Abstract

A 57% SiO2, 3% Al2O3, 34% CaO and 6% Na2O glass (SCNA) has been produced in form of powders and deposited by plasma spray on titanium alloy and stainless steel substrates. The obtained coatings have been subjected to a patented ion-exchange treatment to introduce silver ions in the surface inducing an antibacterial behavior. Silver surface-enriched samples have been characterized by means of X-ray diffraction, SEM observation, EDS analysis, in vitro bioactivity tests, leaching tests by GFAAS (graphite furnace atomic adsorption spectroscopy) analyses, cells adhesion and proliferation, and antibacterial tests using Staphylococcus Aureus strain. In vitro tests results showed that the modified samples acquired an antimicrobial action against tested bacteria maintaining unaffected the biocompatibility of the glass. Furthermore the ion-exchange treatment can be successfully applied to glass-coated samples without affecting the properties of the coatings; the simplicity and reproducibility of the method make it suitable for glass or glass-ceramic coatings of different composition in order to produce coated devices for bone healing and/or prostheses, able to reduce bacterial colonization and infections risks.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Medical devices for implants and prostheses are commonly realized with metallic materials, such as steel or titanium alloys, as they provide satisfactory mechanical and biological behaviour. Metals can be considered as inert materials as they do not have any interaction with bone tissue cells: the adhesion between the device and the host tissue is based only on mechanical bonding of surfaces. Unfortunately, metals do not provide protection against bacteria adhesion and are often easily colonised by them especially if they underwent treatments to enhance roughness (such as sand blasting, acid etching…) [1, 2, 3].

Despite the use of hygienic protocols and preventive antibiotic prophylaxes, infections development remains one of the most serious problems associated to orthopaedic surgery and can cause implant failure and re-operation. Nowadays, infections are kept under control with the use of antibiotics but the increasing bacteria resistance had induced the researchers to found possible alternatives such as orthopaedic implant devices showing antibacterial properties [4–6].

Silver is widely known for its antibacterial properties against most of bacteria species [7–9] and bacterial resistance to silver is an infrequent phenomenon. For this reason, many researchers are studying the possibility to take benefit of the peculiar characteristics of silver and its compounds in order to realize implant materials able to prevent bacteria colonization and thus infections [10–15]. Unfortunately, silver and its compounds become toxic towards cells and tissues if their concentration is higher than a threshold. Clinically silver was already used to coat, for example, the surfaces of devices as urinary catheters or external fixation pins for bone fracture healing. In the first case toxicity does not represent a limitation to the use of silver, as cell tissues does not come in direct contact with silver coated surfaces for prolonged periods. On the other side, silver coated orthopaedic pins revealed a good protection against bacteria colonization, but the amount of silver found in patients blood after implant, resulted higher than the toxicity limit [16]. Silver toxicity is still an open problem and in particular its potentially toxic effects at local and/or systemic levels; local toxicity, even if less dangerous than systemic one, can cause argyria phenomena and cells pain around silver containing devices.

For this reason, the opportunity to control the amount of silver and to confine its presence on the outer surface of an implant material, have become the main goal to realize safe devices, both in terms of compatibility towards host tissues and in terms of reduced bacteria adhesion onto implants’ surfaces.

The aim of this work was the realization of glass-coated metallic devices showing a low affinity towards bacteria due to a silver surface-enrichment, combined with the maintenance of biocompatibility towards host tissues. Several methods can be used to coat a substrate with a glassy layer: enamelling, glazing, plasma-spray, spin casting, sputtering, electrophoresis and pulsed laser ablation. Thermal spraying is a well established technology commonly used to produce coatings for a wide variety of applications [17]. Thermal spray processes can be grouped into three major categories: plasma-arc spray, flame spray, and electric wire-arc spray. The plasma spray technique can be applied for the development of bioactive glass coating and composites [17–25] on titanium and its alloys. By multiple scanning of the substrate, coatings of the desired thickness, usually around 70–150 μm, can be easily developed and for these reasons, in this work, plasma spray was used to produce the coatings.

In order to impart antibacterial properties to the glass coated substrates, the ion-exchange technique was used, following a patented and optimized experimental schedule. The material selected for this study is a silica based glass, characterized by a moderate bioactivity index, so is a good candidate for the realization of long-term stability bioactive coatings on metallic substrates. The glass composition was selected during previous studies, described in the first part of this work [26], aiming to reduce as much as possible the introduced silver, as well as to develop a glass composition which allowed the realization of coatings on metallic substrates (stainless steel and Ti6Al4 V), in order to apply the ion exchange technique directly on coated devices.

2 Experimental

2.1 Materials synthesis and characterization

A 57%SiO2, 3%Al2O3, 34%CaO and 6%Na2O (named SCNA) glass have been used for this work. The glass has been prepared by melting reagent-grade reactants in a platinum crucible at 1500°C for 1 h and then quenching the melt in water to obtain a frit, or pouring the melt in a copper mould to obtain bars. After drying, the frit was ball milled in a planetary miller to obtain powders. After milling, the powders were sieved down to 100 μm (the powder size was selected on the bases of technical requirements for plasma-spray process, performed by Eurocoating S.p.A.). SCNA powders underwent a thermal characterizations by means of Differential Thermal Analysis (DTA-7-Perkin Elmer), Differential Scanning Calorimetry (DSC-7-Perkin Elmer) in order to determine its characteristic temperatures. Thermal Dilatometry (DMA-7-Perkin Elmer) was used to determine the linear thermal expansion coefficient (α) on bulk samples of 8 × 3 × 3 mm3 size, obtained by cutting the annealed SCNA bars.

Metal substrates selected for this work have been Ti6Al4 V alloy and AISI316L steel, as the majority of implant devices for bone healing are realized with them. Ti6Al4 V substrates were provided as disks of 25 mm diameter and 5 mm height and only one surface has been plasma-spray coated with SCNA; this geometry was specifically selected in order to perform mechanical adhesion tests. AISI316L samples were provided as cylinders of 5 mm diameter and 12 mm height and their entire surface has been coated. Metal substrates have been previously sand-blasted with alumina and then ultrasonically cleaned. The plasma spray process parameters have been selected by Eurocoating S.p.A., on the basis of preliminary data. From now on SCNA coated steel samples will be called GCS, while SCNA coated Ti-alloy samples will be called GCT. The main characteristics of the coated samples are summarized in Table 1. The coatings thickness has been evaluated through SEM observations on different sample cross sections and calculated in many section points to verify the thickness homogeneity.

2.2 Mechanical tests

The uniformity and good coating adhesion are important parameters to guarantee the stability of the coatings. The determination of glass coatings adhesion on titanium alloy substrates was carried out according to ISO standard 13779–4 by Eurocoating S.p.A.. The adhesion on stainless steel substrates was only evaluated by qualitative observations due to the geometry of the provided samples.

2.3 Surface modification

Sets of GCS and GCT samples underwent the silver ion-exchange process to modify their surfaces by introducing a controlled amount of silver ions. The ion-exchange process was previously patented [27] and is based on a thermo-chemical treatment of the glassy material in an suitable solution able to exchange mono-valent ions, coming from the glass, with silver ions coming from the solution. The parameters that regulate the process are: silver ions concentration in the solution, time and temperature of the process; by opportunely tuning the ion-exchange parameters it is possible to modulate both the amount of silver ions introduced in the glass and their concentration profile along the glass material cross-section [28, 29]. Such process can be applied, optimising the processing parameters, to any material belonging to the classes of glasses, glass-ceramics and ceramics. This kind of silver-doping treatment of glasses, glass-ceramics and ceramics surfaces, allows imparting antibacterial properties to a wide range of materials, without inducing any radical change in their peculiar properties.

GCS and GCT samples underwent silver ion-exchange treatment in aqueous solutions containing different amounts of silver ions. In this work, different ion-exchange conditions have been evaluated as reported below:

– solution concentration: 0.5 M (I) and 0.05 M(II)

– time and temperature of the exchange process; 30÷50 min and 80÷100°C;

The exchanged glass coatings will be generally called Ag-GC-I and Ag-GC-II since any significant difference between GCS and GCT samples was observed, neither before nor after the ion-exchange treatment.

GC and Ag-GC samples were analyzed by means of X-Ray diffraction (XRD), using the Bragg Brentano camera geometry and the Cu-Kα incident radiation, to verify if any structural change or crystallization phenomena occurred due to plasma-spray process and/or silver ion-exchange treatment. Scanning electron microscopy (SEM Philips 525 M) observations and energy dispersion spectrometry (EDS) were performed to evaluate morphology and composition both on GC and Ag-GC samples.

2.4 In vitro bioactivity test

In vitro bioactivity tests were performed soaking GC and Ag-GC-I samples on simulated body fluid solution (SBF, as reported by Kokubo [30]) at 37°C for periods up to one month. All tests have been performed in triplicate and the sample reactivity was evaluated, after soaking in SBF, by means of SEM observation. The bioactivity test was carried out only on Ag-GC-I to assess the effect of the most brutal ion-exchange condition and the possible effect of the highest silver amount introduced. Ag-GC-II have not been tested for bioactivity due to the results obtained for Ag-GC-I that did not show any modification in the bioactivity.

2.5 Leaching test

The amount of released silver ions from Ag-GC surfaces was investigated on a set of three samples, having the same size and surface area (120 mm2). The procedure followed in this work was the same reported in a previous paper [26]: the samples were soaked into 30 ml of SBF maintained at 37°C up to 30 days. Graphite furnace atomic adsorption spectroscopy (GFAAS) analyses were performed on 1 ml of SBF spiked from each soaking solution after 3 h, 1 day, 2, 7, 14 and 30 days of dipping. For comparative purposes also clean SBF and the solutions in contact with GC have been analysed.

2.6 Antibacterial test

The zone of inhibition test [31] was performed on Ag-GC samples and on GC as control. A Staphylococcus Aureus standard stock (ATCC 29213) was used to characterize Ag-GC-I and Ag-GC-II samples; furthermore the inhibition halo of Ag-GC-I was observed employing one stock isolated from human prosthetic infection: a bacterial broth has been prepared dissolving a S. Aureus disk in 5 ml of brain heart infusion; after overnight incubation at 37°C, 10μl of the suspension have been spread on a Blood-Agar plate and incubated 24 h in order to allow the bacterial colonies growth.

A standard 0.5 Mc Farland (containing approximately 1–2 · 108 CFU/ml) solution was prepared dissolving some bacterial colonies in a physiological solution (turbidity has been evaluated by optical instrument—Phoenix Spec BD McFarland) and a dose of this suspension has been spread on Mueller Hinton agar plates. Silver containing samples were drawn close to the agar plate and incubated 24 h at 35°C.

Broth dilution tests have been also performed on Ag-GC-I and Ag-GC-II samples: a 0.5 Mc Farland suspension has been prepared in the same way described above, an aliquot of bacterial suspension has been introduced in Mueller Hinton broth tubes in order to obtain suspensions approximately containing 5 · 105 CFU/ml. After 24 h incubation at 35°C tubes’ turbidity has been optically evaluated.

Afterwards, washing and vortexing solutions have been analyzed in order to quantify colony forming units (CFU). Washing solution has been prepared by a rapid rinsing of the sample in physiological solution, while the vortexing one was obtained by 1′ vortex at 50 Hz of the sample in physiological solution. Mc Farland index of each solution has been measured and then they have been serially diluted and spread on Blood-Agar plates and after overnight incubation at 35°C CFU, have been counted on plates.

The percentage reduction in bacteria count was calculated by the formula:

where CFU0 is the number of colonies forming units counted on plate containing the solution of untreated samples and CFUAg is the number of bacteria counted on doped silver samples; this formula has been used both for adhered bacteria as for proliferated ones.

All samples were previously dry sterilized at 170°C for 1 h and all products for antibacterial analysis have been purchased from BD-Becton Dickinson.

2.7 All test have been performed in triplicate

2.8 Biocompatibility test

Ag-GC-II biocompatible behavior has been tested using a fibroblast cell line; the cells have been cultured at 37°C in 95% air/5%CO2 in DMEM supplemented with 10% fetal bovine serum (FBS, Sigma), penicillin (100 U ml−1), streptomycin (100 μg ml−1) and L-glutammine 0.03%.

Biocompatibility tests consisted in fibroblasts adhesion and proliferation studies, performed using a starting cell density of 104 cells/cm2; incubated cells have been counted in a Burker camera after being removed with SDS solution from samples surface, respectively after 6 h culture, to evaluate their adhesion, and 24 h culture to estimate the proliferation.

Ag-GC-II behaviour has been compared with GC sample and with a control one; both adhesion and proliferation have been investigated on a set of three samples.

3 Results and discussion

3.1 Thermo mechanical properties of the coatings

Thermal analyses on SCNA powders showed a T g at 685°C. This temperature was detected in order to set the annealing procedure for the glass bars (10 h at 600°C) in order to cut them in small specimens for the determination of the linear thermal expansion coefficient (α). The value of α varies between 6,8 10−6°C−1 and 8,6 10−6°C−1 in the range from 100°C to 600°C. In this temperature gap, α for Ti6Al4 V ranges between 8, 7 10−6°C−1 and 10 10−6°C−1, while for AISI316L it ranges between 16 10−6°C−1 and 17,5 10−6°C−1 (being α for Ti-alloy nearer to the glass than the steel one). Taking into account the theories that describe how to control the interface between a glass coating and a metal substrate, the glass should have a slightly lower thermal expansion than the metal substrate. This feature would induce only small compressive stresses in the glass coating, avoiding the generation of tensile thermal stresses during cooling from the processing temperature to room temperature, which can induce cracks formation or delamination of the coating. Bioactive glasses have a silica content below 60 wt.% (glasses with silica contents greater than 60 wt.% are no longer bioactive). Most of these glasses have thermal expansion coefficients much higher than those of Ti alloys. The thermal expansion coefficient of the glass can be reduced by increasing the SiO2 content, or by adding Al2O3 in the composition, but this reduces bioactivity as well [32, 33], so these compositional modifications should be done in a very controlled way, as in the present work.

Despite the differences in the thermal expansion coefficients between the glass and the two metal substrates, no significant differences between the two metals were observed after the plasma spray of the coatings. In fact, for the plasma spray technique, the difference in the thermal properties of the coatings and of the substrate e, do not affect the main characteristics of the resulting coated sample, as would happen, on the contrary, with enamelling processes.

Moreover, any significant difference between GCS and GCT samples could be observed, being the structure, the morphology and the mechanical adhesion of the glass coating the same on both metallic substrates. Table 1 summarizes some dimensional features of the coated GCS and GCT samples. The coating adhesion, estimated on GCT samples showed a value up to 41.2 ± 9.6 MPa. This value is higher than those detected for various plasma spray coatings of similar thickness made of hydroxyapatite, glasses or glass-matrix composites on Ti6Al4 V substrates, as reported in literature [24, 34, 35].

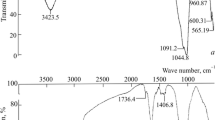

3.2 Phase analysis (XRD) and morphology

The plasma spray process did not bring about any crystallization phenomena on SCNA as can be observed in Fig. 1a and b, where the XRD patterns of the as done glass and of the titanium alloy coated sample have been reported: the only difference is represented by the signal of the Ti substrate at 40.3°. Figure 1c reports the XRD pattern of a GCT sample after ion exchange with the solution with the higher silver concentration (Ag-GC-I) and no evidence of structural modifications after ion exchange on the glass coating appears. No XRD analyses have been carried out on Ag-GC-II samples because if any structural modification occurred in the most severe ion exchange conditions no alteration are expected in the more moderate settings.

As far as the effect on the substrates is concerned, both metallic substrates did not undergo any significant change in their structure or morphology, thus verifying that the process did not cause metal corrosion or structural modifications (Fig. 2). Morphological observations by SEM on coated samples did not point out any dissolution phenomena or variation in the morphology occurring in the glass coating after the silver ion-exchange process. Figure 3 shows a detail of the interface between the Ti substrate and the coating after ion exchange (carried out after the sample cross-sectioning) where no sign of corrosion are evident. The material composition, by means of EDS measurements, showed the presence of silver on Ag-GC surfaces (Fig. 4). Quantification of EDS spectra showed that the amount of silver onto material surface is at about 4.32% (wt.%) for Ag-GC-I and 0.35% (wt.%) for Ag-GC-II. The maximum penetration depth of EDS analysis at the employed voltage (5–15 kV) is of few microns and we assumed that all introduced silver was confined into this volume. This hypothesis has been demonstrated in previous works for more severe ion exchange conditions [28, 29] or for other glass-ceramics in the same exchange conditions [36]. On this basis, it can be stated that the proposed ion exchange technique allowed the modification only of the first superficial layers.

3.3 Leaching tests

Since the specific surface area of GC samples is higher than that of SCNA massive samples, we can expect that all processes correlated to surface mechanisms would be influenced. For this reason, although silver ion-exchange process was performed in the same conditions used for massive SCNA glass samples (as reported in Part I of this work) [26], data collected by GFAAS measurements showed higher amounts of released silver ions, on equal time both for Ag-GC-I and Ag-GC-II. Figure 5a show the release trend comparison between silver containing coatings, ion-exchanged in both Ag+ concentration selected for this work, and SCNA samples. Figure 5b reports the comparison of silver released rate from different samples. The higher amount of silver is released during the first days of contact with SBF solution.

Leaching test showed an amount of released silver in agreement with previous works and with the chosen ion-exchange parameters: coatings, having a higher specific surface area, released a higher amount of silver, proportional to the silver concentration used. The release trend of Ag-GC-I samples is slightly different from Ag-GC-II one: probably, the more severe conditions of ion-exchange led to a deeper diffusion of Ag ions and thus to a slower release.

Nevertheless, in both conditions, silver is rapidly released during the first day of immersion in SBF; this feature is very important because the first period after a surgical treatment is particularly risky for the incidence of infections. For this reason, it would be of interest to inhibit the bacteria adhesion immediately after a device implant, when a fight to colonize its surfaces occurs between host cells and bacteria.

3.4 Bioactivity

The term “bioactivity” refers to the ability of some silica-based glasses to induce in vitro, by immersion in SBF, the formation of a semi-crystalline hydroxycarbonatoapatite (HCA) rich layer. This behaviour is considered an index of their in vivo bioactivity (natural bonding ability to living tissues) through a mechanism that begins with a rapid ions exchange between the alkaline ions from the glass surface and the hydrogen ions from the solution, followed by the formation of silanols, which then undergo polycondensation to develop a silica gel layer. This layer promotes the adsorption of Ca++ and PO4 3− ions from the solution. Subsequently these ions react together forming the HCA layer.

The in vitro tests, performed only on Ag-GC-I, confirmed the low bioactivity of the glass, as verified in a previous work [14]. Since the glass maintained the same degree of bioactivity both after the ion-exchange and after the plasma spray process, the introduced silver, as well as the plasma spray process, are completely irrelevant for the glass reactivity. This result is very interesting because this technique does not influence the substrate characteristics.

3.5 Antibacterial properties

The zone of inhibition tests assessed the antibacterial behaviour of both Ag-GC-I and Ag-GC-II samples: as expected, the inhibition halo due to Ag-GC-I (3–4 mm) is larger than Ag-GC-II halo (2 mm), as Ag-GC-I was obtained using an higher concentration of silver in the solution than Ag-GC-II. Figure 6a, b show two Mueller Hinton Agar plate with three silver doped samples and an untreated one as control.

A further evidence of the antibacterial behaviour of Ag-GC comes from the zone of inhibition test on the stock isolated from human prosthetic infection: Ag-GC-I show a halo of about 5 mm, larger than halo obtained with a standard stock (Fig. 7).

Broth dilution tests (Fig. 8) showed an important antibacterial effect of Ag-GC-I and a more limited one for Ag-GC-II, nevertheless Ag-GC-I showed a reduction of 99.8% for adhered bacteria and of 99.5% for the bacteria proliferated closely to the material. Ag-GC-II provided an adhered bacteria reduction of 94.8% and of 78.7% for proliferated colonies.

Mc Farland index measurement confirmed this trend (Fig. 9), there is a gap of 0.53 Mc Farland between GC and Ag-GC-II, and a gap of 2.02 Mc Farland between GC and Ag-GC-I.

In summary, antibacterial tests showed a marked bacteriostatic behaviour of Ag-treated samples, proportional to the introduced (and thus released) silver amount. The antibacterial effect was corroborated by different tests: broth dilution test, Mc Farland index evaluation and zone of inhibition test; the last one, performed on a stock isolated from human prosthetic infection, is an important confirmation of the antibacterial behaviour of silver doped samples.

As observed in Part I of this work, the introduced silver had a bacteriostatic effect as it inhibited the proliferation of most of the adherent bacteria on the coatings surfaces but it did not kill bacterial cells; nevertheless this was actually the aim of this research: the realization of biocompatible and antibacterial glass-coated metallic devices. Future works will evaluate the possible bactericidal effect of silver ions released from Ag-GC samples.

3.6 Biocompatibility

Antibacterial tests demonstrated that Ag-GCII samples have bacteriostatic properties, so the introduction of an higher amount of silver is not necessary. So only Ag-GCII has been tested for biocompatibility.

Biocompatibility tests confirmed the safety of materials also in the case of Ag-treated samples. Figure 10 shows the amount of living cells counted on untreated and treated samples and on control ones, after 6 h for the adhesion and after 24 h for the proliferation test.

Figure 5b shows that silver release rate reached its maximum value in the first 24 h, so we believe that short time cellular test are sufficient at this stage of the research.

The fibroblasts amount adhered and proliferated on GC and on Ag-GC samples was slightly lower than cells grown on control, but the cells grown on silver doped samples are comparable with those on untreated glass. These cytotoxicity tests confirmed the safety of silver doped coatings toward fibroblast cells.

4 Conclusions

A silica based glass (SCNA) with a low degree of bioactivity was successfully used to coat Stainless steel and Ti6Al4 V samples by Plasma Spray in air (APS). The coated samples have been treated by a patented surface treatment to enrich their surfaces with small amounts of silver ions, in order to induce an antibacterial activity. The parameters of the treatment have been carefully selected in order to obtain a surface with bacteriostatic properties without any cytotoxicity; in particular the total amount of the released silver is under the toxic threshold and on the glass surface any silver compound potentially responsible of toxic effect, precipitated during soaking.

The silver enrichment of the surfaces did not affect the morphology and the structure of the coatings. The bacteriostatic effect of the as treated coatings has been proved by three different antibacterial tests; at the same time the cytotoxicity test confirmed the safety of the silver-doped samples toward fibroblast cells.

The plasma spray process did not induce any change in the glass composition and reactivity and the realized coatings showed a good mechanical strength. For this reason, SCNA glass powders can be used to coat several metallic devices and afterwards the ion-exchange technique can be applied to impart antibacterial properties.

References

H.G. Llinos, R.R. Geoff, Injury 37(2), S3 (2006). doi:10.1016/j.injury.2006.04.003

D. Campoccia, L. Montanaro, C.R. Arciola, Biomaterials 27, 2331 (2006). doi:10.1016/j.biomaterials.2005.11.044

L. Rimondini, M. Fini, R. Giardino, J. Appl. Biomat. Biomech. 3, 1 (2005)

I. Allan, H. Newman, M. Wilson, Biomaterials 22(12), 1683 (2001). doi:10.1016/S0142-9612(00)00330-6

L.A. Brook, P. Evans, H.A. Foster, M.E. Pemble, A. Steele, D.W. Sheel, H.M. Yates, J. Photochem. Photobiol. A: Chem. 187(1), 53–63 (2007). doi:10.1016/j.jphotochem.2006.09.014

W. Chen, Y. Liu, H.S. Courtney, M. Bettenga, C.M. Agrawal, J.D. Bumgardner, J.L. Ong, Biomaterials 27, 32–5512 (2006). doi:10.1016/j.biomaterials.2006.07.003

Q.L. Feng, J. Wu, G.Q. Chen, F.Z. Cui, T.N. Kim, J.O. Kim, J. Biomed. Mat. Res. 52(4), 662 (2000). doi:10.1002/1097-4636(20001215)52:4<662::AID-JBM10>3.0.CO;2-3

H.J. Klasen, Burns 26, 131 (2000). doi:10.1016/S0305-4179(99)00116-3

J.Y. Maillard, S.P. Denyer, EWMA J. 1, 6 (2006)

G. Muller, Y. Winkler, A. Kramer, J. Hosp. Infect. 53(3), 211 (2003). doi:10.1053/jhin.2002.1369

X. Xu, O. Yang, Y. Wang, H. Yu, X. Chen, X. Jing, Eur. Pol. J. 42, 9–2081 (2006). doi:10.1016/j.eurpolymj.2006.03.032

V. Alt, T. Bechert, P. Steinrücke, M. Wagener, P. Seidel, E. Dingeldein et al., Biomaterials 25, 18–4383 (2004). doi:10.1016/j.biomaterials.2003.10.078

A.G. Avent, C.N. Carpenter, J.D. Smith, D.M. Healy, T. Gilchrist, J. Non-Cryst. Solid 328, 31 (2003)

J.M. Schierholz, L.J. Lucas, A. Rump, G.J. Pulverer, J. Hosp. Infect. 40, 257 (1998). doi:10.1016/S0195-6701(98)90301-2

J. Hardes, H. Ahrens, C. Gebert, A. Streitbuerger, H. Buerger, M. Erren, A. Gunsel, C. Wedemeyer, G. Saxler, W. Winkelmann, G. Gosheger, Biomaterials 28(18), 2869 (2007)

A. Massè, A. Bruno, M. Bosetti, A. Biasibetti, M. Cannas, P. Gallinaro, Appl. Biomater. 53(5), 600 (2000). doi:10.1002/1097-4636(200009)53:5<600::AID-JBM21>3.0.CO;2-D

C. Gabbi, A. Cacchioli, B. Locardi, E. Guadagnino, Biomaterials 16, 515 (1995). doi:10.1016/0142-9612(95)91123-G

A. Oliva, A. Salerno, B. Locardi, V. Riccio, F. Della Ragione, P. Iardino, V. Zappia, Biomaterials 19, 1019 (1998). doi:10.1016/S0142-9612(97)00249-4

J.A. Helsen, J. Proost, J. Schrooten, G. Timmermans, E. Brauns, J. Vandertraeten, J. Eur. Cer. Soc. 17, 147 (1997). doi:10.1016/S0955-2219(96)00176-8

T.M. Lee, E. Chang, B.C. Wang, C.Y. Yang, Surf. Coat Technol. 79, 170 (1996). doi:10.1016/0257-8972(95)02463-8

F.L.S. Carvalho, C.S. Borges, J.R.T. Branco, M.M. Pereira, J. Non-Cryst. Solid. 247, 64 (1999). doi:10.1016/S0022-3093(99)00033-2

M. Ferraris, P. Rabajoli, L. Paracchini, F.J. Brossa, Am. Ceram. Soc. 79, 6–1515 (1996). doi:10.1111/j.1151-2916.1996.tb08759.x

E. Verné, M. Ferraris, A. Ventrella, L. Paracchini, A. Krajewski, A. Ravaglioli, J. Eur. Ceram. Soc. 18, 4–363 (1998). doi:10.1016/S0955-2219(97)00134-9

E. Verné, M. Ferraris, C. Jana, L. Paracchini, J. Eur. Ceram. Soc. 20, 473 (2000). doi:10.1016/S0955-2219(99)00181-8

E. Verné, E. Bona, E. Angelini, F. Rosalbino, P. Appendino, J. Eur. Ceram. Soc. 22, 2315 (2002). doi:10.1016/S0955-2219(02)00030-4

E. Verné, M. Miola, C. Vitale Brovarone, M. Cannas, S. Gatti, G. Fucale, G. Maina, A. Massé, S. Di Nunzio, submitted to J. Mat. Sci. Mat. Med.

S. Di Nunzio, E. Vernè, Process for the production of silver-containing prosthetic devices. WO 2006/058906

E. Vernè, S. Di Nunzio, M. Bosetti, P. Appendino, C. Vitale Brovarone, G. Maina, M. Cannas, Biomaterials 26/25, 5111 (2005). doi:10.1016/j.biomaterials.2005.01.038

S. Di Nunzio, C. Vitale Brovarone, S. Spriano, D. Milanese, E. Vernè, V. Bergo, G. Maina, P. Spinelli, J. Eur. Ceram. Soc. 24, 2935 (2004). doi:10.1016/j.jeurceramsoc.2003.11.010

T. Kokubo, H. Takadama, Biomaterials 27, 2907 (2006). doi:10.1016/j.biomaterials.2006.01.017

NCCLS M2-A9 “Performance Standards for Antimicrobial Disk Susceptibility Tests, Approved Standard – Ninth Edition

L.L. Hench, J. Am. Ceram. Soc. 81, 1705 (1998)

L.L. Hench, J. Am. Ceram. Soc. 74, 1487 (1991). doi:10.1111/j.1151-2916.1991.tb07132.x

H. Li, K.A. Khor, P. Cheang, Eng. Fract. Mech. 74(12), 1894 (2007). doi:10.1016/j.engfracmech.2006.06.001

Y.C. Yang, E. Chang, Thin Solid Films 444(1–2), 260 (2003). doi:10.1016/S0040-6090(03)00810-1

E. Vernè, S. Ferraris, M. Miola, G. Fucale, G. Maina, G. Martinasso, R.A. Canuto, S. Di Nunzio, C. Vitale Brovarone (2008) Adv. Appl. Ceram. 107(5), 234 (2008)

Acknowledgments

The authors would like to acknowledge INSTM, Eurocoating s.p.a., that partially funded the research activity and Dr. Arturo Sabbioni which has realized plasma spray coatings.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miola, M., Ferraris, S., Di Nunzio, S. et al. Surface silver-doping of biocompatible glasses to induce antibacterial properties. Part II: plasma sprayed glass-coatings. J Mater Sci: Mater Med 20, 741–749 (2009). https://doi.org/10.1007/s10856-008-3618-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-008-3618-8

and Ag-GC-II ■

and Ag-GC-II ■