Information about the phase and crystallinity of obtained products was done by using X-ray diffractometer (XRD, Rigaku Co., Japan) with Cu K α (λ = 1.540 Å) radiation over Bragg angle ranging from 20 to 80°. Transmission electron microscopy (TEM) was done by JEOL JEM 2010 operating at 200 kV, JEOL Ltd., Japan. The surface composition of nanofibers was detected by X-ray Photoelectron spectroscopy analysis (XPS, AXIS-NOVA, Kratos analytical Ltd, UK) with the following conditions: base pressure; 6.5 × 10−9 Torr, resolution (Pass Energy); 20 eV and scan step; 0.05 eV/step.

2.3 Procedure

2.3.1 Preparation of hydroxyapatite nanoparticles

The preparation of HAp NPs was done by following our previous methodologies [15–17]. Keeping in view, bone has 65–70% hydroxyapatite and 30–35% organic compounds (on a dry weight basis). Collagen is the main organic compound present in the natural bone (95%), besides there are other organic compounds existing in small concentrations such as chondroitin sulfate, keratin sulfate and lipids (e.g. phospholipids, triglycerides, fatty acids, cholesterol,…etc.) [18]. Bovine bones taken from fumer of Egyptian cows were carefully washed by water and acetone to remove the fats and other solid impurities associated with them. After washing, the bones have been dried at 160°C for 48 h. The cleaned bones were grinded to particle size less than 450 μm. The grinded bones were placed in an open alumina crucible then heated in the furnace (Lenton Thermal Designs Ltd., South Korea). The grinded bone sample was heated to 850°C at heating rate of 10°C/min with soaking time of 1 h. The obtained calcined bone powder was further grinded by ball milling to decrease the particle size.

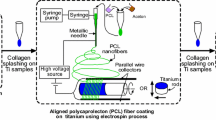

2.3.2 Fabrication of nanofibers by electrospinning

The electrospinning process was utilized to produce TiO2 nanofibers containing HAp and silver NPs. Typically, a sol–gel was prepared by mixing Ti(Iso) and PVAc (20 wt%, in DMF) with a weight ratio of 2:3. After this 1 g of HAp powder was added to this solution and then few drops of acetic acid were added till the solution becomes transparent. To fabricate the sol–gels containing silver, step wise methodology was adopted. Silver nitrate solutions in 1 g of DMF were mixed with previously prepared Ti(Iso)/PVAc/HAp solutions to prepare final solutions containing 1, 3 and 5 wt% AgNO3 with respect to Ti(Iso). Afterwards, these solutions were homogeneously mixed under stirred conditions for 10 min. A high voltage power supply (CPS-60 K02V1, Chungpa EMT Co., South Korea), capable of generating voltages up to 60 kV, was used as a source of electric field for spinning of sol–gels. Solution to be electrospun was supplied through a plastic syringe attached to a capillary tip. The copper wire originating from positive electrode (anode) connected with graphite pin was inserted into the solution and a negative electrode (cathode) was attached to a metallic collector. Briefly, the solutions were electrospun at 15 kV and 15 cm working distance (the distance between the needle tip and the collector). The as-spun fibers were initially dried for 24 h at 80°C under vacuum in presence of P2O5 and then calcined in air atmosphere at 600°C for 1 h with heating rate of 5°C/min.

2.3.3 Release of silver nanoparticles from nanofibers

By following our previously, described method, the release of silver NPs from the nanofibers was performed by utilizing the properties of porous membrane composed of dialysis tubing [19]. Briefly, the nanofibers highest concentration (i.e. 5 wt%) weighing 100 mg in 5 ml of PBS solution where loaded in a dialysis bag. This slurry was filled in dialysis tubing and placed in 100 ml specially designed glass bottle taking care of evaporation and equipped with controlled temperature system. The PBS solution was placed in the glass bottle sinking the dialysis tubing; the media was stirred (100 rpm) at 37 ± 2°C. To check the amount of the released silver, the first sample was withdrawn within short times (i.e. after 1 h), later, another sample was taken after 48 h. During this period, after every 3 h an amount of distill water was with drawn and replaced with fresh one so as to have complete washing with water. In order to check the amount of silver released totally, 2 samples were pipetted out. One sample was named as before washing (i.e. after initial 1 h), and last one was named as after washing (i.e. after final 48 h). Later on the silver release measurements were performed by using HP 8453 UV–visible spectroscopy system, Germany. The optical density (OD) was measured at wavelengths from 400 to 1,100 nm for highest (5 wt%) silver combination, respectively. The spectra obtained were analyzed by HP ChemiStation software 5890 series.

2.3.4 Sample preparation and procedure for antimicrobial test

Analysis of antimicrobial test was carried out by making samples from silver-free TiO2/HAp nanofibers and silver containing ones by following previously established procedure elsewhere [20]. The samples were made by mixing nanofibers to give final concentration of 5 mg/ml in double distill water. These nanofiber/colloidal solutions were subjected to mild sonication and subsequently filtered through a Whatman filter paper. The nanofiber laden filter paper were dried in an oven for 1 h and small disks of uniform size (5 mm diameter) containing 50 ± 10 μg nanofibers were punched out. Further on these, disks impregnated with nanofibers were autoclaved at 120°C for 1 h. After preparation sterile circular disks containing nanofibers, from autoclave the microbial population were efficiently raised and spectroscopically checked to reach density of 1.5 × 108 cells/ml by 0.5 McFarland method. The test has been carried out as follow, a cell suspension of 1.5 × 108 cells/ml was inoculated with cotton swabs from bacterial suspension over petri plates containing solidified nutrient agar medium. The inoculated agar plates were allowed to dry for 5–10 min after the inoculation. Later on disks containing nanofibers were placed over nutrient agar plate and further on plates were inverted and incubated for 12 h at 37°C to observe the zones of inhibition.

3 Results and discussion

3.1 Nanofiber identification and morphological appearance

The electrospinning of sol–gels containing various amounts of silver from 0 to 5% afforded membranes consisting of well-defined nanofibers with very smooth, uniform and bead-free nanofibers is shown in Fig. 1a–d. The addition of HAp and silver NPs over TiO2 nanofiber did not affect the morphologies before calcinations in all the formulations. However, the nanofibers after calcinations resulted in decrease in average diameter of the nanofibers compared with nanofibers before calcinations as indicated in Fig. 1e–h. Overall, average diameter of the nanofibers was in the range of 500–700 nm. The diminishing size of nanofiber diameter after calcination can be explained as removal of the polymer (PVAc) by calcinations which utilized high temperature of 600°C for 1 h. The nanofibers modified with silver did not reveal any noticeable change in the fiber diameter or morphology as the silver content was increased. However, increase in silver content more than cited limit in this study (i.e. 5%) resulted in producing nanorods rather than nanofibers.

3.2 Crystalline feature of prepared nanofibers

The polymer is an essential constituent in the sol–gel to achieve the electrospinning process. Metal alkoxides are the best candidates to form gel structure due to their tendensity of hydrolysis and condensation in the polymer matrix. Consequently, PVAc, Ti(Iso), HAp and silver mixture can form proper sol–gel. It was expected that calcinations of the as-prepared nanofibers revealed complete elimination of the PVAc polymer and decomposition of the inorganic silver salt precursors. In order to prove these findings and to identify each three components (i.e. TiO2/HAp/Silver), we have performed XRD analysis which is highly trustable technique utilized to investigate the nature of any crystalline compounds. In this intrest the XRD pattern of obtained HAp and modified nanofibers after calcination are presented in Fig. 2. As shown in this figure, spectra featured as pure HAp which consists of synthesized HAp. It can be seen strong diffraction peaks at 2θ values for HAp are at 25.87, 28.12, 31.77, 32.90, 34.08, 40.45, 46.71 and 49.46° corresponding to the crystal planes (002), (102), (211), (300), (202), (221), (222) and (213). All the peaks originating from this spectra are matching with the standard HAp according to the JCPDS data [21, 22]. Therefore, it can be concluded that the calcination processes have eliminated the other impurities from the bovine bones and the obtained molecular skeleton consists of pure HAp [18]. Further on the spectra of the TiO2 nanofibers containing HAp and silver content of (i.e. 0, 1, 3 and 5%) are also presented in this figure. As shown in this figure, the result affirms the formation of pure anatase titanium dioxide, in all nanofiber combinations. As the existence of strong diffraction peaks at 2θ values of 25.28, 48.05, 53.89, 55.06, 62.69, 68.72, 70.31 and 75.03°corresponding to the crystal planes (111), (200), (105), (211), (204), (116), (220) and (215), respectively indicates the formation of anatase titanium dioxide [23]. The existence of HAp in the TiO2 nanofibers is also present in all combinations. It can be also seen that strong diffraction peaks at 2θ values for HAp inside the all nanofiber formulations are matching with the synthesized HAp used for electrospinning. While as compared with its other modified counterparts obtained from electrospinning of silver nitrates, the spectra posses some extra peaks of pure silver metal in addition to TiO2 and HAp. For instance diffraction peaks at 2θ values for pure silver were located at 38.11, 44.27, 64.42 and 77.47° corresponding to the crystal planes (111), (200), (220) and (311) in accordance with JCPDS data [24]. It is interesting to mention that the intensities of peaks obtained for silver from XRD analysis were increasing with increase in the concentration of original silver nitrate used as original sol–gel. Overall, results satisfy the presence of crystalline nature of all three components respectively (i.e. TiO2/HAp/Silver).

3.3 Transmission electron microscope analysis of obtained nanofibers

It is well known that transmission electron microscope analysis (TEM) can be utilized to differentiate between the crystalline and amorphous structure of the materials, especially by analyzing the high resolution TEM (HR-TEM). To investigate this peculiar phenomenon, Fig. 3 shows the TEM images of nanofibers prepared after calcinations process. As shown in Fig. 3a which consists of (TiO2/HAp/Silver 0%) it appears to be having composite nature of the two compounds (i.e. TiO2/HAp). The Fig. 3b further shows the high resolution TEM (HR-TEM) image of the marked area from former figure (Fig. 3b). This image clearly shows apparent strips which indicate high crystallinity for the marked area, and therefore one can confidently say that calcinations process had removed the entire polymer associated with nanofibers.

TEM image of nanofibers prepared from a solution titanium dioxide and hydroxyapatite containing 0 wt% silver nitrate after calcination (a). Panel b shows high resolution image of indicated area. Panel c shows TEM image of nanofibers prepared from a solution titanium and hydroxyapatite containing 5 wt% silver nitrate. Panel d shows high resolution image of indicated area

Moreover, the nanofiber modified with silver (i.e. 5 wt%) is shown in Fig. 3c. As shown in this figure, one can clearly observe distinguishable morphology than the pristine nanofiber (Fig. 3a) which consists of 0% silver. To further know more insight about the locations silver NPs, one can observe the Fig. 3d representing the HR-TEM of corresponding figure as indicated by arrow. It can be seen there are small NPs around 5–8 nm size, which are predominating everywhere on the surface of nanofiber. It is noteworthy to mention that the mother solution used for electrospinning having silver nitrate which thermally decomposes at 300°C [25]. This further on confirms the XRD results, which indicated presence of silver. Therefore, small NPs can be assigned as metallic silver NPs.

To precisely investigate the location of each synthesized components present in nanofibers, we have invoked TEM-EDS analysis. In this regard Fig. 4a and b shows obtained data from pristine nanofibers which appears to be having composite nature of the two compounds. As shown in Fig. 4b, the line mapping which indicates compound mapping is presented in this figure. The corresponding compound mapping results are shown in Fig. 4c, d and e. From these figures one can clearly reveal the presence to titanium, calcium and phosphorous accounting for HAp. These results further fully confirms that the nanofiber do consist of titanium as a main base and also contains small amount of HAp NPs allover the nanofiber.

TEM-EDX image of nanofibers prepared from a solution titanium and hydroxyapatite containing 0 wt% silver nitrate (a). Panel b shows the linear EDX analysis along the line appearing in the figure. Arrows indicate the position of silver nanoparticles. Results of line mapping for three compounds analyzed as titanium (c) (red), calcium (d) (green), and phosphorous (e) (violet)

For investigating, location of silver over modified nanofiber (TiO2/HAp/Silver 5%) results was indicated in Fig. 5. Figure 5a shows the one of modified nanofiber with 5% silver content the apparent white areas according to the previous normal TEM (Fig. 3c, d) analysis these white zones might be explained as silver NPs. However, gray areas which form the matrix of nanofiber can be explicated as the TiO2 and HAp as observable in Fig. 5a and b respectively. The typical compound mapping of this nanofiber combination is indicated in Fig. 5c, d, e and f which are obtained from the line EDS analyses at the dashed yellow lines as in shown in Fig. 5a and b. The compounds have been identified are as titanium (red), calcium (violet), phosphorous (cyan) and silver (green). The silver metal has been detected in places matching the white apparent particles in Fig. 5a as shown in the dashed yellow line in this figure (marked by arrows) which affirms the aforementioned hypothesis that the white particles can be explained as silver. These results further confirm the XRD analyses which clearly show the presence of three compounds in nanofibers.

TEM-EDX image of nanofibers prepared from a solution containing 5 wt% silver nitrate (a). Panel b shows the linear EDX analysis along the line appearing in the figure. Arrows indicate the position of silver nanoparticles. Results of line mapping for three compounds analyzed as titanium (b) (red), calcium (c) (violet), phosphorous (d) (cyan) and silver (e) (green)

3.4 Surface topography of nanofibers

As far as antimicrobial activity is concerned the formation of naked silver NPs on the surface of implant can be more beneficial then the NPs present inside. In other words presence of silver NPs on the surfaces of nanofibers can lead to direct contact with microbes which can be more effective in terms of microbial inhibition. In order to prove the synthesized silver NPs do reside on the surfaces of formulated nanofibers XPS analyses have been invoked. Figure 6 shows the XPS results of nanofibers obtained from sol–gels having different silver nitrate contents. As shown in this figure and the corresponding inset, the appearance of peaks at 364 and 370 eV corresponding to Ag 3d5/2 and Ag 3d3/2 orbitals, respectively, indicates the presence of Ag0 on the surface [26]. Interestingly, the intensities of these peaks increased with increase of the silver nitrate content in the electrospun solution as shown in inset figure. Overall, one can confidently say that the produced nanofibers possess silver NPs on the surfaces of nanofibers rather than inside.

3.5 Silver release studies from nanofibers

Dialysis method is a wonderful way to estimate the release of drug compounds from nano materials by using dialysis tubing [27, 28]. This semi-permeable membrane consists of a spongy matrix of crosslinked polymers, the pore rating is referred to as Molecular Weight Cut Off (MWCO), which is an indirect measure of the retention performance. Since our prepared nanofibers are quit big enough to be retained by 12,000–14,000 molecular weight of dialysis tubing which we used. Since the maximum amount of silver concentration (i.e. 5 wt%) used to make nanofiber formulations it was necessary check the in vitro release profiles of this combination in this study. To be sure that the silver NPs are firmly bounded with the nanofibers and will not be lost under harsh conditions, e.g., when introduced in patient body, we performed series of wash experiments by replacing the distill water after every 1 h as aforementioned in (Sect. 2.3.3) during dialyses process. In this regard, nanofibers loaded in dialyse tubing were vigorously stirring for 48 h. During this time period, every 1 h; distilled water was replaced by fresh one. To precisely invoke spectrophotometer, the obtained media from dialyses (i.e. before and after washing) were checked as differences in release profiles. At this stage, Fig. 7 shows the obtained UV–Vis absorption spectra of before and after washing of nanofibers. As shown in this figure, nanofiber containing silver NPs showed absorbance band in the range of 450 nm and this absorbance is attributed to the characteristic surface plasmon resonance of silver NP [29]. Moreover, nearly no much difference between the spectra was observed for the before and after washing from the residual washing extracts. Accordingly, it can be concluded that silver NPs are still remaining in the washed nanofibers, almost no losses in the silver NPs had taken place with the replacement of large amount of water. Presuming the high release of silver NPs from highest nanofiber combination can be toxic to human cells. It is noteworthy, to mention that in one of the previous studies a 10 wt% silver was used to fabricate some polymer nanofibers. However, in those studies the effect of silver containing nanofibers was checked by culturing the fibroblasts which later on showed non toxic effects on growing cells [28]. Overall, the unaltered release pattern from washing extracts satisfied the need of using adapted procedure as safe implant material.

3.6 Test for zones of inhibition

For the dental or bone prostheses, the major problem faced is pre and post operative infections. Former can be linked to various health problems and strategy to overcome this problem is a major challenge for scientists till now. Basic reason for this is dental plaques (biofilm) which is a major cause of various diseases and leads to dental caries or periodontal problems (such as gingivitis). Moreover, in case of bone implants microbial infections is also a major problem faced by patients. Among microorganisms the most common etiological agents are E. coli and S. aureus. For this particular reason we have selected these two microbial strains as a model organism to address the antimicrobial nature of our prepared materials. Silver is considered material of choice, for antimicrobial dressings and it is also established that silver enhances the epithelization [30]. Silver and its forms are potent antimicrobials against various bacterial species. The exact mechanism how silver participates in distortion of bacteria is unfortunately still unclear. However, it is believed that sliver mainly makes denaturation and oxidization for cell wall which lead to rupture the internal cell organelles, resulting in the death of the bacterial cell [31]. It is also well known when a critical amount of antibacterial compound (capable of inhibiting microbial growth) is in contact with bacterial strains the clear area near that contact is formed and these areas are referred as zones of inhibition [20]. Figure 8 shows high magnification optical images of the zone of inhibition for 12 h incubated petriplates of E. coli and S. aureus grown in presence of circular disk containing nanofibers. It was observed that in case of pure TiO2/HAp nanofibers which contains 0% silver these zones of inhibition were missing due to lack of silver content. While as, other counterpart which contain a certain amount of silver showed clear zone of inhibition. It is noteworthy to mention that formation of zones of inhibition around the disks is an indicator for inhibition of bacterial colonies near the vicinity of disk edges. Due to diffusion of silver NPs from the nanofiber disks, it may lead to kill the microorganism around the disk area which results in formation of clear circular zones. It is considered that diameter of the inhibited area is a measure of the effectiveness or resistance of the bacteria towards organic antimicrobial agent. However, a previous work reported that zone of inhibition by using silver is only qualitative and provides no means of assessing quantities of silver that have been released [32]. Therefore, diameter of a zone is not in itself sufficient to determine efficacy of silver and its forms. Accordingly, we did not find any significant major difference between (3 and 5%) silver content in the nanofiber mats. However, it was observed that zones of inhibition are clearer in case of S. aureus than E. coli. The possible reason resides with the make up of cell wall for two different bacteria. As the later do contain double layered cell and former contains single layer. Meanwhile, similar effect of silver on S. aureus and E. coli was studied by other researchers which indicated that antibacterial activity of the silver based NPs for E. coli were lower than S. aureus [33]. Overall, results generously indicate well establishing facts of using these antimicrobial nanofibers as desired and suitable candidates for future dental and bone implant materials.

4 Conclusions

Nano-biotechnological approach to engineer TiO2 modified nanofibers containing HAp and silver NPs can be easily electrospun to form smooth nanofibers. Keeping in view the importance of HAp as bone inducer and silver as antimicrobial agent our prepared material in the form of nanofibers will be material of choice for future implants. Moreover, the obtained TiO2 nanofibers can be modified with HAp and silver NPs and can be confirmed by analyzing the samples by XRD and TEM. The addition of silver nitrate to this sol–gel does not affect the general morphology of either as prepared electrospun nanofiber mats or nanofibers after calcinations. XPS analyses can be used to confirm the silver NPs are present on the surfaces of nanofibers. The antimicrobial test has been conducted to ensure that the obtained nanofibers can be used as antimicrobial implant which can reduce the need of using high doses of antibiotics during the recovery from surgery. Avoiding using any complex method, rather than simple electrospinning process can open a new avenue for the prepared nanofibers to be used in future biomedical implant applications.

References

Rack HJ, Qazi JI. Titanium alloys for biomedical applications. Mater Sci Eng, C. 2006;26:1269–77.

Ektessabl AM, Otsuka T, Tsuboi Y, Honno Y, Mokuno Y, Fujll K, Albrektsson T, Sennerby L, Johansson C. Preliminary experimental results on mapping of the elemental distribution of the organic tissues surrounding titanium-alloy implants. Nucl Instrum Methods Phys Res, B. 1996;109:278–83.

Liu X, Chu PK, Ding C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng, R. 2004;47:21–49.

Guéhennec LL, Soueidan A, Layrolle P, Amouriq Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater. 2007;23:844–54.

Ban S, Iwaya Y, Kono H, Sato H. Surface modification of titanium by etching in concentrated sulfuric acid. Dent Mater. 2006;22:1115–20.

Sollazzo V, Pezzetti F, Scarano A, Piattelli A, Bignozzi CA, Massari L, Brunelli G, Carinci F. Zirconium oxide coating improves implant osseointegration in vivo. Dent Mater. 2008;24:357–61.

LeGeros RZ. Calcium phosphates in oral biology and medicine. Basel, Switzerland: Karger; 1991.

Okumura M, Ohgushi H, Dohi Y, Katuda T, Tamai S, Koerten HK, Tabata S. Osteoblastic phenotype expression on the surface of hydroxyapatite ceramics. J Biomed Mater Res A. 1998;38:122–9.

Cong Z, Jianxin W, Huaizhi F, Bing L, Xingdong Z. Repairing segmental bone defects with living porous ceramic cylinders: an experimental study in dog femora. J Biomed Mater Res A. 2000;55:28–32.

Atiyeh BS, Costagliola M, Hayek SN, Dibo SA. Effect of silver on burn wound infection control and healing: review of the literature. Burns. 2007;33:139–48.

Thornes B, Murray P, Bouchier-Hayes D. Development of resistant strains of Staphylococcus epidermidis on gentamicin-loaded bone cement in vivo. Bone Joint Surg Br. 2002;84:758–60.

Simon S. Bacterial silver resistance: molecular biology and uses and misuses of silver compounds. FEMS Microbiol Rev. 2003;27:341–53.

Barnes CP, Sell SA, Boland ED, Simpson DG, Bowlin GL. Nanofiber technology: designing the next generation of tissue engineering scaffolds. Adv Drug Deliv Rev. 2007;59:1413–33.

Aryal S, Bajgai MP, Khil MS, Kang H-S, Kim HY. Biomimetic hydroxyapatite particulate nanofiber modified silicon: in vitro bioactivity. J Biomed Mater Res A. 2008;88A:384–91.

Barakat NAM, Khil MS, Omran AM, Sheikh FA, Kim HY. Extraction of pure natural hydroxyapatite from the bovine bones bio waste by three different methods. J Mater Process Technol. 2009;209:3408–15.

Barakat NAM, Khalil KA, Sheikh FA, Omran AM, Gaihre B, Khil SM, Kim HY. Physiochemical characterizations of hydroxyapatite extracted from bovine bones by three different methods: extraction of biologically desirable. Mater Sci Eng, C. 2008;28:381–7.

Sheikh FA, Barakat NAM, Kanjwal MA, Kwang P, Park SJ, Kim HY. Synthesis of polyvinyl alcohol (PVA) nanofibers incorporating hydroxyapatite nanoparticles as future implant materials. Macromol Res. 2010;18:59–66.

Samuel L, Turek MD, Lippincott JB. Orthopaedics: principles and applications, 2nd ed. 1985. pp. 113 and 136.

Sheikh FA, Barakat NAM, Kanjwal MA, Aryal S, Khil MS, Kim HY. Novel self-assembled amphiphilic poly(ε-caprolactone)-grafted-poly(vinyl alcohol) nanoparticles: hydrophobic and hydrophilic drugs carrier nanoparticles. J Mater Sci Mater Med. 2009;20:821–31.

Case CL, Johnson TR. Laboratory experiments in microbiology. California: Benjamin Cummings Pub Inc; 1984. p. 126–9.

Lopatin CM, Pizziconi V, Alford TL, Laursen T. Hydroxyapatite powders and thin films prepared by a sol-gel technique. Thin Solid Films. 1998;326:227–32.

Joint Committee on Powder Diffraction Standards, JCPDS, Card no 09-0432 (1994).

Joint Committee on Powder Diffraction Standards, JCDPS, Card no 21-1272 (1969).

Joint Committee on Powder Diffraction Standards, JCDPS, Card no 04-0783 (1953).

Barakat NAM, Woo KD, Kanjwal MA, Choi KE, Khil MS, Kim HK. Surface resonances, optical properties, and electrical conductivity thermal hystersis of silver nanofibers produced by the electrospinning technique. Langmuir. 2008;24:11982–7.

Briggs D. Surface analysis of polymers by xps and static sim, 1st ed. Wiley, 2nd ed. Cambridge: Cambridge University Press; 1993.

Sheikh FA, Barakat NAM, Kim BS, Aryal S, Khil M-S, Kim HY. Self-assembled amphiphilic polyhedral oligosilsesquioxane (POSS) grafted poly(vinyl alcohol) (PVA) nanoparticles. Mater Sci Eng, C. 2009;29:869–76.

Sheikh FA, Barakat NAM, Kanjwal MA, Jeon SH, Kang HS, Kim HY. Self synthesize silver nanoparticles in/on polyurethane nanofibers: nanobiotechnological approach. J Appl Polym Sci. 2010;115:3189–98.

Patel K, Kapoor S, Davei DP, Mukherjee TJ. Synthesis of nanosized silver colloids by microwave dielectric heating. Chem Sci. 2005;117:53–60.

Tian J, Wong KKY, Ho CM, Lok CN, Yu WY, Che CM, Chiu JF, Ta PKH. Topical delivery of silver nanoparticles promotes wound healing. ChemMedChem. 2007;2:129–36.

Lala NL, Ramaseshan R, Bojun L, Sundarrajan S, Barhate RS, Ying-jun L, Ramakrishna S. Fabrication of nanofibers with antimicrobial functionality used as filters: protection against bacterial contaminants. Biotechnol Bioeng. 2007;97:1357–65.

Gallant-Behm CL, Yin HQ, Liu S, Heggers JP, Langford RE, Olson ME, Hart DA, Burrell RE. Comparison of in vitro disc diffusion and time kill-kinetic assays for the evaluation of antimicrobial wound dressing efficacy. Wound Repair Regen. 2005;13:412–21.

Shahverdi AR, Fakhimi A, Shahverdi HR, Minaian S. Synthesis and effect of silver nanoparticles on the antibacterial activity of different antibiotics against Staphylococcus aureus and Escherichia coli. Nanomed Nanotechnol Biol Med. 2007;3:168–71.

Acknowledgments

This work was supported by a grant of the Korean Ministry of Education, Science and Technology (The Regional Core Research Program/Center for Healthcare Technology and Development, Chonbuk National University, Jeonju 561-756, Republic of Korea). This work was also supported by Priority Research Centers Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2009-0093816). Author is thankful to KBSI, Jeonju branch, for providing facilities to perform TEM EDS.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sheikh, F.A., Barakat, N.A.M., Kanjwal, M.A. et al. Electrospun titanium dioxide nanofibers containing hydroxyapatite and silver nanoparticles as future implant materials. J Mater Sci: Mater Med 21, 2551–2559 (2010). https://doi.org/10.1007/s10856-010-4102-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-010-4102-9