Abstract

Biodegradable and bioactive β-tricalcium phosphate (β-TCP) coatings were prepared on magnesium (Mg) in order to improve its biocompatibility by a chemical method. The tensile bonding strength of β-TCP coating and Mg substrate was measured by the standard adhesion test (ISO 13779-4). And the cytocompatibility of β-TCP coated Mg was studied by using human osteoblast-like MG63 cells. It was found that the MG63 cells could grow well on the surface of β-TCP coated Mg and the cell viability on β-TCP coated Mg was above 80% during the cocultivation of MG63 cells and β-TCP coated Mg for 10 days, indicating no cytotoxicity. It was concluded that the β-TCP coated Mg had good cytocompatibility. The degradation of Mg substrate with β-TCP coating in vitro was studied in detail by XRD, EDX, SEM, and ICP. The results showed that a bone-like apatite continually formed on the surface of the sample with the degradation of both Mg substrate and β-TCP coating in Hank’s solution (a simulated body fluid). The biodegradation mechanism was preliminarily analyzed in the paper.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Magnesium (Mg) is attractive as a bone substitute material due to its suitable biomechanical compatibility [1], biodegradation [2], and good biocompatibility [3]. However, previous studies indicated that the degradation of Mg alloys was too fast to match the growth of the bone tissues [4] and even resulted in some toxicity in vivo. The purity of Mg alloys has been much improved with progressing of the metallurgical techniques, which can well slow down the degradation rate of Mg and its alloys. Another important method to reduce the degradation rate of Mg is surface modification. For implant applications, a small number of preliminary surface treatment methods for Mg alloys have been reported, including carbonate treatment [5], alkali–heat treatment [1, 6], ion plating of Ti [7], fluoride-conversion coating [8], and microarc oxidation [9], each with its merits and limitations. To expand the repertoire in this respect, the present study attempts to prepare a bioactive coating with good biocompatibility and biodegradation on Mg.

Calcium–phosphate (Ca–P) coatings have been widely used in clinic due to their favorable biocompatibility and osteo-conductive properties. Many studies have been conducted by depositing Ca–P coatings on metal implants to combine the biocompatibility of ceramics with the excellent strength of metals [10, 11]. The β-tricalcium phosphate (β-TCP), which has good chemical stability, relatively high mechanical strength, and favorable bioabsorption rate [12], is promising to be coated on Mg to improve the possibility of applying Mg in biomedical fields. Bioactive β-TCP coating was well prepared on Mg by a low temperature chemical method in the paper.

As the Mg samples in the tests are intended to be employed as hard tissue substitutes, therefore, in vitro cytocompatibility test on osteoblasts is necessary to fully investigate the possibility of using Mg as biomedical implants. The cytocompatibility tests using MTT assay [13] by cocultivation of material samples with human bone derived cells (HBDC), an osteoblast lineage (MG63), and a macrophage lineage (RAW264.7) have been used to determine the cytotoxicity of cobalt and chromium metal ions [14] and composite materials including HA [15]. In the work, the human osteoblast-like MG63 were cocultivated with β-TCP coated Mg in order to evaluate the biocompatibility of Mg as a bone substitute material.

The biodegradation is an important property of Mg as a bone substitute material. At present, the study on the biodegradation of the surface modified Mg and its alloys is still fewer [16, 17], and the relevant mechanism is not so clear, including the Mg with β-TCP coating. In this study, the biodegradation behavior of Mg with β-TCP coating was preliminarily studied in vitro in order to give more information for further development of Mg based biomaterials.

2 Experimental

2.1 Preparation of β-TCP coating

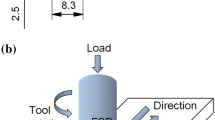

Samples of dimensions 10 mm × 10 mm × 2 mm were cut from commercially pure Mg ingots (99.99%). The samples were ground and dry polished with SiC papers successively up to 1,200 grits. The polished samples were ultrasonically rinsed for 10 min in alcohol and dried in a warm air stream and then followed by an immersion in a supersaturated Na2HPO4 solution at room temperature for 3 h and a heat-treatment at 400°C for 10 h. After the alkali and heat treatments, they were ultrasonically cleaned again in distilled water for 10 min and then were placed into the falcon tubes filled with a mixture of Na2HPO4 · 12H2O (23.75 g/l) and Ca(NO3)2 (18.2 g/l) in deionized water at 70°C for 48 h. The samples were then washed with distilled water and dried in air. The surface morphology of the coating and the phases formed after treatment were studied by scanning electron microscope (SHIMADZU, SSX-550) and X-ray diffraction (Rigaku, D/MAX-2500PC18kW) using CuKα line generated at 50 kV and 300 mA. The chemical composition was studied by energy dispersive X-ray spectroscopy (Oxford EDX System). The tensile bonding strength of the coatings was measured by a standard adhesion test (ISO 13779-4). This was done by applying a uniaxial tensile load to a cylindrical test assembly of 25 mm in diameter composed of a β-TCP coated specimen bonded to an uncoated component. The two pieces of test assembly were bonded together using an adhesive bonding glue. The tensile strength was calculated by dividing the load at failure to the cross-sectional area. The tensile load was applied at a constant cross-head velocity of 1 mm/min using a universal testing machine. Five samples were tested for each condition.

2.2 Cytocompatibility tests

2.2.1 Cell culture

MG63, the human osteoblast-like cells, obtained from China medical University, were cultured in DMEM medium at 37°C in 5% CO2 humidified atmosphere and the plastic cell culture dishes, isolated by a 2% agarose gel layer with pH 7.4 PBS to prevent non-specific cell adhesion, were used. All the samples were immersed in the cell culture medium for 24 h in a 24 wells microplate which had been sterilized in 75% ethanol for 10 min and immersed in PBS overnight. Then a drop of 50 μl of 5 × 106 cells was seeded on the top of each sample, which was absorbed by the substrates. The same amount of cells was also seeded on the plastic control surface. Cells were attached to the samples for 15 min before additional medium was added. The cells were further incubated at 37°C in 5% CO2 for various periods of time and were fed once every other day.

2.2.2 Cell viability and proliferation

In the cell viability and proliferation study, the number of living cells was measured by the MTT-based colorimetric assays. The assay relies upon the ability of living cells to reduce the tertrazolium salt into the soluble colored formazan product. After 1, 4, 7, and 10 days cell incubation on the Mg samples or the control plastic, non-adherent cells were removed by twice gentle washes in PBS. About 1 ml of 16% MTT in DMEM medium was added per well and incubated at 37°C in a 5% CO2 incubator for 3 h. Then 100 μl of the homogenized solution was transferred to the 96-well plates and the optical density was recorded at 492 nm using an MRX ELISA reader. Results were reported as the optical density units. Background absorbance was obtained by incubation of the MTT in DMEM medium and subtracted from the results.

2.2.3 Live/dead staining and SEM observation

Cell live/dead staining was performed to determine the viable and non-viable MG63 cells, after cultured on the β-TCP coated Mg for 4 h. The living and dead cells were, respectively, stained with AO–EB at room temperature, and then visualized using a Leica DMLB fluorescence microscope.

For morphological analysis of the MG63 cells after cultured on the β-TCP coated Mg samples for 10 days, the samples were examined using SEM. Samples were washed with PBS for three times and fixed with 1.5% glutaraldehyde in PBS overnight at 4°C. After washing with PBS, the cells were dehydrated through a series of graded concentrations of ethanol and then finally dried for 48 h in air at room temperature. The samples were then viewed in a low vacuum for 30 Pa using a scanning electron microscope (HITACHI, S-3400N) operated at an accelerating voltage of 20 kV.

2.2.4 Statistical analysis

Statistical analysis was carried out by a one-way analysis of variance (one-way ANOVA) using statistics package for social science (SPSS v 13.0) software. The results were compared using a LSD–Dunnett’s post hoc test and differences were considered as significant when P < 0.05. Experiments were performed three times with three replicates for each sample and all graphs are expressed as mean ± standard error (SE) where n = 3.

2.3 In vitro biodegradation test

The β-TCP coated Mg and the naked Mg samples were cleaned in ethanol prior to corrosion tests. The samples with size of 10 mm × 10 mm × 2 mm were immersed in 100 ml of an acellular Hank’s solution (Na+ 142.1, K+ 5.33, Mg2+ 0.9, Ca2+1.26, Cl− 146.8, HCO3 − 4.2, HPO4 2− 10.78, SO4 2− 0.41 mM) with initial pH of 7.22 at 37°C. The solution was not refreshed again. After immersion of the samples in Hank’s solution for 1, 2, 3, 4, and 8 weeks, the pH values of Hank’s solution were detected. Mg and Ca concentrations of Hank’s solution, before and after soaking the samples, were measured using inductively coupled plasma atomic emission spectrometry (ICP-AES; SPS-1500VR, Seiko Instruments Inc., Japan).The surface morphology, composition, and structure of the β-TCP coated Mg sample before and after biodegradation were analyzed using SEM, EDS, and XRD.

3 Results

3.1 Preparation of β-TCP coating and cytocompatibility

Figure 1 shows the surface micrograph after calcifying. The C–P coating was composed of crystal in flakes. EDS analysis in Table 1 shows an overall Ca/P ratio of 1.54 for the C–P coating that is close to 1.5 for the Ca/P ratio of β-TCP. EDS analysis is consistent with the XRD result. In Fig. 8, the XRD result shows that the coating is composed of pure β-TCP before biodegradation. The tensile adhesion strength of β-TCP coating and Mg substrate is shown in Table 2. It can be seen that the adhesion strength of the coatings is 16.1 ± 3.4 MPa.

After 4 h cell incubation, the fluorescence photo shows the adhesion of many viable MG63 cells on the β-TCP coated Mg which means surface modified Mg has good affinity, as shown in Fig. 2. Cell proliferation was checked over a period of 10 days with that of plastic culture dishes as the control. Figure 3a shows a general increase of the number of cells on the control substrate as well as on the β-TCP coated Mg for the 10 days, as determined by increase in the optical density. Also at this time, there is a significantly higher number of MG63 cells on the β-TCP coated Mg compared with that of on the naked Mg. Figure 3b indicates the MG63 cell viability on naked Mg and β-TCP coated Mg. The cell viability is above 80% on β-TCP coated Mg which means no obvious inhibitory effect on cell growth was detected due to the good biocompatibility of β-TCP coating. However, an obvious decrease in cell viability was observed on naked Mg compared with that of on β-TCP coated Mg. The cell viability is less than 80% on the naked Mg that means some extent of cell toxicity of the naked Mg.

At about the 10th day, the cells proliferate well and spread throughout the surface of the sample. The morphology of cell is in good condition. Figure 4 presents the SEM micrographs of MG63 cells cultured on the β-TCP coated Mg for 10 days, in which the cells appear flattened and fibrous bodies can be observed on the surface due to the extracellular matrix proteins synthesized by the cells. It is concluded that MG63 cells can well grow on the β-TCP coated Mg and the β-TCP coated Mg has good cytocompatibility.

3.2 In vitro degradation evaluation

The study on the biodegradation of the β-TCP coated Mg and the naked Mg samples were carried out in 100 ml Hank’s solution, respectively. The pH values of Hank’s solution were recorded at the given time intervals and are shown in Fig. 5. The pH values of the solution with β-TCP coated Mg were found to be less than eight during the first month, which means Mg ions slowly released during this period of time. While the pH values of the solution with naked Mg quickly increased to over eight at the first week. The physiological conditions with high pH values are not compatible with cell growth. During the subsequent 2 weeks, the slight decrease of pH values of two groups of solution might be mainly due to the presence of a bone-like apatite shown in Fig. 7 that consumed the OH− in the Hank’s solution. Other studies also found that the precipitation of apatite-like calcium phosphates was also accompanied by a slight decrease of pH value [18]. However, the pH values still increased with continuous release of the Mg ions after some time.

The ICP-AES analysis reveals the changes of Mg and Ca concentrations in Hank’s solution after soaking β-TCP coated Mg, as shown in Fig. 6. In the first 3 weeks, the Mg ions were slowly released. In the meantime, the content of Ca ions was higher than that of initial Hank’s solution, which indicated that the Ca ions were releasing from β-TCP coating. However, the Ca ions showed the negative gain after about 3 weeks. Correspondingly, the slight decrease of both the pH value and the number of Mg ions suggested that the Ca ions and Mg ions might be consumed by formation of a new product. Then the Ca ions in Hank’s solution were continuously consumed, which indicated that the Ca ions were supersaturated around the β-TCP and a new apatite continually grew on the sample surfaces with increase of time, while continuous increase of pH values and the release of Mg ions represented the continuous degradation of Mg in Hank’s solution.

After soaking in Hank’s solution for 2 weeks, the fibrous products on the β-TCP coated Mg were observed by SEM, as shown in Fig. 7. The XRD patterns of the surface before and after biodegradation are shown in Fig. 8. It can be seen that Ca5(PO4)3(OH) (hydroxyapatite, HA) presented on the surface of Mg sample, together with some CaPO3(OH) and Na2CaMg(PO4)2 after the biodegradation. And the corresponding compositions analyzed by EDS are listed in Table 1. The atomic ratio of Ca/P became 1.24 after the biodegradation owing to the transformation of some β-TCP (Ca/P = 1.5) to HA (Ca/P = 1.67), and the presence of CaPO3(OH)(Ca/P = 1) and some Na2CaMg (PO4)2(Ca/P = 0.5), resulting in the formation of a complex C–P coating.

Figure 9a shows the cross-sectional morphology of the β-TCP coated Mg before biodegradation and the coating thickness was about 85 μm. The cross-sectional morphology of the β-TCP coated Mg after soaking in Hank’s solution for 2 months is shown in Fig. 9b. It can be seen that thickness of the β-TCP coating decreased to about 40 μm and a number of tiny needle-like precipitates could be observed on the top surface of the β-TCP coating, which indicated that a bonelike apatite of 70 μm in thickness simultaneously formed on the surface of the β-TCP coating.

4 Discussion

4.1 Character of β-TCP coating

The present study reports to deposit pure β-TCP coating on Mg substrate using a low temperature chemical method. Mg can slowly react with water to form Mg(OH)2. The presence of OH− environment makes it easy to transform HPO4 2− into PO4 3−, the forming mechanism of β-TCP on Mg is as follows.

A strong demand for Ca–P coatings prepared on metal substrate is excellent adhesion strength to ensure long-term fixation. Compared with other techniques, chemical methods are simple and easily controllable, applicable to implants of complex shape and low temperature processes. The last point is particularly important in the surface modification of Mg implants due to the low melting point of Mg. Many methods have been studied to deposit Ca–P coating on different metal substrates. Plasma-spraying is the most popular technology commercially used for depositing HA coatings onto titanium-base and other metal-base implants and had high adhesion strength [19–21]. Table 2 lists the interfacial bond strengths of different metal substrates and Ca–P coating, which is in a range of 12–65 MPa reported elsewhere. However, plasma-spraying is a high temperature and line-of-sight process. Potential problems with this technology include exposure of substrates to intense heat, residual thermal stresses in coatings, and the inability to coat complex shapes with internal cavities. Other alternative methods including electron-beam deposition [23, 24], electrochemical deposition [25, 26], magnetron sputtering [27], and sol–gel [28], laser cladding [29]. In these processes, such as electron-beam deposition, magnetron sputtering, and laser cladding, high temperature is involved in order to obtain high bonding strength. One of the big problems is the deleterious effects of high temperature on the Mg substrate of low melting point although they are advantageous in giving relatively higher bond strength between the metal substrate and Ca–P coating. The sol–gel [28] or electrochemical deposition [25] technique is an alternate process available to obtain a thin layer of coating over a metallic substrate, however, the biodegradable β-TCP coating on Mg substrate is necessary to have a quite thickness due to its special biodegradation property.

The results in Table 2 show that the bonding strength of β-TCP coating and Mg substrate in this work is between 12.7 and 19.5 MPa, which is lower comparing with that of some methods shown in Table 2 [19–30]. However, according to ISO 13779-2 Part 2, the adhesion to the substrate shall be determined in accordance with the method described in ISO 13779-4 and shall have a value for adhesion strength of not less than 15 MPa. The bonding strength of 16.1 ± 3.4 MPa in the study can satisfy the requirement.

4.2 Biodegradation

An appropriate way to control magnesium corrosion is to stabilize the corrosion products in the protective corrosion layer. Especially calcium is known to reduce the susceptibility of magnesium to corrode when added in amounts of a few tenths of weight percents [31, 32]. The β-TCP precipitation layer could behave as a barrier that restricts the contact of Mg with solution, thus effectively slackens the release of Mg ions and H2, and provides the MG63 cells a suitable pH environment. The MTT assay results have indicated that MG63 cells could well proliferate and survive on the surfaces of β-TCP coated Mg, which proving that Mg with β-TCP coating has good cytocompatibility. Comparing with that on β-TCP coated Mg, MG63 cells viability was less than 80% on naked Mg, indicating some cell toxicity. It is mainly due to that the corrosion rate of Mg is too fast that resulted in the higher pH values in DMEM and the release of H2 also has some effects on cell growth [4]. All the above results proved that the β-TCP coating prepared on the Mg can well decrease the biodegradation rate and has good biocompatibility.

Bone growth on the implant surface requires the presence of sufficient amount of calcium and phosphate ions, and a local supersaturation of the body fluid with these ions is a necessary condition for increase of bone growth [33]. β-TCP is an important mineral in the process of bone development by acting as a provisional reservoir of calcium and phosphate ions to supersaturate the local body fluid around the implant. In the present study, a new bone-like apatite layer continually formed on the β-TCP coating of Mg with biodegradation of the substrate in Hank’s solution for some time, which can be interpreted as follows:

On the one hand, from Fig. 6 it can be seen that Ca ions were continually releasing with soaking Mg with β-TCP coating at the initial stage, which resulted in a supersaturation of Ca ions in Hank’s solution. A supersaturated level of calcium is suitable for nucleations of the Ca and P, resulting in increases of Ca and P contents on the Mg. This mechanism has also been reported by Pham et al. [34]. A conclusion has been drawn by Lu and Leng [35] who declared that increases of Ca and P become more kinetically favorable when the concentration of Ca is higher than the normal level. During the degradation of β-TCP coated Mg in Hank’s solution, the degradation of β-TCP coating resulted in an enhanced Ca content. This may be due to the transformation of biodegradable β-TCP to a more stable HA phase, and at the time some CaPO3(OH) also presented in Hank’s solution in Fig. 8, as follows [36]:

Both CaPO3(OH) and β-TCP are the precursor phases of HA [37]. Moreover, it has been reported that CaPO3(OH) is an important mineral in the process of bone development [38]. Among the common forms of calcium phosphates, HA is the most stable one in the human body environment. While the highly non-biodegradable nature of HA could sometimes be a disadvantage [39] and a biphasic C–P coating mainly consisting of HA and some other less stable phase could be more desirable [40, 41] as to the bone substitute materials. Therefore, the preparation of β-TCP coating on Mg is very desirable for bone growth.

On the other hand, Mg is believed to have the ability of triggering increases of Ca and P on its surface. The enhanced Mg ions concentration result in an elevated calcium concentration [42], which is suitable for nucleation of the Ca and P contained compound. This mechanism can also be verified as that Mg has the ability of osteoconductivity [42, 43]. Mg(OH)2 and H2 could usually form during Mg degradation as in Eq. 1, which could increase the pH value of the solution that accelerates the apatite nucleation by increasing the ionic activity of apatite [44]. HA may continually form [45] on the β-TCP coated Mg with the presence of OH− during the biodegradation of Mg as follows:

It should be also noticed that alkalinisation of the medium may increase the metabolism of osteoblastic cells as reported in the other studies [46], which can also expect a good result of cell proliferation on the β-TCP coated Mg scaffold.

Other studies also showed that some bioactive ceramics, e.g., bioglass, sintered hydroxyapatite, and glass-ceramic A-W, when implanted into the bone defects, also spontaneously form a layer of biologically active bonelike apatite on their surfaces to induce a chemical integration of bone tissue [47]. Previous research has correlated the ability of biomaterials upon soaking in SBF to develop a bone-like apatite to strengthen the bone bonding in vivo [48]. Therefore, the in vitro formation of bone-like apatite on the β-TCP coated Mg after soaking in Hank’s solution demonstrates their potential abilities of bone bonding. To further assess the suitability of the β-TCP coated Mg for applications, such as embedding β-TCP coated Mg to bone and an in vivo degradation study should be performed in the next step.

5 Conclusion

Pure β-TCP coating was well precipitated on the surface of Mg with a chemical route after the alkali-heat pretreatment. And the bonding strength of β-TCP coating and Mg substrate is 16.1 ± 3.4 MPa in the study, which can satisfy the critical value of ISO 13779-2 Part 2 required. It was easier for the MG63 cells to adhere and proliferate on the β-TCP coated Mg than on naked Mg, which indicates Mg with β-TCP coating has good cytocompatibility. Biodegradation of Mg and β-TCP coating in Hank’s solution was studied in the present work. The β-TCP coating could slow down the biodegradation rate of Mg at the early stage. Continuous increase of pH value indicated that Mg ions kept releasing with increase of time and a bonelike apatite could continuously form on the β-TCP coated Mg with the biodegradation of both Mg and β-TCP coating. The improved formation ability of bonelike apatite could be explained in two aspects. One is that the supersaturated level of Ca ions around β-TCP should account for the increased growth of Ca ions and corresponding P ions on the β-TCP coated Mg. The other is that the corrosion of Mg could result in the release of Mg ions and the increase of pH values of the solution, which could accelerate the formation of apatite. The whole study shows that the β-TCP coated Mg is promising as a bone substitute material.

References

L.C. Li, J.C. Gao, Y. Wang, Surf. Coat. Technol. 185, 92 (2004). doi:10.1016/j.surfcoat.2004.01.004

C. Di Mario, H. Griffiths, O. Goktekin, N. Peeters, J. Verbist et al., J. Interv. Cardiol. 17, 391 (2004). doi:10.1111/j.1540-8183.2004.04081.x

S.R. Kim, J.H. Lee, Y.T. Kim, D.H. Riu, S.J. Jung et al., Biomaterials 24, 1389 (2003). doi:10.1016/S0142-9612(02)00523-9

E.D. McBride, J. Am. Med. Assoc. 111(27), 2464 (1938)

Y. Al-Abdullat, S. Tsutsumi, N. Nakajima, M. Ohta, H. Kuwahara, K. Ikeuchi, Mater. Trans. 42, 1777 (2001). doi:10.2320/matertrans.42.1777

A. Yamamoto, H. Tsubakino, Mater. Trans. 44, 511 (2003). doi:10.2320/matertrans.44.511

E. Zhang, L.P. Xu, K. Yang, Scr. Mater. 53, 523 (2005). doi:10.1016/j.scriptamat.2005.05.009

K.Y. Chiu, M.H. Wong, F.T. Cheng, H.C. Man, Surf. Coat. Technol. 202, 590 (2007). doi:10.1016/j.surfcoat.2007.06.035

P. Shi, W.F. Ng, M.H. Wong, F.T. Cheng, J. Alloy Compd. (2008). doi:10.1016/j.jallcom.2008.01.102

Y. Li, I.-S. Lee, F.-Z. Cui, S.-H. Choi, Biomaterials 29, 2025 (2008). doi:10.1016/j.biomaterials.2008.01.009

Y.W. Song, D.Y. Shan, E.H. Han, Mater. Lett. (2008). doi:10.1016/j.matlet.2008.02.048

R. Famery, N. Richard, P. Boch, Ceram. Int. 20, 327 (1994). doi:10.1016/0272-8842(94)90050-7

G. Ciapetti, E. Cenni, L. Pratelli, A. Pizzoferrato, Biomaterials 14, 359 (1993). doi:10.1016/0142-9612(93)90055-7

C. Fleury, A. Petit, F. Mwale, J. Antoniou, D.J. Zukor, M. Tabrizian, Biomaterials 27, 3351 (2006). doi:10.1016/j.biomaterials.2006.01.035

A.P. Marques, R.L. Reis, J.A. Hunt, Biomaterials 23, 1471 (2002). doi:10.1016/S0142-9612(01)00272-1

G. Song, Corros. Sci. 49, 1696 (2007). doi:10.1016/j.corsci.2007.01.001

C. Liu, Y. Xin, X. Tian, P.K. Chu, Thin Solid Films 516, 422 (2007). doi:10.1016/j.tsf.2007.05.048

S. Jalota, Sarit.B. Bhaduri, A. Cuneyt Tas, Mater. Sci. Eng. C 27, 432 (2007). doi:10.1016/j.msec.2006.05.052

X. Zheng, M. Huang, C. Ding, Biomaterials 21, 841 (2000). doi:10.1016/S0142-9612(99)00255-0

M. Inagaki, Y. Yokogawa, T. Kameyama, J. Eur. Ceram. Soc. 26, 495 (2006)

Yung.-Chin. Yang, Surf. Coat. Technol. 201, 7187 (2007). doi:10.1016/j.surfcoat.2007.01.027

H. Li, K.A. Khor, Surf. Coat. Technol. 201, 2147 (2006). doi:10.1016/j.surfcoat.2006.03.024

E.-J. Lee, S.-H. Lee, H.-W. Kim, Y.-M. Kong, H.-E. Kim, Biomaterials 26, 3843 (2005). doi:10.1016/j.biomaterials.2004.10.019

T. Fujihara, M. Tsukamoto, N. Abe et al., Vacuum 73, 629 (2004). doi:10.1016/j.vacuum.2003.12.082

X.F. Xiao, R.F. Liu, Y.Z. Zheng, Surf. Coat. Technol. 200, 4406 (2006). doi:10.1016/j.surfcoat.2005.02.205

J. Sun, Y. Han, X. Huang, Surf. Coat. Technol. 201, 5655 (2007). doi:10.1016/j.surfcoat.2006.07.052

M. Chen, D. Liu, C. You, X. Yang, Z. Cui, Surf. Coat. Technol. 201, 5688 (2007). doi:10.1016/j.surfcoat.2006.07.057

H.-W. Kim, Y.-M. Kong, C.-J. Bae, Y.-J. Noh, H.-E. Kim, Biomaterials 25, 2919 (2004). doi:10.1016/j.biomaterials.2003.09.074

D. Wang, C. Chen, J. Ma, T. Lei, Appl. Surf. Sci. 253, 4016 (2007). doi:10.1016/j.apsusc.2006.08.036

F.-H. Lin, Y.-S. Hsu, S.-H. Lin, J.-S. Sun, Biomaterials 23, 4029 (2002). doi:10.1016/S0142-9612(02)00154-0

A. Beck, Magnesium und seine Legierungen (Springer, Berlin, 1939)

E.F. Emley, Principles of Magnesium Technology (Pergamon Press, Oxford, 1966)

L.L. Hench, J. Am. Ceram. Soc. 81, 1705 (1998)

M.T. Pham, M.F. Maitz, W. Matz, H. Reuther, E. Richter, G. Steiner, Thin Solid Films 379, 50 (2000). doi:10.1016/S0040-6090(00)01553-4

X. Lu, Y. Leng, Biomaterials 26, 1097 (2005). doi:10.1016/j.biomaterials.2004.05.034

T.S. Sampath Kumar, I. Manjubala, J. Gunasekaran, Biomaterials 21, 1623 (2000). doi:10.1016/S0142-9612(00)00014-4

R.Z. LeGeros, in Hydroxyapatite and Related Materials, ed. by P.W. Brown, B. Constantz (CRC Press, Boca Raton, 1994), p. 3

F. Li, Q.L. Feng, F.Z. Cui, H.D. Li, H. Schubert, Surf. Coat. Technol. 154, 88 (2002). doi:10.1016/S0257-8972(01)01710-8

M. Eldeeb, M. Roszkowski, J. Oral Maxillofac. Surg. 46, 33 (1988). doi:10.1016/0278-2391(88)90333-3

I. Manjubala, M. Sivakumar, Mater. Chem. Phys. 71, 272 (2001). doi:10.1016/S0254-0584(01)00293-0

J. Pena, M. Vallet-Regi, J. Eur. Ceram. Soc. 23, 1687 (2003). doi:10.1016/S0955-2219(02)00369-2

K.S. TenHuisen, P.W. Brown, J. Biomed. Mater. Res. 36, 306 (1997). doi:10.1002/(SICI)1097-4636(19970905)36:3<306::AID-JBM5>3.0.CO;2-I

F. Witte, J. Reifenrath, P.P. Müller, H.-A. Crostack, J. Nellesen, F.W. Bach, D. Bormann, M. Rudert, Mat.-wiss. u. Werkstofftech 37, 504 (2006). doi:10.1002/mawe.200600027

P.N. De Aza, F. Guitian, A. Merlos, E. Lora-Tamayo, S. De Aza, J. Mater. Sci.: Mater. Med. 7, 399 (1996). doi:10.1007/BF00122007

T.S.B. Narasaraju, D.E. Phebe, J. Mater. Sci. 32, 1 (1996). doi:10.1007/BF00355120

W.B. Busa, R. Nuccitelli, Am. J. Physiol. 246, R409 (1984)

L.L. Hench, R.J. Splinter, W.C. Allen, T.K. Greenlee, J. Biomed. Mater. Res. Symp. 2, 117 (1971). doi:10.1002/jbm.820050611

T. Kokubo, H. Kushitani, S. Sakka, T. Kitugi, T. Yamanuro, J. Biomed. Mater. Res. 24, 721 (1990). doi:10.1002/jbm.820240607

Acknowledgments

This work was partly supported by a fund from Chinese Academy of Sciences, Applied Research of Bioactive Bone Implanted Materials (No. KGCX2-YW-207).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geng, F., Tan, L.L., Jin, X.X. et al. The preparation, cytocompatibility, and in vitro biodegradation study of pure β-TCP on magnesium. J Mater Sci: Mater Med 20, 1149–1157 (2009). https://doi.org/10.1007/s10856-008-3669-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-008-3669-x